Sourcing electrolyzers in China? This guide reveals how to choose the right OEM partner, focusing on the advantages of specialized PEM technology for renewable projects and achieving the lowest total cost of ownership.

1. Introduction: The Green Hydrogen Gold Rush & Your Biggest Challenge

The global energy landscape is undergoing a seismic shift. With projections from the Hydrogen Council estimating the green hydrogen market could reach $2.5 trillion by 2050, we are in the early days of a new industrial gold rush. This incredible opportunity has ignited a wave of innovation, with companies worldwide racing to develop everything from grid-scale hydrogen storage solutions to integrated home hydrogen electrolyzer systems.

For visionary OEMs and project developers like you, the potential is limitless. But as you stand on the precipice of this opportunity, you face the single greatest challenge that will define your success or failure: your manufacturing supply chain.

Finding a hydrogen electrolyzer manufacturer is easy. Finding a true partner—one who can provide consistent quality, deep technical collaboration, and the agility to scale with your vision—is incredibly difficult.

In today’s market, supply chain disruptions, quality control failures, and communication breakdowns can derail a project, costing millions and erasing your first-mover advantage.

This is not another generic list of Chinese manufacturers. This is an insider’s guide written from the trenches by the engineering and manufacturing specialists at Hele Titanium Hydrogen. As a professional OEM/ODM partner specializing in Proton Exchange Membrane (PEM) technology, we live and breathe the challenges you face.

Our goal is to arm you with the knowledge to look beyond the megafactories and find a partner who will become a seamless, strategic extension of your own team.

2. The China Advantage: Why the World’s Workshop is Ground Zero for Hydrogen

For decades, China has been the world’s workshop for electronics and consumer goods. Today, that same ecosystem of speed, scale, and supply chain mastery is being focused on the green energy transition, with electrolyzer manufacturing in China at its epicenter. Understanding this “China Advantage” is crucial for any company looking to source high-performance, cost-effective equipment.

- Unmatched Supply Chain Depth: The most complex and costly components of a PEM electrolyzer are the materials within the stack—titanium flow field plates, platinum and iridium catalysts, and the proton exchange membrane itself.

China’s dominant position in the processing of these raw materials provides a level of vertical integration that is unmatched anywhere else in the world.

This means faster access, reduced lead times, and greater cost control compared to manufacturers who have to import these critical components. - Unprecedented Speed and Scale: The manufacturing culture in China is built on rapid iteration and massive scalability. The time it takes to move from a final prototype to the first full production run is often a fraction of what it would be in Europe or North America.

For an OEM looking to capture market share, this speed is a decisive competitive advantage. - Government-Fueled Innovation: China’s national commitment to becoming a leader in the hydrogen economy has resulted in significant government investment in research, development, and production infrastructure.

This policy support de-risks the manufacturing process and fuels a hyper-competitive environment that accelerates technological advancement and drives down the overall electrolyzer cost for the end buyer.

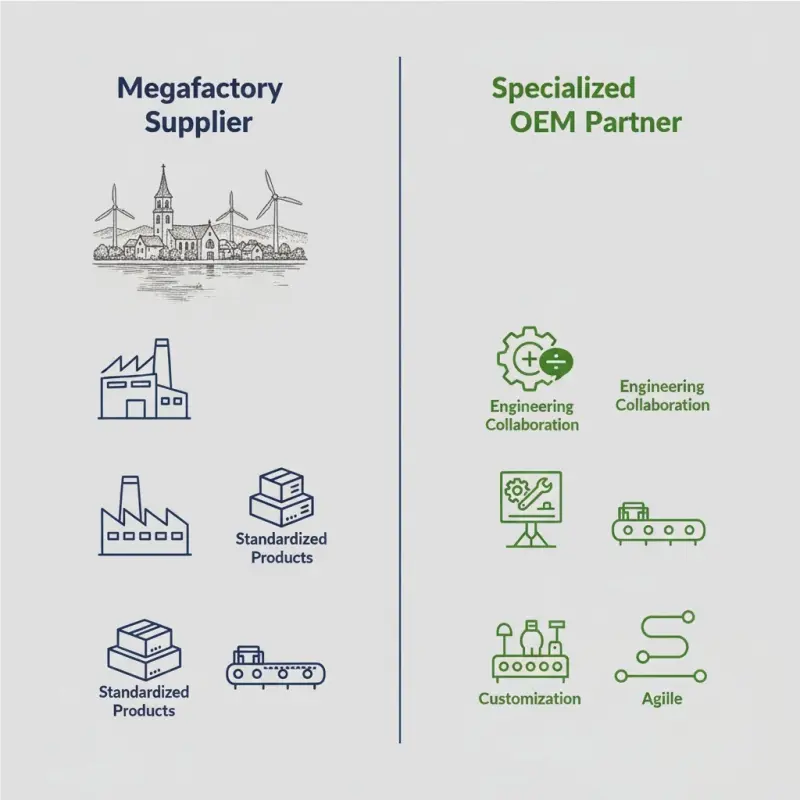

3. The Critical Choice: Megafactory Supplier vs. Specialized OEM Partner

Navigating the Chinese manufacturing landscape reveals a critical fork in the road for any buyer. The path you choose will fundamentally shape your product, your business model, and your long-term success.

The choice is between two distinct types of manufacturers: the Megafactory Supplier and the Specialized OEM Partner.

The Megafactory Supplier: Titans of Scale

These are the giants of the industry, often multi-billion dollar corporations with massive, vertically-integrated production facilities. They are masters of producing standardized equipment at a colossal scale.

- Primary Technology: They often focus on traditional alkaline electrolyzer technology, which is mature and suitable for massive, state-funded projects requiring thousands of cubic meters of hydrogen per hour.

- Business Model: Their model is built on volume. They produce a set catalog of large-scale products and are geared towards selling to massive utility companies or EPCs (Engineering, Procurement, and Construction).

- Pros: Enormous production capacity, established name recognition, and potentially lower upfront capital cost (CAPEX) on their standardized, large-scale units.

- Cons for an OEM:

- Rigidity: Customization is often difficult, slow, and expensive, if available at all. Their production lines are not designed for agility.

- Lack of Deep Collaboration: As an OEM, you are a small part of their massive operation. Gaining direct access to their core engineering team for deep technical collaboration can be nearly impossible.

- Not a Partnership: You are a customer purchasing a product, not a partner building a unique solution together.

- Rigidity: Customization is often difficult, slow, and expensive, if available at all. Their production lines are not designed for agility.

The Specialized OEM Partner: Architects of Innovation

This is a different breed of manufacturer. They are defined by their deep focus, agility, and a business model built entirely around partnership.

- Primary Technology: They concentrate on mastering a specific, high-performance technology, such as the PEM electrolyzer. This focus allows them to achieve a level of technical excellence and product optimization that broader manufacturers cannot match.

- Business Model: Their success is intrinsically linked to the success of their OEM partners. They are structured to provide deep customization, collaborative engineering, and flexible production runs.

- Pros:

- Deep Customization: They can modify everything from operating pressure and stack dimensions to control system integration to meet your exact product specifications.

- Direct Engineering Access: You work directly with their engineers, creating a seamless feedback loop that accelerates development and solves problems quickly.

- Agility & Flexibility: They are built to handle variable order sizes, from initial prototypes to full-scale production runs, growing with your needs.

- Deep Customization: They can modify everything from operating pressure and stack dimensions to control system integration to meet your exact product specifications.

- Cons: They may not be the right fit for building a single, 100-megawatt utility-scale plant, but they are the perfect fit for an OEM looking to manufacture a line of 10, 100, or 1,000 integrated hydrogen systems.

Key Takeaway: The right choice depends entirely on your business model. If you are buying a standard commodity product for a massive project, a megafactory might suffice. If you are building an innovative product line and need a true manufacturing partner, the specialist is your strategic advantage.

4. Why PEM Technology is the Future for Renewable-Powered Hydrogen

As a specialized OEM partner, our deep focus is on PEM (Proton Exchange Membrane) technology. We believe it is the superior choice for the vast majority of modern clean energy applications, particularly those integrated with renewable sources. Here’s why this technical choice matters for your business.

Dynamic Response: Perfectly Paired with Nature

Renewable energy sources like solar and wind are intermittent. Power output can fluctuate dramatically from one minute to the next.

A key weakness of traditional alkaline electrolyzers is their slow ramp rate; they cannot respond quickly to these changes, leading to wasted energy or the need for expensive battery storage.

PEM electrolyzers, by contrast, are incredibly dynamic. They can ramp from 10% to 100% power in seconds, perfectly tracking the output of a solar panel or wind turbine. This ability to capture every available electron from a renewable source means more green hydrogen production per day, maximizing the return on your investment in solar or wind infrastructure.

Superior Efficiency & Purity: Lowering Your Long-Term Costs

While the initial CAPEX is important, the true electrolyzer cost is its Total Cost of Ownership (TCO). PEM electrolyzers operate at a higher current density and offer greater overall system efficiency than most alkaline systems. This means they produce more hydrogen for every kilowatt-hour of electricity consumed.

Over a 10-year operational lifespan, this superior efficiency can save hundreds of thousands of dollars in electricity costs—the single largest operational expense.

Furthermore, PEM technology naturally produces hydrogen with 99.999% purity, which is essential for sensitive applications like hydrogen fuel cells, without the need for expensive downstream purification equipment.

Compact Footprint: Enabling Innovative Product Design

PEM electrolyzer stacks are significantly more compact and energy-dense than their alkaline counterparts. For an OEM, this is a game-changing advantage. Whether you’re designing a containerized refueling station, an all-in-one home hydrogen energy storage unit, or a mobile power generator, the smaller footprint of a PEM system allows for greater design freedom and more integrated, elegant solutions.

5. The Ultimate OEM Partner Vetting Checklist

Before you sign any contract, you must conduct rigorous due diligence. Arm yourself with these critical questions to separate the true partners from the mere assemblers.

1. Technical Expertise: “Can you detail your in-house capabilities for the core stack components, specifically the Membrane Electrode Assembly (MEA)?”

- What to Listen For: A true expert will discuss their process for catalyst coating, membrane selection, and hot-pressing techniques. They control the quality of the “engine” of the electrolyzer.

- Red Flag: An assembler will give a vague answer, saying they “source high-quality MEAs.” This means they have no deep control over the most critical performance component.

2. Quality Control: “Walk me through your QC process, from raw material verification to final system testing.”

- What to Listen For: Look for a multi-stage process. This should include Positive Material Identification (PMI) for incoming titanium, electrochemical testing of MEAs, pressure/leak testing of the assembled stack, and a full functional test of the final system under load. Ask to see their ISO 9001:2015 certification.

- Red Flag: A generic answer like “we test everything before it ships.” This lacks the detail and rigor required for industrial-grade equipment.

3. Customization Process: “Describe your standard procedure for a new OEM project.”

- What to Listen For: A structured, phased approach: 1) Initial technical consultation and requirements review. 2) Collaborative design and 3D modeling. 3) Prototype manufacturing and testing. 4) Production ramp-up and quality assurance.

- Red Flag: “Just send us your specs.” This indicates a transactional, not a collaborative, relationship.

4. Supply Chain Transparency: “How do you mitigate supply chain risks for critical materials like iridium and membranes?”

- What to Listen For: A strategic answer about long-term supplier relationships, safety stock of critical components, and dual-sourcing strategies.

- Red Flag: “Don’t worry, we have good suppliers.” This dismisses a very real and critical business risk.

5. After-Sales & OEM Support: “What level of engineering support can we expect during our own product integration phase?”

- What to Listen For: A commitment to providing dedicated engineering support, detailed integration manuals, and troubleshooting assistance. A true partner invests in your success post-sale.

- Red Flag: “We have a customer service hotline.” This is not the dedicated, high-level support an OEM requires.

Case Study Insight: A German OEM developing a containerized sustainable energy solution approached us after their previous supplier delivered stacks that failed to meet pressure requirements. It was a critical design flaw.

Our engineering team immediately initiated a collaborative design review, co-developing a reinforced bipolar plate and end-plate solution.

We manufactured and delivered a fully tested prototype in just four weeks, getting their project back on track and securing a long-term partnership. This is the difference between a supplier and a partner.

6. Hele Titanium Hydrogen: Your Specialized PEM Manufacturing Partner

Throughout this guide, we have outlined the critical factors for success in sourcing your electrolyzer: choosing a specialized partner over a generalist supplier, leveraging the superior performance of PEM technology, and conducting rigorous due diligence.

Hele Titanium Hydrogen was founded to be the partner we’ve just described.

We are the specialized OEM partner from Section 3. Our entire business is structured around co-designing and manufacturing high-performance PEM water hydrogen generators for innovative companies like yours.

- Our PEM Focus is Your Competitive Advantage: We don’t dilute our expertise. We have dedicated 100% of our R&D and manufacturing resources to mastering PEM technology.

This singular focus means we understand the nuances of catalyst loading, membrane hydration, and flow field design required to extract maximum performance and longevity from every stack we build. - A Partnership Built on Engineering Collaboration: Our OEM service is a hands-on, collaborative journey. Your engineers will work directly with our engineers. We use a structured process to ensure your unique requirements are translated perfectly from the CAD file to the production floor. We become an extension of your R&D team.

- Uncompromising Quality, Verified and Certified: We don’t just talk about quality; we live it. Our facility is ISO 9001:2015 certified, and our multi-stage QC process—from raw material verification to a 72-hour final system test—is our guarantee of reliability and performance.

- Agility for Your Growth: We are built for the OEM lifecycle. We can support you with single prototype units, low-volume initial production runs, and seamlessly scale with you to thousands of units as your market demand grows.

7. Frequently Asked Questions (FAQ)

Q1: What is the typical lead time for a custom OEM order?

For initial prototypes, lead times are typically 4-6 weeks after design finalization. For mass production, lead times range from 8-12 weeks depending on volume and supply chain conditions. We provide a detailed timeline for every project.

Q2: How do you protect our intellectual property (IP) during a custom project?

We take IP protection very seriously. All OEM partnerships are governed by a comprehensive Non-Disclosure Agreement (NDA). Your proprietary designs and information are held in the strictest confidence.

Q3: Can your PEM electrolyzers be used for a home hydrogen electrolyzer system?

Absolutely. The compact, efficient, and safe design of our smaller-scale PEM stacks makes them an ideal core component for OEMs developing integrated residential energy storage and home hydrogen systems.

Q4: What is your minimum order quantity (MOQ) for OEM partners?

We do not have a strict MOQ for our dedicated OEM partners. We understand the need for prototypes and initial small-batch runs and are structured to support your project from the very beginning.

8. Conclusion & Your Next Step

The journey to launching a successful product in the green hydrogen economy is complex and filled with challenges. Your choice of manufacturing partner will be the single most important decision you make.

Sourcing an electrolyzer in China is not about finding the lowest price on a specification sheet; it’s about finding a strategic partner who can deliver quality, reliability, and the collaborative spirit necessary to turn your vision into a market-leading reality.

For companies that value customization, deep technical excellence, and a true partnership, a specialized PEM OEM partner is the clear, strategic choice.

Stop searching for a supplier. Start a conversation with a partner.

If you’re ready to build your product on a foundation of proven technology and collaborative excellence, our team is ready to listen.

- Schedule a Free Technical Consultation with our engineering team to discuss your specific OEM requirements.

- Download Our PEM Technology Whitepaper to dive deeper into the performance advantages for renewable projects.

- Explore Our OEM & Manufacturing Services to see how we can support your project from concept to completion.

Email Us: heletitaniumhydrogen@gmail.com

Phone/WhatsApp: 086-13857402537