OEM Manufacturing Process for Hydrogen Generators: A Complete Guide

1. Introduction

Hydrogen generators are vital components in the transition toward clean energy. From fueling hydrogen-powered vehicles to supporting critical medical and industrial applications, these systems play a key role in providing on-demand, high-purity hydrogen.

To meet varying industry needs, OEM (Original Equipment Manufacturer) manufacturing offers tailored solutions that enhance performance, ensure compatibility, and improve efficiency. This article dives deep into the OEM manufacturing process for hydrogen generators, guiding you through every stage—from initial design to final quality inspection—while emphasizing critical elements for successful project execution.

2. Understanding OEM Manufacturing for Hydrogen Generators

What is OEM Manufacturing?

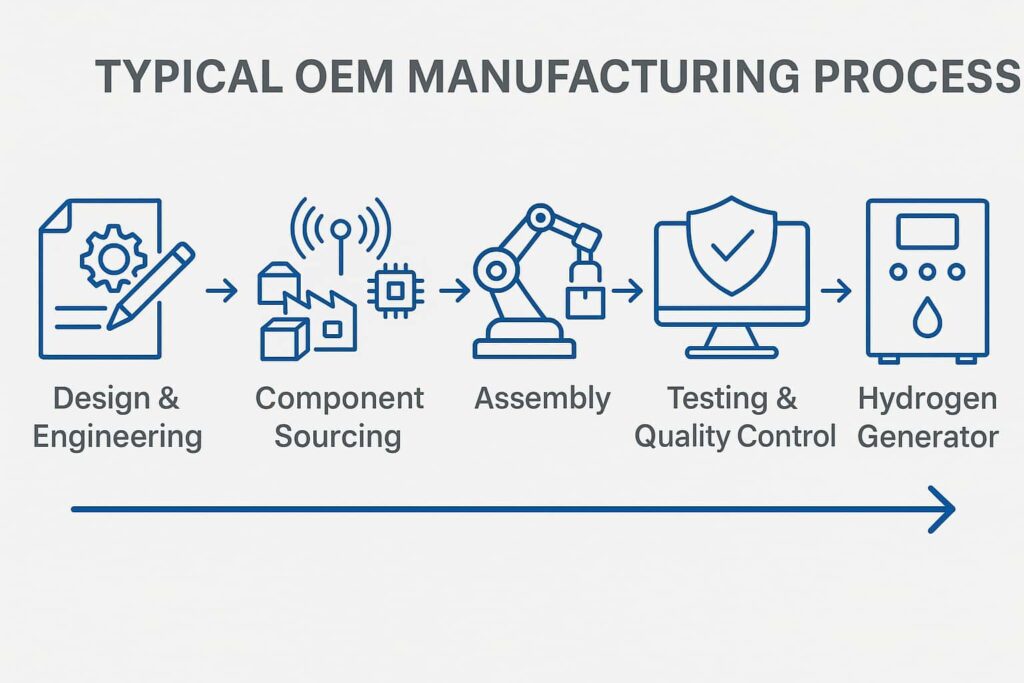

OEM manufacturing involves producing components or complete products based on a client’s proprietary specifications and designs. In the context of hydrogen generators, OEM partners take care of engineering, sourcing, production, assembly, and testing—delivering ready-to-integrate systems.

Why Choose OEM Manufacturing?

OEM manufacturing offers several advantages:

- Cost Efficiency: Leveraging established infrastructure and supply chains.

- Customization: Tailored hydrogen production capacity, form factors, and integration points.

- Scalability: Ability to scale from prototype to mass production.

Industries Relying on OEM Hydrogen Generators

OEM hydrogen generators serve numerous sectors, including:

- Energy: For grid balancing and renewable storage.

- Automotive: Fuel cell electric vehicles (FCEVs).

- Aerospace: Propellant production and life support systems.

- Healthcare: Supplying ultra-pure hydrogen for lab and medical applications.

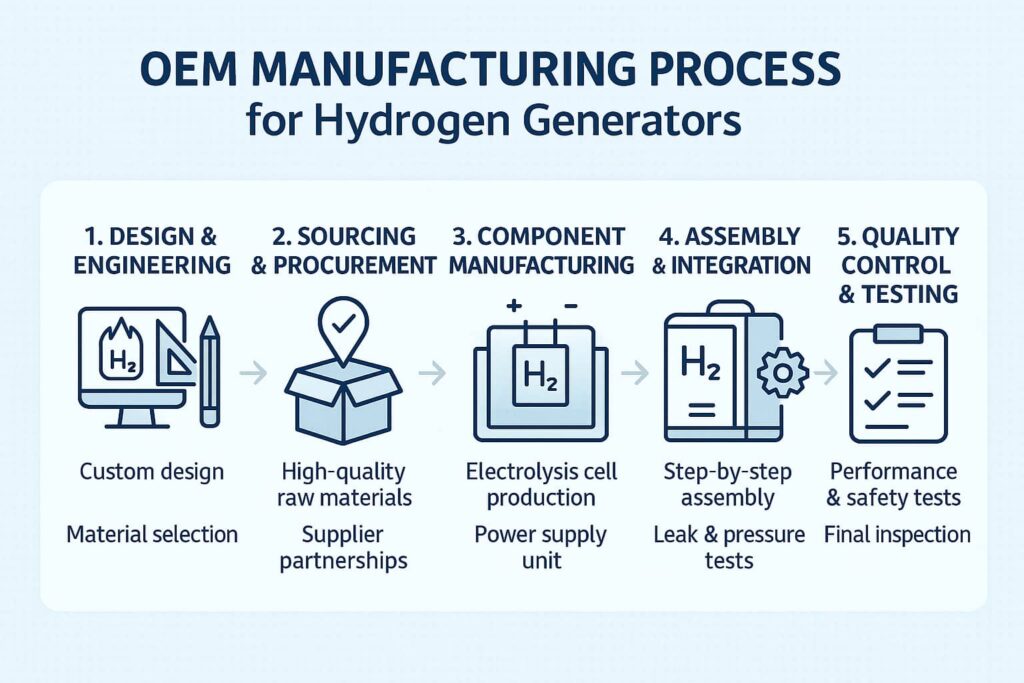

3. Step-by-Step OEM Manufacturing Process

3.1 Design & Engineering

The OEM process starts with translating client requirements into actionable designs:

- Custom Designs: Developed to match flow rate, pressure range, and operating conditions.

- Material Selection: Corrosion-resistant stainless steel, high-performance polymers, and specialized catalysts are chosen for durability.

- CAD Modeling & Prototyping: Digital modeling ensures error-free production, and physical prototypes allow for real-world testing.

3.2 Sourcing & Procurement

Precision hydrogen generation demands high-quality raw materials:

- Supplier Networks: Established partnerships with membrane, electrode, and seal manufacturers.

- Component Quality: Selection is based on thermal stability, conductivity, and gas impermeability.

3.3 Component Manufacturing

Each hydrogen generator consists of multiple core components:

- Electrolysis Cells: The heart of the system, converting water into hydrogen and oxygen.

- Gas Separation Systems: Remove oxygen and other impurities.

- Power Supply Units: Deliver regulated voltage for stable electrolysis.

- Control Units: Enable real-time monitoring and diagnostics.

3.4 Assembly & Integration

Once components are ready, the system is assembled with extreme precision:

- Structured Assembly: Sequential fitting of electrolyzer stacks, tubing, and electronics.

- Testing for Leaks: Vacuum and pressure tests ensure airtight systems.

- Automation Integration: Incorporation of IoT sensors and programmable logic controllers (PLCs) for safety and remote operation.

3.5 Quality Control & Testing

Every OEM hydrogen generator undergoes rigorous validation:

- Performance Testing: Efficiency rates, hydrogen purity levels (typically 99.999%), and run-time durability are evaluated.

- Safety Certifications: Compliance with CE, ISO 22734, UL, and other applicable standards.

- Final Inspection: A full-functionality check before shipment ensures field readiness.

4. Key Considerations in OEM Hydrogen Generator Manufacturing

Optimizing Efficiency

Maximizing hydrogen output while minimizing energy consumption is critical. OEM manufacturers achieve this by:

- Fine-tuning Electrodes: Using low-resistance, high-surface-area materials.

- Advanced Membranes: Enhancing ion conductivity for quicker reaction rates.

Safety is Non-Negotiable

OEM manufacturers integrate various safety mechanisms, such as:

- Explosion-Proof Designs

- Built-In Gas Leak Detectors

- Emergency Shutoff Systems

Scalability & Flexibility

From small-scale laboratory units to industrial-grade generators, OEM systems must:

- Be modular, allowing future expansion.

- Offer flexibility, supporting both high-volume and small-batch production.

5. Choosing the Right OEM Manufacturer

Selecting a reliable OEM partner involves evaluating:

| Criteria | Importance |

|---|---|

| Experience | Years of hydrogen tech manufacturing and integration |

| Certifications | Compliance with CE, ISO 9001, and hydrogen-specific standards |

| R&D Capability | In-house innovation to improve performance and reduce costs |

| Technical Support | Post-sale service, installation, and troubleshooting |

Case Study Snapshot:

A global OEM manufacturer developed compact hydrogen generators for a European medical equipment provider, reducing system size by 40% and improving hydrogen purity to 99.9999%.

6. Future Trends in Hydrogen Generator Manufacturing

PEM Technology Enhancements

Proton Exchange Membrane (PEM) advancements are:

- Lowering manufacturing costs

- Increasing energy conversion efficiency

- Reducing system size without compromising output

Green Hydrogen Production

- Electrolyzers Powered by Renewables: Solar and wind power integration is making hydrogen production fully carbon-free.

- Waste Heat Recovery: Boosting efficiency by using heat generated during electrolysis.

Automation & AI

- Predictive Maintenance: AI algorithms detect wear and alert operators before breakdowns occur.

- Smart Assembly Lines: Robotics improve consistency, especially in membrane stacking and sealing.

7. Conclusion

The OEM manufacturing process for hydrogen generators is a highly specialized, detail-driven operation that ensures safe, efficient, and high-performance hydrogen production systems. From design to final inspection, each step adds value—ensuring you receive a product built to meet your specific requirements.

Choosing the right OEM partner not only guarantees a reliable product but also positions your business to thrive in the growing hydrogen economy. As advancements in green energy and automation accelerate, OEM hydrogen generator manufacturing will remain at the forefront of sustainable innovation.

Frequently Asked Questions (FAQs)

1. What is an OEM hydrogen generator?

An OEM hydrogen generator is a hydrogen production unit designed and manufactured by a company based on a client’s unique specifications.

2. How long does OEM hydrogen generator production take?

Depending on complexity, production time ranges from 4 to 12 weeks, including design, prototyping, and testing.

3. Can OEM hydrogen generators be customized for specific applications?

Yes, they can be tailored for automotive, medical, aerospace, and industrial use, with precise flow, purity, and pressure levels.

4. What materials are used in hydrogen generator manufacturing?

Common materials include stainless steel, PTFE, platinum or nickel catalysts, and high-performance polymers.

5. Are OEM hydrogen generators safe?

Yes, they are built with strict safety features like gas leak detectors, pressure relief valves, and certified explosion-proof housings.

6. What certifications should an OEM hydrogen generator have?

Look for ISO 22734, CE, UL, and local regulatory compliance to ensure product safety and performance.

🔗 External Resource: Hydrogen Europe – Hydrogen Production Standards