Understanding PEM Electrolyzers: A Key to Sustainable Hydrogen Production

In the quest for sustainable energy solutions, hydrogen stands out as a versatile and clean energy carrier. Among the various methods of hydrogen production, Proton Exchange Membrane (PEM) electrolyzers have emerged as a promising technology. This article delves into the intricacies of PEM electrolyzers, exploring their components, design, and significance in the hydrogen economy.

What is a PEM Electrolyzer?

A PEM electrolyzer is a device that uses electricity to split water into hydrogen and oxygen. The core component of this process is the electrolyzer stack, which consists of multiple electrolyzer cells. Each cell is equipped with a proton exchange membrane that facilitates the separation of hydrogen and oxygen molecules.

Key Components of a PEM Electrolyzer

- Electrolyzer Cell: The basic unit of a PEM electrolyzer, where the actual electrolysis takes place. Each cell contains a membrane electrode assembly (MEA) that includes a proton exchange membrane, catalyst layers, and gas diffusion layers.

- Electrolyzer Stack: A series of interconnected electrolyzer cells. The stack design is crucial for optimizing the efficiency and output of hydrogen production.

- Electrolyzer Stack Design: The design of the stack influences the overall performance of the electrolyzer. Factors such as material selection, cell configuration, and cooling mechanisms play a significant role in enhancing efficiency and durability.

- Hydrogen Electrolyzer Stack: A specialized stack designed to maximize hydrogen production. These stacks are engineered to operate at high current densities and pressures, ensuring a steady output of high-purity hydrogen.

The Science Behind PEM Electrolyzers

PEM electrolyzers operate on the principle of electrolysis, where an electric current is passed through water to produce hydrogen and oxygen. The proton exchange membrane serves as a solid electrolyte, allowing only protons to pass through while blocking electrons. This selective permeability is key to the electrolyzer’s efficiency and safety, as it prevents the mixing of hydrogen and oxygen gases.

Advantages of PEM Electrolyzers

- High Efficiency: PEM electrolyzers have a high conversion efficiency, meaning they can produce more hydrogen for a given amount of electricity compared to other types of electrolyzers.

- Compact Design: The compact and modular design of PEM electrolyzers makes them suitable for a wide range of applications, from small-scale residential systems to large industrial setups.

- Rapid Response: PEM electrolyzers can quickly adjust to changes in power input, making them ideal for integration with renewable energy sources like solar and wind.

- High Purity Hydrogen: The hydrogen produced by PEM electrolyzers is of high purity, requiring minimal post-processing for use in fuel cells and other applications.

Innovations in Electrolyzer Stack Design

Recent advancements in electrolyzer stack design have focused on improving efficiency, reducing costs, and increasing the lifespan of the stacks. Research and development efforts have led to the creation of advanced materials and innovative configurations that enhance the performance of PEM electrolyzers.

Notable Developments

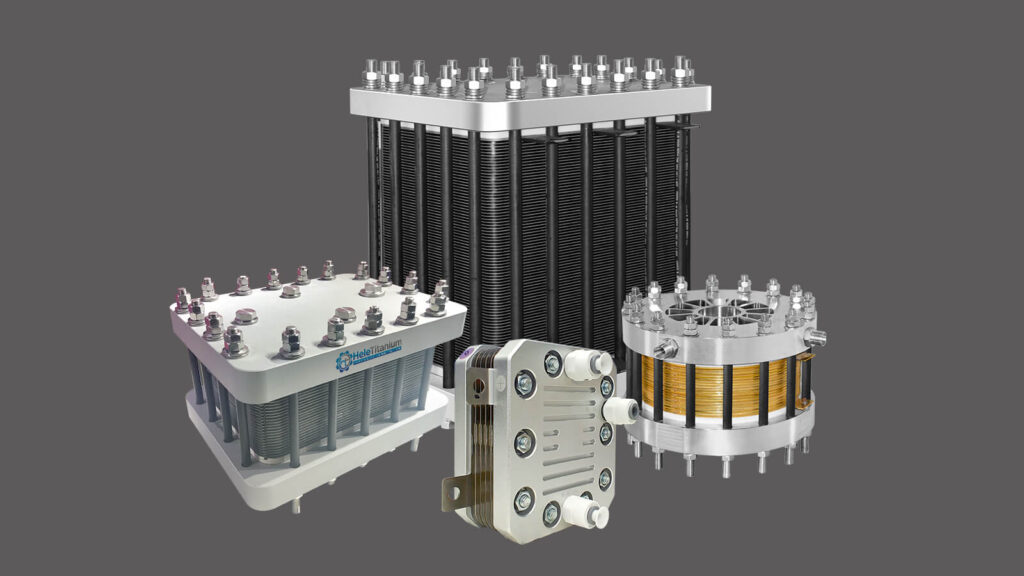

- Titan Series PEM Electrolyzer Stacks: Known for their advanced patented design, these stacks offer lower voltage operation and higher efficiency. Available in various configurations, they cater to different scales of hydrogen production.

- LBE Series PEM Water Electrolyzer Stacks: These stacks are designed for both small and large-scale applications, with an emphasis on durability and lifetime performance. They are highly configurable, supporting a range of power outputs.

- High-Pressure Operation: Modern PEM electrolyzer stacks are capable of operating at high pressures, allowing for direct storage of hydrogen in high-pressure tanks. This capability is crucial for applications requiring compact storage solutions.

Challenges and Future Prospects

While PEM electrolyzers offer numerous advantages, they are not without challenges. The high cost of materials, particularly the noble metal catalysts, remains a significant barrier to widespread adoption. However, ongoing research is focused on developing cost-effective alternatives and improving the scalability of PEM electrolyzers.

The Road Ahead

The future of PEM electrolyzers looks promising, with increasing interest from both the private and public sectors. As the demand for clean hydrogen grows, advancements in electrolyzer technology will play a pivotal role in shaping a sustainable energy landscape.

- Integration with Renewable Energy: PEM electrolyzers are well-suited for integration with renewable energy sources, providing a means to store excess energy as hydrogen. This capability is essential for balancing supply and demand in renewable energy systems.

- Expansion of Hydrogen Infrastructure: The development of a robust hydrogen infrastructure, including production, storage, and distribution networks, will be critical for the widespread adoption of hydrogen as an energy carrier.

- Policy Support and Investment: Government policies and investments in hydrogen technology will drive innovation and commercialization, accelerating the transition to a hydrogen-based economy.

Conclusion

PEM electrolyzers represent a crucial technology in the transition to a sustainable energy future. With their high efficiency, compact design, and adaptability to renewable energy sources, they offer a viable solution for clean hydrogen production. As advancements in electrolyzer stack design continue to unfold, the potential for PEM electrolyzers to revolutionize the hydrogen economy becomes increasingly apparent.

For those interested in exploring the world of PEM electrolyzers further, consider delving into the latest research, attending industry conferences, or connecting with experts in the field. By staying informed and engaged, you can be part of the movement towards a cleaner, more sustainable energy future.

Internal and External Links

- Internal Link: Explore more on hydrogen production technologies

- External Link: Learn about the latest advancements in PEM electrolyzer technology