OEM PEM Electrolyzer Manufacturer: Custom Solutions & Wholesale Supply, Partner with a trusted OEM PEM electrolyzer manufacturer. Get custom, scalable PEM stacks and wholesale hydrogen generation equipment.

We offer guaranteed ≥ 60,000 operating hours, global logistics, [Hele Titanium Hydrogen]: Your Strategic OEM PEM Electrolyzer Manufacturing Partner for Custom, Scalable Hydrogen Solutions, and competitive TCO for B2B buyers. Request your quote!

I. Introduction: The Strategic Imperative of OEM PEM Electrolysis

The global commitment to decarbonization has firmly established green hydrogen technology as the essential energy carrier of the 21st century. At the core of this monumental shift is the PEM electrolyzer (Proton Exchange Membrane), the technology that efficiently splits water using renewable power. For any business seeking to integrate this core technology—from system integrators and EPC firms to energy developers—securing a reliable OEM PEM electrolyzer manufacturer isn’t merely procurement; it’s a critical strategic partnership that determines project viability and profitability.

A. The Green Hydrogen Mandate and PEM’s Role

Global installed electrolyzer capacity is skyrocketing, necessitating high-performance systems capable of dynamic response. PEM electrolyzers are the technology of choice due to their unique ability to rapidly ramp up and down, perfectly aligning with the intermittent nature of solar and wind power.

This capability is paramount for securing revenue streams from grid balancing and maximizing renewable asset utilization.

B. Defining the OEM Advantage in Hydrogen Generation

An OEM PEM electrolyzer manufacturer provides far more than a simple component. We offer a fast track to market, allowing you to bypass years of complex research and development (R&D) in specialized electrochemistry and materials science. Partnering with a dedicated electrolysis OEM delivers:

- Accelerated Market Entry: You integrate proven, certified technology, shrinking your timeline from years to months.

- Specialization & De-risking: Access deep, certified expertise in PEM stack design and manufacturing.

- Scalable Supply Chain: Guaranteed volume necessary for both pilot projects and large-scale, international deployment.

C. The [Hele Titanium Hydrogen] Promise

At [Hele Titanium Hydrogen], we stand as a specialized electrolysis OEM, focused exclusively on the design, development, and high-volume electrolyzer manufacturing capabilities of PEM systems. We are your technical Fuel cell technology partner, delivering bespoke hydrogen solutions that are superior in performance and commercially optimized for TCO.

II. Technical Deep Dive: The PEM Electrolyzer Advantage in OEM Systems

The decision to purchase a PEM system is driven by distinct, measurable technical advantages crucial for dynamic, high-purity hydrogen applications.

A. Why PEM is Preferred for Modern OEM Integration

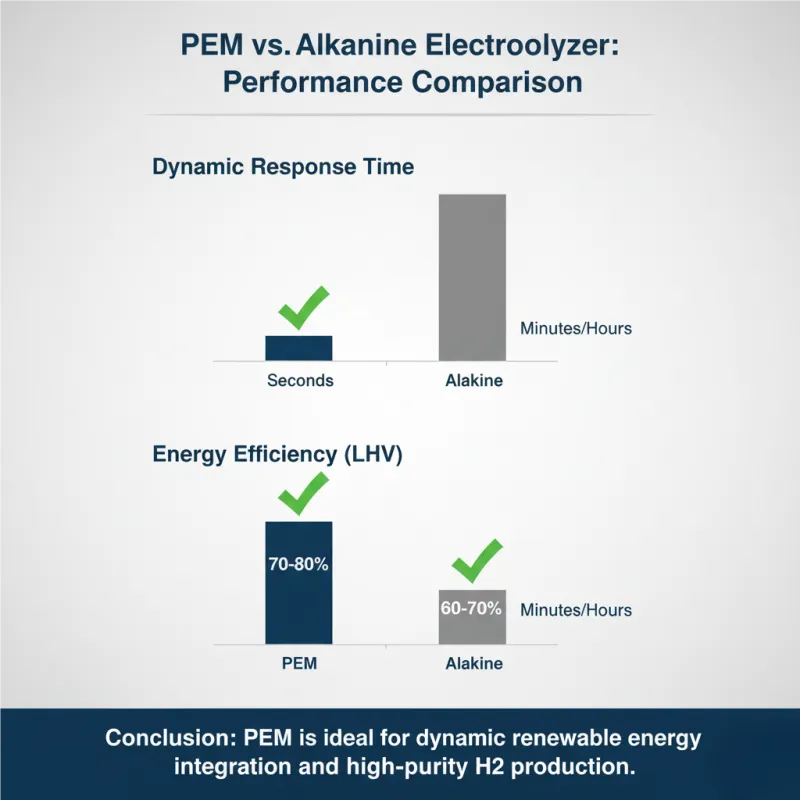

| Feature | PEM Electrolyzer (Best Practice) | Alkaline Electrolyzer (Traditional) | Advantage for OEM Integration |

|---|---|---|---|

| Dynamic Response Time | ≈ 2 seconds | Minutes to Hours | Grid Balancing: Essential for seamless renewable energy integration and fast load-following. |

| Current Density | High 1 to 3 A/cm2 | Low (0.2 to 0.8 A/cm2) | Compact Footprint: Enables smaller, modular systems for containerized hydrogen production equipment. |

| Hydrogen Purity | Very High (≥99.999%) | Requires extensive downstream purification | Fuel Cell Readiness: Direct input for sensitive applications and Hydrogen fuel cell suppliers. |

| Operating Pressure | High (35 bar) | Low (Typically ambient) | Reduced Compression Costs: Saves energy and capital expenditure (CAPEX). |

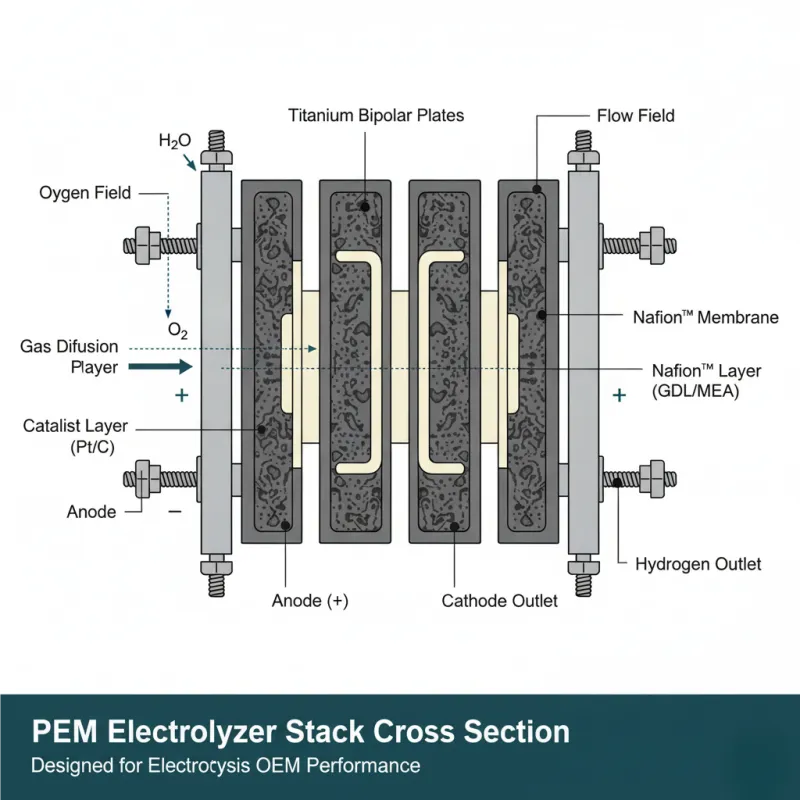

B. Core Components & Technical Specifications: The [Hele Titanium Hydrogen] Edge (E-E-A-T)

Our commitment to E-E-A-T is rooted in our control over core component quality and engineering:

- The PEM Stack (The System Heart): We guarantee optimal performance through precision component management.

- Materials Expertise: We utilize high-grade Titanium Bipolar Plates for unmatched corrosion resistance in the acidic PEM environment. Our R&D focuses on optimizing low-iridium type catalysts to manage cost volatility while delivering high performance.

- Proof of Durability: While industry standards cite 30,000 to 60,000 operating hours, our advanced stack engineering allows us to confidently guarantee ≥60,000 operating hours with verified, minimal voltage degradation, ensuring a superior return on investment (ROI).

- System Efficiency: Our current-generation stacks are benchmarked at ≤4.5 kWh/Nm3 (LHV) at nominal load, directly translating to market-leading operational expenditure (OPEX) savings for the end-user.

III. The Need for OEM Partnership: Mitigating Risk and Maximizing ROI

Developing a proprietary PEM system is an endeavor fraught with financial and technical risks. For instance, achieving stable stack degradation rates requires years of specialized testing that few companies can afford to develop in-house. Partnering with a proven OEM PEM electrolyzer manufacturer like [Hele Titanium Hydrogen] eliminates this uncertainty.

A. OEM Partnership Benefits: The Value Proposition

- Cost Optimization & TCO Reduction: We leverage significant economies of scale in wholesale PEM stack production and material procurement to reduce your Bill of Materials (BoM). This, combined with our durability guarantees, results in a market-leading Total Cost of Ownership (TCO).

- Accelerated Time-to-Market: You gain immediate access to a commercially ready, certified system, shrinking your product timeline from years to months and capturing market share faster.

- Risk Mitigation: We absorb the complexities of certification, performance guarantees, and critical material supply chain risks.

B. The “White-Label” Opportunity for Integrators

For companies focused on rapid market entry, our white-label electrolyzer solutions provide the fastest path to commercialization. We supply the high-performance PEM core, customized Balance of Plant (BoP) interfaces, and system software, ready for your branding, establishing you as an immediate hydrogen generation OEM leader.

💡 Lead Magnet: Don’t start from scratch. Download our OEM Commercial Kit for a detailed TCO comparison showing a 30%+ reduction in initial CAPEX and long-term OPEX achieved by utilizing our optimized ≥60,000 hour PEM stack solutions.

IV. [Hele Titanium Hydrogen]’s Definitive OEM & Manufacturing Capabilities

Our authority as a OEM PEM electrolyzer manufacturer is built on technical discipline, scalable production, and rigorous quality control.

A. Expertise & E-E-A-T: Our Foundation in PEM

With [Insert Years of Experience] years focused exclusively on PEM technology, our technical team comprises certified experts in high-current electrochemistry and materials engineering.

- Certifications & Compliance: We adhere strictly to ISO 9001:2015 (Quality Management) and maintain CE marking. All systems are designed to comply with relevant safety standards like IEC 62282.

- Innovation Proof: Our R&D team focuses on proprietary stack sealing and current distribution methods that demonstrably enhance performance stability, distinguishing our systems from generic wholesale PEM stack offerings.

B. Customization: Turning Your Spec Sheet into Reality

Custom PEM electrolysis solutions are our core business. We treat every partnership as a co-development project through our PEM electrolyzer design capabilities:

- Stack Performance Tailoring: We engineer operating parameters, including customized current density, pressure, and temperature ranges, to perfectly match your project’s needs. Our standard pressure output is 35 bar, minimizing compression stages.

- System Integration (BoP): We design the entire auxiliary system, including power electronics, cooling systems, and gas handling, to fit your exact physical and thermal envelope, supporting any industrial PEM system design.

- Control Systems: We offer full SCADA/PLC integration capabilities using protocols like Modbus TCP/IP, enabling the advanced remote diagnostics and automation required for large-scale scalable electrolyzer manufacturing projects.

C. Manufacturing and Supply Chain Reliability

Our authority stems from our audited capacity and control:

- Scalable Production: Our facility boasts an annual scalable electrolyzer manufacturing capacity of [Insert MW/Year Capacity], positioning us to reliably meet demand for large-scale international hydrogen production equipment orders.

- Global Supply Chain Resilience: We maintain robust dual-sourcing agreements for all critical components (membranes, catalysts, titanium) to mitigate supply chain volatility and guarantee reliable delivery schedules—a non-negotiable factor for B2B foreign trade.

- Quality Assurance & Testing (FAT Protocol): Every custom unit undergoes a rigorous 72-hour Factory Acceptance Test (FAT). This protocol validates performance, confirms ultra-high purity (≥99.999%), and ensures thermal stability before shipping.

D. Technical Support & Post-Sales Service

Our B2B partnership includes:

- Comprehensive Training: Detailed operation and maintenance training for your field service teams, focusing on best practices to preserve stack lifespan.

- Remote Diagnostics: Optional 24/7 remote monitoring services to predict maintenance needs and maximize uptime.

E. Case Studies: Proven Results in Custom PEM Electrolysis

| Project Type | Client & Region | Solution Provided | Quantifiable Result |

|---|---|---|---|

| Grid Balancing | European Power Grid Operator | Custom 5 MW PEM electrolyzer stack adapted for rapid load-following (<10 seconds response). | Increased grid stability revenue by 18% and minimized stack degradation rate by 22% through optimized controls. |

| Mobility | Asian Hydrogen fuel cell supplier | High-pressure (35 bar) OEM PEM electrolyzer core for continuous cycle operation at refueling stations. | Reduced external hydrogen compression energy usage by 30%, leading to significantly lower OPEX per kilogram of dispensed hydrogen. |

| Industrial | Semiconductor Manufacturer | Custom electrolysis equipment source for ultra-high purity hydrogen (≥ 99.9999%) delivered directly to the cleanroom. | Achieved 0% defect rate due to hydrogen contamination over one year, validating the strict purity standards of our bespoke hydrogen solutions. |

V. Applications and Target Industries for Custom PEM Solutions

We enable leaders across the hydrogen value chain with our custom PEM electrolyzer solutions.

A. Fueling the Hydrogen Economy (Mobility)

We provide the OEM hydrogen generator production core for high-throughput hydrogen refueling stations. Our high-pressure output minimizes the costly and complex downstream compression required by Hydrogen fuel cell suppliers.

B. Grid Balancing and Power-to-X

Our dynamic PEM systems are the ideal scalable PEM stack solution for utilizing renewable power curtailment, supporting grid stability, and creating storable, transportable energy vectors (Power-to-Gas, Power-to-Ammonia).

C. High-Purity Industrial Demand

Our ≥ 99.999% purity systems are essential for specialized industries where gas contamination is intolerable, including semiconductor manufacturing, specialized welding, and high-tech material processing.

Don’t let standardized equipment create costly bottlenecks. Download our full OEM Solutions Brochure to see application-specific designs and technical specifications.

VI. Strategic Partnership: Why [Hele Titanium Hydrogen] Excels

Choosing your OEM PEM electrolyzer manufacturer is a decade-long commitment. We provide the expertise and security required for large-scale international projects.

A. Commitment to Quality, Not Just Cost

We focus on delivering the highest possible TCO over the system’s lifespan. Our advanced PEM stack designs, featuring high-quality Titanium Bipolar Plates, ensure superior durability and minimize the need for costly unscheduled maintenance, proving that premium quality is the most cost-effective solution in the long run.

B. Foreign Trade Expertise & Logistics

As an experienced foreign trade partner, we streamline international transactions:

- Incoterms & Payment Flexibility: We are expert in all major trade terms (FOB, CIF, DDP) and offer flexible, milestone-based payment structures (including L/C options) essential for secure, high-value B2B international wholesale PEM stack transactions.

- Logistical Precision: We manage specialized, shock-dampening packaging and ensure full customs compliance for all hydrogen production equipment, guaranteeing safe and timely delivery globally.

C. Competitive Edge: The PEM Specialty

Our exclusive focus on PEM technology means our R&D is highly specialized, positioning us as a leader in dynamic operation and high purity—the most critical factors in the rapidly evolving green hydrogen market. We are the electrolysis OEM built for the future.

VII. Getting Started: Your Path to a Custom OEM Solution

Ready to discuss securing a reliable, custom hydrogen generation system? Our process is transparent and technically rigorous.

A. The Consultation Process

- Discovery: Initial technical meeting to align on project requirements, power availability, and application goals.

- Technical Proposal: Our engineers deliver a detailed solution outlining the proposed custom PEM electrolyzer design, performance guarantees, and detailed financial breakdown.

- Manufacturing & Delivery: Execution follows FAT testing and certified global logistics.

B. Requesting a Quote: Information to Include in Your RFQ

To ensure we deliver a precise and competitive quote, please provide:

- Required hydrogen capacity (in MW or Nm3)

- Operating pressure required (e.g., 35 bar)

- Power source characteristics (min/max ramp rates, voltage specs)

- Integration environment (Containerized, indoor industrial, climate zone)

- Annual volume projection for wholesale PEM stack supply.

C. Strong Call to Action (CTA)

Don’t let standardized equipment compromise your project’s performance or profit margins. Partner with the dedicated OEM PEM electrolyzer manufacturer that specializes in Custom PEM electrolysis solutions.

🔥 Contact [Hele Titanium Hydrogen] today for a free, no-obligation technical consultation and project assessment. Secure your competitive edge in the green hydrogen market!

VIII. Future Trends in OEM PEM Electrolyzer Manufacturing

To maintain topical authority, we acknowledge that the future of green hydrogen requires constant innovation. [Hele Titanium Hydrogen] is actively engaged in developing:

- AI-Driven Performance Optimization: Integrating machine learning algorithms into control systems to predict optimal operating points and reduce stack degradation by up to 15%.

- Larger Modular Units: Developing 5 MW and 10 MW scalable PEM stack units for utility-scale Power-to-X projects, standardizing deployment for easier electrolyzer system integrator adoption.

- Catalyst Strategy: Continuously researching alternative and low-PGM catalysts to sustainably manage the cost and supply chain of the essential iridium, ensuring long-term price stability for our OEM partners.

IX. Conclusion: Forging the Future of Green Hydrogen

Choosing [Hele Titanium Hydrogen] means selecting a strategic electrolysis OEM partner committed to technical excellence and commercial security. Our blend of scalable electrolyzer manufacturing capacity, proven E-E-A-T, and expertise in global B2B logistics ensures that your project receives the optimal system, guaranteed reliability, and market-leading TCO.

We are ready to build the future of hydrogen with you.

👉 Send Your Inquiry Now: Discuss your capacity, pressure, and integration requirements with our technical sales team. [Click Here to Get a Custom Quote!]

How to Choose the Right OEM PEM Electrolyzer Manufacturer

When selecting a partner, consider:

- Technical Expertise: Years of experience and R&D capabilities

- Customization: Ability to adapt systems for your application

- Certifications: ISO, CE, or UL compliance

- Support: Availability of training, maintenance, and global service

Evaluating Technical Expertise

Request case studies or technical documentation to validate the manufacturer’s performance metrics.

Comparing Customization and After-Sales Service

Look for flexible service contracts, remote monitoring options, and spare parts logistics that ensure uptime and reliability.

Getting Started: Requesting a Custom Quote

Information to Include in Your RFQ

- Desired hydrogen output (Nm³/h)

- Power supply specifications

- Integration requirements (solar, wind, grid)

- Pressure and purity targets

- Expected delivery timeline

Typical Lead Times and Production Schedules

Depending on size and complexity, lead times may range from 3 to 9 months, including design validation, assembly, and factory acceptance testing (FAT).

Future Trends in OEM PEM Electrolyzer Manufacturing

AI and Automation in Electrolyzer Production

Advanced automation, digital twins, and AI-driven quality control are reshaping electrolyzer manufacturing, reducing costs and improving reliability.

Growth of Hydrogen Infrastructure

As nations invest in green hydrogen corridors, OEM manufacturers play a key role in scaling infrastructure and ensuring global standardization.

FAQs About OEM PEM Electrolyzer Manufacturers

Q1. What does an OEM PEM electrolyzer manufacturer do?

They design and produce PEM electrolyzer systems for integration by other companies under private labels or joint projects.

Q2. Can OEM PEM electrolyzers be customized?

Yes, OEM manufacturers offer flexible stack sizes, operating pressures, and energy integration options.

Q3. What certifications should a reliable manufacturer have?

Look for ISO 9001, ISO 22734, and CE compliance for hydrogen systems.

Q4. How long is the typical delivery time?

Production lead times range between 3–9 months based on project scope.

Q5. What’s the lifespan of a PEM electrolyzer?

Most OEM PEM electrolyzers last 50,000–80,000 hours, depending on maintenance and usage.

Q6. How do I get a quote from an OEM PEM electrolyzer manufacturer?

Submit an RFQ detailing capacity, pressure, and power requirements. Most manufacturers respond within one week.

Hele Titanium Hydrogen: Your Trusted Hydrogen Generator OEM & Manufacturing Partner

Hele Titanium Hydrogen stands as a reliable and experienced partner in the hydrogen generator OEM supply chain. We specialize in the design, development, and manufacturing of high-performance PEM Water Hydrogen Generators, offering comprehensive OEM & Manufacturing services tailored to your specific needs.

Take the Next Step

Ready to explore the possibilities of partnering with Hele Titanium Hydrogen?

- Browse our Products to see our range of PEM Water Hydrogen Generators.

- Learn more about our Services and how we can support your OEM & Manufacturing needs.

- Contact Us today to discuss your specific requirements.

- Explore our FAQ to get answers to common questions.

- Visit our Blog for the latest insights and updates on hydrogen technology.

Email Us: heletitaniumhydrogen@gmail.com

Phone/WhatsApp: 086-13857402537