Fueling the Future – Why Green Hydrogen is Gaining Momentum

The global energy landscape is undergoing a monumental transformation, driven by an urgent need to decarbonize and embrace sustainable alternatives. At the forefront of this revolution is green hydrogen, emerging as a versatile and potent energy carrier poised to redefine how we power our world. Particularly in the transportation sector, green hydrogen offers a zero-emission solution, critical for heavy-duty vehicles, fleet logistics, and public transport looking to drastically reduce their carbon footprint.

However, realizing the promise of hydrogen mobility hinges on establishing a robust, efficient, and readily accessible refueling infrastructure. The challenge lies in producing hydrogen cost-effectively and sustainably at the point of need. This is where PEM electrolyzers for hydrogen refueling stations step in as a game-changer. These advanced systems provide an on-site, scalable, and environmentally friendly method for generating high-purity hydrogen, directly powering the next generation of fuel cell electric vehicles (FCEVs).

This comprehensive guide, brought to you by Hele Titanium Hydrogen, will delve into the profound advantages of Proton Exchange Membrane (PEM) electrolyzer technology, illuminating why it is the unparalleled choice for hydrogen refueling applications. We will explore the technical superiority, operational benefits, and strategic considerations for selecting a trusted manufacturing partner. Our goal is to equip you with the knowledge to make informed decisions and accelerate your journey into the green hydrogen economy.

Ready to explore how Hele Titanium Hydrogen can be your partner in building the future of hydrogen refueling?

Chapter 1: The Science Behind the Solution – How PEM Electrolyzers Work

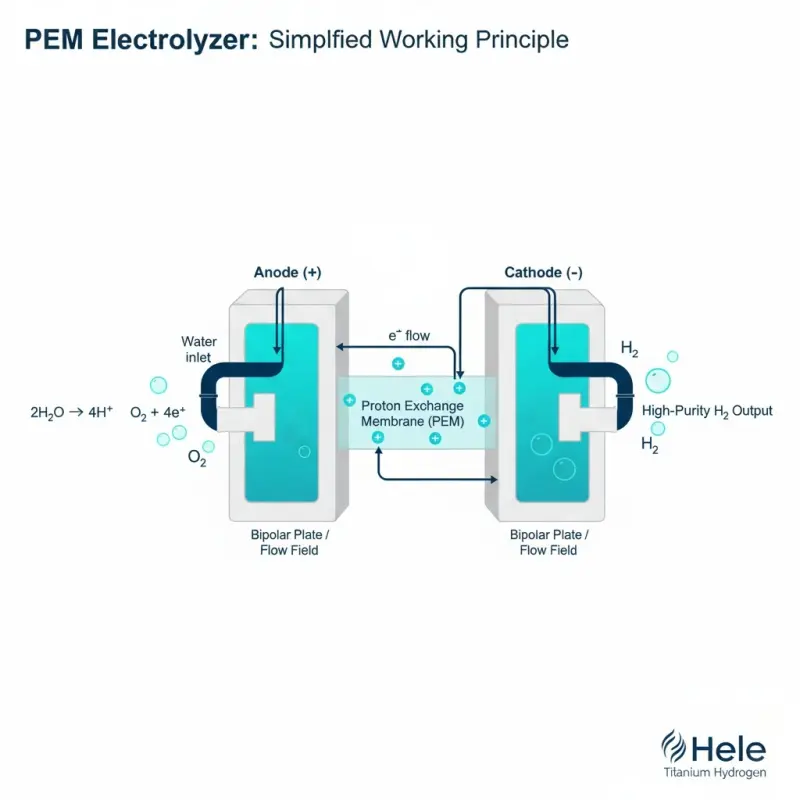

At its core, a PEM electrolyzer performs a deceptively simple yet profoundly impactful chemical reaction: splitting water (H₂O) into its constituent elements, hydrogen (H₂) and oxygen (O₂), using electricity. This process, known as electrolysis, is fundamental to green hydrogen production when powered by renewable energy sources like solar or wind.

1.1. The Electrocatalytic Split: Understanding the Core Process

The heart of the PEM electrolyzer is the Proton Exchange Membrane (PEM), a solid polymer electrolyte. Unlike traditional alkaline electrolyzers that use a liquid electrolyte (like KOH), the PEM is a thin, ion-conductive membrane.

The process unfolds as follows:

- Water Input: Deionized water is fed to the anode (positive electrode) side of the electrolyzer.

- Oxidation at Anode: At the anode, electrical energy, often supplied by renewables, facilitates the splitting of water molecules. Water loses electrons, producing oxygen gas (O₂), free electrons (e⁻), and positively charged hydrogen ions (protons, H⁺).

- Reaction: 2H₂O → O₂ + 4H⁺ + 4e⁻

- Proton Transport through PEM: The key distinguishing feature of PEM technology is the membrane itself. This specialized membrane is permeable only to protons (H⁺), allowing them to pass through while blocking the passage of electrons and oxygen gas. This ensures the separation of products and results in high-purity hydrogen.

- Reduction at Cathode: The electrons, unable to cross the membrane, travel through an external circuit to the cathode (negative electrode). At the cathode, these electrons recombine with the protons that have crossed the membrane, forming hydrogen gas (H₂).

- Reaction: 4H⁺ + 4e⁻ → 2H₂

- High-Purity Output: The result is separate streams of high-purity hydrogen gas (typically >99.999%) from the cathode side and oxygen gas from the anode side.

1.2. Key Components for Optimal Performance

The efficiency and longevity of a PEM electrolyzer depend heavily on the quality and design of its core components:

- Proton Exchange Membrane (PEM): This thin polymer film is the technological centerpiece. It must be highly conductive to protons, chemically stable, and resistant to gas crossover to ensure hydrogen purity. Materials like Nafion® are commonly used.

- Electrodes (Anode & Cathode): These are typically porous structures coated with precious metal catalysts (e.g., platinum for the cathode, iridium or ruthenium oxide for the anode). These catalysts accelerate the electrochemical reactions, reducing the energy input required.

- Bipolar Plates & Flow Fields: These plates serve multiple functions:

- Distributing water to the electrodes.

- Collecting the produced hydrogen and oxygen gases.

- Providing electrical conductivity between individual cells within a stack.

- Facilitating heat removal. Their design is crucial for uniform reactant distribution and efficient product removal.

- Gas Diffusion Layers (GDLs): Positioned between the electrodes and bipolar plates, GDLs manage fluid flow, electrical contact, and mechanical support.

1.3. Why PEM Stands Out: A Comparative Edge

While other electrolysis technologies exist (e.g., Alkaline, Solid Oxide Electrolyzers), PEM systems offer distinct advantages, particularly for dynamic applications like hydrogen refueling stations:

- Dynamic Response: PEM electrolyzers can rapidly adjust their power input and hydrogen output, making them ideal for coupling with intermittent renewable energy sources.

- High Current Density: They operate at higher current densities, leading to more compact systems for a given hydrogen production rate.

- High Purity Hydrogen: The inherent design of the PEM membrane ensures the production of extremely high-purity hydrogen, directly suitable for sensitive fuel cells without extensive post-purification.

This foundational understanding underscores why PEM technology is not just an option, but often the optimal choice for modern green hydrogen infrastructure.

Chapter 2: Unpacking the Value: Commercial Benefits of PEM Electrolyzers for Hydrogen Refueling

For businesses and investors venturing into the hydrogen economy, the choice of electrolysis technology profoundly impacts operational efficiency, cost-effectiveness, and environmental sustainability. Here, PEM electrolyzers for hydrogen refueling stations demonstrate unparalleled commercial advantages, making them the preferred technology for on-site hydrogen generation solutions.

2.1. Superior Dynamic Performance & Seamless Renewable Integration

The Achilles’ heel of many traditional energy systems is their inability to adapt to the variable nature of renewable energy. PEM electrolyzers, however, are engineered for this variability:

- Fast Response & Black Start Capability: Unlike conventional electrolyzers that may require hours to ramp up, PEM systems can achieve full hydrogen production within minutes, or even seconds, from a cold start (black start). This agility is critical for hydrogen refueling station electrolyzers that need to match fluctuating energy supply from solar or wind, or respond quickly to sudden demand spikes from vehicles.

- Load Following Capability: PEM electrolyzers can efficiently adjust their hydrogen output (load follow) across a wide operational range, from 5% to 100% of their capacity. This means they can maximize the utilization of intermittent renewable energy, absorbing excess power when available and ramping down during lulls, preventing energy curtailment and optimizing green hydrogen production.

- Hele Titanium Hydrogen Angle: At Hele Titanium Hydrogen, our PEM designs are meticulously optimized for seamless integration with renewable energy sources. This ensures that you can harness every available watt of green power, leading to truly sustainable and cost-effective hydrogen generation for your refueling infrastructure.

2.2. Unrivaled Hydrogen Purity for Fuel Cell Vehicles

The integrity of hydrogen fuel is paramount for the longevity and performance of fuel cell electric vehicles (FCEVs). Impurities, even at minute levels, can poison fuel cell catalysts, leading to degradation and costly repairs.

- Ultra-High Purity Output: PEM electrolyzers inherently produce hydrogen of extremely high purity, typically exceeding 99.999% (5.0 purity). This level of purity is often directly compliant with international standards for fuel cell grade hydrogen (e.g., ISO 14687), minimizing or even eliminating the need for expensive and complex secondary purification systems.

- Reduced Operational Costs (OPEX): By bypassing additional purification steps, commercial electrolyzer systems save on capital expenditure for purification equipment and ongoing operational costs associated with its maintenance and energy consumption.

- Enhanced Fuel Cell Longevity: Providing consistently pure hydrogen protects the sensitive components of FCEVs, ensuring longer fuel cell stack life and reducing maintenance downtime for your fleet.

- Hele Titanium Hydrogen Angle: Our PEM generators consistently deliver the ultra-high purity hydrogen required for even the most demanding fuel cell applications. This commitment ensures optimal vehicle performance, extended fuel cell lifespan, and compliance with the strictest industry standards, giving you peace of mind.

2.3. Compact Footprint and Modular Scalability

Space is a premium, especially in urban environments where many hydrogen refueling stations are being planned.

- Space Efficiency: PEM electrolyzers, due to their higher current density operation and simpler system architecture, boast a significantly smaller physical footprint compared to other electrolysis technologies. This makes them ideal for installation in constrained locations or for integration into existing refueling infrastructure without extensive site modifications.

- Modular Design for Future-Proofing: PEM systems are typically constructed in a modular fashion, allowing for easy expansion. As hydrogen demand grows, additional electrolyzer modules can be integrated, scaling production capacity without overhauling the entire system. This flexibility reduces initial capital outlay and future-proofs your investment.

- Hele Titanium Hydrogen Angle: Hele Titanium Hydrogen specializes in compact, modular PEM solutions designed for easy integration and future expansion. We empower you to make the most of your available space while providing a clear pathway for increasing hydrogen production capacity as your needs evolve.

2.4. High Efficiency Across Operating Ranges

Efficiency directly translates to the cost of hydrogen. Higher efficiency means less electricity is consumed per kilogram of hydrogen produced, driving down operational expenses.

- Optimized Energy Conversion: Modern PEM electrolyzers offer high energy conversion efficiency, particularly when operating within their optimal range. This means more of your electrical energy is converted into usable hydrogen.

- Efficiency at Partial Loads: Critically, PEM electrolyzers maintain good efficiency even when operating at partial loads. This is a significant advantage for dynamic H2 station technology that experiences fluctuating demand throughout the day.

- Hele Titanium Hydrogen Angle: Our relentless commitment to research and development ensures Hele Titanium Hydrogen PEM electrolyzers offer industry-leading efficiency. This directly contributes to a lower total cost of hydrogen for our clients, enhancing profitability and environmental performance.

2.5. Enhanced Safety & Reliability

Safety is paramount in any energy infrastructure, particularly with hydrogen.

- Inherent Design for Safety: PEM electrolyzers typically operate at lower temperatures than SOEC, reducing thermal management complexity. The solid membrane inherently separates the product gases, minimizing the risk of mixing.

- Robust Materials & Construction: Utilizing corrosion-resistant materials and robust engineering ensures the long-term reliability and safety of the system.

- Predictive Maintenance: Modern PEM systems often incorporate advanced sensor technology and remote monitoring, enabling predictive maintenance and ensuring continuous, safe operation.

- Hele Titanium Hydrogen Angle: Every Hele Titanium Hydrogen PEM electrolyzer is built to rigorous safety standards, incorporating advanced design principles and quality materials to ensure highly reliable and secure operation for your hydrogen refueling station electrolyzer.

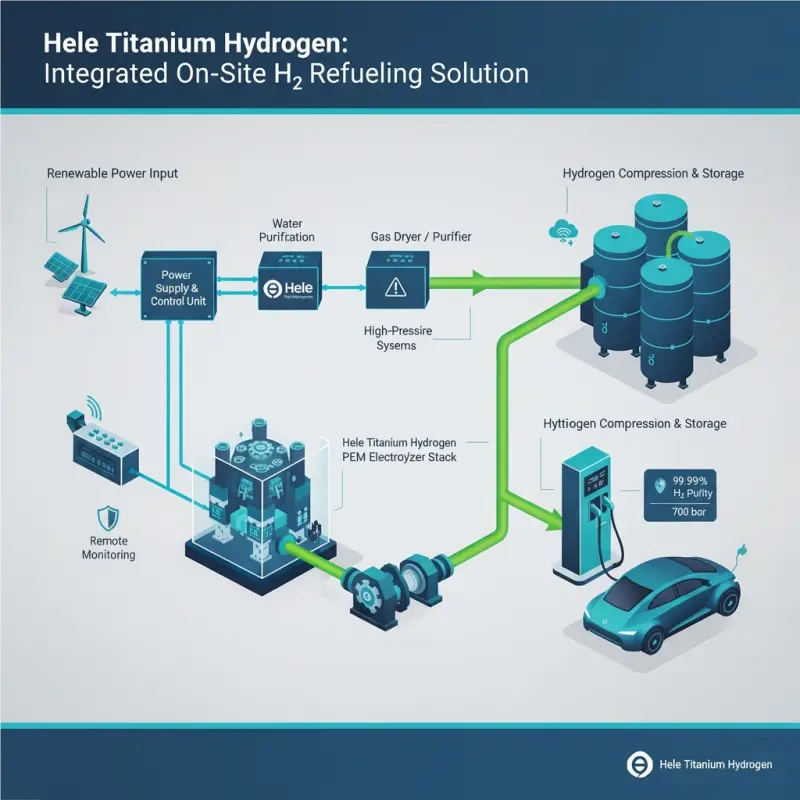

Chapter 3: Strategic Implementation: Integrating PEM Electrolyzers into Your Hydrogen Ecosystem

Implementing PEM electrolyzers for hydrogen refueling requires a holistic approach, considering not just the electrolyzer itself but its integration into a complete hydrogen generation and dispensing ecosystem. This strategic planning ensures maximum efficiency, safety, and return on investment.

3.1. On-Site Production: The Direct Advantage

The most compelling argument for PEM electrolyzers in refueling stations is their suitability for on-site hydrogen generation solutions.

- Reduced Logistics & Costs: Producing hydrogen directly at the refueling station eliminates the need for hydrogen to be transported from a central production facility. This cuts out significant logistical costs (transportation, handling, cryogenics for liquid hydrogen) and reduces the associated carbon footprint of delivery.

- Enhanced Supply Security: On-site generation provides stations with greater control over their hydrogen supply, reducing reliance on external suppliers and shielding against supply chain disruptions. This ensures consistent availability for FCEV users.

- Reinforced Green Credibility: When powered by directly connected renewable energy (solar, wind), on-site PEM electrolysis unequivocally positions your station as a provider of 100% green hydrogen production, enhancing your brand’s environmental credentials.

3.2. Essential Balance of Plant (BOP) Components

The electrolyzer is the core, but a successful hydrogen refueling station requires several crucial supporting systems, collectively known as the Balance of Plant (BOP). Hele Titanium Hydrogen provides expertise in integrating these components seamlessly:

- Water Purification System: Electrolyzers require highly purified water (deionized or demineralized) to prevent fouling and ensure efficient operation and membrane longevity. A robust water treatment system is non-negotiable.

- Hydrogen Compression & Storage: Produced hydrogen at low pressure (e.g., 30 bar) must be compressed to high pressures (e.g., 350 bar or 700 bar) for vehicle refueling. This involves multi-stage compressors and high-pressure storage tanks, carefully sized to match daily demand and buffer capacity. For larger demands, liquid hydrogen storage may be considered, but it adds complexity.

- Cooling Systems: Electrolysis is an exothermic process (generates heat). Efficient cooling systems are necessary to maintain optimal operating temperatures for the PEM stack, maximizing efficiency and lifespan.

- Power Supply & Conditioning: Integrating the electrolyzer with the electrical grid or renewable sources requires appropriate power electronics, rectifiers, and control systems to deliver stable and clean power.

- Gas Dryers & Purifiers (if needed): While PEM produces high purity, a final drying stage might be beneficial in certain climates or for specific applications to ensure moisture content is below vehicle specifications.

- Hele Titanium Hydrogen Angle: Hele Titanium Hydrogen offers not just the core electrolyzer but also unparalleled expertise in helping our clients integrate complete balance of plant systems. We act as your knowledgeable partner, ensuring a cohesive, safe, and efficient on-site solution tailored to your specific operational environment.

3.3. Advanced Monitoring & Control Systems

Modern hydrogen refueling stations leverage sophisticated digital control systems to ensure optimal performance, safety, and reliability.

- Remote Operation & Optimization: These systems allow for remote monitoring of all key parameters (production rate, purity, pressure, temperature, energy consumption), enabling operators to optimize performance and troubleshoot issues from a central location.

- Fault Detection & Safety Interlocks: Integrated safety protocols and automated shutdown mechanisms are crucial for rapid response to any anomalies, enhancing the overall safety of the station.

- Data Logging & Reporting: Comprehensive data logging supports performance analysis, efficiency improvements, and compliance reporting.

Chapter 4: Addressing Key Considerations & Hele Titanium Hydrogen’s Solutions

While PEM electrolyzers for hydrogen refueling offer undeniable benefits, discerning buyers also weigh potential considerations. At Hele Titanium Hydrogen, we believe in transparency and providing proactive solutions to these key areas, demonstrating why we are a reliable PEM electrolyzer supplier.

4.1. Navigating Initial Investment (CAPEX) with a Focus on TCO

The initial capital expenditure (CAPEX) for any new technology, including advanced PEM electrolyzers, can be a significant consideration. However, focusing solely on the upfront cost can be misleading.

- The Importance of Total Cost of Ownership (TCO): A more accurate financial assessment considers the Total Cost of Ownership (TCO), which includes CAPEX, operational expenses (OPEX like electricity, water, maintenance), and expected lifespan. PEM’s high efficiency, reliability, and low maintenance requirements often lead to a significantly lower TCO over the system’s lifetime compared to seemingly cheaper alternatives.

- Driving Down OPEX: As discussed, PEM’s superior efficiency directly translates to lower electricity consumption per kilogram of hydrogen, which is the largest component of OPEX. Its high purity output reduces or eliminates costly purification steps.

- Government Incentives & Support: Many governments worldwide offer substantial incentives, subsidies, and tax breaks for green hydrogen projects, significantly offsetting initial CAPEX. Staying informed about these programs is crucial.

- Hele Titanium Hydrogen Angle: While initial investment is always a consideration, Hele Titanium Hydrogen focuses on delivering PEM solutions with an optimized TCO through superior efficiency, long operational lifespans, and reduced maintenance needs. We help our clients model these long-term savings, providing a clearer picture of their return on investment.

4.2. Ensuring Long-Term Performance: Membrane & Electrode Durability

The heart of the PEM electrolyzer, the membrane and electrodes, are critical for continuous, high-performance operation. Their durability directly impacts the system’s lifespan and maintenance schedule.

- Continuous Improvement in Materials Science: Ongoing research and development in materials science are consistently yielding more robust and durable PEM membranes and electrode catalysts. This translates to extended stack lifetimes and reduced replacement frequencies.

- Operating Conditions Matter: Proper operating conditions – precise temperature control, optimal water quality, and adherence to manufacturer guidelines – are vital for maximizing the lifespan of these critical components.

- Hele Titanium Hydrogen Angle: Hele Titanium Hydrogen utilizes advanced, high-quality materials and rigorous quality control in the manufacturing of our PEM stacks. This dedication ensures exceptional membrane and electrode durability, leading to reliable, long-term operation with predictable maintenance cycles and a lower overall cost of ownership.

4.3. Scalability for Growing Demand

The hydrogen economy is still in its nascent stages, but growth projections are steep. Ensuring your initial investment can grow with demand is crucial.

- Inherent Modular Design: As highlighted, the modular nature of PEM electrolyzers makes them uniquely scalable. This means you can start with a capacity that meets current needs and easily add additional modules as demand for hydrogen vehicles in your region increases. This phased investment approach de-risks initial projects.

- Future-Proofing Infrastructure: Choosing a modular custom hydrogen generator system ensures your infrastructure remains relevant and capable of meeting future market expansion without requiring a complete overhaul.

- Hele Titanium Hydrogen Angle: Our modular PEM electrolyzer designs are inherently scalable, allowing you to seamlessly increase hydrogen production capacity as your refueling network expands. This flexibility makes Hele Titanium Hydrogen an ideal partner for long-term infrastructure development.

Chapter 5: Partnering for Success: Why Choose Hele Titanium Hydrogen as Your OEM Manufacturer

In the rapidly evolving hydrogen sector, selecting the right technology partner is as crucial as choosing the technology itself. As a dedicated commercial electrolyzer manufacturer and reliable PEM electrolyzer supplier, Hele Titanium Hydrogen stands ready to power your hydrogen ambitions.

5.1. Unmatched Expertise in PEM Water Hydrogen Generators

Our specialization is our strength. Unlike general energy companies, Hele Titanium Hydrogen focuses exclusively on the design, development, and manufacturing of high-performance PEM water hydrogen generators.

- Deep Technical Knowledge: Our team possesses profound expertise in PEM technology, from fundamental electrochemistry to advanced system integration. This specialization allows us to innovate faster and deliver optimized solutions.

- Continuous Innovation: We are committed to ongoing research and development, constantly improving our stack designs, materials, and overall system efficiency to stay at the forefront of the industry.

- Hele Titanium Hydrogen Angle: As a dedicated manufacturer of high-performance PEM water hydrogen generators, Hele Titanium Hydrogen brings specialized expertise, cutting-edge innovation, and a singular focus to every project, ensuring you receive the best possible solution.

5.2. Proven Track Record & Uncompromising Quality Manufacturing

Experience and quality are non-negotiable for critical infrastructure projects.

- Trusted OEM Supply Chain Partner: Hele Titanium Hydrogen has established itself as a reliable and experienced partner in the hydrogen generator OEM (Original Equipment Manufacturer) supply chain. We understand the stringent requirements of B2B clients and deliver on our promises.

- Rigorous Quality Control: Our manufacturing processes adhere to the highest international quality standards. Every component, every stack, and every complete system undergoes extensive testing to ensure performance, durability, and safety.

- Consistency and Reliability: Our reputation is built on delivering consistent, high-quality products that perform reliably in demanding operational environments.

- Hele Titanium Hydrogen Angle: Our commitment to excellence is backed by a proven track record of successful OEM partnerships and stringent quality assurance processes. You can trust Hele Titanium Hydrogen to deliver robust and dependable products that meet your exact specifications.

5.3. Tailored OEM & Custom Manufacturing Services

We understand that every hydrogen project has unique requirements. Generic solutions often fall short.

- Flexible Customization: Hele Titanium Hydrogen offers comprehensive OEM & Manufacturing services, specifically designed to meet your bespoke needs. Whether it’s specific capacity requirements, integration into existing infrastructure, or unique operational parameters, we can customize our PEM electrolyzer solutions.

- Collaborative Design & Development: Our engineers work closely with your team from concept to commissioning, ensuring the final product perfectly aligns with your project’s technical and commercial objectives.

- Scalable Solutions: From individual stack components to complete skid-mounted systems, we provide modular and scalable solutions that grow with your business.

- Hele Titanium Hydrogen Angle: We are not just a supplier; we are your strategic partner. Hele Titanium Hydrogen excels in developing tailor-made PEM electrolyzer solutions through our flexible OEM & Manufacturing services, ensuring a perfect fit for your specific project requirements.

5.4. Global Support & A True Partnership Philosophy

Your success is our success. We believe in fostering long-term, supportive relationships with our clients.

- Dedicated Customer Support: Our commitment extends beyond product delivery. We provide dedicated technical support, troubleshooting assistance, and expert guidance throughout the lifespan of our products.

- After-Sales Service: We understand the importance of uptime for refueling stations. Our after-sales service ensures that any issues are resolved promptly and efficiently.

- Long-Term Collaboration: Hele Titanium Hydrogen is interested in building enduring partnerships, providing ongoing value and support as the hydrogen economy expands.

- Hele Titanium Hydrogen Angle: At Hele Titanium Hydrogen, we view our clients as true partners. We offer comprehensive support from initial consultation through design, manufacturing, installation guidance, and robust after-sales service, ensuring your project’s sustained success.

Chapter 6: Case Studies & Real-World Impact

The theoretical advantages of Hele Titanium Hydrogen PEM electrolyzers translate into tangible benefits in real-world applications. Here are examples of how our technology, or similar implementations, are driving the hydrogen economy forward:

6.1. Accelerating Fleet Decarbonization: The Logistics Hub Revolution

Imagine a major logistics company operating hundreds of heavy-duty trucks. Faced with stringent emission regulations and escalating fuel costs, they seek a sustainable solution. By installing Hele Titanium Hydrogen PEM electrolyzers at their central distribution hub, coupled with renewable energy sources, they establish an on-site green hydrogen production facility.

- Outcome: Trucks refuel directly at the hub with hydrogen generated from local solar arrays. This eliminates diesel consumption, reduces greenhouse gas emissions to zero, and provides significant fuel cost savings due to localized production and reduced transportation overheads. The modular design allows for expansion as the hydrogen fleet grows.

- Impact: A major step towards fully decarbonized logistics, setting a precedent for sustainable operations in the industry.

6.2. Enabling Green Energy Hubs: The Municipal Refueling Network

A forward-thinking municipality envisions a network of publicly accessible hydrogen refueling stations to support its growing fleet of fuel cell buses and refuse trucks, as well as private FCEVs. They partner with Hele Titanium Hydrogen to implement a decentralized H2 station technology strategy.

- Outcome: Multiple hydrogen refueling station electrolyzers are strategically placed across the city, each featuring our compact PEM units. These stations utilize local grid power, supplemented by direct connections to municipal solar farms. The rapid response time of the PEM electrolyzers ensures quick refueling for high-traffic public transport routes.

- Impact: A resilient, locally sourced green hydrogen network that enhances air quality, promotes public adoption of FCEVs, and reduces the municipality’s reliance on fossil fuels, all built on reliable Hele Titanium Hydrogen PEM technology.

6.3. Industrial Partner Empowerment: OEM Integration for Specialized Applications

A specialized engineering firm develops advanced hydrogen power solutions for remote mining operations, requiring robust, self-sufficient hydrogen generation. They choose Hele Titanium Hydrogen as their custom hydrogen generator OEM partner.

- Outcome: Working closely with the engineering firm, Hele Titanium Hydrogen designs and manufactures bespoke, ruggedized PEM electrolyzer modules optimized for harsh environmental conditions and seamless integration into the firm’s overall power system. This allows the firm to offer a complete, reliable, and sustainable power solution to their clients.

- Impact: Hele Titanium Hydrogen enables a partner to enter a specialized market with a high-performance, custom-engineered green hydrogen component, expanding the reach of sustainable energy solutions into challenging industrial sectors.

Conclusion: Powering Your Hydrogen Future with Hele Titanium Hydrogen

The transition to a hydrogen economy is not just an aspiration; it’s a rapidly accelerating reality. At the heart of this transformation for sustainable mobility and industrial decarbonization are PEM electrolyzers for hydrogen refueling stations. Their unparalleled dynamic response, superior hydrogen purity, compact design, and high efficiency make them the definitive choice for modern, forward-thinking businesses and project developers.

For those looking to establish or expand their hydrogen infrastructure, the advantages of on-site green hydrogen production with PEM technology are clear: reduced costs, enhanced supply security, and undeniable environmental benefits. But success in this critical domain hinges on partnering with an expert manufacturer who understands the nuances of this advanced technology.

Hele Titanium Hydrogen stands as your premier OEM and manufacturing partner for high-performance PEM water hydrogen generators. Our deep expertise, unwavering commitment to quality, flexible custom hydrogen generators services, and true partnership philosophy ensure that your investment in hydrogen technology is robust, efficient, and future-proof. We are dedicated to providing the reliable PEM electrolyzer supplier solutions you need to thrive in the green energy landscape.

Is your organization ready to invest in the future of green hydrogen mobility? Partner with a specialist who understands your needs and can deliver tailored, high-performance solutions.

Take the Next Step with Hele Titanium Hydrogen Today.

Explore the possibilities of partnering with Hele Titanium Hydrogen. We are more than just a supplier; we are your strategic ally in shaping a sustainable energy future.

- Browse our Products to see our advanced range of PEM Water Hydrogen Generators. Discover the innovation and quality that set us apart.

- Learn more about our OEM & Manufacturing Services and how we can support your unique project needs with custom-engineered solutions.

- Contact Our Experts Today to discuss your specific requirements. Let us provide a customized consultation and detailed technical specifications for your next project.

- Explore our FAQ section for immediate answers to common questions about PEM technology and our offerings.

- Visit our Blog for the latest insights, industry updates, and expert perspectives on hydrogen technology.

Reach Out Directly: Email Us: heletitaniumhydrogen@gmail.com

Phone/WhatsApp: 086-13857402537

Join the movement towards a cleaner, more sustainable future with Hele Titanium Hydrogen.

Appendix A: The Global Context – Why Green Hydrogen is Indispensable Now

The urgency for green hydrogen production has never been greater. Global mandates for carbon reduction, fluctuating fossil fuel prices, and increasing consumer demand for sustainable solutions are converging to create an unprecedented opportunity for hydrogen.

- Decarbonization Imperative: Nations worldwide are committing to net-zero emissions targets. Hard-to-abate sectors like heavy-duty transport (trucks, buses, trains, maritime shipping), industrial processes (steel, ammonia production), and aviation cannot be fully electrified. Hydrogen offers a clean alternative.

- Energy Security: Green hydrogen, produced from diverse renewable sources, enhances energy independence and security by reducing reliance on imported fossil fuels, particularly relevant for nations lacking domestic oil and gas reserves.

- Grid Balancing and Storage: Electrolyzers, especially dynamic PEM systems, act as crucial flexible loads, helping to balance electricity grids challenged by intermittent renewable energy generation. They can convert surplus renewable electricity into storable hydrogen, effectively acting as long-duration energy storage.

- Economic Growth and Job Creation: Investment in hydrogen infrastructure, including commercial electrolyzer manufacturers and hydrogen refueling station electrolyzer deployments, stimulates economic growth, fosters innovation, and creates new jobs across the value chain.

This global momentum underscores why choosing proven, efficient technology like PEM electrolyzers for hydrogen refueling is not just a technical decision, but a strategic business imperative. Businesses that embrace this shift now will be leaders in the future energy economy.

Appendix B: Regulatory Landscape and Standards for Hydrogen Refueling

Navigating the regulatory environment is critical for any hydrogen infrastructure project. Compliance with international and national standards ensures safety, interoperability, and market acceptance.

- Hydrogen Purity Standards: For FCEVs, hydrogen purity is strictly regulated. ISO 14687:2019 is the key international standard specifying the quality characteristics of hydrogen fuel for proton exchange membrane fuel cell (PEMFC) road vehicle applications. Hele Titanium Hydrogen PEM electrolyzers are designed to consistently meet or exceed these stringent requirements, guaranteeing the longevity and performance of fuel cell vehicles.

- Safety Codes and Standards: The handling and storage of hydrogen demand rigorous safety protocols. International codes (e.g., ISO 22734 for hydrogen generators, SAE J2601 for refueling protocols, NFPA 2 for hydrogen technologies code) provide guidelines for design, installation, operation, and maintenance of H2 station technology. Working with an experienced reliable PEM electrolyzer supplier like Hele Titanium Hydrogen ensures that your system components are compliant and integrated safely.

- Environmental Regulations: Projects involving green hydrogen production are subject to environmental impact assessments and permits. The ability of PEM electrolyzers to integrate with renewables and produce zero-emission hydrogen helps streamline these processes.

- Hele Titanium Hydrogen Angle: We understand the complexities of global and local regulatory landscapes. Our engineering team designs and manufactures PEM electrolyzers with built-in compliance, making it easier for our partners to deploy and operate their on-site hydrogen generation solutions confidently.

Appendix C: The Future Outlook – Advancements in PEM Electrolyzer Technology

The journey of PEM technology is one of continuous innovation. The coming years promise even greater efficiencies, lower costs, and broader applications, further solidifying the role of PEM electrolyzers for hydrogen refueling.

- Cost Reduction Through Scale and Innovation: As production scales up, manufacturing costs for PEM electrolyzer stacks and balance of plant components are projected to decrease significantly. Innovations in materials (e.g., reducing precious metal loading, developing non-precious metal catalysts), improved cell designs, and advanced manufacturing techniques will further drive down CAPEX.

- Enhanced Durability and Lifespan: Ongoing research focuses on improving the long-term durability of PEM membranes and electrodes, targeting operational lifespans of 80,000 hours or more for commercial applications. This will directly reduce OPEX by extending maintenance intervals and minimizing component replacement.

- Increased Efficiency: While already highly efficient, new designs and operational strategies aim to push electrical efficiency even higher, further reducing the energy cost per kilogram of hydrogen.

- System Integration and Digitization: Future PEM systems will feature even more advanced integration with renewable energy management systems, smart grid technologies, and AI-driven predictive maintenance, optimizing performance and reducing human intervention.

- Hele Titanium Hydrogen’s Role in Innovation: At Hele Titanium Hydrogen, we are not just observers of these trends; we are active contributors. Our dedicated R&D team continuously explores these advancements, integrating the latest innovations into our custom hydrogen generators to ensure our clients always benefit from state-of-the-art technology. We are committed to pushing the boundaries of what reliable PEM electrolyzer supplier can offer.

Beyond the Article: Your Strategic Partner in Hydrogen

This in-depth exploration of PEM electrolyzers underscores their pivotal role in the future of hydrogen mobility and sustainable energy. From the fundamental science to commercial benefits, strategic implementation, and future advancements, the evidence points to PEM as the optimal choice for hydrogen refueling station electrolyzers.

Hele Titanium Hydrogen is more than just a commercial electrolyzer manufacturer; we are your strategic partner, committed to providing the highest quality Hele Titanium Hydrogen PEM solutions that drive your success. Our expertise in on-site hydrogen generation solutions positions us uniquely to support your green energy initiatives.

Ready to Turn Vision into Reality?

The hydrogen economy is here, and the time to act is now. Don’t let complexity deter your progress. Partner with an expert who can guide you through every step.

- Request a Quote for your specific project. Provide us with your requirements, and our team will prepare a tailored proposal.

- Download our Product Brochure for detailed specifications and features of our PEM Water Hydrogen Generators.

- Schedule a Consultation with one of our hydrogen specialists. Discuss your project’s unique challenges and opportunities in a personalized session.

- Explore our Client Testimonials to see how Hele Titanium Hydrogen has empowered other businesses to achieve their green hydrogen goals.

Your success in the hydrogen market is our priority.

Email Us Today: heletitaniumhydrogen@gmail.com

Call/WhatsApp Us: 086-13857402537

Hele Titanium Hydrogen – Innovating for a Sustainable Future, Together.