Explore the most trusted PEM electrolyzer OEM suppliers globally. Streamline your hydrogen production supply chain today with the right manufacturing ally.

Introduction

If your team is evaluating PEM electrolyzer OEM suppliers for 2025 projects, this guide gives you everything needed to shortlist fast and buy with confidence. We translate technical complexity into clear, commercial insights for procurement, engineering, and executive stakeholders.

Why PEM now? Global hydrogen demand is rising with decarbonization goals, while project financiers and EPCs increasingly prefer bankable, scalable partners. Selecting the right OEM manufacturer affects lifetime efficiency, uptime, capex/opex, and delivery risk. This article blends a practical selection framework, a curated supplier directory, and case-based proof points—so you can move from research to RFI/RFQ with clarity.

PEM Electrolysis in Plain

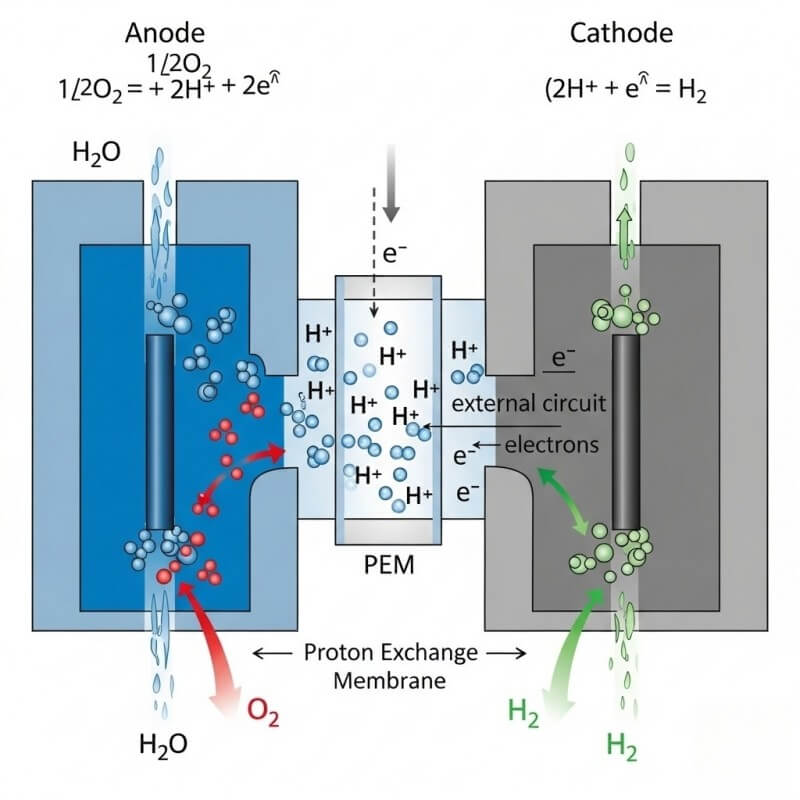

How it works. A Proton Exchange Membrane separates water into hydrogen and oxygen when electricity passes through the cell. The membrane lets protons travel while blocking gases, enabling clean, pressurized hydrogen output. For buyers, the net result is a compact system that responds quickly to variable renewable energy and produces high-purity H₂ suitable for fuel cells and industrial use.

Advantages you can bank on

- High efficiency & dynamic response: Ideal for coupling with wind/solar and for load-following operations.

- Compact, modular footprint: Simplifies siting and scaling.

- High purity hydrogen: Supports mobility, electronics, and other purity-sensitive industries.

- Fast start-stop: Reduces wasted energy and enables flexible operations.

Where PEM shines

- Industrial hydrogen (refining substitutes, metallurgy, glass, electronics).

- Mobility (fueling depots for buses, trucks, forklifts).

- Energy storage (power-to-gas, seasonal storage, and grid services).

Why Choosing the Right OEM Partner Determines Project ROI

Quality and uptime drive economics. Stack durability, cell uniformity, catalyst utilization, coatings, and balance-of-plant integration all determine lifetime efficiency and opex. A proven OEM lowers commissioning friction, warranty claims, and downtime—boosting project IRR.

The risks of getting it wrong. Unverified suppliers can mean slipshod QC, long lead times, weak documentation, and poor after-sales. That shows up as overruns, penalties, or underperforming assets. Insist on traceable materials, audited QA, and bankable references.

Selection Framework: 7 Criteria for Supplier Shortlisting

- Technical expertise & references

- Ask for nameplate ranges, efficiency curves, degradation rates, stack lifetimes, and reference lists with contacts.

- Manufacturing scale, QA, and localization

- Capacity (MW/yr), line automation, incoming inspection, MES/traceability, and options for local assembly/service.

- Stack/output range & customization

- From lab-scale to multi-MW skids, containerized solutions, pressure options, water quality tolerance, and site-specific engineering.

- Certifications & compliance

- Look for relevant ISO (e.g., 9001/14001), CE/UL marks, pressure vessel codes, and HSE policies.

- Commercial terms

- Transparent pricing (CAPEX breakdown), Incoterms, payment terms, and realistic lead times with liquidated damages where appropriate.

- After-sales & training

- Spares strategy, technician training, remote monitoring, and guaranteed response times.

- Reputation, ESG, and financial stability

- Bankability matters for lenders and offtakers; review credit, governance, and sustainability reports.

Supplier Directory: Top PEM electrolyzer OEM suppliers 2025

The following companies are recognized in the market for PEM technology and deployments. We include quick facts and source links so your team can verify details during due diligence.

Hele Titanium Hydrogen (China) — Direct OEM/ODM Partner

Who we are. Hele Titanium Hydrogen is a professional manufacturer and wholesale supplier of PEM water hydrogen generators. We support OEM/ODM, flexible order quantities, and tailored engineering to match your application (industrial, mobility, or distributed energy). Why buyers choose us

- Direct factory pricing with rigorous QC and full documentation package.

- Custom engineering (stack sizing, footprint, interfaces, enclosure standards).

- Responsive support across pre-sale sizing, installation guidance, commissioning, and after-sales service. Ideal for: Distributors, EPCs, and end users seeking a cost-effective, customizable OEM partner with quick communication and export readiness. Contact: Send your RFI/RFQ to request technical datasheets, drawings, and a project-specific proposal.

Nel Hydrogen (Norway)

Global electrolyzer specialist delivering PEM stacks and systems from small-scale H-Series to MW-class modules (PSM) for on-site hydrogen generation. (Nel Hydrogen)

Best for: Broad portfolio, mature references, and modular rollouts.

Siemens Energy (Germany)

Siemens Energy’s Elyzer family uses PEM technology designed for coupling with renewables, emphasizing high efficiency and power density with quality gas output and low maintenance. (Siemens Energy)

Best for: Large integrated projects tied to wind/solar, with digitalization and grid integration.

ITM Power (UK)

Manufacturer focused on PEM electrolysis; offers modular systems for green hydrogen production, highlighting purity and decarbonization of logistics/heavy industry. (ITM Power)

Best for: Projects seeking EU-based PEM expertise and modular deployment paths.

Cummins (Hydrogenics) (USA/Canada)

HyLYZER® PEM portfolio spans industrial-class units; public case work includes large-scale green hydrogen production (e.g., in Québec). (Cummins Inc.)

Best for: Industrial projects needing bankable references and global support.

Plug Power (USA)

Expanded into PEM via Giner ELX acquisition; now offers PEM stacks/systems within Plug’s broader hydrogen ecosystem. (Plug Power, Q4 Financials)

Best for: Vertically integrated solutions across production, storage, and fuel cell use cases.

Ohmium (USA/India)

Designs and manufactures modular, scalable PEM electrolyzers; has deployments across multiple sectors and recent strategic investment signals market confidence. (ohmium.com, 3M News Center)

Best for: Modular field deployments and rapid scaling.

Elogen (France)

French PEM maker with deliveries to European projects; recently announced a 2.5-MW PEM electrolyzer for the CrossWind energy hub in the Netherlands. (gtt.fr, Hydrogen Insight)

Best for: EU projects prioritizing local PEM supply and pilot-to-commercial scaling.

Quick-Scan Comparison Table

| Supplier | HQ | Tech | Indicative Strengths | Notable Proof Point |

|---|---|---|---|---|

| Hele Titanium Hydrogen | China | PEM | OEM/ODM, customization, responsive lead times | Direct factory partner (contact for references) |

| Nel Hydrogen | Norway | PEM | Full range from small to MW modules | H-Series & PSM portfolio. (Nel Hydrogen) |

| Siemens Energy | Germany | PEM | High efficiency, grid-coupled | Elyzer family for renewables. (Siemens Energy) |

| ITM Power | UK | PEM | Modular, purity focus | EU deployments in industry & mobility. (ITM Power) |

| Cummins (Hydrogenics) | USA/Canada | PEM | Industrial scale, bankable | Bécancour (up to 8.2 t/day). (Cummins Inc.) |

| Plug Power (Giner ELX) | USA | PEM | Vertical integration | Giner ELX acquisition. (Plug Power, Q4 Financials) |

| Ohmium | USA/India | PEM | Modular PEM, scaling fast | 3M strategic investment. (3M News Center) |

| Elogen | France | PEM | EU PEM footprint | CrossWind 2.5 MW PEM delivery. (gtt.fr, Hydrogen Insight) |

Tip: Use this directory as a shortlist starter—then issue an RFI/RFQ to 3–5 suppliers to compare fit, terms, and delivery risk.

Case Studies & Proof Points (What “Good” Looks Like)

1) Grid-scale, renewables-coupled PEM

- Siemens Energy PEM (Silyzer) references show how PEM can follow volatile renewable output while maintaining product gas quality and stable control via established automation systems. This capability is crucial for power-to-gas and hybrid plant designs. (Cluster de Energía (4e Chile), Siemens Energy)

2) Industrial-scale green hydrogen

- Cummins HyLYZER® at Bécancour, Québec demonstrates phased ramp-up to ~8.2 tons/day low-carbon hydrogen, leveraging hydro-electric power. This is a benchmark for industrial production scale and bankability. (Cummins Inc.)

3) Modular deployments

- Ohmium highlights modular PEM blocks suitable for distributed sites—transit depots, industrial parks, and behind-the-meter assets—supporting quicker time-to-value. (ohmium.com)

4) EU PEM manufacturing

- Elogen recently delivered a 2.5-MW PEM electrolyzer for the CrossWind energy hub in the Netherlands—evidence of PEM’s role in advanced renewable hubs in the EU. (gtt.fr, Hydrogen Insight)

How to Contact, Compare, and Negotiate with OEMs

1) Build a crisp RFI/RFQ (and send to your shortlist) Include: target output (Nm³/h or kg/day), duty cycle & ramp rate, power quality, ambient/site conditions, H₂ purity/pressure, water quality, enclosure & footprint constraints, applicable codes, metering & data needs, delivery window, and acceptance test criteria.

2) Evaluate technical performance with apples-to-apples data

- Efficiency: Specify conditions (LHV/HHV, temperature, pressure).

- Degradation: Ask for annualized stack performance loss and replacement intervals.

- Balance-of-plant: Compressors, dryers, chillers—clarify what’s included.

- Digitalization: Remote monitoring, alarms, predictive maintenance.

3) Audit before you buy

- Factory Acceptance Test (FAT): Witness key tests; verify serial numbers, QA records, and documentation packs (P&IDs, IOM manuals, spare parts lists).

- Site Acceptance Test (SAT): Define success criteria, safety interlocks, and data acceptance windows.

- Warranty & service levels: Set response times, spare kits, and escalation paths.

4) Structure bankable commercial terms

- Incoterms: Align on EXW/FOB/CIF, insurance, and customs documentation.

- Milestones: Tie payments to deliverables (drawings approved, FAT passed, shipment, SAT).

- Schedule: Include LDs for late delivery and clear force majeure clauses.

- Performance guarantees: Efficiency, purity, and uptime with remedies.

5) Work with partners who teach you Good OEMs provide training, spare kits, and transparent lifecycle cost models. They’re proactive about design risks, grid interconnection, and permitting.

Future Trends Shaping the PEM Supply Chain

- Higher efficiency, less precious metal: Ongoing R&D aims to reduce iridium loading and improve membrane/catalyst durability—lowering cost per kg of H₂.

- Modularization & standard interfaces: Skid-based designs with standard piping/electrical interfaces cut installation time and de-risk scaling.

- Digital twins & predictive O&M: Better telemetry improves uptime, parts planning, and energy optimization.

- Regionalization & resilience: Expect more localized assembly/service to shorten lead times and meet content requirements.

FAQs

1) What project sizes are best suited for PEM vs. other electrolysis types?

PEM excels from kilowatt to multi-megawatt scales where fast response, compactness, and high purity matter—especially with wind/solar coupling. Alkaline systems can be competitive at very large baseload plants; your duty cycle and purity requirements should guide the choice.

2) How do I compare efficiencies fairly?

Ask vendors to state kWh/kg at a defined pressure, temperature, and H₂ purity, specifying LHV vs. HHV basis. That ensures apples-to-apples comparisons.

3) What affects stack lifetime most?

Start-stop frequency, water quality, temperature control, and current density. Proper pretreatment, thermal management, and conservative operating windows extend life.

4) How long does commissioning usually take?

It depends on site readiness and system size. Define FAT/SAT checklists up front and plan for utilities, interlocks, and safety sign-offs to streamline commissioning.

5) Can I add capacity later?

Yes—modular PEM skids are designed for staged buildouts. Confirm physical space, power availability, and pipe rack allowances to scale smoothly.

6) What should be in my after-sales plan?

Spare parts kits, preventive maintenance schedules, remote monitoring, technician training, and clear response SLAs.

7) Do I need deionized water?

Most PEM systems require high-purity water within strict conductivity limits; confirm specs and pretreatment needs with the OEM.

8) How can I validate supplier claims?

Request references, witness a FAT, and examine QA records. Look for public case studies and deployments from reputable sources (e.g., Siemens Energy, Cummins). (Siemens Energy, Cummins Inc.)

Conclusion & Strong B2B CTA

Selecting among PEM electrolyzer OEM suppliers is a high-stakes decision that shapes your project’s efficiency, uptime, and bankability. Use the 7-point selection framework, verify with case-backed references, and compare commercial terms that fairly allocate risk. The directory above gives you a strong head start—from EU giants to modular innovators—so you can proceed confidently to RFI/RFQ.

Why partner with Hele Titanium Hydrogen now As a professional manufacturer and wholesale supplier of PEM water hydrogen generators, Hele Titanium Hydrogen offers OEM/ODM customization, responsive engineering support, and export-ready documentation—helping EPCs, distributors, and end users accelerate timelines and control costs.

👉 Call to Action:

- Send your RFI/RFQ to receive datasheets, drawings, and a tailored proposal (stack size, pressure, purity, footprint).

- Request a virtual factory tour and sample documentation pack (P&IDs, QA records, test reports).

- Book a 30-minute engineering consult to right-size CAPEX and de-risk installation.

External Sources & Further Reading

- Nel Hydrogen — PEM product portfolio and modules. (Nel Hydrogen)

- Siemens Energy — Elyzer family (PEM) for green hydrogen. (Siemens Energy)

- ITM Power — PEM technology & products. (ITM Power)

- Cummins (Hydrogenics) — HyLYZER specs & Bécancour case study. (Cummins Inc.)

- Plug Power — Giner ELX acquisition (PEM). (Plug Power, Q4 Financials)

- Ohmium — Modular PEM; 3M investment news. (ohmium.com, 3M News Center)

- Elogen — EU PEM delivery updates. (gtt.fr, Hydrogen Insight)

Hele Titanium Hydrogen: Your Trusted Hydrogen Generator OEM & Manufacturing Partner

Hele Titanium Hydrogen stands as a reliable and experienced partner in the hydrogen generator OEM supply chain. We specialize in the design, development, and manufacturing of high-performance PEM Water Hydrogen Generators, offering comprehensive OEM & Manufacturing services tailored to your specific needs.

Take the Next Step

Ready to explore the possibilities of partnering with Hele Titanium Hydrogen?

- Browse our Products to see our range of PEM Water Hydrogen Generators.

- Learn more about our Services and how we can support your OEM & Manufacturing needs.

- Contact Us today to discuss your specific requirements.

- Explore our FAQ to get answers to common questions.

- Visit our Blog for the latest insights and updates on hydrogen technology.

Email Us: heletitaniumhydrogen@gmail.com

Phone/WhatsApp: 086-13857402537