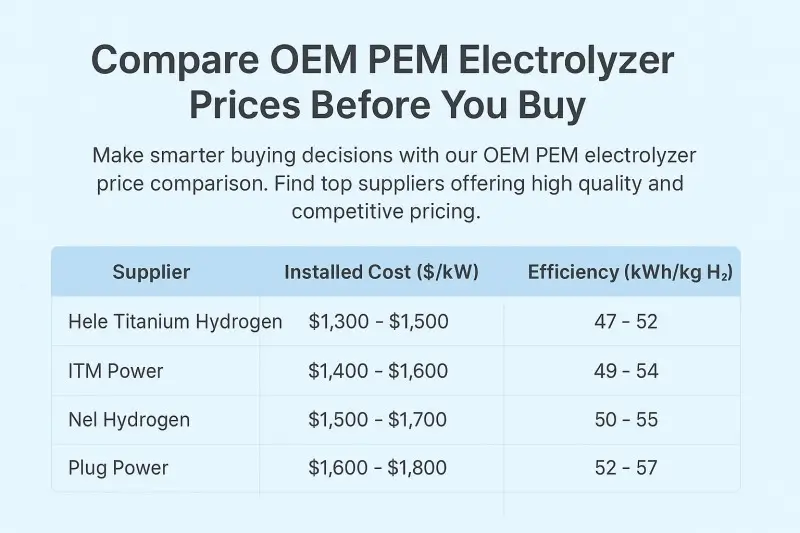

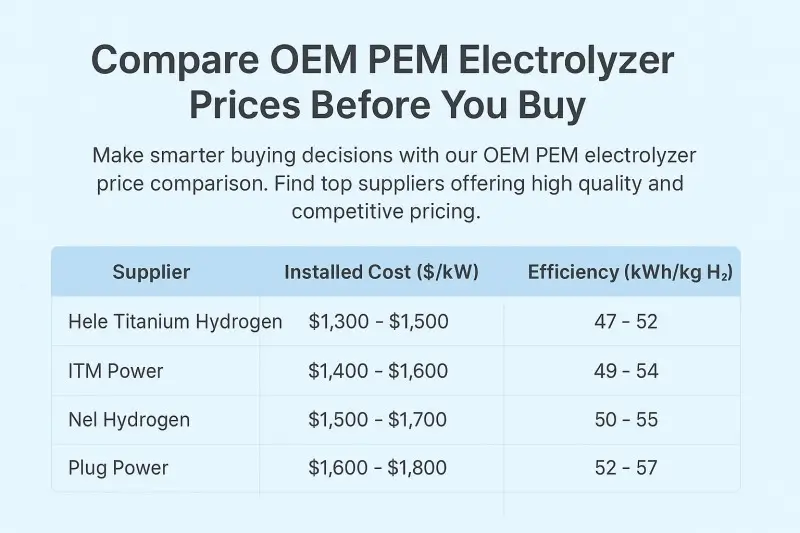

Make smarter buying decisions with our OEM PEM electrolyzer price comparison. Find top suppliers offering high quality and competitive pricing.

Introduction: Why Price Comparison is Essential in Today’s Hydrogen Market

The global hydrogen economy is expanding at record speed, driven by clean energy policies, decarbonization goals, and growing demand for industrial and mobility applications. At the heart of this movement lies the Proton Exchange Membrane (PEM) electrolyzer—a compact, efficient, and scalable technology that converts water into high-purity hydrogen.

For businesses looking to invest, the stakes are high. A PEM electrolyzer purchase can cost millions of dollars, and without a proper PEM electrolyzer price comparison, buyers risk paying more than necessary, overlooking hidden operational expenses, or partnering with suppliers who lack reliability.

This guide from Hele Titanium Hydrogen—a professional OEM manufacturer of PEM hydrogen generators—explains pricing drivers, benchmarking tools, supplier comparisons, and procurement strategies. By the end, you’ll be fully equipped to make smarter buying decisions and secure the best long-term value.

Understanding PEM Electrolyzers: The Backbone of Green Hydrogen

How PEM Electrolyzers Work

PEM electrolyzers use a proton exchange membrane and precious metal catalysts to split purified water into hydrogen and oxygen. Powered by direct current (DC) electricity—often from renewable sources—they generate ultra-pure hydrogen suitable for fuel cells, industrial feedstocks, and energy storage.

Why Businesses Choose PEM over Alkaline

While alkaline electrolyzers are cheaper upfront, PEM systems offer unique advantages:

- Faster load response—ideal for renewable integration

- Higher hydrogen purity—critical for fuel cells and electronics

- Smaller footprint—easier to integrate and scale modularly

- Better efficiency—reduces long-term electricity costs

These features make PEM electrolyzers the preferred choice for projects requiring flexibility, purity, and future scalability.

Main Factors That Shape PEM Electrolyzer Pricing

Installed Capacity and Cost Per Kilowatt

Electrolyzers are typically priced in installed $/kW terms.

- Current market range: $1,300–$1,700/kW installed

- Equivalent to: $4,500–$6,500 per kg/day hydrogen production capacity

Larger projects benefit from economies of scale, with costs expected to fall below $500/kW in the next decade as manufacturing expands.

Efficiency and Long-Term Power Costs

Operating costs matter as much as capital costs. PEM electrolyzers consume 50–60 kWh per kg of hydrogen. With electricity making up 70–80% of hydrogen’s levelized cost, even a small efficiency improvement saves millions over a project’s lifetime.

Balance of Plant and Hidden Costs

Beyond the electrolyzer stack, buyers must account for:

- Power electronics

- Water purification systems

- Gas separation and compression units

- Controls and safety systems

Turnkey systems cost more upfront but reduce integration risks.

Raw Materials and Durability

Platinum catalysts and durable membranes increase costs but extend stack lifetime. Shorter-lived stacks may appear cheaper initially but increase replacement and downtime costs.

Logistics, Tariffs, and Regional Factors

Total price depends on shipping costs, import duties, and local assembly availability. Partnering with suppliers who have global logistics expertise helps reduce delays and hidden costs.

How to Benchmark PEM Electrolyzer Prices

Price Normalization: $/kW and kWh/kg Metrics

Normalize vendor quotes to a consistent metric:

- CAPEX ($/kW installed)

- Efficiency (kWh/kg hydrogen)

This makes it possible to compare “apples to apples” across suppliers.

Calculating Levelized Cost of Hydrogen (LCOH)

LCOH = (Annualized CAPEX / Annual H₂ Production) + Electricity Cost per kg + O&M Costs

Example (1 MW system):

- Installed cost: $1,500/kW

- Efficiency: 55 kWh/kg

- Electricity: $0.06/kWh

- Capacity factor: 80%

Result: LCOH ≈ $5–$7/kg hydrogen before subsidies.

Warranty, Service, and After-Sales Value

A lower upfront price may mask poor after-sales support. Compare:

- Warranty coverage (stack vs. balance of plant)

- Service response times

- Spare part availability

- Certification compliance (UL, CE, PED, ISO)

Supplier Comparison: What Buyers Should Know

Hele Titanium Hydrogen (Featured Supplier)

Hele Titanium Hydrogen stands out by offering:

- Durable stacks with extended lifetimes and low degradation rates

- High efficiency designs reducing electricity consumption

- Custom turnkey systems covering power, water, gas, and safety controls

- Responsive global service with spare parts stocked in key regions

- Certified products meeting international standards (CE, ISO, PED)

Most importantly, Hele provides fast quotations, customized technical guidance, and a total cost of ownership (TCO) analysis tailored to your site conditions.

Other Market Suppliers (Overview Only)

- ITM Power: Modular PEM systems, strong in Europe

- Nel Hydrogen: Scalable production, both alkaline and PEM

- Plug Power: U.S. focus, mobility ecosystem integration

- Cummins (Hydrogenics): Diversified solutions, growing PEM capacity

While competitors offer strong portfolios, Hele differentiates through faster delivery times, tailored engineering, and highly competitive pricing.

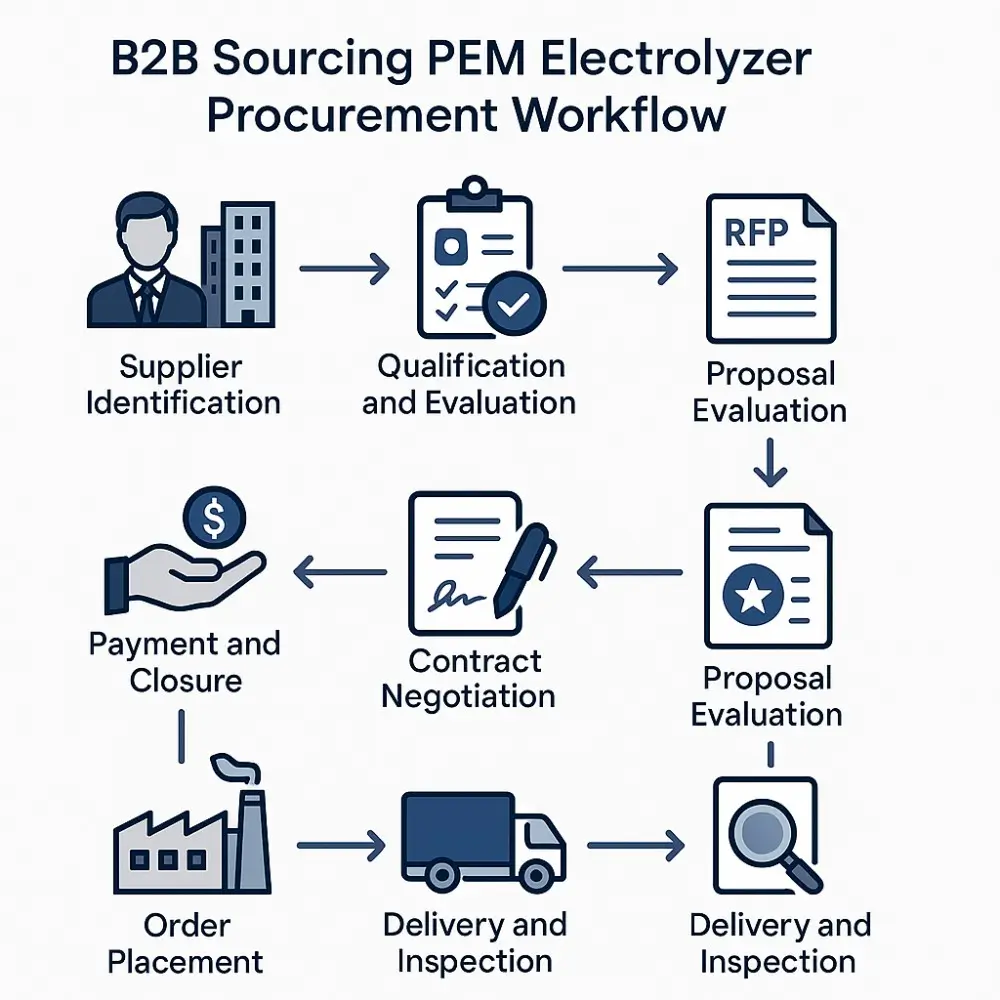

Practical Procurement Checklist

Before contacting suppliers, define:

- Required hydrogen output (kg/hr or Nm³/hr)

- Electrolyzer DC power rating (kW)

- Hydrogen purity and delivery pressure

- Duty cycle and renewable load-following needs

- Water quality, temperature, and grid availability

- Scope of supply (compression, storage, monitoring)

- Compliance requirements (local certifications)

👉 Tip: Download Hele Titanium Hydrogen’s RFQ template to streamline vendor comparisons and accelerate your procurement process.

Project Timelines, Lead Times, and Risk Mitigation

Typical MW-scale projects take 24–36 months, including:

- Site permitting & preparation

- Equipment procurement (6–12 months lead time)

- Installation and commissioning

- Testing and ramp-up

Risk reduction strategies:

- Engage suppliers early in planning

- Request phased deliveries for modular builds

- Verify logistics and customs handling experience

Hele Titanium Hydrogen offers flexible delivery schedules and dedicated project managers to minimize delays.

How to Negotiate the Best PEM Electrolyzer Price

- Request at least three detailed quotes for price benchmarking

- Normalize costs by $/kW and kWh/kg for clear comparison

- Negotiate for extended warranties, remote support, and training

- Explore government subsidies and financing packages to lower CAPEX

- Validate supplier references and conduct site visits or factory tours

Hele Titanium Hydrogen supports buyers by providing financing guidance and assisting with grant applications in select regions.

Why Hele Titanium Hydrogen Offers the Best Value

Choosing Hele Titanium Hydrogen means:

- OEM Quality at Competitive Pricing – Direct factory supply eliminates unnecessary markups.

- Custom Engineering Support – Systems tailored to your site and duty cycle.

- Strong Warranty & Service – Coverage for stacks, BOP, and responsive after-sales.

- Global Reach – Export-ready products shipped with full certification.

- Proven Track Record – References in industrial, mobility, and renewable projects worldwide.

With Hele, you’re not just buying equipment—you’re investing in a long-term hydrogen partner.

Frequently Asked Questions (FAQs)

1. What is the typical cost per kW for PEM electrolyzers?

$1,300–$1,700 per installed kW, depending on capacity and scope.

2. Can PEM electrolyzers be customized for different industries?

Yes. Hele Titanium Hydrogen provides tailored systems for energy storage, chemical processing, and fueling applications.

3. What is the delivery time for PEM electrolyzers?

Standard delivery is 6–12 months. Hele offers faster lead times for select models.

4. What after-sales services are available?

Hele provides on-site commissioning, remote monitoring, spare parts, and global service teams.

5. Are financing or leasing options available?

Yes, financing support and guidance on government incentives are available in key regions.

6. What certifications does Hele Titanium Hydrogen provide?

Products comply with ISO, CE, and PED standards, ensuring global acceptance.

Conclusion and Call to Action

A PEM electrolyzer purchase is one of the most critical investments for any green hydrogen project. By conducting a structured PEM electrolyzer price comparison, normalizing vendor quotes, and considering long-term service value, B2B buyers can minimize risks and maximize ROI.

👉 Contact Hele Titanium Hydrogen today to:

- Receive a customized price quote within 5 business days

- Download our procurement checklist & RFQ template

- Schedule a technical consultation tailored to your project

Make the smart choice for your hydrogen future—partner with Hele Titanium Hydrogen, your trusted OEM PEM electrolyzer manufacturer.

🔗 External Resource: U.S. Department of Energy – Hydrogen and Fuel Cell Technologies Office

Hele Titanium Hydrogen: Your Trusted Hydrogen Generator OEM & Manufacturing Partner

Hele Titanium Hydrogen stands as a reliable and experienced partner in the hydrogen generator OEM supply chain. We specialize in the design, development, and manufacturing of high-performance PEM Water Hydrogen Generators, offering comprehensive OEM & Manufacturing services tailored to your specific needs.

Take the Next Step

Ready to explore the possibilities of partnering with Hele Titanium Hydrogen?

- Browse our Products to see our range of PEM Water Hydrogen Generators.

- Learn more about our Services and how we can support your OEM & Manufacturing needs.

- Contact Us today to discuss your specific requirements.

- Explore our FAQ to get answers to common questions.

- Visit our Blog for the latest insights and updates on hydrogen technology.

Email Us: heletitaniumhydrogen@gmail.com

Phone/WhatsApp: 086-13857402537