Discover the top considerations for choosing turnkey hydrogen production system suppliers. Learn why PEM electrolyzers and containerized turnkey systems accelerate OEM product launches and reduce TCO.

Introduction — Why OEMs Should Care About Turnkey Hydrogen Solutions

Hydrogen is accelerating from niche proof-of-concept projects into mainstream industrial use — and OEMs (original equipment manufacturers) risk losing market share if they don’t offer hydrogen-ready products or integrated solutions. For an OEM, working with turnkey hydrogen production system suppliers lets you get on-site, ready-to-deploy hydrogen without building the production know-how in-house. That means faster time-to-market, predictable costs, and a single accountable partner for equipment, integration and service — exactly what B2B buyers need when they scale new product lines. Global momentum is strong: total hydrogen production reached roughly 97 million tonnes in 2023, and low-emission hydrogen project announcements are growing rapidly. (IEA)

What Is a Turnkey Hydrogen Production System?

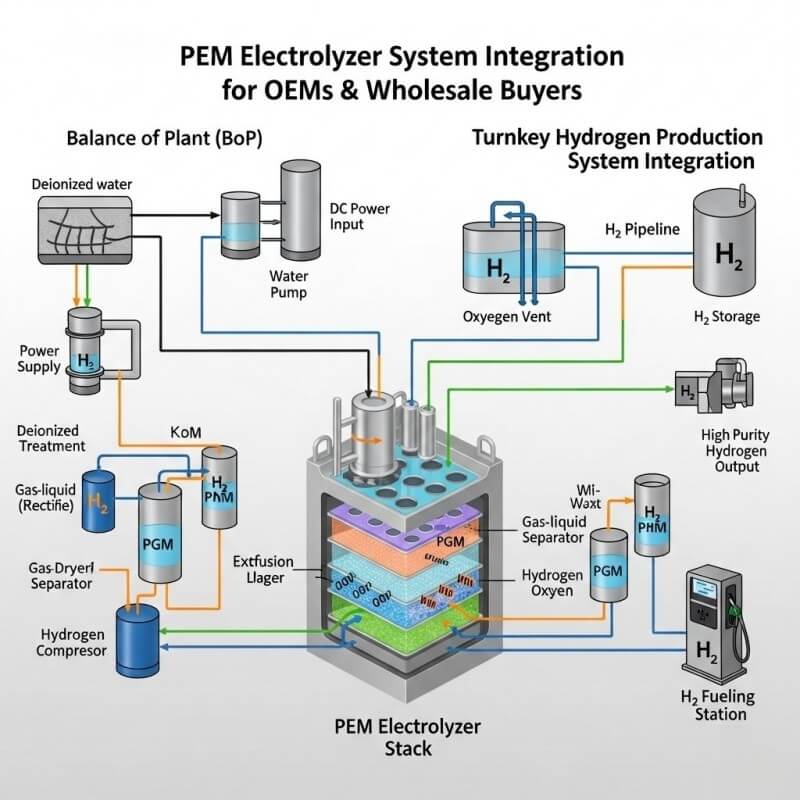

A turnkey hydrogen production system is a full-scope solution delivered by a single supplier that includes everything necessary to produce, condition, store and dispense hydrogen at the customer’s site. Typical scope:

- Production module — the electrolyzer (PEM, alkaline, or other) or reformer (SMR)

- Balance of Plant (BoP) — power management, water purification, pumps, compressors, heat exchangers

- Storage & dispensing — high-pressure tanks, refueling islands, piping and dispensers

- Controls & automation — PLC/SCADA, safety systems and monitoring dashboards

- Mechanical, electrical & civil works — skids, containerization, foundations, interconnects

- Commissioning & training — site acceptance testing, operator education

- Service & warranty — remote monitoring, spare parts, scheduled maintenance

Containerized “plug-and-play” systems are a popular turnkey format for OEMs because they minimize site works and speed installation. (Kyros Hydrogen Solutions)

Why Turnkey Solutions Are Ideal for OEMs

Working with experienced turnkey hydrogen production system suppliers gives OEMs three practical benefits: reduced complexity, faster deployment, and focused capital allocation.

1. Reduced technical complexity Instead of sourcing stacks, balance-of-plant, compressors and controls from multiple vendors and integrating them yourself, turnkey suppliers deliver an engineered system that’s tested off-site and proven to work together. This reduces engineering hours and integration risk. (IDTechEx)

2. Faster time-to-market A pre-integrated, modular system — especially containerized solutions — can be installed and commissioned far quicker than a home-built plant. OEMs launching hydrogen-enabled products (e.g., fuel-cell forklifts, mobile refueling units) can get customer trials running months sooner. Real deployments (e.g., major logistics centers) show this advantage in practice. (DC Velocity, Supply Chain 24/7)

3. Predictable Total Cost of Ownership (TCO) Turnkey suppliers package CAPEX, installation, and defined service contracts, making project economics more transparent. When suppliers also offer financing or long-term service agreements, OEMs can move costs from unpredictable integration budgets to a single contract. (IDTechEx)

4. Performance guarantees and scalability Established suppliers can guarantee hydrogen purity, flow rate and uptime, and many turnkey systems are modular — letting OEMs scale capacity by adding parallel units rather than redesigning the plant.

5. Focus on core competencies OEMs can keep R&D, manufacturing and sales in-house and outsource hydrogen production expertise. This reduces organizational disruption and accelerates commercial rollout.

Balanced View: Challenges & Risks of Turnkey Hydrogen Systems

No solution is risk-free. OEMs should weigh these common concerns:

- Higher perceived upfront cost: Some turnkey systems carry a premium versus sourcing parts piecemeal — although EPC and integration savings often offset that premium. (NREL)

- Supplier lock-in: Relying on a single supplier can limit flexibility for future upgrades unless contract terms are negotiated for interoperability and spare-parts access.

- Supply-chain lead times: Electrolyzer stacks and power electronics may have long lead times during growth periods; check manufacturer capacity and delivery timelines. (The Department of Energy’s Energy.gov)

- Regulatory & safety compliance: Hydrogen projects require careful permitting and adherence to local codes — turnkey suppliers’ experience with international certification is a major differentiator. (Financial Times)

How to Choose the Right Turnkey Hydrogen Production System Supplier — A Checklist for OEMs

When evaluating suppliers, ask targeted questions and request documented proof points:

- Technology expertise & TRL — Do they specialize in PEM, alkaline or another technology? What is their proven track record at your target scale (kW → MW)? Check technical targets and supplier test reports. (The Department of Energy’s Energy.gov, Hydrogen Program)

- System integration & testing — Are systems fully integrated and factory-tested (FAT)? Do they offer containerized or skid-mounted options? (Kyros Hydrogen Solutions)

- Customization & footprint — Can they tailor hydrogen purity, pressure, and site footprint to your product and space constraints?

- Scalability & modularity — Can capacity be increased by adding modules without large civil works?

- References & case studies — Ask for customer references—especially other OEMs or logistics operators. Public projects (e.g., Amazon, automotive OEM partnerships) are useful benchmarks. (DC Velocity, Toyota Material Handling Europe)

- Service & spare parts — Do they provide remote monitoring, 24/7 support, and local spares inventory?

- Safety & compliance — ISO, CE, ASME and local approvals matter for import/export and installations.

- Energy efficiency & operating data — Request real system electricity consumption in kWh/kg H₂ (not just stack-level data). DOE and program studies provide baselines you can compare against. (Hydrogen Program, The Department of Energy’s Energy.gov)

- Total cost of ownership & financing — Ask for lifetime O&M forecasts, degradation rate assumptions, and financing/leasing options.

Specific questions to ask suppliers: What is your system’s full-system energy use (kWh/kg H₂)? What water quality is required? What are mean time between failures (MTBF) and stack replacement intervals? What safety systems and redundancies are included?

Types of Turnkey Hydrogen Production Systems (and what OEMs should pick)

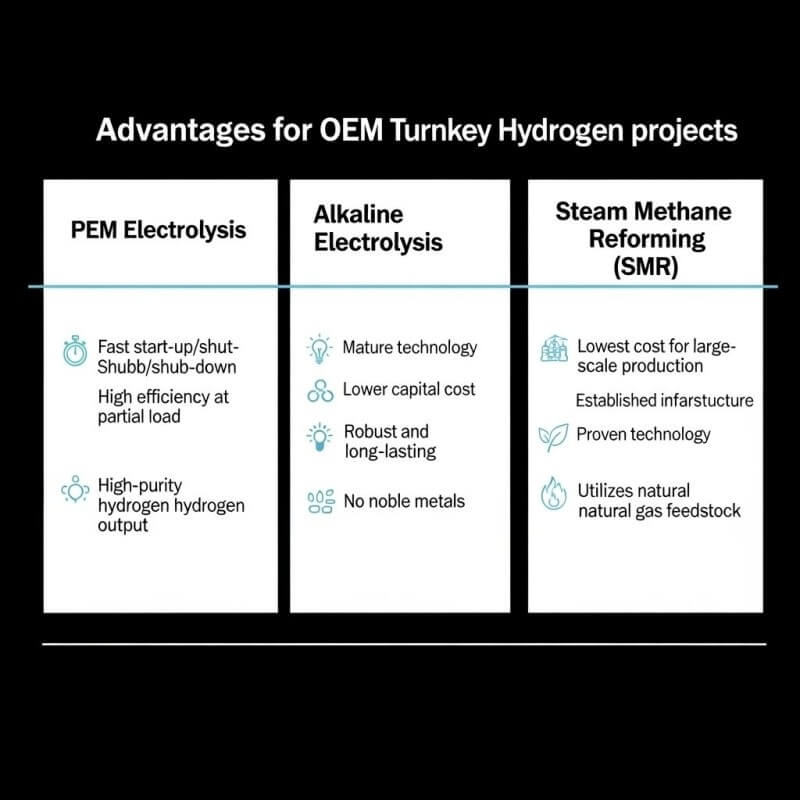

Below is a practical summary of the main technologies you’ll see from turnkey suppliers.

PEM (Proton Exchange Membrane) Electrolysis — best fit for many OEMs

- Why it’s attractive: High purity hydrogen, fast dynamic response (good for pairing with variable renewables), compact footprint, and suitable for containerized systems for on-site refueling or testing. (ACS Publications, ScienceDirect)

- Typical energy use: System-level values in studies often range 50–60 kWh/kg H₂ today; DOE targets aim to lower this further. (Hydrogen Program, The Department of Energy’s Energy.gov)

Alkaline Electrolysis

- Why choose it: Lower capital cost per kW for established plants; good for steady, large-scale production where rapid load-following is not required. Technical maturity is high but footprint and dynamic performance are less attractive than PEM. (The Department of Energy’s Energy.gov, ScienceDirect)

Solid Oxide Electrolysis (SOEC)

- Pros/cons: High theoretical efficiencies at elevated temperature, attractive for industrial heat integration. Still earlier stage for wide commercial deployment — better for long-range planning. (ACS Publications)

Steam Methane Reforming (SMR) with Carbon Management

- Why it’s used: Mature and cost-effective for large volume hydrogen today, but unless paired with carbon capture and storage (CCS) it’s not low-emission. Many turnkey suppliers offer hybrid SMR + CCS solutions for “blue” hydrogen. (IEA)

Global Market Outlook — Why Now Is the Time to Partner

The hydrogen industry is moving from pilot to scale. Global hydrogen production was ~97 Mt in 2023; announced low-emissions hydrogen capacity could reach tens of millions of tonnes by 2030 if projects proceed. Market research estimates the hydrogen market could grow strongly through 2030 with high single-digit CAGR in value terms. These macro trends mean OEMs who lock in reliable turnkey partners today will be better positioned to serve growing demand. (IEA, MarketsandMarkets)

Case Studies — Real Deployments That Matter to OEMs

1. On-site PEM electrolyzer for material-handling fleets (example: Amazon / Plug Power installations) Large logistics operators have installed on-site electrolyzers to fuel fuel-cell forklifts. A 1 MW electrolyzer installation can supply hydrogen for hundreds of forklifts at a busy distribution center — enabling green, reliable refueling and reduced dependence on external fuel deliveries. This shows the commercial viability of containerized turnkey systems for material handling OEM channels. (EEPower, DC Velocity)

2. Turnkey electrolyzer + fueling stations (example: Nel delivered turnkey fueling systems to vehicle fleets) Manufacturers like Nel have delivered turnkey electrolyzer + HRS (hydrogen refueling station) packages to projects that included integrated compressors and dispensers, demonstrating how suppliers can own the engineering and delivery risk for fleet operators and OEM partners. (Nel Hydrogen)

3. OEM R&D and testbeds OEMs developing hydrogen-powered prototypes (drones, forklifts, mobile equipment) have used small to mid-scale turnkey PEM modules for rapid R&D cycles — avoiding long procurement and installation lead times while gaining real operational data.

These public examples demonstrate the practical benefits of turnkey partners: speed, packaged warranties, and proven field performance. (Supply Chain 24/7, Nel Hydrogen)

How PEM Hydrogen Generators Give OEMs a Competitive Edge (Practical Benefits from a PEM OEM Partner)

If your OEM products need high-purity hydrogen or rapid start/stop operation, PEM is often the best technical fit:

- High purity & fuel-cell compatibility — PEM systems routinely meet the purity specs for polymer electrolyte membrane fuel cells used in many OEM applications. (ACS Publications)

- Compact, modular designs — Smaller footprint and containerized skids ease factory or site integration. (Kyros Hydrogen Solutions)

- Fast dynamic response — PEM electrolyzers can ramp quickly to match variable renewable inputs or intermittent test cycles. (ScienceDirect)

- Lower lifecycle integration risk — A supplier that designs the stack, BoP and control system reduces cross-vendor interface issues.

Hele Titanium Hydrogen — what to expect from a seasoned PEM partner (Use this paragraph to communicate your company’s value proposition.) Hele Titanium Hydrogen designs and manufactures PEM water electrolyzers tailored for OEMs: compact skids, containerized turnkey units, tailored control integration, worldwide export packaging, and B2B after-sales support. We provide technical datasheets, site integration drawings, and ROI analyses to help OEM procurement teams evaluate investments quickly.

Future Trends That OEMs Should Watch

- Cost declines from scale & learning curves: Continued electrolyzer factory scale-up is forecast to reduce stack and system costs. (The Department of Energy’s Energy.gov, CEEPR)

- Digitalization & predictive maintenance: Remote monitoring, AI-driven fault detection and fleet analytics will reduce downtime and O&M cost.

- Energy market coupling: Electrolyzers increasingly run as flexible loads, charging when electricity prices fall — suppliers offering smart energy management deliver better economics. (The Department of Energy’s Energy.gov)

- Policy & hubs: Regional hydrogen hubs, subsidies and offtake commitments (e.g., industrial offtake) will shape viable project locations and economics. (IEA)

Comparison Table — Quick Tech Snapshot

| Feature | PEM Electrolyzer | Alkaline | SMR (+CCS) |

|---|---|---|---|

| Hydrogen purity | Very high | High | Variable |

| Dynamic response | Fast | Slower | N/A (steady) |

| Typical system energy use (kWh/kg) | ~50–60 (system today) | ~52–60 | ~Depends on process |

| Best for | OEMs, variable renewables, fuel-cell vehicles | Large steady production | Very large scale industrial H₂ (with CCS) |

| Commercial readiness | Mature & scaling | Very mature | Mature (but not low-carbon without CCS) |

| Sources: DOE, hydrogen program assessments, tech reviews. (Hydrogen Program, The Department of Energy’s Energy.gov) |

Frequently Asked Questions (FAQs)

Q1 — What’s the typical electricity requirement for electrolysis?

A: Modern system-level electricity use for PEM and alkaline systems is commonly reported around 50–60 kWh per kg H₂ today; DOE studies use similar baselines and are targeting lower values with R&D. Exact numbers depend on system design and BoP losses. (Hydrogen Program, The Department of Energy’s Energy.gov)

Q2 — Is PEM better than alkaline for OEM on-site systems?

A: For compact, modular, fast-responding on-site systems that need high purity (fuel cells, laboratory use, specialty applications), PEM is usually the better choice. For large, steady-state production where cost per kW is paramount, alkaline can be competitive. (ACS Publications, The Department of Energy’s Energy.gov)

Q3 — How long does it take to install a turnkey electrolyzer?

A: Containerized turnkey units can be delivered, installed and commissioned in a matter of weeks to a few months depending on permitting, site works, and logistics. Full on-site civil works can extend schedules. Ask suppliers for typical lead times for comparable projects. (Kyros Hydrogen Solutions)

Q4 — What warranties and service terms should I expect?

A: Look for multi-year system warranties, stack performance guarantees, remote monitoring, and options for spare parts or service contracts. Clarify stack replacement costs and lead times. (IDTechEx)

Q5 — Are turnkey suppliers able to help with financing?

A: Many suppliers and integrators now offer financing, leasing, or power-purchase/hydrogen-purchase agreements (H2PA) to improve project economics — especially for large fleet or utility-scale customers. Ask for examples. (IDTechEx)

Q6 — How do I compare suppliers’ efficiency claims?

A: Ask for system-level energy-use data (kWh/kg) over expected lifetime, not just stack cell efficiency. Request test reports, degradation curves and measured BOP consumption. DOE technical targets and independent assessments offer useful baselines. (Hydrogen Program, The Department of Energy’s Energy.gov)

Q7 — How safe is a turnkey hydrogen installation?

A: When designed and installed to code (ISO, local standards) and with proper ventilation, leak detection and trained staff, on-site hydrogen systems are safe. The supplier should document safety analysis, alarms and emergency procedures.

Conclusion & Call to Action

OEMs that move now to partner with reliable turnkey hydrogen production system suppliers gain a measurable advantage: faster product launches, clearer project economics, and lower integration risk. If you manufacture hydrogen-enabled products or need on-site hydrogen for testing, distribution, or customer solutions, choosing the right turnkey partner is a business decision — not a technical experiment.

Ready to evaluate turnkey PEM options? Contact Hele Titanium Hydrogen for: a free preliminary project assessment, product datasheet and CAPEX/OPEX model tailored to your application. Request a quote or downloadable technical pack today — we’ll benchmark supplier options against your production, footprint and ROI targets.

Selected Sources & Further Reading

- IEA — Global Hydrogen Review 2024. (IEA)

- U.S. Department of Energy — Technical targets for PEM electrolysis / Hydrogen Shot. (The Department of Energy’s Energy.gov)

- U.S. DOE Hydrogen Program — Clean hydrogen production cost scenarios (PEM). (Hydrogen Program)

- NREL / MIT reviews on electrolyzer efficiencies and techno-economic analysis. (NREL, CEEPR)

- Industry deployments and supplier case examples (Plug Power, Nel, Amazon electrolyzer installation). (EEPower, Nel Hydrogen, DC Velocity)

Hele Titanium Hydrogen: Your Trusted Hydrogen Generator OEM & Manufacturing Partner

Hele Titanium Hydrogen stands as a reliable and experienced partner in the hydrogen generator OEM supply chain. We specialize in the design, development, and manufacturing of high-performance PEM Water Hydrogen Generators, offering comprehensive OEM & Manufacturing services tailored to your specific needs.

Take the Next Step

Ready to explore the possibilities of partnering with Hele Titanium Hydrogen?

- Browse our Products to see our range of PEM Water Hydrogen Generators.

- Learn more about our Services and how we can support your OEM & Manufacturing needs.

- Contact Us today to discuss your specific requirements.

- Explore our FAQ to get answers to common questions.

- Visit our Blog for the latest insights and updates on hydrogen technology.

Email Us: heletitaniumhydrogen@gmail.com

Phone/WhatsApp: 086-13857402537