Introduction to OEM Hydrogen Generators

As the world pivots toward cleaner energy solutions, OEM hydrogen generators for fuel cells customization and integration are gaining prominence. These specialized systems are designed by original equipment manufacturers (OEMs) to produce hydrogen efficiently, enabling fuel cells to convert it into electricity with zero emissions. The shift to hydrogen as a clean fuel source underlines the need for dependable and customizable generation systems that can seamlessly integrate with various fuel cell configurations.

OEM hydrogen generators are not just off-the-shelf products—they are tailored solutions that adapt to the unique demands of different sectors like transportation, power generation, and heavy industry. Their customization allows for flexibility in capacity, design, safety, and compatibility, which are essential for high-performance fuel cell integration.

Importance of Customization in OEM Hydrogen Generators

Customization in hydrogen generators ensures they align with the end-user’s operational requirements. Whether for stationary or mobile fuel cell applications, tailored systems:

- Optimize energy output by aligning with fuel cell capacity and voltage needs.

- Improve safety and compliance with specific regulatory frameworks in different regions.

- Support diverse environments, from high-humidity areas to remote installations with minimal maintenance access.

For example, an automotive hydrogen fuel cell system requires compact, lightweight hydrogen generation modules that can integrate with vehicle power systems. Conversely, industrial applications may demand higher throughput, redundancy, and digital control systems.

Key Components of Hydrogen Generators

OEM hydrogen generators typically include the following core components:

| Component | Function |

|---|---|

| Electrolyzer | Splits water into hydrogen and oxygen using electricity |

| Compressor | Pressurizes the hydrogen for storage or direct fuel cell use |

| Purification System | Removes impurities to meet fuel cell-grade hydrogen specs |

| Control Unit | Manages performance, safety, and integration with external systems |

Advanced systems also integrate sensors, automated valves, and cooling units to enhance reliability and efficiency.

Types of Hydrogen Production Technologies

Different hydrogen generation technologies support various applications. OEMs typically select or develop these based on customer requirements:

- PEM Electrolysis (Proton Exchange Membrane): Fast response, compact, suitable for renewable integration.

- Alkaline Electrolysis: Cost-effective, long-standing technology, better suited for large-scale stationary use.

- Steam Methane Reforming (SMR): Fossil-based, high-output—best for industrial sites with CO₂ capture add-ons.

Green hydrogen production (zero-carbon) is increasingly preferred for sustainability goals, especially in transport and urban energy grids.

How Fuel Cells Use Hydrogen Efficiently

Fuel cells convert hydrogen into electricity through electrochemical reactions, producing only water and heat as byproducts. Integration with customized OEM hydrogen generators ensures:

- Optimal gas flow rates for energy output needs

- Stable supply without storage delays

- Enhanced system lifespan via purity control and balanced operation

Various fuel cells (PEMFC, SOFC, AFC) benefit from tailored hydrogen supply systems that match their electrical demands and operating environments.

Continuing the long-form article on OEM hydrogen generators for fuel cells customization and integration…

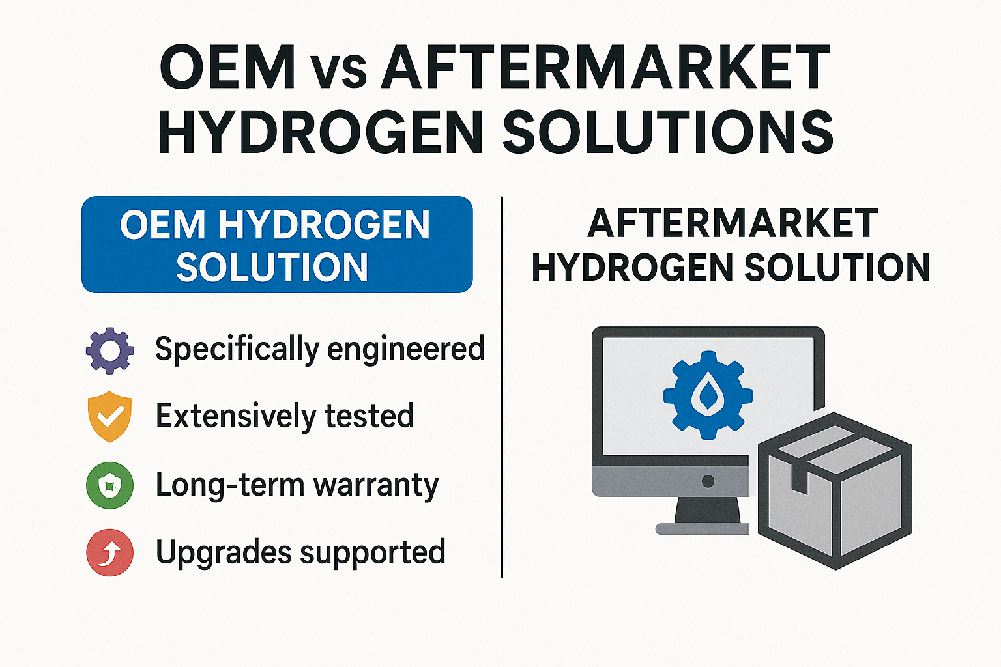

OEM vs Aftermarket Hydrogen Solutions

When selecting a hydrogen generator, the choice between OEM and aftermarket systems is crucial. OEM hydrogen generators are:

- Specifically engineered to integrate seamlessly with the associated fuel cell system.

- Tested extensively for performance, safety, and compliance by the original manufacturer.

- Supported with long-term warranties and upgrades, ensuring reliability and scalability.

Aftermarket solutions, while often cheaper, may lack the precision, safety standards, and real-time compatibility of OEM systems. In mission-critical applications, such as aerospace or public transit, the stakes are too high for mismatched components.

Integration of Hydrogen Generators with Fuel Cell Systems

Seamless integration is key to maximizing the efficiency of hydrogen-powered systems. Successful integration involves:

- Electrical compatibility: Synchronizing voltage, current, and load demands.

- Thermal management: Sharing or isolating heat sources between systems to improve performance.

- Control system coordination: Enabling real-time communication between hydrogen generator and fuel cell software (SCADA, PLCs, etc.).

For instance, integrating a hydrogen generator into a marine fuel cell application requires corrosion-resistant components, compact design, and vibration-tolerant mounts.

Custom Engineering and Modular Design Approaches

OEMs increasingly offer modular hydrogen generator platforms, allowing easy scalability and rapid deployment. Custom engineering enables:

- Configurable hydrogen output from a few liters per minute to several thousand Nm³/h.

- Flexible form factors for mobile units, skid-mounted setups, or containerized systems.

- Plug-and-play integration kits that simplify deployment in hybrid energy systems.

This flexibility is critical for companies expanding into hydrogen use without completely overhauling existing infrastructure.

Industry Applications and Use Cases

Customized OEM hydrogen generators are making waves across diverse industries:

- Automotive: Hydrogen-powered buses and trucks rely on lightweight, compact generation systems.

- Aviation: Unmanned aerial vehicles (UAVs) and prototype aircraft integrate high-purity hydrogen for long-range missions.

- Industrial Power: Facilities use hydrogen generators for peak shaving, process heat, or backup power.

- Telecommunications: Remote cell towers deploy fuel cells with integrated hydrogen generators for uninterrupted service.

These systems help reduce carbon emissions, enhance energy independence, and meet ESG targets.

Compliance, Safety, and Regulatory Standards

Hydrogen is a flammable gas, and its storage and use are tightly regulated. OEM hydrogen generators are designed to comply with:

- ISO 22734 for hydrogen generators using water electrolysis

- SAE J2719 for hydrogen fuel quality

- ATEX/IECEx certifications for explosive atmospheres

- Local fire and safety codes in transport, building, and industrial sectors

Incorporating built-in leak detection, pressure relief systems, and redundant controls ensures safe operation in any environment.

Digital Monitoring and IoT in Hydrogen Systems

Smart hydrogen generators come equipped with digital interfaces for:

- Real-time monitoring of hydrogen output, pressure, and purity

- Remote diagnostics and software updates

- Predictive maintenance powered by AI and machine learning

These features help OEMs and users reduce downtime, improve efficiency, and extend equipment life. Integration with centralized SCADA or cloud-based dashboards also supports energy optimization across facilities.

Cost-Benefit Analysis of Custom OEM Hydrogen Solutions

While initial costs may be higher than standard units, custom OEM hydrogen generators deliver superior long-term value:

| Factor | Benefit |

|---|---|

| Tailored design | Reduces energy waste and overcapacity |

| High purity output | Enhances fuel cell lifespan |

| Automated operations | Cuts labor and maintenance costs |

| Modularity | Allows phased investment and expansion |

| Compliance-ready | Minimizes fines and retrofit costs |

Over a 10-year lifecycle, businesses often recover their investment through improved uptime, lower fuel costs, and government incentives.

Challenges in Customizing and Integrating Hydrogen Generators

Despite the benefits, customization can present challenges:

- Complex engineering: Requires deep technical expertise and detailed planning

- Supply chain constraints: Certain specialized parts or electrolyzers may have long lead times

- Regulatory approvals: Integration into existing infrastructure may trigger permit delays

- Cost management: Balancing innovation with affordability is key

Close collaboration between OEMs, integrators, and end-users is essential for successful deployment.

Innovations and Trends in Hydrogen Generator OEM Market

The market for OEM hydrogen generators is evolving rapidly. Key trends include:

- Green hydrogen production powered by solar, wind, or hydroelectric sources

- Decentralized generation for off-grid or microgrid applications

- Compact, portable hydrogen units for defense, emergency services, or field operations

- Hybrid systems combining hydrogen, solar, and batteries for full autonomy

OEMs are also investing in advanced materials like graphene and ceramic membranes to boost efficiency and durability.

Selecting the Right OEM Partner for Custom Hydrogen Solutions

Choosing the right OEM partner involves more than comparing specs. Ask:

- Does the OEM have experience in your specific industry?

- Are their systems certified and proven in the field?

- Can they offer after-sales support and spare parts globally?

- Do they offer simulation tools and digital twins to optimize system design?

Trusted OEMs like Nel Hydrogen, Plug Power, Hydrogenics, and Cummins offer turnkey solutions backed by R&D and global support.

Future Outlook for OEM Hydrogen Generator Integration

As hydrogen becomes a cornerstone of decarbonization strategies, demand for custom OEM hydrogen generators will soar. Projections indicate:

- 25% annual market growth through 2030

- Hydrogen hubs and corridors linking generators with industrial and transport users

- Government subsidies for green hydrogen projects accelerating OEM innovation

OEMs are expected to play a central role in building resilient, carbon-free energy ecosystems worldwide.

FAQs about OEM Hydrogen Generators for Fuel Cells

1. What is an OEM hydrogen generator? An OEM hydrogen generator is a hydrogen-producing system built by the original equipment manufacturer and designed to integrate seamlessly with specific applications or fuel cell systems.

2. Can OEM hydrogen generators be customized for different industries? Yes. They can be tailored in terms of output, size, control systems, and environmental tolerances to meet industry-specific needs.

3. What are the benefits of OEM vs third-party hydrogen generators? OEM generators ensure compatibility, certified safety, and optimized integration—reducing risk and boosting performance compared to generic or aftermarket options.

4. Are there portable OEM hydrogen generators for mobile use? Yes, compact and modular systems are available for vehicles, marine vessels, UAVs, and field operations, designed for easy deployment and integration.

5. How do OEM hydrogen generators ensure safety? They incorporate leak detection, automatic shutdowns, pressure relief valves, and conform to global standards like ISO 22734 and SAE J2719.

6. What fuels OEM hydrogen generators—renewable or fossil energy? Many use electricity from renewable sources (solar, wind, hydro) for electrolysis, while others can use natural gas in steam methane reformers (SMRs).

Conclusion: Why Custom OEM Hydrogen Solutions Matter

OEM hydrogen generators for fuel cells customization and integration are revolutionizing how industries transition to clean energy. Their tailored design, seamless integration, and superior safety features make them the ideal solution for powering the hydrogen economy. As technology evolves and demand grows, these systems will remain at the heart of innovation—empowering everything from zero-emission vehicles to resilient industrial infrastructure.

🔗 Explore more about hydrogen integration at the International Hydrogen Energy Programme.