Looking for precision PEM electrolyzer manufacturers in China? Discover the top OEM suppliers, compare certifications, and learn how to vet reliable partners for long-term hydrogen projects.

Introduction: Why PEM Electrolyzers Matter in the Green Hydrogen Economy

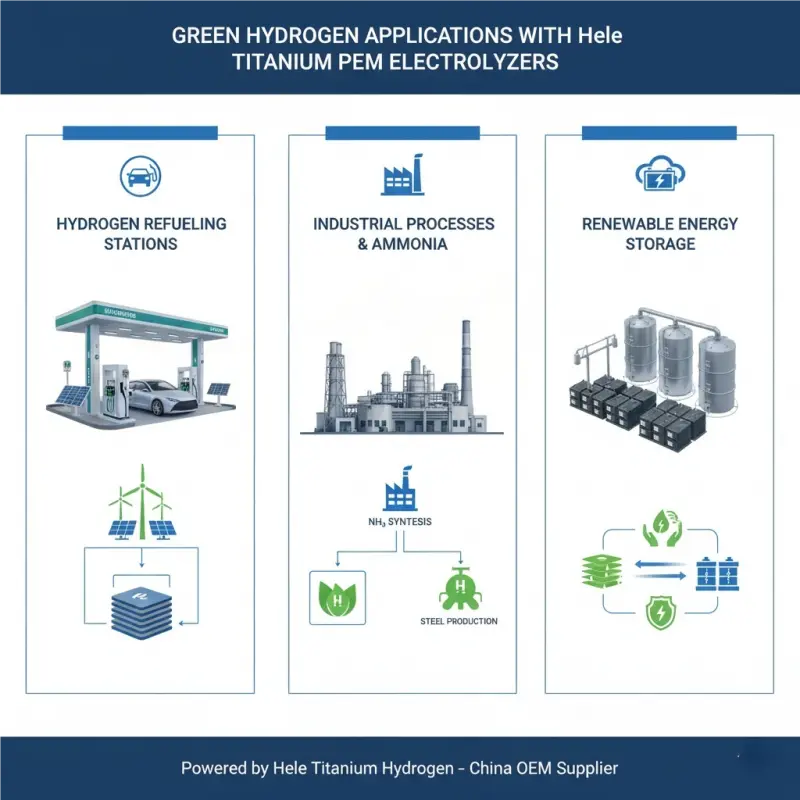

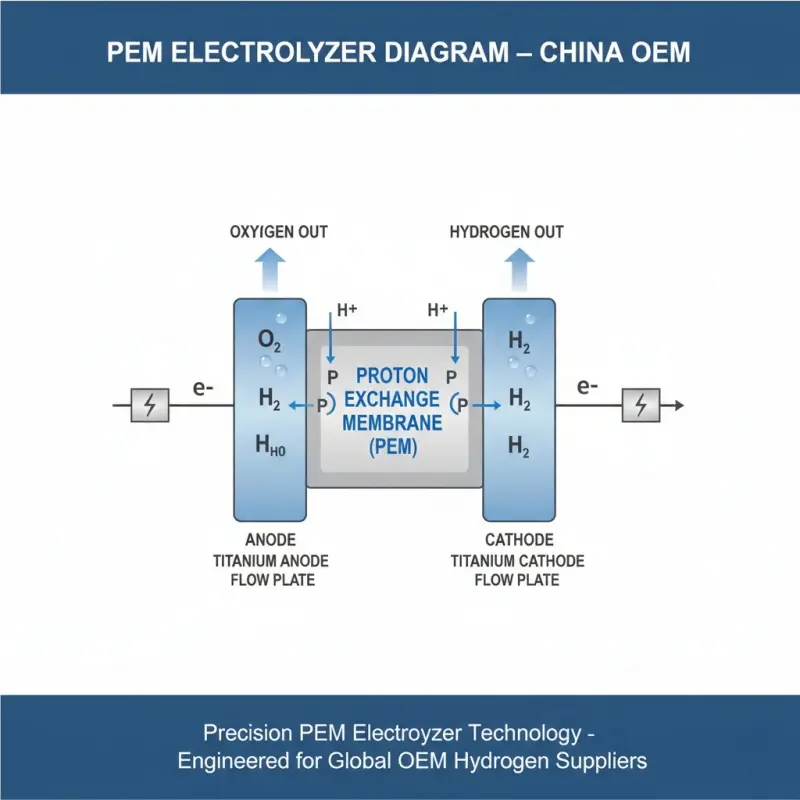

In an era where decarbonization, clean energy, and net-zero targets are driving massive investments, Proton Exchange Membrane (PEM) electrolyzers have emerged as a critical technology. They convert water into hydrogen and oxygen using electricity, and when powered by renewables, they produce green hydrogen — a clean fuel for transportation, energy storage, industrial processes, and more.

Precision is everything in PEM electrolyzer design: efficiency, durability, response time, safety, gas purity. Because hydrogen is sensitive to impurities and process inefficiencies cascade into project costs, any compromise in manufacturing precision can sharply raise operating costs or risk failure.

China has fast become one of the world’s most active hubs for PEM electrolyzer manufacturing. With strong government incentives, scale in industrial production, rapidly advancing R&D, and increasing export orientation, Chinese OEMs are now legitimate options for foreign buyers looking for both cost-competitive and technically reliable PEM solutions.

But sourcing from China also comes with challenges — variable product quality, differing standards, IP risks, logistical issues, and sometimes opacity around certifications. This guide helps you navigate all of that. It identifies leading precision PEM electrolyzer manufacturers in China, lays out how to evaluate OEMs, compares them, and gives you a procurement roadmap — especially if you are considering working with Hele Titanium Hydrogen as a primary partner.

What Makes a Precision PEM Electrolyzer?

If you are shopping for a PEM electrolyzer, “precision” means more than just “it works.” It means excellence in core technical and business metrics — precision in design, materials, testing, and delivery. Let’s break down what to look for.

Key Performance Indicators (KPIs)

- Efficiency (kWh per kilogram of H₂): Lower energy consumption per unit of hydrogen produced reduces your OPEX significantly.

- Purity of Hydrogen: For many applications (fuel cells, semiconductors, pharmaceutical uses), you’ll need 99.99% or higher. Precision manufacturing of membranes, seals, and gas separation matters.

- Pressure handling, Temperature tolerance, and Dynamic Response Time: How fast the electrolyzer reacts to load changes (renewables fluctuation), how it handles heating, and what pressure it delivers gas at.

- Durability / Lifetime: Number of cycles, hours of operation before performance degradation. Materials choice (membranes, catalysts, bipolar plates) and stack design are central.

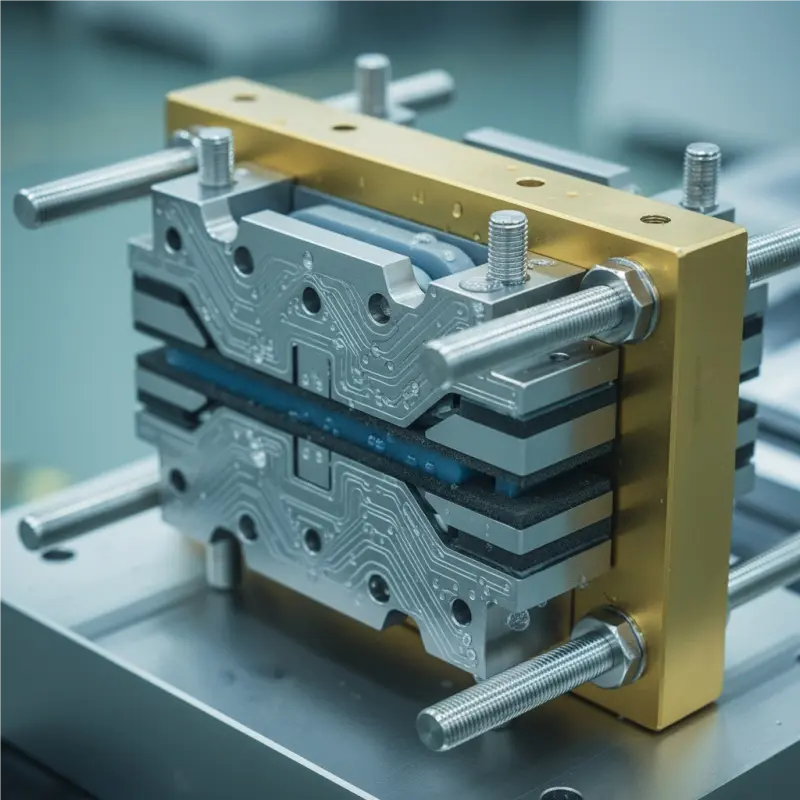

Components that Demand High Precision

- Membrane Electrode Assembly (MEA): The heart of the stack; membrane quality, catalyst loading, uniformity, thickness tolerances, humidity handling.

- Bipolar Plates / Flow Fields / End Plates: Machined or stamped plates must ensure uniform current distribution, minimal resistance, minimal gas crossover. Sometimes titanium or other corrosion-resistant materials are used.

- Seals, Gaskets, and Assembly Tolerances: Precision here avoids leaks, pressure loss, safety issues.

- Balance of Plant (BoP): Pumps, purifiers, controls, power conditioning — poor quality here undermines the stack quality.

Other Factors: Testing, Certifications, Designs

- R&D investment for performance optimization (catalyst use, scale-up).

- In-house testing labs and performance validation under different conditions.

- Certifications: ISO 9001, CE, possibly ASME, PED, or national standards. Buyers should ask for test reports (efficiency, pressure, lifetime).

Understanding these criteria helps you compare OEMs meaningfully and avoid being misled by specs that don’t have backup or validation.

Why Source Precision PEM Electrolyzers from China?

Foreign buyers often ask: is China really a viable source for high-quality PEM electrolyzers? The answer is increasingly yes — under the right conditions. Here are key advantages, and what to watch out for.

Advantages

- Cost-Effectiveness Chinese manufacturing can drastically reduce capital and component costs. Labor, overhead, and many supply-chain parts cost less than in Europe or North America. Also, many OEMs are scaling up, and economies of scale are improving. For small- to mid-sized PEM systems, the cost per kW from good Chinese suppliers can be substantially lower. Supporting this, multiple reports suggest Chinese PEM output is cheaper — though efficiency might lag initially. (S&P Global)

- Manufacturing Capacity and Speed of Scaling China’s industrial infrastructure is extensive. Many factories have the ability to scale from pilot/medium volumes up to MW class. Government support (subsidies, incentives, green hydrogen targets) further boosts capacity. OEMs often have large component fabrication capabilities, such as membrane production, titanium anode plate fabrication, etc.

- Technological Innovation and R&D Momentum R&D is accelerating. New national standards (e.g. GB/T 45539-2025 for technical requirements for PEM electrolyzers, and GB/T 45541-2025 for performance testing) have been approved. These help bring consistency and transparency. (MPR China Certification GmbH) Also many manufacturers are working on improving hydrogen purity, reducing energy consumption, improving load-following behavior.

- Government Policy & Standardization China has rolled out standards and regulatory frameworks to support hydrogen technologies, including PEM electrolysis. National standard approvals and guidelines make it easier for international buyers to verify performance. (MPR China Certification GmbH)

Risks & What to Watch For

- Quality Control Variation: Not all manufacturers are equal. Some may cut corners on components, or not test thoroughly.

- Certifications & Compliance: Buyers must ensure OEMs hold relevant international or at least nationally recognized certifications. Also request test reports, not just marketing claims.

- Intellectual Property (IP) & Transparency: NDA, inspections, auditing may be required.

- Logistics, Export Documentation & After-Sales Support: Shipping large systems, dealing with customs, spare parts, servicing abroad can be harder.

Top Precision PEM Electrolyzer Manufacturers in China (2025 List)

Here are leading Chinese OEMs or companies with strong capabilities in precision PEM electrolyzer technologies. This is not exhaustive but includes strong candidates. One of these — Hele Titanium Hydrogen — is featured in detail.

| OEM | Location | Product Range / Capacity | Certifications & Standards | Strengths and Key Projects |

|---|---|---|---|---|

| Hele Titanium Hydrogen | Songshan Lake, Dongguan City, Guangdong; also and Baoji, China (heletitaniumhydrogen.com) | From small-scale units (e.g. CH-10 Nm³/h) to industrial scale (e.g. CH-60 Nm³/h and MW-class) PEM electrolyzers. (heletitaniumhydrogen.com) | Products delivering ≥99.99% H₂ purity, rapid response times (<30s), robust titanium anode designs. Compliance with international standards (clients globally). Customized designs and high efficiency. (heletitaniumhydrogen.com) | Strong R&D, titanium anode expertise, flexibility in customization, good footprint in industrial, energy storage, refueling applications. Good export experience. Featured OEM partner. |

| Guangdong Taiji Power Co., Ltd. | Guangdong Province | PEM & AEM membrane assemblies; full hydrogen production & storage systems. (taijipower.en.made-in-china.com) | Certifications: ISO 9001, ISO 14001, IATF16949; 47 patents; strong in system integration & testing. (taijipower.en.made-in-china.com) | Leading MEA and membrane development; strong order volumes; export clients in Europe, Asia Pacific. Good reputation for stable supply. |

| Shandong Saikesaisi Hydrogen Energy Co. Ltd. | Shandong Province | Electrolyzers beyond 1 MW, PEM tech for industrial applications. (S&P Global) | Local and export certifications; increasing R&D footprint. | Has publicly stated ambitions to impact pricing and capacity. Competitive in large-scale projects. |

| Shanghai H-Ray S&T Co., Ltd. | Shanghai | MEA, PEM stacks, compact high-efficiency PEM/Ryzer cabinet systems. (Made in China) | OEM/ODM capacity, own R&D brand, likely ISO etc. | Good for modular PEM stacks and smaller scale systems. May be faster for prototypes or smaller orders. |

| BriHyNergy Shenzhen Co., LTD | Shenzhen, Guangdong | MEM / MEA / PEM stack / channel testing / bench test devices. (Made in China) | Maker of high-stability MEA, own testing benches; OEM/ODM capabilities. | Strong in component quality, smaller runs; useful for research, pilot, mid-scale clients. |

| Suzhou Green Hydrogen New Energy Technology Co., Ltd. | Suzhou, Jiangsu Province | PEM hydrogen generators and electrolyzers; both large and small scale. (Made in China) | Likely ISO 9001 etc.; focused on hydrogen generator systems. | Good for full system solutions; possibly lower cost margins; good for project clients who need turnkey systems. |

Featured OEM in Detail: Hele Titanium Hydrogen

Overview & History Hele Titanium Hydrogen is based in Guangdong (Songshan Lake, Dongguan), with manufacturing and engineering facilities. They also have a presence in Baoji, known for titanium material suppliers. The company has built its reputation on producing precision PEM water electrolyzers for both small / mid-scale industrial applications and for scalable MW+ deployment. (heletitaniumhydrogen.com)

Product Specialties

- CH-60 Nm³/h Model: Industrial scale electrolyzer with high hydrogen production (≈60 Nm³/h), 99.99% purity, compact footprint (~0.97×0.90×0.85 m). Rapid response (<30s) and titanium anode design for durability. (heletitaniumhydrogen.com)

- CH-10 Nm³/h and similar models: Smaller units, for refueling stations, on-site supply, etc. Customization allowed (stack size, electrode materials, etc.) (heletitaniumhydrogen.com)

Strengths

- Material expertise, especially with titanium anode and corrosion-resistant components.

- Custom engineering & one-stop service: design, manufacturing, testing, after-sales support.

- High purity, rapid dynamic response, and industrial durability are strong selling points.

- Export experience: they emphasize “trusted globally” use. (heletitaniumhydrogen.com)

Potential Weaknesses / Things to Clarify

- Lead time for large / MW-class orders might be longer, depending on whether components are fully in house or supplied externally.

- Certifications: need to verify all necessary international safety, pressure vessel, and export approvals for client’s country (e.g. PED in EU, ASME in US).

- After-sales support network: for remote locations, service, spare parts, maintenance training matter.

Comparison Table: Leading Chinese OEMs

| OEM | Typical Output / Scale | Certifications | Special Materials or Design Features | Price Range / Competitive Strengths | Ideal Client Types |

|---|---|---|---|---|---|

| Hele Titanium Hydrogen | Small (10-60 Nm³/h) to industrial / MW scale | High‐purity output (~99.99%), titanium aodes, rapid response, likely ISO/CE etc. | Titanium anode, compact footprint, strong material durability | Competitive pricing, good customization, strong materials | Industrial users, refueling stations, energy storage projects |

| Taiji Power | Medium scale, component-to-system integration | ISO 9001, ISO 14001, IATF16949, local certifications | MEA, membrane technologies, coagulation in flow field design, strong test center | Offers lower entry cost, shorter lead times for mid scale | Companies needing full system packages, pilot / mid projects |

| Saikesaisi | Large industrial / MW scale | Local and export standard certifications, R&D investment | System scale design, ability to integrate renewables, large stack size | Often cost-advantaged for big orders | Large scale hydrogen production, chemical plants, ammonia etc. |

| Shanghai H-Ray S&T | Small to mid scale, stack & module producer | Likely ISO, OEM/ODM brands | High stability MEA, custom cabinet systems, faster prototyping | Lower CAPEX for smaller orders, smaller MOQ | R&D institutions, smaller producers, early stage projects |

| BriHyNergy | MEA, component, stack level | Testing labs, component quality | Specialization in MEA, test benches, stable performance | Good for buyer who wants strong components or custom stacks | OEMs, research labs, clients wanting high-quality smaller components |

| Suzhou Green Hydrogen New Energy | Full hydrogen generator systems | Standard international certs (ISO etc.) and likely system safety approvals | Turnkey system design | Good full solutions, less time needed to assemble system from parts | Project developers, clients wanting end-to-end delivery |

How to Vet a Chinese PEM Electrolyzer Manufacturer

When you are comparing manufacturers, it’s essential to have a robust vetting process. Don’t just look at marketing brochures—dig deeper.

Due Diligence Checklist

- Legal & Financial Verification

- Check business license, company registration.

- Confirm ownership, years in operation. Suggest at least 3-5 years in serious production.

- Audit financial statements if possible (or at least ask for references and proofs of completed projects).

- Certifications & Standards

- ISO 9001 is a must. Also ask for safety standards relevant in your region (CE, PED, ASME, UL, etc.).

- National standard compliance of China (e.g. the recent GB standards for PEM electrolyzers) is useful if exporting. (MPR China Certification GmbH)

- Pressure vessel certification if units operate under high pressure.

- Technical & Manufacturing Capabilities

- In-house R&D: does the OEM develop its own membranes, catalysts, or are they buying all from third parties?

- Production facility: capacity in relevant size (kW to MW), control over core components (MEA, bipolar plates, etc.).

- Quality control processes: assembly tolerance, leak testing, electrical performance, gas purity measurement, accelerated aging tests.

- References / Track Record

- Ask for case studies or project portfolios. Prefer references from clients in markets with similar regulatory / operational conditions as yours.

- Inspect sample units, or ask for pilot deliveries if possible.

- Support & After-Sales

- Warranty terms (stack lifetime, performance retention).

- Supply of spare parts and technical support.

- Ability to provide training, manuals, remote diagnostics.

- Intellectual Property & Transparency

- NDAs when sharing technical requirements.

- Clarity on who owns the design, modifications, customizations.

- Logistics, Export, and Delivery

- Can the manufacturer handle export-grade packaging, customs documents, certifications for import?

- Lead times, shipping risk, installation support.

Procurement Process: From Inquiry to Delivery

Here’s a suggested roadmap for getting from first inquiry to commissioning — helps avoid surprises and ensure you get exactly what you ordered.

- Initial RFQ (Request for Quotation)

- Provide detailed technical specs: hydrogen production rate (Nm³/h), purity required, operating pressure, temperature range, dynamic response time, expected lifetime.

- Ask for data: efficiency curves, degradation rates, gas crossover, turn-down ratio, and safety features.

- Product Demonstration / Pilot Testing

- If feasible, get sample units tested in your own conditions (or ask for lab test results under similar conditions).

- Ask for performance guarantees (e.g. efficiency at certain load, retention after N hours).

- Factory / Facility Audit

- Either in person or via third-party auditor or virtual walkthrough.

- Inspect manufacturing of membranes, stacks, material sources, assembly lines, QC labs.

- Contract Negotiation

- Define payment terms (e.g. partial advance, upon delivery, upon commissioning).

- Specify performance warranties (efficiency, purity, lifetime).

- Include liability for defects, delays.

- Define what is included: installation, commissioning, spare parts, training.

- Logistics & Export Documentation

- Ensure all paperwork (export license, safety documentation, pressure vessel certs) is in place.

- Plan shipping: sea freight, handling during transit, customs in destination.

- Packaging standards: protection, safety valves, etc.

- Installation, Commissioning, After-Sales

- Support from OEM for installation (if onsite) or remote guidance.

- Testing post-installation.

- Ongoing maintenance schedule.

- Clear channel for spare parts.

Key Considerations for Global Buyers

When buying from China, or from any foreign OEM, several business and technical variables come into play beyond the equipment spec.

- Performance Requirements vs Total Cost of Ownership: The cheapest upfront cost may not be cheapest long term. Energy efficiency, serviceability, spare parts, and warranty matter.

- Scalability & Modularity: If you expect hydrogen demand to rise, modular designs or OEMs who can scale production matter.

- Regulatory & Safety Compliance: Local environmental, safety, and electrical codes. Pressure ratings. Certifications.

- Currency & Financial Risk: Payment in foreign currency; inflation, import duties, tariffs. Protect with contracts.

- Cultural & Communication Differences: Time zones, language barriers. Use clear contracts, specifications. If possible, engage local representation or a sourcing agent.

Overcoming Common Sourcing Challenges

Below are practical ways to address common issues when sourcing PEM electrolyzers from China.

| Challenge | Mitigation Strategy |

|---|---|

| Quality Variation | Always ask for test data, inspections, third-party lab reports. Use premium OEMs. Do factory visits or virtual audits. |

| Certifications / Standard Discrepancies | Clarify necessary certifications in your country. Ensure OEM has or can acquire them. Include certification deliverables in contract. |

| Long Lead Times / Supply Chain Delays | Order early. Ensure key components are in stock (membranes, catalysts, rare materials). Include buffer times. |

| IP & Contract Risks | Use NDAs. Use clear design ownership clauses. Possibly register IP in your jurisdiction. |

| After-Sales Support | Negotiate warranty and support terms upfront. Clarify spare parts availability. Consider OEMs with overseas service partners. |

| Logistics & Export Compliance | Work with freight forwarders experienced in hydrogen tech, pressure vessels. Ensure OEM can prepare required export documentation. |

Future Trends in PEM Electrolyzer Technology

To stay ahead, you’ll want a partner who is not only capable now but is innovating for the future.

- Lower Catalyst Load & Alternative Catalyst Materials: Reducing precious metals (e.g. platinum, iridium) without losing efficiency.

- Better Membrane Materials: Longer life, better resistance to impurities, higher temperature operation.

- Digital Monitoring, AI / IoT: Real-time diagnostics, predictive maintenance, efficiency optimization.

- Standardization and Modular Designs: To lower cost, simplify logistics, enable easier scaling.

- National and International Standards Convergence: As China rolls out GB standards, more match with EU, US standards; helps with export and acceptance.

FAQ: Sourcing PEM Electrolyzers from China

Q1: What is the typical lead time for a 1 MW PEM electrolyzer from a Chinese manufacturer?

A1: Lead times vary depending on the manufacturer, customization, and component availability. For a reputable OEM with good capacity, expect 6 to 12 months from contract signing to delivery of a 1 MW system—this includes design, testing, production, export. Delays may occur if key components (membranes, catalysts, titanium parts) are backordered.

Q2: Do Chinese OEMs provide operational training and maintenance support?

A2: Many do, especially higher-tier firms. For example, Hele Titanium Hydrogen offers customization, design support, and after-sales service. But the level of training, spare part availability, and local presence will vary. Always clarify in the contract whether training, installation supervision, and ongoing support are included.

Q3: How do I ensure the electrolyzer meets international safety and performance standards?

A3: Before contracting: request third-party test reports, ask for certifications such as CE, PED, ASME, or equivalents. Ask whether the product has been used in applications with regulatory oversight (fuel stations, industrial process) in comparable markets. Include performance guarantees.

Q4: What are the real costs beyond the equipment price?

A4: Consider total cost of ownership: shipping, customs/import duties, installation, energy consumption, maintenance, spare parts, downtime, and warranty. Efficiency losses and degradation over time often make a big difference.

Q5: Can I get modular or expandable PEM electrolyzer systems from Chinese OEMs?

A5: Yes. Many Chinese producers, including Hele Titanium, offer modular systems or stack-based designs that allow expansion by adding more stacks or modules. This design helps you scale as demand grows.

Q6: What minimum project size or order quantity should I be prepared for?

A6: It depends on the OEM. Some accept small or pilot-scale orders (e.g. tens of Nm³/h or small stacks), others are optimized for medium or large scale (hundreds of kW to MW). In many cases, MOQ (minimum order quantity) is negotiable when working directly with the factory as a B2B partner.

Conclusion & Next Steps: Securing Your Hydrogen Future

Sourcing precision PEM electrolyzers from China is no longer just about cost—it’s about strategic advantage. With the right partner, you can gain:

- High-performance hardware (efficiency, purity, lifetime)

- Competitive pricing due to scale and material advantages

- Access to evolving technology and strong R&D

- Export-ready products if certifications are properly handled.

If you are selecting a partner, Hele Titanium Hydrogen stands out as a mature, flexible, material-focused OEM with global export experience. With their titanium anode designs, customizable systems (from small units to large scale), and commitment to performance, they are well placed to serve international clients.

Hele Titanium Hydrogen: Your Trusted Hydrogen Generator OEM & Manufacturing Partner

Hele Titanium Hydrogen stands as a reliable and experienced partner in the hydrogen generator OEM supply chain. We specialize in the design, development, and manufacturing of high-performance PEM Water Hydrogen Generators, offering comprehensive OEM & Manufacturing services tailored to your specific needs.

Take the Next Step

Ready to explore the possibilities of partnering with Hele Titanium Hydrogen?

- Browse our Products to see our range of PEM Water Hydrogen Generators.

- Learn more about our Services and how we can support your OEM & Manufacturing needs.

- Contact Us today to discuss your specific requirements.

- Explore our FAQ to get answers to common questions.

- Visit our Blog for the latest insights and updates on hydrogen technology.

Email Us: heletitaniumhydrogen@gmail.com

Phone/WhatsApp: 086-13857402537