Trusted PEM Electrolyzer Exporters to the USA brief Description: Discover the most reliable PEM electrolyzer exporters shipping to the USA with certifications, logistics expertise, and OEM manufacturing options. Learn why Hele Titanium Hydrogen is your trusted partner for green hydrogen production.

I. Introduction: The USA’s Green Hydrogen Opportunity

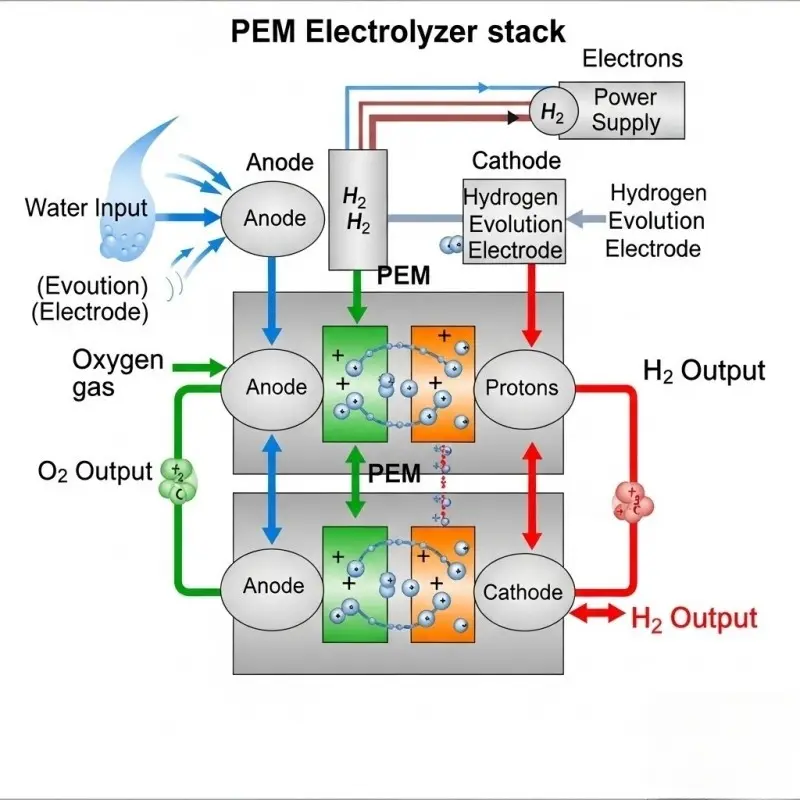

The United States is entering a new era of clean energy, with green hydrogen production emerging as a cornerstone of its energy transition strategy. At the heart of this movement are PEM (Proton Exchange Membrane) electrolyzers—advanced systems capable of producing high-purity hydrogen from water using renewable electricity.

Why does this matter for US businesses? From fueling hydrogen-powered vehicles to decarbonizing heavy industries, PEM electrolyzers are unlocking new opportunities for growth, sustainability, and compliance with tightening emissions regulations.

Yet, for US buyers and project developers, choosing the right PEM electrolyzer exporter is no simple task. Factors such as certifications, compliance with US standards, logistics, and long-term support all play a decisive role in project success.

This guide explores everything you need to know about finding trusted PEM electrolyzer exporters to the USA, with actionable insights, case studies, and a comparison of leading suppliers. More importantly, it highlights why Hele Titanium Hydrogen has become the go-to OEM partner for businesses seeking reliable, cost-effective, and certified PEM water hydrogen generators.

II. The PEM Electrolyzer Market in the USA (2025–2030)

The US PEM electrolyzer market is growing at an unprecedented pace, fueled by federal incentives and the country’s pledge to reach net-zero emissions by 2050. According to industry reports:

- The global PEM electrolyzer market is expected to grow at a CAGR of 30%+ through 2030, with some estimates valuing the market at over $7.2 billion by 2030.

- The USA is one of the fastest-growing regions, driven by the Inflation Reduction Act (IRA), which provides generous tax credits for hydrogen production. The IRA’s Section 45V offers a Clean Hydrogen Production Tax Credit of up to $3 per kilogram for hydrogen with low carbon intensity.

- Hydrogen demand in the USA is projected to quadruple by 2030, with PEM electrolyzers being the technology of choice for renewable-powered projects.

Key Drivers of US PEM Electrolyzer Growth

- Government Support: Hydrogen hubs funded by the Department of Energy (DOE) and tax credits like the IRA are accelerating the market.

- Industrial Decarbonization: Industries like steel, cement, and chemicals require zero-carbon hydrogen to meet sustainability goals and reduce their carbon footprint.

- Hydrogen Mobility: The expansion of hydrogen fueling stations for hydrogen fuel-cell vehicles (FCEVs) is poised to fuel tremendous growth in this space.

- Energy Storage: Hydrogen is being used as a solution to balance renewable energy fluctuations, providing energy storage for excess wind and solar power.

👉 Opportunity for Importers: US-based developers often rely on certified international exporters due to limited domestic supply capacity. This creates an attractive opening for suppliers like Hele Titanium Hydrogen to serve the USA market.

III. Why Choose PEM Electrolyzers for Hydrogen Production?

When it comes to electrolyzers, buyers typically compare alkaline vs. PEM technology. Here’s why PEM is increasingly preferred in the US market:

- Higher Efficiency: PEM electrolyzers achieve superior energy conversion, with efficiencies of 60–75%, reducing operating costs.

- High Purity Hydrogen: They produce hydrogen with over 99.99% purity without additional purification, which is critical for fuel cells and sensitive industrial applications.

- Dynamic Response: PEM systems can ramp up from 0% to 100% capacity in seconds, making them ideal for integrating with intermittent renewable sources like solar and wind power.

- Compact & Modular: PEM electrolyzers have a smaller footprint compared to alkaline systems, making them space-efficient, scalable, and easy to integrate into existing facilities.

- Durability: Modern PEM electrolyzers boast long lifespans with minimal downtime.

💡 Hele Titanium Hydrogen leverages titanium-based components to maximize durability and efficiency in its PEM hydrogen generators.

IV. Key Considerations When Choosing a PEM Electrolyzer Exporter to the USA

Selecting the right exporter is about much more than just price. Here are 7 critical factors US buyers must evaluate:

1. Technical Expertise & Experience

- Years of PEM electrolyzer manufacturing & export experience.

- Proven R&D capabilities and innovation track record.

- Integration support for renewable energy and industrial applications.

2. Product Quality & Performance

- Verified efficiency and output data.

- Long lifespan & durability testing.

- Proven success in large-scale deployments.

3. Certifications & Compliance

For the US market, certifications are a non-negotiable requirement for safety and regulatory compliance.

- UL (Underwriters Laboratories) Certification: Essential for electrical safety and market access in the USA.

- ASME (American Society of Mechanical Engineers): Adherence to the Boiler and Pressure Vessel Code (BPVC) is critical for high-pressure systems.

- ISO & CE Certifications: Compliance with ISO standards ensures quality management and consistency, while CE marking is often recognized as a quality benchmark.

4. Manufacturing Capacity & Scalability

- Can they meet your current AND future demand?

- Flexible capacity for pilot projects and utility-scale plants.

5. Service & Support

- Pre-sales consultation.

- Installation & commissioning guidance.

- Ongoing maintenance and remote monitoring.

6. Pricing & Financing

- Transparent, competitive quotes.

- Financing or leasing options.

- TCO (Total Cost of Ownership) analysis.

7. Reputation & References

- Client testimonials.

- Case studies of successful projects.

- Recognition within hydrogen industry networks.

👉 Hele Titanium Hydrogen checks all the above boxes—offering certified PEM electrolyzers, flexible OEM services, and proven export success to North America.

V. Why Hele Titanium Hydrogen is Your Ideal OEM Partner

While the US market has several international suppliers, Hele Titanium Hydrogen stands out as a reliable and cost-effective partner, specializing in B2B supply chain optimization.

The OEM Manufacturing Advantage

Unlike traditional European exporters, Hele Titanium Hydrogen excels at OEM manufacturing. This means we can provide fully customized PEM water hydrogen generators designed to your specific requirements, bypassing the markup of middlemen. Our factory-direct pricing translates to a lower Total Cost of Ownership (TCO) for your project.

Our Quality Assurance Process

We don’t just assemble products; we control the entire manufacturing process, from raw material to finished good. Our commitment to using premium, corrosion-resistant titanium-based components ensures our electrolyzers are highly durable and efficient. Every unit undergoes rigorous quality checks and performance testing to guarantee it meets international standards.

Direct Comparison: Hele Titanium Hydrogen vs. Other Exporters

| Feature | Hele Titanium Hydrogen | Nel, ITM, Siemens |

|---|---|---|

| Cost | Competitive, factory-direct pricing | Typically higher, premium pricing |

| OEM Flexibility | Specializes in custom solutions & tailored designs | Limited customization, focus on standard products |

| Certifications | US-ready with UL, ISO, ASME, CE compliance | Certifications vary by region |

| Export Experience | Proven success in shipping to North America | Strong global presence, but less focused on OEM B2B supply |

| After-Sales Support | Dedicated support, spare parts, and remote monitoring | Standardized support packages |

👉 Lead Magnet CTA: “Download our 2025 PEM Electrolyzer Buyers Checklist to evaluate suppliers—and see why US companies choose Hele Titanium Hydrogen. [Request Now]”

VI. Case Studies: PEM Electrolyzer Success in the USA

The viability of PEM technology is not theoretical; it’s proven in real-world applications across the USA.

Case Study 1: Renewable Energy Storage

- Application: A utility company in California integrated a PEM electrolyzer with a solar farm. The electrolyzer converts excess solar energy into hydrogen, which is stored and then used to power a fuel cell during peak demand.

- Benefit: This system balances the grid, increases the utilization of renewable energy, and provides a reliable energy source for local power needs.

- Result: The project demonstrated the viability of PEM for grid storage, with a 95% utilization efficiency.

Case Study 2: Hydrogen Refueling Station

- Application: A transport company in Texas deployed an on-site PEM electrolyzer to produce hydrogen for a fleet of hydrogen trucks.

- Benefit: On-site production eliminated the high costs and logistical complexities of delivered hydrogen.

- Result: The station enabled daily fueling for over 30 hydrogen trucks, cutting CO₂ emissions and significantly reducing operational costs compared to diesel.

Hele Titanium Hydrogen supplies OEM hydrogen generators that are specifically designed to meet the technical and commercial requirements of US industrial buyers, enabling them to replicate these results.

VII. Logistics & Import Regulations for the USA

Importing PEM electrolyzer systems into the US requires navigating a complex process. An experienced exporter is your best asset to avoid costly delays.

- Tariffs & Duties: Certain components may be subject to trade tariffs, which must be accounted for in the project budget.

- Customs Clearance: All documentation, including safety declarations and certifications, must be precise and complete to ensure smooth clearance.

- Shipping & Handling: The equipment must be properly packaged and handled to protect sensitive components during transit.

Why work with an experienced exporter? To avoid costly delays and unexpected fees.

💡 Hele Titanium Hydrogen offers full logistics support, including documentation for US customs clearance, ensuring a hassle-free delivery.

VIII. Future Trends in PEM Electrolyzers & US Hydrogen Market

The PEM electrolyzer market is continuously evolving. Staying informed about these trends will help you make a future-proof investment.

- Falling Costs: Technological advancements in membranes and the increasing scale of production are expected to drive down the cost of PEM systems.

- Scaling Up: The US is investing in larger hydrogen hubs and fueling networks, leading to a demand for larger and more powerful modular systems.

- OEM Growth: The demand for customized solutions tailored to specific industries will continue to grow as more businesses adopt hydrogen technology.

IX. Why Hele Titanium Hydrogen is Your Ideal OEM Partner

At Hele Titanium Hydrogen, we don’t just manufacture—we partner with our clients. We bring over a decade of expertise in designing and producing PEM hydrogen generators, specializing in OEM and custom solutions for US projects.

- Decade of Expertise: Over 10 years of practical experience in the titanium industry gives us an in-depth understanding of material science and manufacturing.

- OEM & Custom Solutions: We build PEM water hydrogen generators tailored to your exact needs, from small-scale lab units to large industrial systems.

- High-Efficiency Titanium Technology: Our use of high-quality titanium components ensures exceptional durability and long-term performance.

- End-to-End Service: We support you at every step, from initial design consultation to manufacturing, shipping, and after-sales support.

📩 Contact Hele Titanium Hydrogen today:

- Email: heletitaniumhydrogen@gmail.com

- Phone/WhatsApp: +86-13857402537

- [Browse Our Products] | [Request a Free Quote]

X. FAQs

1. What certifications are required to import PEM electrolyzers into the USA?

UL, ISO, CE, and ASME certifications are essential for compliance. Hele Titanium Hydrogen provides all required documentation.

2. How long does shipping from China to the USA take?

Typically 20–35 days depending on the destination port and customs clearance.

3. Do you offer OEM customization?

Yes, Hele Titanium Hydrogen specializes in OEM solutions tailored to US industries and specific project requirements.

4. What is the lifespan of a PEM electrolyzer?

With proper maintenance, a PEM electrolyzer can operate for 60,000–80,000 hours, depending on the operational profile.

5. Can PEM electrolyzers integrate with renewable projects?

Yes, they are specifically designed to handle variable loads from intermittent renewable sources like solar and wind power.

6. Do you provide after-sales support and spare parts?

Yes, we offer comprehensive after-sales support, including remote monitoring and spare parts services to ensure maximum uptime.

7. How does PEM differ from alkaline electrolysis?

PEM electrolysis uses a solid polymer electrolyte membrane, which allows for a faster response time, higher hydrogen purity, and a more compact design compared to alkaline electrolysis.

XI. Conclusion

The USA’s hydrogen future is unfolding rapidly, and PEM electrolyzers are at the heart of this transition. For US buyers, selecting a trusted exporter ensures compliance, efficiency, and long-term success.

With certified technology, OEM flexibility, and proven export expertise, Hele Titanium Hydrogen is your ideal partner for PEM water hydrogen generators. We are ready to help you navigate the complexities of the US market and achieve your green hydrogen goals.

👉 Take the Next Step Today: 📩 Email us at heletitaniumhydrogen@gmail.com or call +86-13857402537 to request a free consultation.