Best PEM Stacks for Industrial Hydrogen Production: A Complete Buyer’s Guide Discover the advantages of PEM stacks for industrial hydrogen use. Learn how Hele Titanium Hydrogen delivers high-performance PEM solutions to maximize uptime, efficiency, and ROI.

I. Introduction

The demand for industrial hydrogen is projected to increase by more than 50% over the next decade, driven by the global push for decarbonization and clean energy. From steelmaking and refining to ammonia and methanol production, hydrogen is becoming the backbone of sustainable industrial operations.

But producing hydrogen at scale requires reliable, efficient, and cost-effective technology. This is where PEM stacks for industrial hydrogen use stand out.

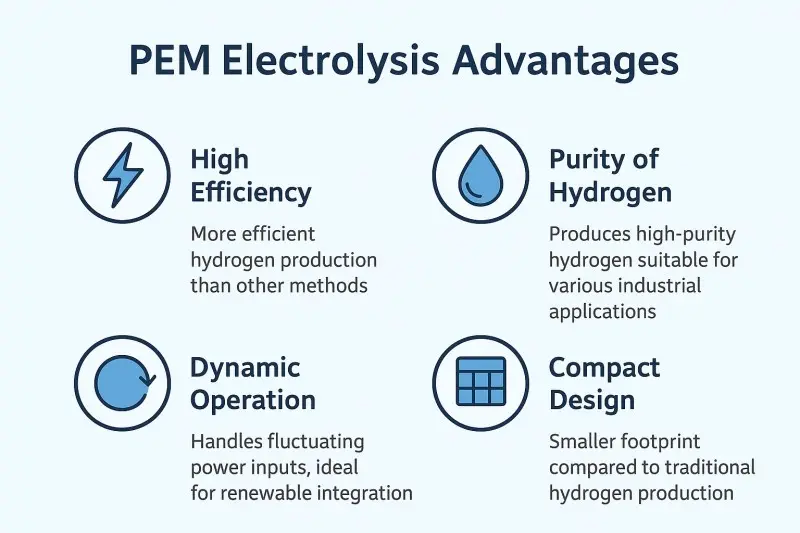

Proton Exchange Membrane (PEM) technology offers high efficiency, rapid response to fluctuating power loads, and exceptional hydrogen purity — making it the technology of choice for modern industrial hydrogen systems.

In this article, we’ll guide you through:

- How PEM stacks work.

- The advantages and challenges of PEM technology.

- Key factors to consider when choosing PEM stacks.

- Why Hele Titanium Hydrogen is your trusted OEM partner.

- Future trends shaping the hydrogen economy.

II. What Are PEM Stacks and Why They Matter for Industrial Hydrogen?

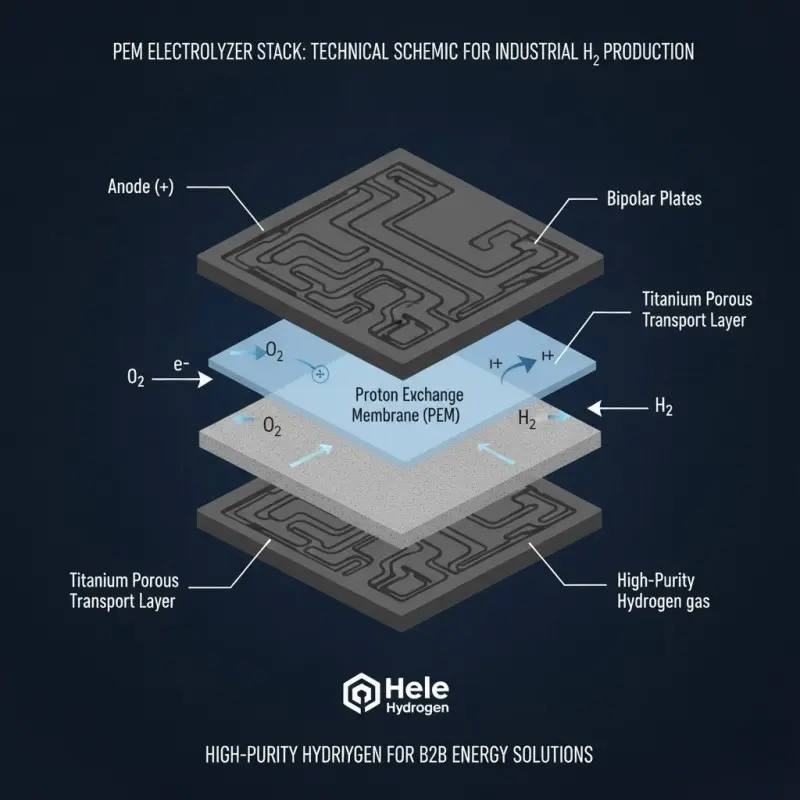

How PEM Electrolysis Works

PEM electrolysis splits water into hydrogen and oxygen using a proton exchange membrane as the electrolyte. The stack — composed of membranes, electrodes, and bipolar plates — is the “heart” of the system, determining efficiency, durability, and hydrogen output.

PEM vs. Other Electrolysis Technologies

| Technology | Efficiency | Hydrogen Purity | CapEx | Scalability | Ideal Use Case |

|---|---|---|---|---|---|

| PEM Electrolysis | High (65–75%) | Very High (>99.99%) | Medium-High | Modular & Scalable | Industrial hydrogen, renewable integration |

| Alkaline Electrolysis | Moderate (55–65%) | High | Low | Large but rigid | Mature, low-cost plants |

| Solid Oxide Electrolysis (SOEC) | Very High (80%+) | Very High | Very High | Still emerging | High-temp industrial processes |

Key takeaway: PEM stacks provide the best balance of efficiency, purity, and scalability — especially when paired with renewable energy.

III. Challenges in Industrial Hydrogen Production

While PEM stacks are highly promising, buyers must account for a few challenges:

- Cost: PEM systems typically require higher initial investment than alkaline electrolysis.

- Durability: Harsh industrial conditions (pressure, water purity, heat) impact lifespan.

- Scaling Up: Meeting multi-megawatt demands requires modular system integration.

This makes supplier choice critical — the right partner ensures optimized design, reliable materials, and long-term service support.

IV. Key Factors When Choosing PEM Stacks for Industrial Use

Performance Metrics

- Current Density & Voltage Efficiency: High efficiency reduces operating costs.

- Hydrogen Production Rate: Must match your industrial demand profile.

Durability & Reliability

- Stack Lifespan: Top suppliers provide stacks lasting 50,000+ hours.

- Material Selection: Titanium, corrosion-resistant alloys, and advanced membranes extend durability.

ROI & Total Cost of Ownership (TCO)

- Initial CapEx vs. Opex: Electricity and maintenance often outweigh purchase costs.

- Payback Period: Efficient PEM stacks pay off faster through reduced energy consumption.

Procurement Checklist

- Proven industrial track record.

- OEM customization options.

- Technical support & global service.

- Warranty and after-sales guarantees.

V. Hele Titanium Hydrogen: Advanced PEM Solutions for Industrial Use

At Hele Titanium Hydrogen, we specialize in PEM water hydrogen generators designed for industrial reliability and performance.

Our Advantages

- High-Performance PEM Stacks: Engineered for maximum efficiency and purity.

- OEM & Manufacturing Services: Customized solutions for industrial-scale hydrogen projects.

- Durability First: Titanium-based components ensure corrosion resistance and long service life.

- Global Supply Chain Support: From design to delivery, we partner with clients worldwide.

- After-Sales Service: Comprehensive technical support, maintenance, and warranty coverage.

👉 Explore our Products 👉 Learn more about our OEM Services

VI. Industrial Applications of PEM Stacks

PEM stacks are driving the transition to clean hydrogen across industries:

- Chemical Industry: Ammonia & methanol production with reduced CO₂ emissions.

- Refining: Hydrogen for hydrocracking and desulfurization.

- Steelmaking: Replacing coal in direct reduction of iron ore.

- Energy & Power: Integration with renewables for green hydrogen storage.

- Transportation: Fueling heavy-duty trucks, ships, and future hydrogen corridors.

Hele Titanium Hydrogen enables industries to cut emissions, stabilize energy costs, and secure sustainable operations with PEM-based hydrogen systems.

VII. Future Trends in PEM Technology

- Advanced Membranes: Longer lifespans and higher efficiency.

- Cost Reduction: Economies of scale & streamlined manufacturing.

- Green Hydrogen Integration: Seamless operation with solar, wind, and hydro.

- Large-Scale Deployment: Multi-megawatt plants scaling to gigawatt hydrogen hubs.

Hele Titanium Hydrogen is actively investing in R&D to stay ahead of these innovations.

VIII. FAQs About PEM Stacks for Industrial Hydrogen Use

1. What is the lifespan of a PEM stack?

Typically 50,000–80,000 hours, depending on operating conditions and water quality.

2. How do PEM stacks compare to alkaline electrolysis?

PEM offers higher efficiency, hydrogen purity, and modular scalability but at a higher initial cost.

3. Can PEM stacks be customized for my industry?

Yes — Hele Titanium Hydrogen offers OEM customization to match capacity, pressure, and integration needs.

4. What maintenance is required?

Periodic inspections, water quality management, and stack replacement cycles. Our team provides full service support.

5. How scalable are PEM stacks?

PEM stacks are modular, meaning production can be scaled up simply by adding more stacks.

6. What support does Hele Titanium Hydrogen provide?

From system design to after-sales service, we offer global OEM partnerships and technical support.

IX. Conclusion: Partner with Hele Titanium Hydrogen

PEM stacks for industrial hydrogen use are the key to producing clean, efficient, and scalable hydrogen. By choosing the right supplier, industries can maximize uptime, lower operating costs, and future-proof their hydrogen strategy.

At Hele Titanium Hydrogen, we deliver high-performance PEM stacks backed by OEM expertise, global supply chain strength, and reliable after-sales support.

📌 Take the Next Step

- Browse Our Products

- Explore Our OEM Services

- Contact Us Today to discuss your hydrogen project.

📧 Email: heletitaniumhydrogen@gmail.com

📞 Phone/WhatsApp: 086-13857402537