The Strategic Gateway to the Hydrogen Economy

The global transition to sustainable energy is no longer a future prospect; it is a present-day reality. At the heart of this revolution is green hydrogen, and according to projections by the Hydrogen Council, the market is expected to reach over $2.5 trillion by 2050. The technology making this possible is the Proton Exchange Membrane (PEM) water electrolyzer.

The Challenge: For renewable energy developers, technology startups, and established industrial firms, the opportunity is immense. However, the barrier to entry for manufacturing advanced PEM electrolyzers is staggering. It requires millions in capital investment for specialized facilities, mastery of complex electrochemical processes, and navigating a fragile global supply chain for critical materials.

The Solution: This is where a strategic partnership with a PEM water electrolyzer OEM services provider becomes the most powerful tool in your arsenal. Original Equipment Manufacturing (OEM) allows you to bypass these hurdles, leveraging the expertise, infrastructure, and economies of scale of an established manufacturer to bring your proprietary product to market under your own brand, faster and more cost-effectively than you ever could alone.

Who This Guide Is For: This definitive guide is for the visionaries and decision-makers shaping the hydrogen future:

- Renewable energy project developers

- Hydrogen technology startups and scale-ups

- System integrators for refueling stations and power-to-x plants

- Industrial gas companies expanding into green hydrogen

- Any organization seeking to launch a branded line of high-performance PEM electrolyzers.

This comprehensive guide will outline what to expect from a world-class PEM electrolyzer OEM partner and provide a checklist for selecting the right one to protect your intellectual property, guarantee quality, and scale your vision into a global success.

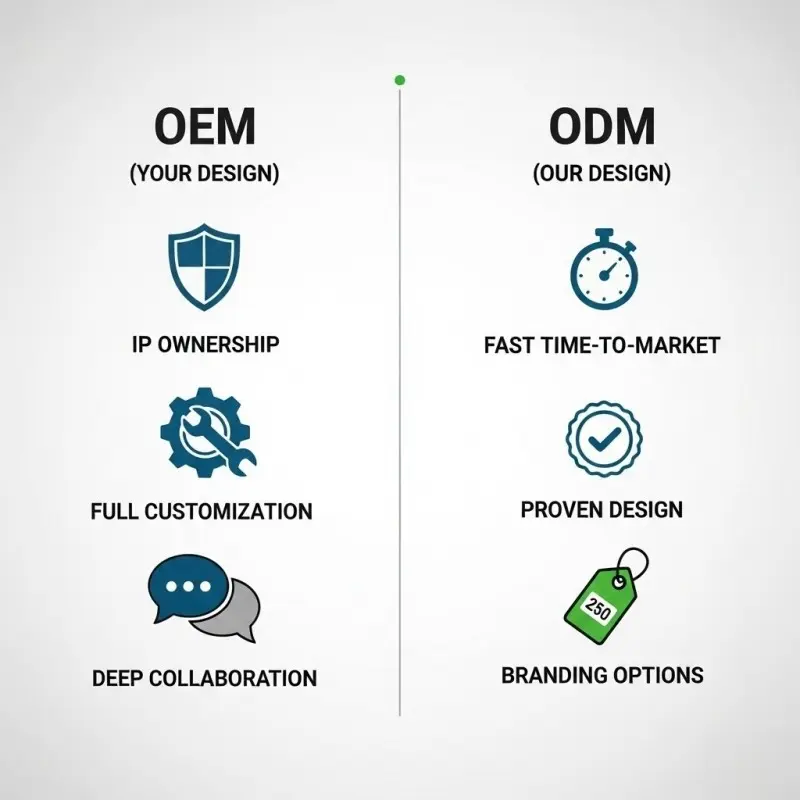

I. OEM vs. ODM for Hydrogen Electrolyzers: Defining Your Partnership

Before embarking on your manufacturing journey, it’s crucial to understand the distinction between OEM and ODM. Choosing the right model is fundamental to your business strategy.

What is PEM Electrolyzer OEM (Original Equipment Manufacturing)?

In an OEM partnership, you provide the proprietary design, engineering specifications, and intellectual property (IP). The OEM partner, like Hele Titanium Hydrogen, acts as your dedicated manufacturing force. We build your product exactly to your specifications, under strict confidentiality, and deliver it with your brand name.

- Best for: Companies with unique, in-house designs, patented technology, or specific performance requirements that demand a tailored manufacturing solution. You maintain full control and ownership of your IP.

What is PEM Electrolyzer ODM (Original Design Manufacturing)?

In an ODM relationship, the manufacturer provides a pre-engineered, market-validated product design that you can then brand as your own. This model significantly reduces your R&D burden and accelerates time-to-market.

- Best for: Companies looking to quickly enter the market with a reliable product without investing heavily in their own R&D, or for applications where a standard, high-quality solution is sufficient.

To help you decide, here is a clear comparison:

| Feature | OEM (Original Equipment Manufacturing) | ODM (Original Design Manufacturing) |

|---|---|---|

| Design Control | Total Control: You own the design and specifications. | Limited Control: You select from the manufacturer’s existing designs. |

| IP Ownership | 100% Yours: Your intellectual property is protected and manufactured. | Manufacturer Owned: You are licensing a pre-existing product design. |

| Time-to-Market | Longer: Requires prototyping, testing, and process validation. | Faster: The product is already designed and often certified. |

| Upfront Investment | Higher: Involves tooling costs, R&D, and prototyping. | Lower: Minimal to no R&D or tooling costs required. |

| Customization Level | Extremely High: Every aspect can be tailored to your exact needs. | Low: Typically limited to branding, colors, and packaging. |

Hele Titanium Hydrogen offers both OEM and ODM pathways, ensuring we can provide the optimal solution for your business goals and resources.

II. The Hele Titanium Hydrogen OEM Portfolio: Core Services for Your Success

Choosing an OEM partner means choosing a set of capabilities. A top-tier provider offers more than just assembly; they offer an integrated ecosystem of services designed to optimize your product for performance, cost, and reliability. Here is what you should expect from expert electrolyzer manufacturing.

1. Collaborative Engineering & Design for Manufacturability (DFM)

A great design on paper doesn’t always translate to an efficient product in reality. Our DFM process is a critical collaborative step. Our engineers analyze your CAD files and technical drawings not to change your vision, but to enhance it. We identify opportunities to:

- Optimize Material Usage: Refine designs for efficient use of high-cost materials like titanium and platinum-group catalysts, reducing your per-unit cost.

- Improve Assembly Efficiency: Suggest minor modifications that can dramatically reduce assembly time and labor costs during scaled production.

- Enhance Thermal Management & Durability: Ensure your design allows for optimal heat dissipation and fluid dynamics, crucial for the electrolyzer stack’s long-term health and performance.

2. Precision Manufacturing of Core Components

The performance of a PEM electrolyzer is determined by the quality of its core components. Our state-of-the-art facility provides precision hydrogen production OEM services, focusing on:

- Titanium Bipolar Plates: We specialize in the stamping, CNC machining, and advanced coating of titanium bipolar plates. Titanium is the superior material choice for its exceptional corrosion resistance in the harsh acidic environment of a PEM cell, ensuring maximum lifespan and preventing ion contamination that can poison the catalyst.

- Membrane Electrode Assembly (MEA) Integration: The MEA is the heart of the electrolyzer. Our process of catalyst coating and hot-pressing the proton exchange membrane is conducted in a Class 10,000 cleanroom environment. This prevents airborne contaminants from compromising the MEA’s efficiency and longevity.

- Automated Stack Assembly & Compression: We utilize torque-calibrated equipment to ensure perfectly uniform compression across the entire stack. Improper compression can lead to gas leaks or damage to the MEA. Every single stack undergoes a rigorous multi-stage leak testing protocol, including helium leak detection, to guarantee its integrity.

3. End-to-End Customization: Performance, Form Factor, and Branding

Your product needs to meet your market’s unique demands. Our customized electrolyzers service allows for unparalleled flexibility:

- Performance Customization: Tailor the number of cells, active surface area, and catalyst loading to achieve your specific targets for hydrogen output (Nm³/h), operating pressure (up to 3.0 MPa), and purity (up to 99.999%).

- Integration Customization: We can modify port configurations (gas/water outlets), overall stack dimensions, and mounting points to ensure seamless and simple integration into your Balance of Plant (BoP) and final product enclosure.

- Branding & Aesthetics: Make the product truly yours. We offer laser-etching for your logo on the stainless steel end plates, custom-printed data plates with your serial numbering system, and fully branded packaging solutions.

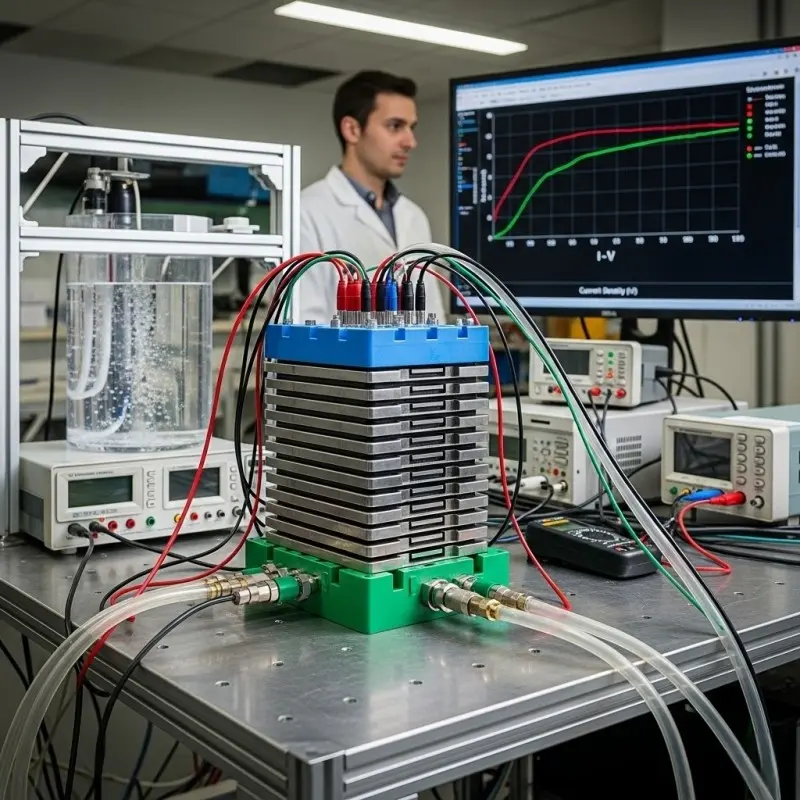

4. Rigorous Quality Assurance & Performance Validation

Trust is built on verifiable performance. Every single electrolyzer stack that leaves our facility is accompanied by a detailed quality and performance report. Our multi-point validation protocol includes:

- Individual cell voltage monitoring under load.

- Polarization curve (I-V curve) testing to confirm electrochemical efficiency.

- Verified hydrogen output measurement at nominal and peak power.

- Long-duration stability and gas purity testing.

Our processes are ISO 9001:2015 certified, ensuring that every step, from raw material inspection to final packaging, adheres to the highest international standards of quality.

Ready to discuss your technical specifications? Download our OEM Services & Technical Capabilities Brochure to see the full scope of our manufacturing prowess.

III. The Strategic Imperative: De-Risking Your Hydrogen Venture with an OEM Partner

Entering any new market carries risk. The green hydrogen market, with its high-tech and capital-intensive nature, is no exception. Partnering with an experienced hydrogen technology OEM is one of the most effective risk mitigation strategies your business can deploy.

Mitigating Financial Risk

The most obvious benefit is the avoidance of millions of dollars in upfront capital expenditure (CapEx). Building a specialized manufacturing facility, purchasing precision machinery, and hiring a skilled technical workforce is a monumental financial undertaking. With an OEM partnership, you convert that massive CapEx into a predictable, scalable operational expense (OpEx), freeing up capital to invest in your core competencies: R&D, marketing, and sales.

Mitigating Technical Risk

PEM electrolyzer manufacturing is a highly specialized field. There are countless pitfalls in stack design, material selection, and assembly that can lead to underperformance, premature degradation, or catastrophic failure. By partnering with Hele Titanium Hydrogen, you leverage over a decade of focused R&D and hands-on manufacturing experience. We have already solved the complex problems, so you don’t have to.

Mitigating Supply Chain Risk

The supply chain for critical PEM components—such as Nafion™ membranes, iridium catalysts, and porous transport layers—is tight and globally complex. An OEM partner with established, high-volume purchasing relationships can secure these materials more reliably and at a better price point than a new market entrant. We manage the entire supply chain, insulating your production from volatility and ensuring a steady flow of components to meet your demand.

IV. Your Buyer’s Checklist: 7 Criteria for Selecting the Right PEM Electrolyzer OEM Partner

Not all OEM providers are created equal. Your brand’s reputation and your product’s performance depend on making the right choice. Use this checklist to rigorously evaluate potential partners.

- Verifiable Technical Expertise & Track Record

- Ask: “Can you provide anonymized case studies or performance data from past OEM projects with similar requirements to ours?”

- Pro Tip: Look for a partner with deep expertise in both electrochemistry and precision mechanical engineering.

- Robust Quality Management System (QMS)

- Ask: “Can we review your quality manual and ISO 9001 certification? What is your testing protocol for 100% of manufactured stacks?”

- Pro Tip: A world-class partner will be proud to share their quality processes and will welcome an audit of their facility.

- Ironclad Intellectual Property (IP) Protection

- Ask: “What specific measures, both legal (NDA) and physical (facility security), do you take to protect our designs and trade secrets?”

- Pro Tip: Ensure their Non-Disclosure Agreement (NDA) is comprehensive and mutually protective.

- Demonstrable Scalability and Capacity

- Ask: “What is your current production capacity in MW/year, and what are your expansion plans? Can you provide a roadmap for how you would scale production to meet our 5-year forecast?”

- Pro Tip: A good partner will be able to handle your journey from initial prototypes to full-scale mass production seamlessly.

- Transparent and Proactive Communication

- Ask: “Who will be our dedicated project manager and single point of contact? What is the standard frequency and format for project updates?”

- Pro Tip: Excellent communication is the bedrock of a successful OEM partnership. Look for responsiveness and clarity from your very first interaction.

- Supply Chain Transparency and Resilience

- Ask: “Can you share information on the origin and qualification process for your key raw materials, like membranes and catalysts?”

- Pro Tip: This demonstrates their commitment to quality and their ability to manage supply chain risks effectively.

- Comprehensive After-Sales Support and Warranty

- Ask: “What does your standard warranty cover, and for how long? What level of technical support do you provide for system integration challenges post-delivery?”

- Pro Tip: A true partner’s commitment doesn’t end when the product ships.

V. Real-World Success: OEM Partnership Case Studies

Theory is one thing; results are another. Here are two anonymized examples of how our PEM electrolysis OEM services have empowered clients to achieve their goals.

Case Study 1: The Agile Startup – Speed-to-Market

- Challenge: A well-funded European startup had developed a groundbreaking, highly efficient PEM stack design for residential energy storage but lacked any manufacturing capabilities. They needed to get a certified product to market within 24 months to secure their next round of funding.

- Solution: Hele Titanium Hydrogen engaged in a rapid DFM process, optimizing their design for mass production in just 8 weeks. We produced and validated prototypes in 4 months, allowing them to proceed with system certification in parallel with our production line setup.

- Result: The client launched their product 16 months ahead of schedule compared to their plan of building their own factory. They successfully secured Series B funding and have since scaled their production order with us by 400%.

Case Study 2: The Industrial Integrator – Deep Customization

- Challenge: A leading North American provider of hydrogen refueling stations needed a custom electrolyzer stack. Their existing off-the-shelf supplier’s product was inefficient at the high pressures they required and had a footprint that complicated their station design.

- Solution: Our engineering team worked with their designers to create a completely custom stack. We developed a unique bipolar plate flow field design to maximize efficiency at high pressure and engineered a vertical, compact form factor with custom port locations.

- Result: The new, OEM-manufactured stack delivered a 12% increase in hydrogen production efficiency at their target operating pressure and reduced the overall system footprint by 30%, simplifying installation and reducing site costs. They now use this custom Hele-manufactured stack as the standard across their entire product line.

VI. The Future of PEM Electrolysis Manufacturing & Your Competitive Edge

The PEM water electrolysis landscape is evolving rapidly. Partnering with an OEM at the forefront of manufacturing innovation ensures your product won’t be obsolete in a few years. Key trends we are actively integrating include:

- Automation & Robotics: Implementing automated systems for MEA fabrication and stack assembly to increase precision, boost throughput, and reduce human error.

- Advanced Materials R&D: Continuously testing and validating new catalysts, membranes, and coating technologies to push the boundaries of efficiency and reduce reliance on rare materials.

- Digitalization & Industry 4.0: Utilizing digital twins and data analytics to monitor production lines in real-time, enabling predictive maintenance and providing unprecedented quality control and traceability for every stack we produce.

By choosing Hele Titanium Hydrogen, you are not just getting a manufacturer; you are gaining a partner committed to keeping your product at the cutting edge of hydrogen technology OEM.

VII. Conclusion: Build Your Hydrogen Future on a Foundation of Trust and Expertise

The journey to a greener planet is paved with innovation and collaboration. For companies poised to make their mark on the hydrogen economy, PEM water electrolyzer OEM services offer the most efficient, cost-effective, and low-risk pathway to launching a world-class product.

The success of this journey, however, hinges on one critical decision: choosing the right partner. The ideal OEM manufacturer is more than a supplier on a purchase order; they are an extension of your team, a guardian of your intellectual property, and a co-collaborator in your success. They provide the foundation of manufacturing excellence upon which you can build your brand.

Hele Titanium Hydrogen is ready to be that foundation.

Take the Next Step on Your OEM Journey:

- Ready to transform your design into a market-leading product? Contact our OEM solutions team today for a confidential consultation and to get your project started.

- Need more technical detail? Download our comprehensive OEM Services Brochure for an in-depth look at our capabilities, materials, and quality processes.

- Have a specific engineering question? Schedule a no-obligation 30-minute technical call with one of our lead electrolyzer engineers to discuss your project’s unique challenges.

Email Us: heletitaniumhydrogen@gmail.com Phone/WhatsApp: +86-13857402537

VIII. Frequently Asked Questions (FAQ)

Q: What is the typical Minimum Order Quantity (MOQ) for PEM electrolyzer OEM services?

A: MOQs vary depending on the complexity and customization of the project. For fully custom designs, we typically start with a prototype and pilot run phase before defining an MOQ for mass production. We are flexible and work to create a plan that aligns with your business’s scaling strategy.

Q: What is the lead time from design finalization to first prototype delivery?

A: While this depends on the project’s specifics, a typical timeline for the first functional prototype is between 12-16 weeks after the DFM process is complete and the design is frozen. We prioritize clear communication and provide a detailed project timeline upfront.

Q: Can you assist with the design and supply of the Balance of Plant (BoP)?

A: Our core expertise is the PEM electrolyzer stack itself. However, we have an extensive network of trusted partners and can provide technical support and recommendations for sourcing high-quality BoP components (power supplies, water purifiers, gas dryers, etc.) that are compatible with our stacks.

Q: What are the primary cost drivers in PEM electrolyzer manufacturing?

A: The main cost drivers are the precious metal catalysts (platinum and iridium), the proton exchange membrane, and the titanium bipolar plates. Our DFM process and volume purchasing power are specifically focused on optimizing the use of these materials to deliver the best possible cost-performance ratio for our clients.

Q: What is your warranty policy on OEM-manufactured stacks?

A: We offer a comprehensive manufacturer’s warranty that covers defects in materials and workmanship. The specific duration and terms are tailored to the operating parameters and application of the final product and are clearly defined in our OEM supply agreement.

Q: How do you manage international shipping and customs clearance?

A: We have extensive experience in global logistics. Our team handles all aspects of secure, industrial-grade packaging and coordinates with international freight forwarders to ensure your products arrive safely and on time. We provide all necessary documentation for smooth customs clearance in your destination country.

Hele Titanium Hydrogen: Your Trusted Hydrogen Generator OEM & Manufacturing Partner

Hele Titanium Hydrogen stands as a reliable and experienced partner in the hydrogen generator OEM supply chain. We specialize in the design, development, and manufacturing of high-performance PEM Water Hydrogen Generators, offering comprehensive OEM & Manufacturing services tailored to your specific needs.

Take the Next Step

Ready to explore the possibilities of partnering with Hele Titanium Hydrogen?

- Browse our Products to see our range of PEM Water Hydrogen Generators.

- Learn more about our Services and how we can support your OEM & Manufacturing needs.

- Contact Us today to discuss your specific requirements.

- Explore our FAQ to get answers to common questions.

- Visit our Blog for the latest insights and updates on hydrogen technology.

Email Us: heletitaniumhydrogen@gmail.com

Phone/WhatsApp: 086-13857402537