Introduction: The Manufacturing Barrier to Hydrogen Innovation

The global green hydrogen market is on a trajectory to exceed $130 billion by 2030. At the heart of this revolution lies Proton Exchange Membrane (PEM) water electrolysis technology, renowned for its efficiency, dynamic response, and compact footprint. As a visionary company in this space, you possess the ambition and perhaps even a groundbreaking design to capture a piece of this booming market.

However, a significant gap often exists between a brilliant prototype and a commercially viable, mass-produced product. The path is fraught with daunting challenges: the exorbitant capital expenditure for a production facility, the immense complexity of sourcing and qualifying critical components like membranes and catalysts, the relentless demand for rigorous quality control, and the ever-present fear of intellectual property (IP) leakage.

This is where the strategic power of a PEM water electrolyzer OEM services partnership becomes not just an option, but a critical business imperative. Choosing the right PEM electrolyzer OEM manufacturer is the most effective way to de-risk your market entry, accelerate your timeline, and scale your operations without the monumental upfront investment. This guide will provide you with the framework to select a partner that doesn’t just build your design but becomes a cornerstone of your commercial success, ensuring your hydrogen production OEM goals are met with precision and professionalism.

I. OEM vs. ODM: The First Critical Strategic Choice for Your Business

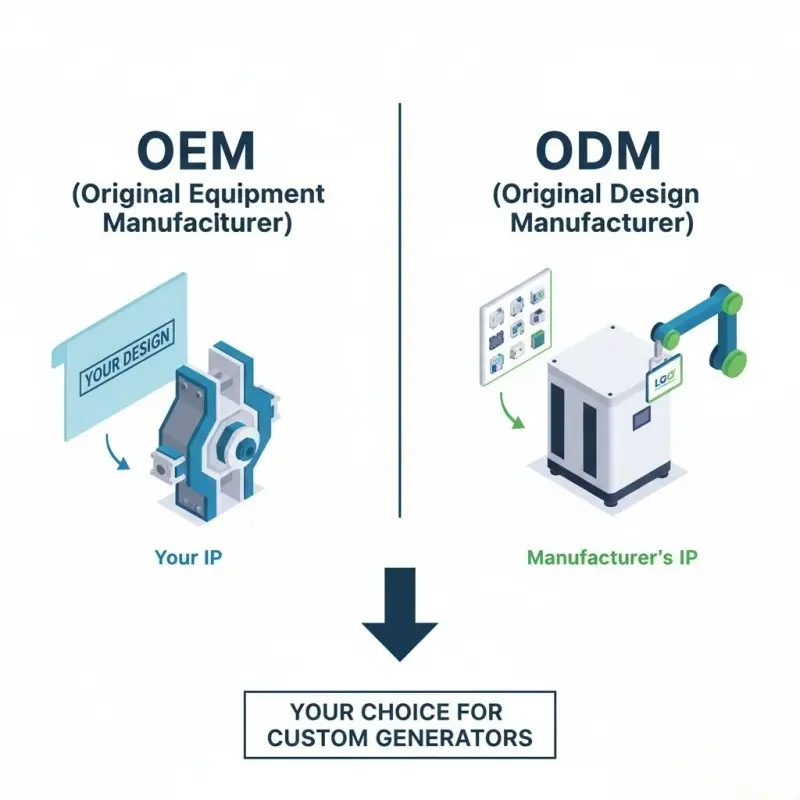

Before embarking on your manufacturing journey, you must choose the path that aligns with your business model and intellectual property strategy. Understanding the distinction between OEM and ODM is paramount.

The OEM Path: For When Your Design is Your Advantage

Original Equipment Manufacturing (OEM) is a partnership model where you, the client, provide the complete design blueprint, technical specifications, and intellectual property. The manufacturer’s role is to execute your vision with precision, building the product exactly to your requirements under your brand name.

- Who it’s for: Technology startups with proprietary designs, established energy companies expanding their portfolio, research institutions commercializing patents, and system integrators requiring custom solutions.

- Key Advantage: Full control over the design and complete ownership of the IP. This is non-negotiable for companies whose competitive edge is their unique technology.

- The Hele Titanium Hydrogen Commitment: We specialize in the true OEM model. We treat your proprietary designs with the utmost confidentiality, acting as a seamless extension of your manufacturing arm. Our focus is on precision execution of your vision, ensuring your innovation remains exclusively yours.

The ODM Path: Speed to Market with Proven Platforms

Original Design Manufacturing (ODM) is a model where the manufacturer provides both the design and the manufacturing. You can apply minor customizations and your branding to an existing, pre-engineered product.

- Who it’s for: Distributors, resellers, companies new to the hydrogen space focusing on branding and market entry, or those needing a quick-to-market solution without core R&D.

- Key Advantage: Dramatically reduced time-to-market and lower initial development costs.

- Our Role: While our core expertise is OEM, we can guide clients toward ODM solutions if it better suits their strategic goals.

| Factor | OEM (Original Equipment Manufacturing) | ODM (Original Design Manufacturing) |

|---|---|---|

| Design Control | High (Your IP) | Low (Manufacturer’s IP) |

| IP Ownership | You retain full ownership | Manufacturer retains design IP |

| Customization | Unlimited (Based on your specs) | Limited to available options |

| Time-to-Market | Longer (Design validation required) | Faster (Off-the-shelf design) |

| Development Cost | Higher initial investment | Lower initial investment |

| Ideal Hele Solution | Full engineering & manufacturing partnership | Recommended for standard branding projects |

II. Beyond the Blueprint: The Hele Titanium Hydrogen OEM Partnership Advantage

Selecting a manufacturer is more than finding the lowest cost per unit. It’s about choosing a strategic partner whose capabilities enhance your product and de-risk your production. Here’s what sets a true partnership apart.

1. Engineering Synergy: From Your Design to Optimized Manufacturability

We believe our value begins long before production starts. Our engineering team conducts a thorough Design for Manufacturability (DFM) analysis on every client design. This collaborative process involves:

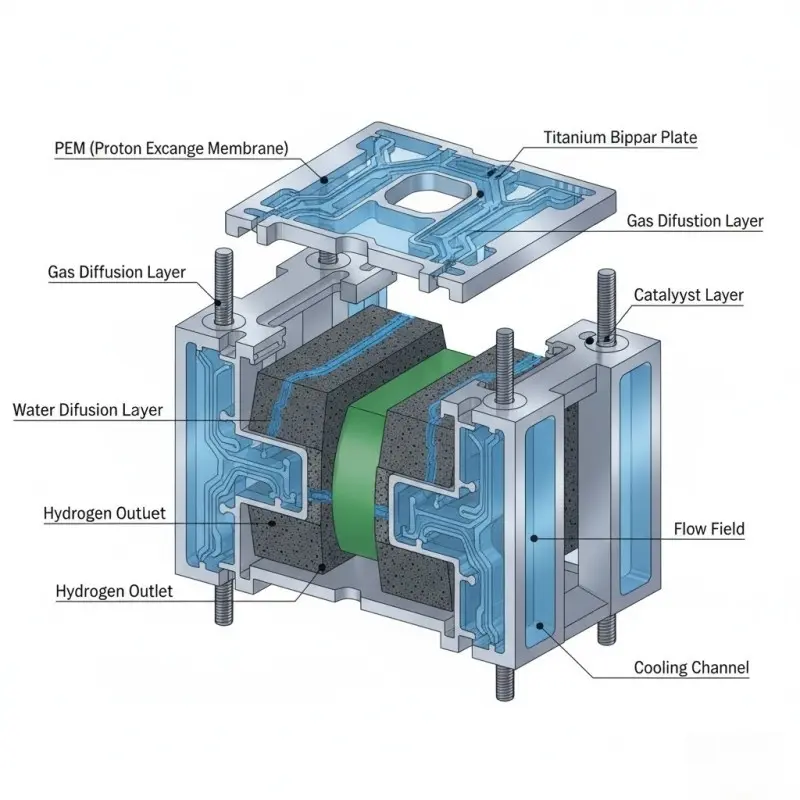

- Material Selection Advisory: We advise on material choices that optimize performance, cost, and longevity. This is where our namesake expertise shines. Our deep knowledge of titanium components—crucial for bipolar plates due to their exceptional corrosion resistance and durability in the harsh PEM environment—can be instrumental in enhancing your stack’s lifespan and reliability.

- Tolerance and Assembly Analysis: We identify potential assembly challenges and suggest modifications for smoother, more efficient production, reducing waste and cost.

- Value Engineering: We seek opportunities to simplify complex parts without compromising performance, ultimately increasing your profit margin.

2. The Titanium Standard: Rigorous Quality and Precision Assembly

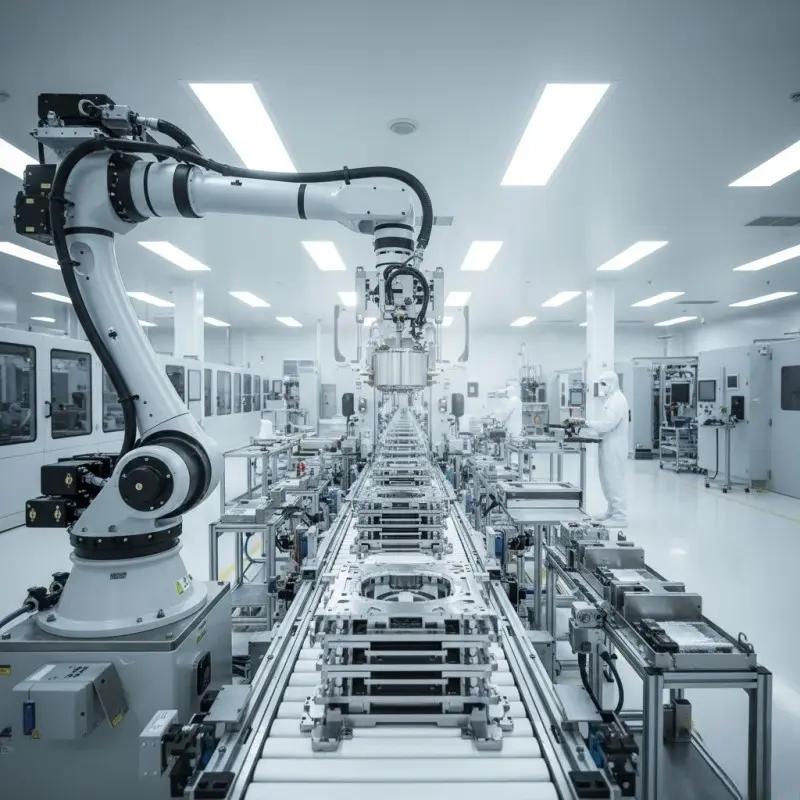

The consistency and reliability of your end product are a direct reflection of our manufacturing ethos. Our process is built on a foundation of precision and quality control.

- Precision Machining: Advanced CNC machinery ensures bipolar plates and other critical components are produced to exact micron-level tolerances.

- Cleanroom Assembly: Our PEM stack assembly is conducted in a controlled environment to prevent contamination of the sensitive MEA (Membrane Electrode Assembly), a critical factor in performance and longevity.

- Multi-Stage Testing: Every unit undergoes a rigorous battery of tests:

- Helium Leak Testing: To ensure perfect sealing and hydrogen purity.

- Performance Validation: Testing key parameters like efficiency, hydrogen output, and pressure under load.

- Safety Function Checks: Verifying all safety interlocks and controls.

- Certified Quality Management: Our adherence to international standards (ISO 9001) is a baseline requirement, not an aspiration.

3. Uncompromising IP Protection: Your Design is Your Property

We understand that your design is your most valuable asset. We build trust by fiercely protecting it through:

- Comprehensive NDAs: Legally binding non-disclosure agreements are the starting point of any conversation.

- Segregated Project Teams: Dedicated engineers and production staff are assigned to your project, ensuring information is shared on a need-to-know basis.

- Secure Data Management: Your designs and technical documents are handled with the highest level of digital security.

4. Scalability and Supply Chain Resilience

A good partner can build a prototype; a great partner can manufacture 10,000 units without compromising quality. We offer flexible MOQs, supporting you from pilot batches for field testing to full-scale mass production. Furthermore, our established, vetted supply chain for critical materials (Nafion™-equivalent membranes, catalyst-coated membranes, titanium) provides stability, insulates you from market volatility, and ensures consistent component quality.

III. The 5-Point Checklist for Selecting Your OEM Partner

Arm yourself with this checklist to evaluate potential manufacturing partners effectively.

- Technical & Material Expertise:

Do they have a proven track record with PEM water electrolysis technology?

Ask specific questions about stack design, flow fields, and material choices. Can they discuss the advantages of titanium over stainless steel for bipolar plates? Their answers will reveal their depth of knowledge.

- A Culture of Quality, Not Just Compliance: Don’t just ask if they are ISO certified. Ask to see their Quality Control plan. How do they statistically process control (SPC) their production line? What is their protocol for a failed test? A reputable electrolyzer manufacturing partner will be transparent about their processes.

- Ironclad IP Protection Protocols: What specific physical and digital measures do they have in place to protect client data?

Get these protocols in writing within your contract.

- Proven Scalability: Can they provide case studies or references from other clients they have scaled with? Ask about their current production capacity and lead times for large orders.

- Communication and Transparency: Is your point of contact a salesperson or an engineer? Will you have a dedicated project manager? What are the reporting protocols (e.g., weekly production updates, quality reports)? Avoid partners who are vague or difficult to reach.

IV. The Partnership Journey: From Initial Dialog to Global Delivery

Our OEM process is designed for clarity, collaboration, and success.

- Stage 1: Discovery & Feasibility: We begin with a signed NDA, followed by a deep-dive technical meeting to understand your design, goals, and requirements. We then provide a preliminary feasibility assessment and a transparent costing outline.

- Stage 2: Design Optimization & Prototyping: Our engineering team performs a DFM analysis and provides suggestions. Upon your approval, we proceed to build and test functional prototypes, providing comprehensive validation data.

- Stage 3: Pilot Run & Certification: We produce a small pilot batch of units for your internal testing, third-party certification, and initial market deployment. This phase ensures everything is perfect before full ramp-up.

- Stage 4: Ramp-Up & Full-Scale Production: We execute the mass production plan, maintaining continuous quality monitoring and providing you with regular production and QC updates.

- Stage 5: Delivery & Continuous Support: We manage global logistics to deliver your customized electrolyzers anywhere in the world. Our partnership continues with comprehensive after-sales support, warranty services, and spare parts availability.

Case Study Insight: Partnering for a European Energy Innovator A leading European cleantech startup approached us with a novel PEM stack design aimed at high-pressure output. While their design was innovative, certain aspects were cost-prohibitive for mass production. Through our DFM process, our engineers suggested an alternative titanium grading and a modified sealing geometry that reduced machining time by 15% without affecting performance. We facilitated a successful pilot run of 50 units, which achieved their necessary certifications. Today, we are their sole manufacturing partner, scaling production to meet their order book of over 200 units per month. This collaboration underscores how engineering synergy is key to successful hydrogen technology OEM partnerships.

V. Conclusion: Forge Your Hydrogen Future with a Foundation of Manufacturing Excellence

The race for green hydrogen dominance is underway. The companies that will lead are those that move fastest and most reliably from concept to commercial scale. This requires a manufacturing foundation that is as robust, innovative, and dependable as the technology itself.

By choosing a partner like Hele Titanium Hydrogen, you gain more than a factory; you gain a strategic ally dedicated to your success. We provide the engineering expertise, manufacturing rigor, and unwavering commitment to quality and IP protection that allows you to focus on what you do best: innovating and growing your market.

Your vision for a greener future deserves a manufacturing partner that can keep pace.

FAQ Section

Q: What is your experience with titanium components in PEM stacks?

A: Titanium is core to our expertise. We possess deep knowledge in machining, treating, and utilizing titanium grades specifically suited for the corrosive environment within a PEM electrolyzer. This expertise directly translates to longer stack life and higher reliability for our clients’ products.

Q: How do you ensure consistent quality across high-volume production runs?

A: Consistency is guaranteed through our statistically controlled processes, automated assembly where applicable, and rigorous in-line testing. Every single unit undergoes performance and leak testing, not just random samples from a batch. Our ISO 9001-certified quality management system provides the framework for this consistency.

Q: Can we start with a small pilot batch before committing to a large order?

A: Absolutely. We encourage and regularly facilitate pilot production runs. This allows you to validate the manufacturing quality, obtain necessary field data, and secure certifications before investing in full-scale production.

Q: What does the communication process look like?

A: You will be assigned a dedicated project manager who is your single point of contact. We provide regular production updates, quality reports, and schedule video calls to ensure you are always informed and in control. We pride ourselves on transparent and proactive communication.

Q: Do you provide support with international certifications and documentation?

A: Yes. We have experience building products to meet various international standards (CE, UKCA, etc.). We provide all necessary manufacturing documentation and test reports to support your certification efforts. However, the responsibility for obtaining the final product certification typically lies with the brand owner (you).

Take the Next Step with Hele Titanium Hydrogen

Ready to explore how our PEM water electrolyzer OEM services can power your growth? We invite you to take the next step.

- 📞 Schedule a Confidential Consultation: Speak directly with our engineering team to discuss your specific project needs and challenges.

- 📧 Request a Custom Feasibility Assessment: Send us your preliminary specifications for an initial high-level evaluation and quote.

- 📥 Download Our OEM Partnership Guide: A detailed PDF outlining our capabilities, processes, and technical specifications.

Contact Us Today to transform your PEM electrolyzer design into a market-ready reality. Let’s build the future of hydrogen, together.

Email Us: heletitaniumhydrogen@gmail.com Phone/WhatsApp: +86 138 5740 2537