Finding the Right PEM Electrolyzer Supplier: A Simple Guide

The world is moving toward clean energy. Green hydrogen is a big part of that future.

PEM technology is what makes green hydrogen work. It’s a clean and smart way to produce it.

Your hydrogen project needs a solid foundation. That foundation is your electrolyzer supplier. A good partner can make all the difference. This guide helps you choose the right one.

What Exactly Is a PEM Electrolyzer?

So, how does this technology work? It’s actually pretty simple.

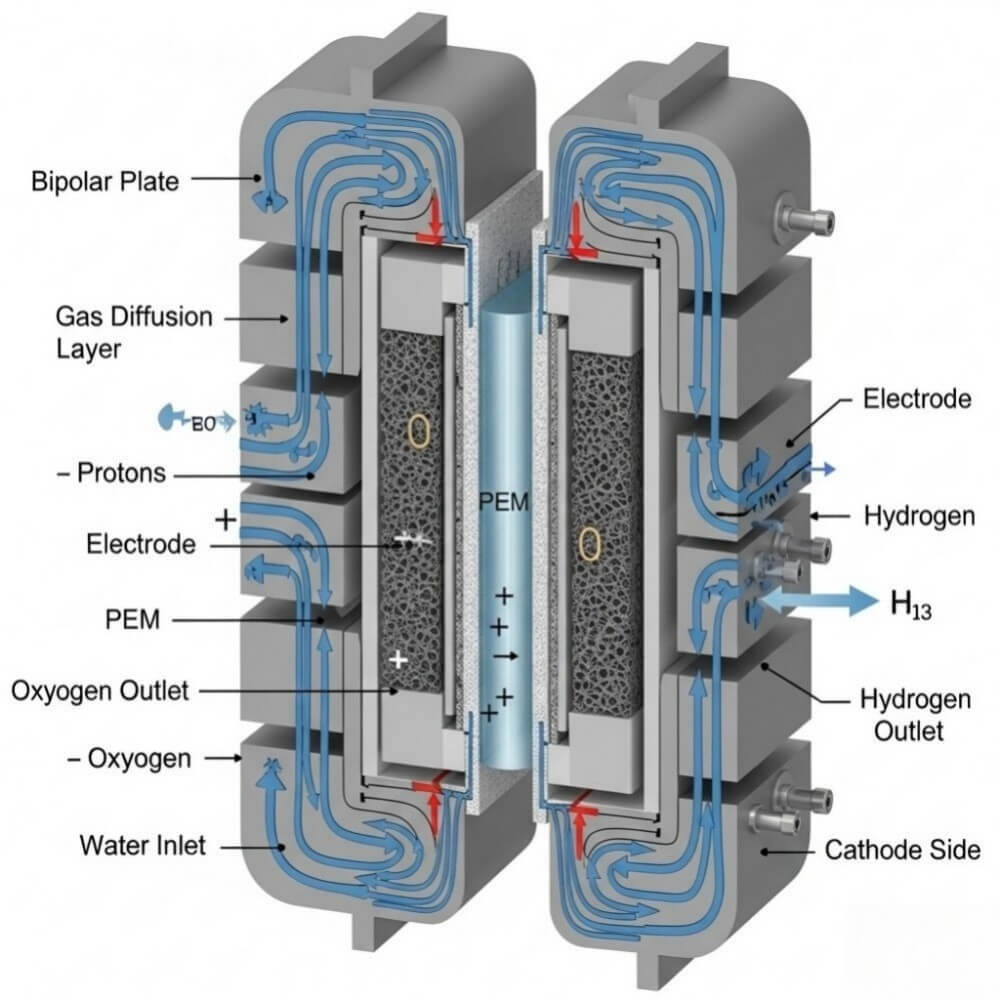

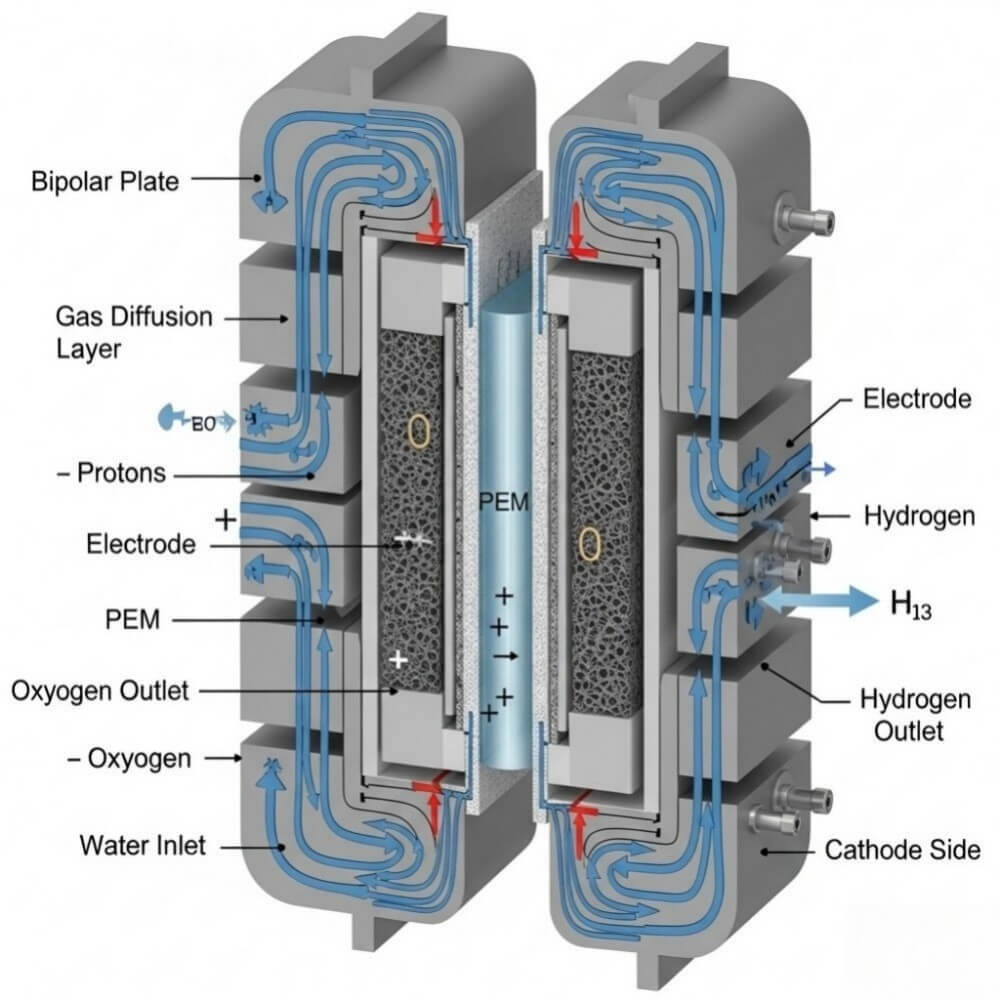

PEM electrolyzers use electricity to split water. This process creates pure hydrogen and oxygen. The core of the machine is called the “stack.”

Think of the stack as the engine. It has a few key parts:

- MEA (Membrane Electrode Assembly): This is where the magic happens. It’s the heart of the whole system.

- Bipolar Plates: These plates move electricity and water around. They also give the stack its structure.

- End Plates: These hold everything together tightly.

- Seals and Gaskets: They prevent any leaks. Safety is key.

- Balance of Plant (BoP): This includes the surrounding water and gas management systems, power electronics, and control systems needed for a fully functional unit.

This tech is popular for good reasons. It’s fast, efficient, and produces very pure hydrogen.

Why Work With an OEM Partner?

You might wonder why you should choose an OEM. They are the specialists who build these systems. You then integrate their tech into your project.

Partnering with an OEM offers some real perks.

You get a solution designed just for you. This helps you avoid one-size-fits-all problems. You can also tap into their expert knowledge. This saves you a lot of time and guesswork.

OEMs build things at a large scale. This scale often means lower costs for you. It helps you get your project running much faster.

The benefits include:

Customization and Flexibility: OEM suppliers can tailor solutions to meet specific pressure, capacity, and integration requirements for unique applications.

Cost-Effectiveness: By leveraging an OEM’s economies of scale in manufacturing and supply chain, you can significantly reduce your capital expenditure.

Access to Specialized Expertise: You gain immediate access to years of dedicated research, development, and engineering expertise in complex electrolysis technology.

Accelerated Time-to-Market: An OEM partnership allows you to focus on your core business and project integration, dramatically shortening your development timeline.

Scalability for Future Growth: Established OEMs have the manufacturing infrastructure to scale production as your hydrogen demand grows.

What to Look for in a Supplier

Choosing a partner requires a close look. Here are some key things to check.

1. How much experience do they have?

A supplier’s track record matters a lot. You want a team that knows what they’re doing.

Ask about their past projects. See if they have patents on their technology. A long history suggests they’re a reliable choice.

2. Does their equipment perform well?

Quality is something you can’t compromise on. The gear needs to be safe and efficient.

Ask for their performance data. Check for quality certifications, like ISO or CE. Find out what materials they use in their stacks. Good materials mean a longer life for your equipment.

- Quality Certifications: Ensure they adhere to international standards like ISO 9001 for quality management and CE marking for safety.

- Performance Metrics: Request detailed data sheets on efficiency (kWh/kg of H2), hydrogen purity, operating pressure range, and expected stack lifetime.

- Material Selection: Inquire about the materials used for critical components like bipolar plates (e.g., coated titanium) and catalysts (e.g., platinum and iridium loading).

- Testing and Validation: Do they have rigorous in-house electrolyzer testing procedures for every stack before it ships?

3. Can they build at the scale you need?

Your supplier must meet your demands. This is true for today and for the future.

Find out their production capacity. Ask about their typical delivery times. A well-managed supply chain is a very good sign.

- Production Capacity: What is their current and projected annual manufacturing capacity (in MW or GW)?

- Lead Times: What are their standard lead times from order to delivery?

- Process Control: Is their manufacturing process automated to ensure consistency and quality?

- Supply Chain Management: Do they have a robust and resilient supply chain for critical raw materials?

4. Are they flexible and helpful?

Your project likely has unique needs. A good partner is willing to adapt.

See if they offer custom designs. Ask how they help with system integration. A collaborative spirit is incredibly valuable.

- Custom Solutions: Can they design custom electrolyzer solutions for non-standard requirements?

- Integration Support: How do they assist with integrating their stack into your complete hydrogen production equipment and control systems?

- Flexibility: Are they a collaborative partner willing to work through technical challenges with your engineering team?

5. What happens after you buy?

The relationship isn’t over after the sale. You’ll probably need support down the road.

Make sure they offer technical help. Ask about their training and warranties. Good after-sales support provides peace of mind.

- Technical Support: Do they offer installation, commissioning, and maintenance support?

- Training and Documentation: Will they provide comprehensive technical manuals and training for your operations team?

- Warranty: What are the terms and length of their product warranty?

Doing Your Homework on a Supplier

Don’t just take their word for it. It’s smart to verify their reputation.

Talk to their current customers if possible. See what their real-world experience has been. Look for any industry awards or recognition.

A company’s financial health is also important. A stable partner is likely to be around for the long term. Pay attention to how they communicate. Are they open, clear, and responsive? That tells you a lot about how they do business.

Thinking About the Full Cost

The initial price tag isn’t the whole story. You should think about the total cost over the machine’s life.

This includes the upfront purchase price. But it also includes the cost of electricity and water. Don’t forget about maintenance costs, too.

A cheaper unit might use more power. This could make it more expensive in the long run. Looking at the big picture helps you find the true value.

Choosing a Forward-Thinking Partner

PEM technology is always getting better. A great supplier is part of that innovation.

They are likely working on new ideas. They might be trying to lower costs. Or maybe they are boosting efficiency.

Choosing an innovative partner helps future-proof your project. It shows they’re invested in long-term success.

Picking your PEM supplier is a huge step. This partnership will shape your entire project. Take your time, ask good questions, and choose a partner you can trust.

Thinking about a hydrogen project? Let’s talk. We can help you find the perfect fit for your needs.

Your Partner in the Hydrogen Economy

Choosing the right PEM electrolyzer OEM supplier is a strategic decision that will profoundly impact your project’s financial viability and technical success. By focusing on technical expertise, manufacturing capability, product quality, and long-term support, you can identify a partner who will not only deliver a high-performance product but also provide the collaborative support needed to thrive in the growing hydrogen economy.

Ready to find the perfect PEM electrolyzer OEM supplier for your project? Contact our team of experts today for a consultation to discuss your specific requirements and get your project started.

Hele Titanium Hydrogen: Your Trusted Hydrogen Generator OEM & Manufacturing Partner

Hele Titanium Hydrogen stands as a reliable and experienced partner in the hydrogen generator OEM supply chain. We specialize in the design, development, and manufacturing of high-performance PEM Water Hydrogen Generators, offering comprehensive OEM & Manufacturing services tailored to your specific needs.

Take the Next Step

Ready to explore the possibilities of partnering with Hele Titanium Hydrogen?

- Browse our Products to see our range of PEM Water Hydrogen Generators.

- Learn more about our Services and how we can support your OEM & Manufacturing needs.

- Contact Us today to discuss your specific requirements.

- Explore our FAQ to get answers to common questions.

- Visit our Blog for the latest insights and updates on hydrogen technology.

Email Us: heletitaniumhydrogen@gmail.com

Phone/WhatsApp: 086-13857402537

top questions often asked about PEM (Proton Exchange Membrane) electrolyzer OEM suppliers

1. What is the expected lifespan of a PEM electrolyzer or stack?

- Generally, high-quality PEM electrolyzers or stacks last between 7–15 years, or around 60,000–80,000 operating hours, with proper maintenance. (heletitaniumhydrogen.com, Wikipedia)

2. How much hydrogen can a typical PEM electrolyzer produce per unit of power?

- A 1 MW PEM electrolyzer typically generates around 20 kg/hour, or about 480 kg/day, depending on operating conditions. (heletitaniumhydrogen.com)

- Production capacity in technical terms:

- Small: 1–10 Nm³/h

- Medium: 50–100 Nm³/h

- Large: > 500 Nm³/h (heletitaniumhydrogen.com)

3. Are PEM electrolyzers compatible with intermittent renewable energy sources like solar or wind?

- Yes, due to their fast startup (<1 minute) and excellent dynamic load response, PEM systems are well-suited for pairing with intermittent renewables. (heletitaniumhydrogen.com, nafion.com)

4. How does PEM compare with alkaline and solid oxide electrolyzers?

- PEM:

- High current density

- Very high purity H₂

- Compact & fast responding systems

- Alkaline:

- Lower upfront cost

- Larger footprint; slower response

- Solid Oxide (SOE):

- High operating temps, higher efficiency

- More complex and expensive (heletitaniumhydrogen.com, Plug Power)

5. What affects the cost per kW of PEM electrolyzers?

- Key cost drivers:

- Technology maturity and efficiency

- Scale—bulk production yields economies

- Customization levels

- Regional costs (manufacturing, shipping, incentives)

- Integration costs (infrastructure, storage, balance-of-plant) (heletitaniumhydrogen.com)

- Current price range (2025 estimate): $700–1,500 per kW, typical average ~$1,000 per kW (heletitaniumhydrogen.com)

6. What are the main technical challenges and supply chain risks?

- Scarcity and price volatility of materials:

- Iridium (for catalysts) and titanium (for bipolar plates) are in limited supply, causing delays and high costs. (P Market Research)

- Component reliability constraints:

- Few suppliers of PFSA membranes create bottlenecks.

- Pandemic and geopolitical factors have caused delivery delays and cost hikes for critical parts. (P Market Research)

7. What certifications and standards should OEM suppliers meet?

- Look for adherence to:

- ISO 22734 (hydrogen electrolyzer safety)

- ISO 9001 (quality management)

- Environmental compliance like REACH and RoHS (heletitaniumhydrogen.com)

8. What are the main components of a PEM electrolyzer system?

- Typical components include:

- Electrodes (with catalyst coatings)

- Proton exchange membrane

- Separator and gas collection system

- Cooling and control systems (Gh2 Solar)

- In industrial systems, also includes:

- Power electronics, water purification, thermal management, sensors, etc. (Balance of Plant, BoP) (heletitaniumhydrogen.com)

9. What efficiency levels do PEM electrolyzers offer?

- PEM systems typically operate between 70–85% efficiency.

- Energy usage: 4.5–7.5 kWh per Nm³ of H₂ (system-level) (heletitaniumhydrogen.com, Wikipedia)

10. How do operational pressure and purity compare to other technologies?

- PEM systems can operate at higher pressures (up to ~100 bar), enabling simplified downstream compression. (heletitaniumhydrogen.com, Reddit, Wikipedia)

- They also deliver hydrogen purity typically above 99.99%, ideal for fuel cells. (heletitaniumhydrogen.com, Wikipedia)

11. What critical performance and durability factors should buyers evaluate?

- Important aspects include:

- Current density capacities

- Stack lifetime and degradation rates

- Gas and water transport efficiency

- Contact resistance and thermal/mechanical stability of components (ACS Industries, heletitaniumhydrogen.com)

12. How can efficiency improvements and supply chain bottlenecks be addressed?

- Innovations like:

- New non-precious catalysts

- Recyclable membranes

- AI-driven monitoring and predictive maintenance

- Blockchain for supply chain transparency (heletitaniumhydrogen.com)

- Additionally, initiatives to recycle iridium from old stacks are underway, aiming to reduce raw material needs. (P Market Research)

FAQ Summary Table

| Key Question | Insights |

|---|---|

| Lifespan | 7–15 years / 60k–80k h |

| H₂ Output (1 MW) | ~20 kg/h or ~480 kg/day |

| Renewable Energy Compatibility | Ideal for intermittent power due to fast start-up |

| Cost per kW | ~$700–1,500 (avg ~$1,000/kW); depends on scale & features |

| Efficiency | 70–85%; ~4.5–7.5 kWh/Nm³ H₂ |

| Key Materials & Risks | Iridium, titanium supply shortages; membrane supplier bottlenecks |

| Certifications | ISO 22734, ISO 9001, REACH, RoHS |

| Performance Metrics | Current density, lifetime, stack degradation, pressure handling |

| Future Innovations | AI, new catalysts, recycling, advanced system integration |