Ultimate Guide: 15 Essential Customization Options for OEM Hydrogen Generators That Maximize Industrial Efficiency

Customization options for OEM hydrogen generators offer unprecedented flexibility for industrial applications. Discover 15 proven strategies to optimize performance, reduce costs, and enhance safety in your hydrogen production systems.

Industrial hydrogen production has revolutionized manufacturing processes across countless sectors, and customization options for OEM hydrogen generators have become the cornerstone of efficient operations. These specialized systems aren’t just plug-and-play solutions; they’re sophisticated pieces of equipment that can be tailored to meet specific industrial requirements, environmental conditions, and production goals.

When businesses invest in hydrogen generation technology, they’re looking for more than standard equipment. They need systems that’ll integrate seamlessly with existing infrastructure while delivering consistent, high-quality hydrogen gas. That’s where OEM customization truly shines, offering flexibility that can transform how industries approach their hydrogen needs.

Understanding OEM Hydrogen Generator Fundamentals

The world of OEM hydrogen generators represents a fascinating intersection of chemistry, engineering, and industrial innovation. These systems have evolved far beyond their basic electrolysis origins to become highly sophisticated machines capable of producing ultra-pure hydrogen for diverse applications ranging from semiconductor manufacturing to fuel cell production.

Modern customization options for OEM hydrogen generators encompass everything from basic capacity adjustments to complex integration with renewable energy sources. Understanding these fundamentals helps industrial decision-makers identify which modifications will deliver the greatest return on investment while ensuring operational reliability.

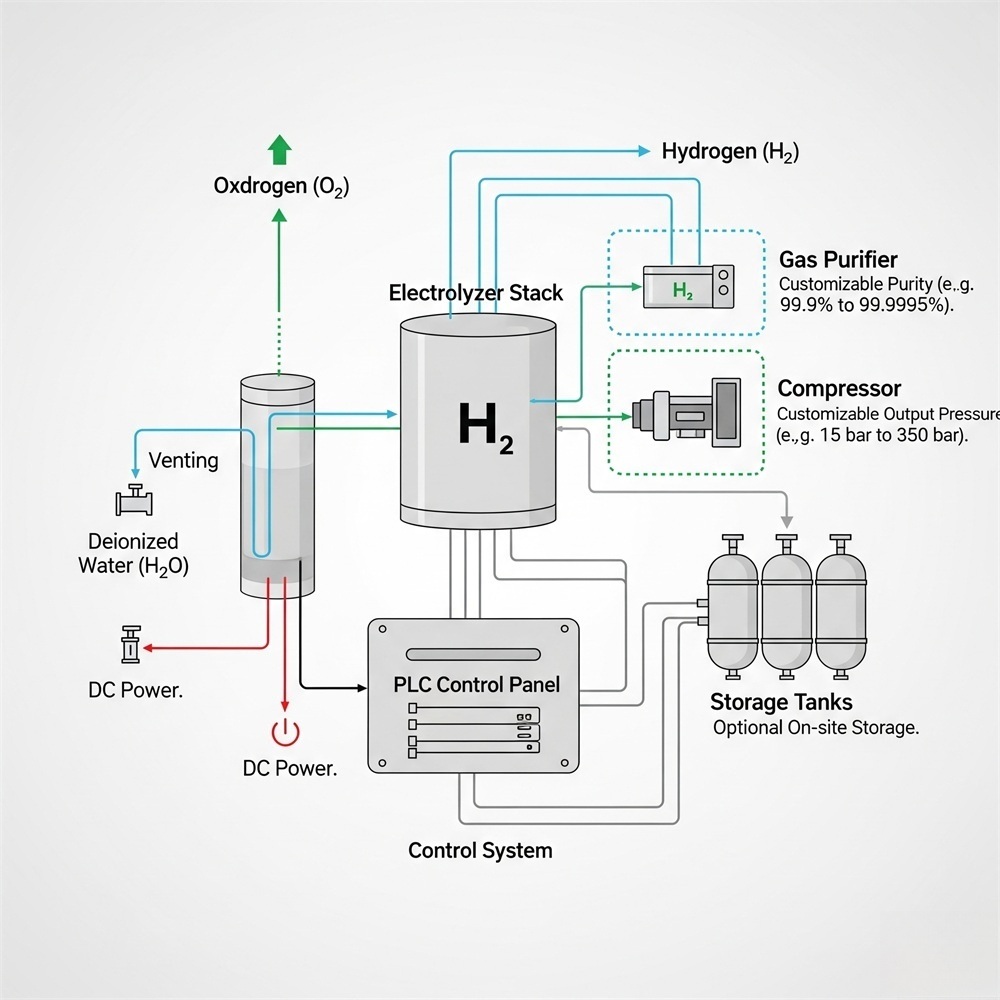

The electrolysis process itself remains relatively straightforward – electric current splits water molecules into hydrogen and oxygen. However, the engineering complexity lies in optimizing every aspect of this process for specific industrial environments. Temperature control, pressure management, purity levels, and safety systems all require careful consideration during the customization phase.

Industrial applications demand different hydrogen specifications. Semiconductor fabrication requires ultra-high purity levels, often exceeding 99.9999%, while metal processing applications might accept lower purity standards. These varying requirements drive the need for customizable purification systems, specialized materials, and precise control mechanisms.

The economic factors surrounding hydrogen generation customization can’t be overlooked. Initial investment costs must be balanced against long-term operational savings, maintenance requirements, and scalability potential. Smart customization decisions often pay for themselves through improved efficiency, reduced downtime, and lower operational costs over the system’s lifetime.

What Makes OEM Hydrogen Generators Different

OEM hydrogen generators distinguish themselves from standard commercial units through their inherent flexibility and customization potential. Unlike off-the-shelf solutions, OEM systems are designed from the ground up to accommodate specific industrial requirements, environmental constraints, and operational preferences.

The manufacturing approach for OEM systems focuses on modularity and adaptability. Components are engineered to work within broader customization frameworks, allowing for significant modifications without compromising system integrity or performance. This design philosophy enables manufacturers to offer truly bespoke solutions rather than forcing customers to adapt their operations to equipment limitations.

Quality control standards for OEM hydrogen generators typically exceed those of commercial units. Since these systems often serve critical industrial processes, manufacturers implement rigorous testing protocols and use premium materials throughout the construction process. This attention to detail extends to customization options, ensuring that modifications maintain the same high standards as base systems.

Core Components That Enable Customization

The electrolysis stack represents the heart of any hydrogen generator, and it’s also the component with the greatest customization potential. Stack configurations can be modified to optimize for different production volumes, purity requirements, and operating conditions. Advanced stack designs incorporate specialized electrode materials, membrane technologies, and cooling systems tailored to specific applications.

Power management systems offer another significant customization opportunity. These components can be engineered to work with various input power sources, from standard grid connections to renewable energy systems with fluctuating output. Smart power management enables load balancing, peak shaving, and integration with energy storage systems.

Control systems have evolved into sophisticated platforms capable of managing complex operational parameters. Customization options include specialized sensors, advanced algorithms for process optimization, and integration capabilities with existing plant management systems. These modifications enable precise control over hydrogen production while maintaining safety and efficiency standards.

Gas purification and handling systems require careful customization based on end-use requirements. Different applications demand varying purity levels, pressure specifications, and delivery methods. Customizable purification trains can include multiple filtration stages, drying systems, and pressure regulation components tailored to specific industrial needs.

Production Capacity Customization Options

Production capacity represents one of the most critical customization decisions when selecting OEM hydrogen generators. The ability to match hydrogen output precisely to industrial demands while maintaining efficiency and cost-effectiveness requires careful analysis of both current needs and future growth projections.

Capacity customization extends beyond simple output volume adjustments. Modern systems can be configured for variable production rates, allowing operators to scale output based on real-time demand fluctuations. This flexibility proves particularly valuable in industries with cyclical hydrogen requirements or seasonal production variations.

The relationship between production capacity and system efficiency isn’t linear. Larger systems don’t automatically provide better per-unit production costs, and smaller systems might struggle with efficiency at low utilization rates. Optimal capacity customization requires detailed analysis of operational patterns, energy costs, and maintenance requirements.

Integration with existing infrastructure significantly influences capacity customization decisions. Systems must be sized not only for hydrogen production requirements but also considering available electrical capacity, cooling systems, and physical space constraints. These factors often drive creative customization solutions that maximize output within existing facility limitations.

Economic modeling plays a crucial role in capacity customization decisions. The relationship between capital costs, operational expenses, and production flexibility must be carefully balanced. Smart capacity customization often involves designing systems that can be easily expanded or modified as operational requirements evolve.

Scaling Output for Industrial Demands

Industrial hydrogen demands vary dramatically across different applications and operating schedules. Semiconductor manufacturing might require steady, consistent output throughout production cycles, while metal processing operations could need surge capacity during specific manufacturing phases. Customization options for OEM hydrogen generators must address these diverse operational patterns.

Modular scaling approaches allow systems to be configured with multiple electrolysis stacks that can operate independently or in coordination. This design enables operators to run partial capacity during low-demand periods while maintaining the ability to scale up quickly when needed. Such flexibility optimizes energy consumption while ensuring adequate hydrogen availability.

Load balancing customizations help manage electrical demand while maintaining consistent hydrogen production. These systems can coordinate with facility power management systems to optimize energy consumption during peak demand periods or take advantage of off-peak electricity rates for hydrogen production and storage.

Modular Design Configurations

Modular design represents a revolutionary approach to hydrogen generator customization, offering unprecedented flexibility in system configuration and future expansion. These designs break traditional monolithic systems into interconnected components that can be mixed, matched, and scaled according to specific operational requirements.

The advantages of modular configurations extend beyond initial customization. Systems can be easily maintained with minimal downtime since individual modules can be serviced while others continue operating. This approach significantly reduces the operational impact of maintenance activities and extends overall system availability.

Future expansion becomes significantly more cost-effective with modular designs. Rather than replacing entire systems to accommodate growth, operators can add additional modules to existing configurations. This scalability makes modular systems particularly attractive for growing businesses or operations with uncertain future hydrogen demands.

Advanced Control System Modifications

Control system customization represents one of the most impactful areas for optimizing hydrogen generator performance. Modern control systems integrate sophisticated sensors, advanced algorithms, and user-friendly interfaces to provide precise management of all operational parameters while maintaining safety and efficiency standards.

The evolution of control system technology has transformed hydrogen generators from simple electrolysis units into intelligent production systems. These advanced controls can optimize performance based on real-time conditions, predict maintenance requirements, and integrate seamlessly with broader facility management systems.

Customization options for control systems range from basic parameter adjustments to complete integration with Industry 4.0 manufacturing environments. Smart sensors monitor everything from electrolyte conductivity to membrane integrity, providing operators with comprehensive system visibility and predictive maintenance capabilities.

Data collection and analysis capabilities built into modern control systems enable continuous optimization of operational parameters. Machine learning algorithms can identify efficiency improvements, predict component wear patterns, and recommend operational adjustments that maximize system performance while minimizing operational costs.

The user interface design significantly impacts operational efficiency and safety. Customizable interfaces can be tailored to specific operator skill levels, operational requirements, and integration needs. Touchscreen displays, mobile device connectivity, and web-based monitoring platforms provide flexibility in how operators interact with their hydrogen generation systems.

Smart Automation Integration

Smart automation transforms hydrogen generators from manually operated equipment into intelligent production systems that can respond dynamically to changing operational conditions. These systems integrate with facility-wide automation platforms to coordinate hydrogen production with downstream processes and energy management systems.

Automated startup and shutdown sequences ensure consistent system performance while minimizing operator intervention. These sequences can be customized based on facility requirements, safety protocols, and integration with other production equipment. Automated systems also provide enhanced safety through consistent execution of critical procedures.

Predictive maintenance capabilities built into smart automation systems monitor component performance and predict maintenance requirements before failures occur. This proactive approach minimizes unplanned downtime while optimizing maintenance costs through better scheduling and parts management.

Remote Monitoring Capabilities

Remote monitoring customizations enable operators to manage hydrogen generation systems from virtually anywhere, providing unprecedented flexibility in operational management. These systems integrate secure communication protocols with comprehensive data collection to deliver real-time system visibility and control capabilities.

Cloud-based monitoring platforms offer scalable solutions that can manage single systems or entire fleets of hydrogen generators. Customizable dashboards provide operators with tailored views of critical operational parameters while mobile applications enable on-the-go system management and alert notification.

Data analytics capabilities built into remote monitoring systems provide insights into operational trends, efficiency patterns, and optimization opportunities. Historical data analysis helps identify long-term performance trends while real-time analytics enable immediate response to operational anomalies.

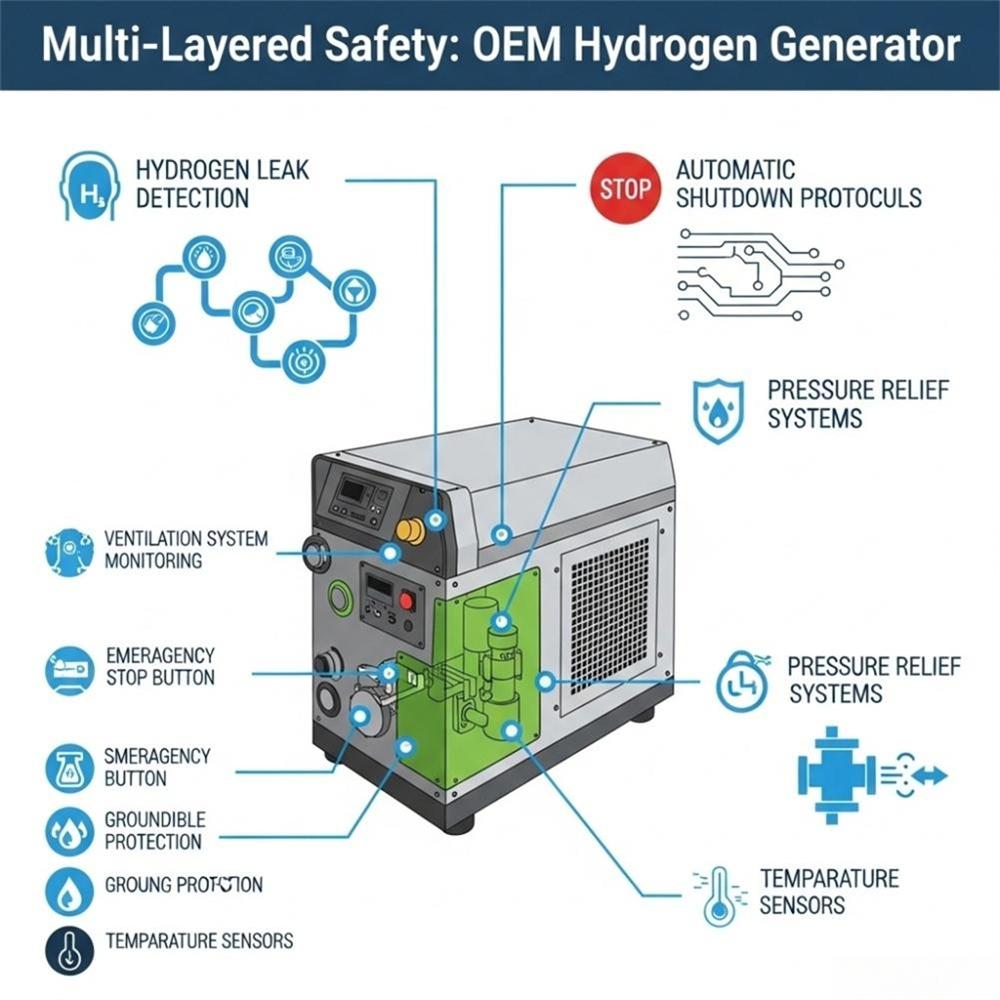

Safety and Compliance Customizations

Safety customization represents perhaps the most critical aspect of OEM hydrogen generator design. Hydrogen’s unique properties – it’s highly flammable, has a wide explosive range, and can cause embrittlement in certain materials – require specialized safety systems tailored to specific installation environments and operational requirements.

Compliance customizations ensure that hydrogen generators meet all applicable safety standards, environmental regulations, and industry-specific requirements. These modifications often involve specialized materials, enhanced safety systems, and comprehensive documentation to satisfy regulatory authorities and insurance requirements.

Risk assessment drives safety customization decisions. Each installation environment presents unique hazards that must be addressed through appropriate design modifications. Indoor installations require different safety approaches than outdoor systems, and systems near occupied areas need enhanced safety measures compared to remote installations.

Emergency response customizations integrate hydrogen generators with facility-wide safety systems. These modifications ensure that hydrogen systems respond appropriately to fire alarms, gas detection systems, and emergency shutdown commands while providing operators with clear guidance during emergency situations.

Documentation and training customizations help ensure safe operation throughout the system’s lifetime. Comprehensive operating procedures, maintenance protocols, and emergency response plans must be tailored to specific installations and operator skill levels.

Explosion-Proof Configurations

Explosion-proof customizations represent specialized engineering solutions designed for installations in hazardous environments. These modifications involve specialized enclosures, certified components, and enhanced safety systems that prevent ignition sources from causing explosions in potentially dangerous atmospheres.

Hazardous area classifications drive explosion-proof customization requirements. Different classification systems worldwide require specific design approaches and certified components. Understanding these requirements during the design phase ensures compliance while avoiding costly modifications after installation.

Purging and pressurization systems provide alternative approaches to explosion-proof design in some applications. These systems maintain positive pressure within equipment enclosures using inert gases, preventing the accumulation of potentially explosive atmospheres around electrical components.

Regulatory Compliance Adaptations

Regulatory compliance customizations address the complex web of local, national, and international standards governing hydrogen generation equipment. These modifications ensure systems meet all applicable requirements while providing documentation necessary for regulatory approval and ongoing compliance monitoring.

International standards such as IEC, ASME, and NFPA provide frameworks for safe hydrogen system design, but local authorities often have additional requirements that must be addressed through customization. Understanding these requirements early in the design process prevents costly modifications and delays during commissioning.

Environmental compliance customizations address emissions, waste handling, and energy efficiency requirements. These modifications might include enhanced water treatment systems, energy recovery capabilities, and monitoring systems to ensure ongoing compliance with environmental regulations.

Power Supply and Energy Optimization

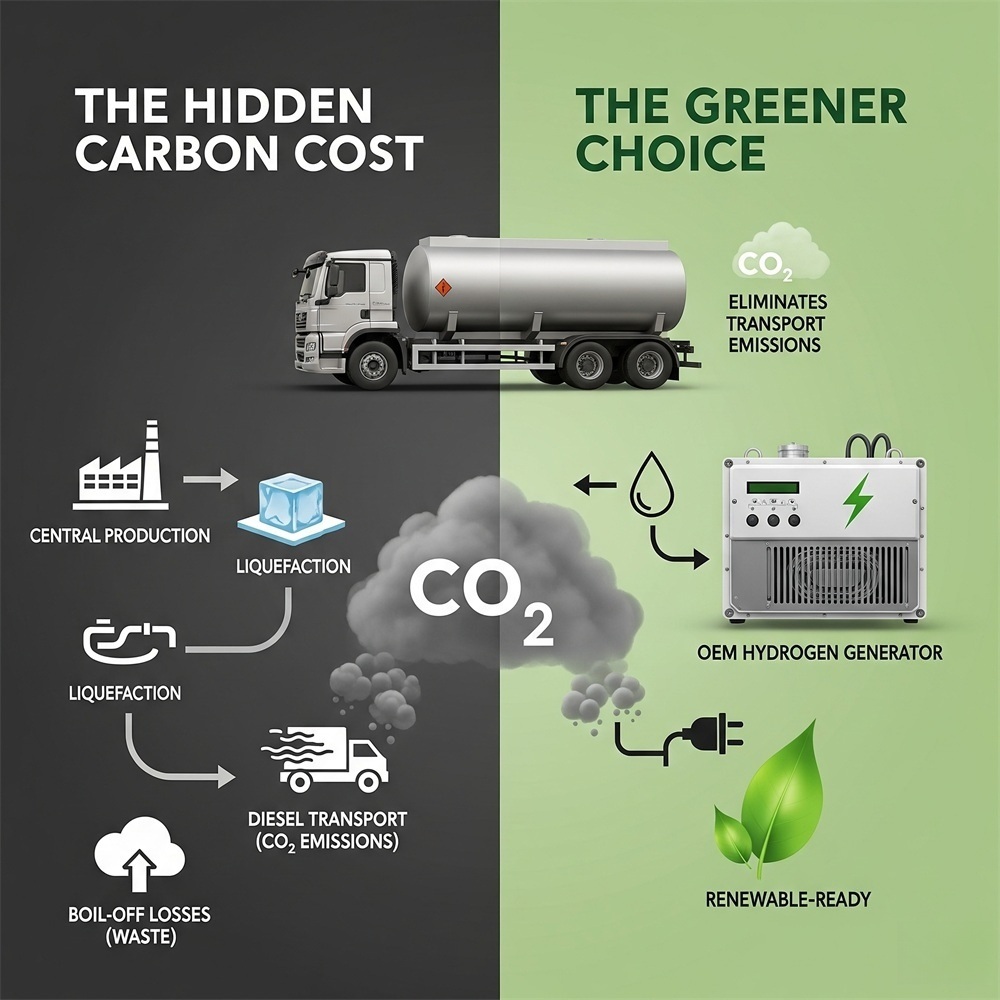

Power supply customization represents a crucial factor in hydrogen generator performance and operational costs. The electrical characteristics of the power supply directly impact system efficiency, hydrogen production rates, and overall operational economics. Modern customization options enable systems to work with various power sources while optimizing energy consumption.

Energy optimization customizations can significantly reduce operational costs while improving system performance. These modifications include power factor correction, harmonic filtering, and load management systems that minimize electrical infrastructure requirements while maximizing energy efficiency.

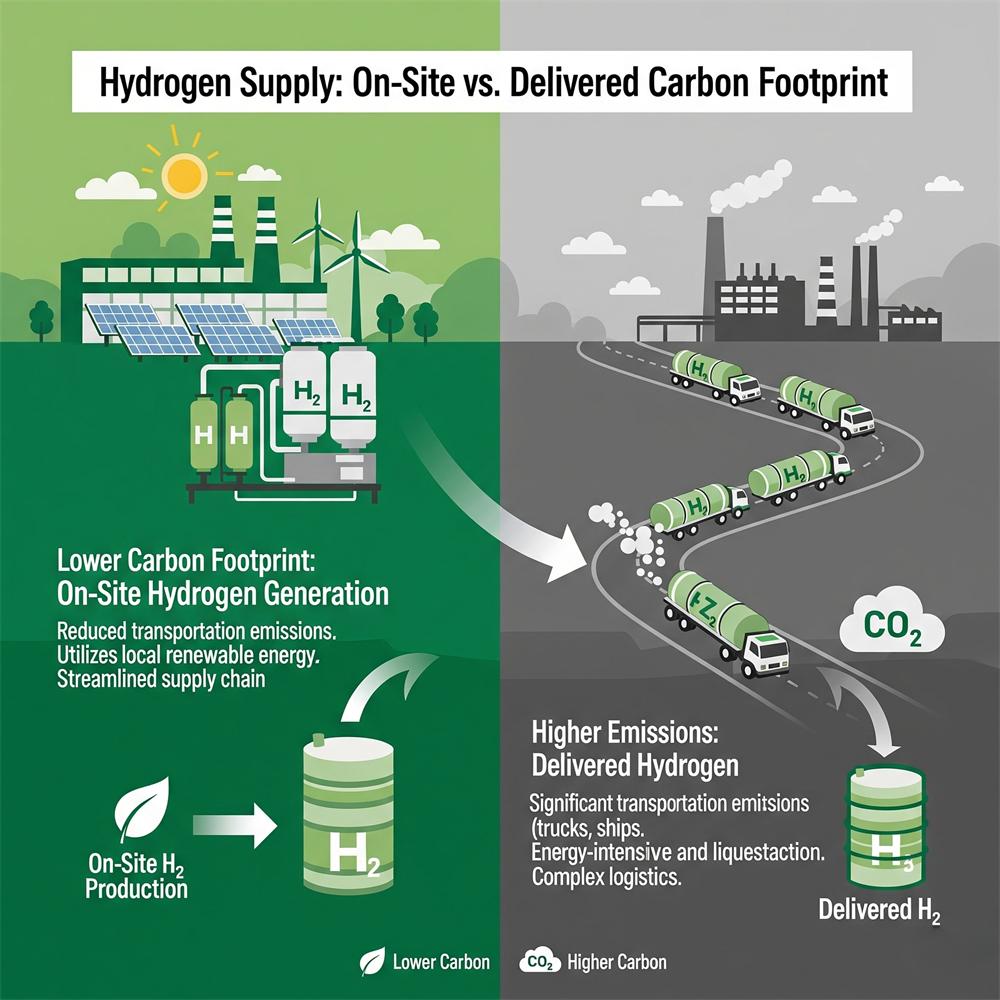

Integration with renewable energy sources requires specialized power management systems capable of handling variable input power. These customizations enable hydrogen generators to operate effectively with solar, wind, and other renewable energy sources while maintaining consistent hydrogen production quality.

Grid independence customizations enable hydrogen generators to operate in remote locations or provide backup power capabilities. These systems integrate energy storage, power conditioning, and control systems to ensure reliable operation regardless of grid availability.

The relationship between power quality and hydrogen production efficiency requires careful consideration during customization. Poor power quality can significantly impact system performance and component longevity. Customized power conditioning systems ensure optimal performance regardless of utility power quality variations.

Renewable Energy Integration

Renewable energy integration represents one of the most exciting customization opportunities for hydrogen generators. These systems can convert excess renewable energy into hydrogen, providing energy storage capabilities while producing valuable hydrogen gas for industrial applications.

Solar integration customizations enable hydrogen generators to operate directly from photovoltaic arrays. These systems include maximum power point tracking, energy storage for consistent operation, and control systems that optimize hydrogen production based on available solar energy.

Wind energy integration requires specialized power conditioning systems capable of handling the variable output characteristics of wind turbines. These customizations include power smoothing, frequency regulation, and control systems that maintain consistent hydrogen production despite fluctuating wind conditions.

Grid Independence Solutions

Grid independence customizations enable hydrogen generators to operate reliably in remote locations or provide backup capabilities during utility outages. These systems integrate energy storage, backup power generation, and intelligent control systems to ensure continuous hydrogen production.

Battery integration provides short-term energy storage for smoothing power fluctuations and maintaining operation during brief utility interruptions. Customized battery management systems optimize charging and discharging cycles while ensuring long battery life and reliable operation.

Generator backup systems provide long-term independence from utility power. These customizations include automatic transfer systems, fuel management, and control integration that ensures seamless transition between utility and backup power sources.

Material and Construction Customizations

Material selection represents a critical customization decision that impacts system performance, longevity, and operational costs. Different materials offer varying levels of hydrogen compatibility, corrosion resistance, and mechanical properties that must be matched to specific operational requirements and environmental conditions.

Construction customizations address the unique requirements of different installation environments. Indoor systems require different approaches than outdoor installations, and systems in corrosive environments need specialized materials and protective coatings to ensure long-term reliability.

Component customization enables optimization for specific operational requirements. Electrode materials, membrane technologies, and structural components can all be selected and modified based on performance requirements, environmental conditions, and economic considerations.

Quality control customizations ensure that materials and construction methods meet or exceed specified requirements. Enhanced inspection procedures, specialized testing protocols, and comprehensive documentation provide assurance that customized systems will perform reliably throughout their operational lifetime.

The economics of material customization must be carefully balanced against performance requirements. Premium materials often provide superior performance and longevity but at increased initial costs. Smart material selection optimizes the balance between performance, reliability, and economic considerations.

Corrosion resistance customizations address the challenges of hydrogen service and environmental exposure. Specialized coatings, cathodic protection systems, and material selection help ensure long-term reliability in challenging operating environments.

Temperature management customizations optimize system performance across different operating temperature ranges. Insulation systems, heating elements, and cooling systems can be customized to maintain optimal operating conditions regardless of environmental temperature variations.

Frequently Asked Questions

Q: What are the most important customization options for OEM hydrogen generators?

A: The most critical customization options for OEM hydrogen generators include production capacity scaling, control system integration, safety configurations, and power supply optimization. Production capacity must match your specific hydrogen demands while allowing for future growth. Control system customizations enable integration with existing facility systems and provide advanced monitoring capabilities. Safety customizations ensure compliance with applicable regulations and address site-specific hazards. Power supply optimization reduces operational costs and enables integration with renewable energy sources.

Q: How do customization options affect the total cost of ownership for hydrogen generators?

A: Customization options significantly impact total cost of ownership through improved efficiency, reduced maintenance requirements, and enhanced operational flexibility. While initial customization costs may increase upfront investment, well-designed modifications often reduce operational expenses through better energy efficiency, automated operation, and predictive maintenance capabilities. The key is selecting customizations that provide clear economic benefits over the system’s operational lifetime.

Q: Can existing hydrogen generators be retrofitted with new customization options?

A: Many customization options can be retrofitted to existing hydrogen generators, though the feasibility depends on the specific modifications and original system design. Control system upgrades, safety enhancements, and monitoring capabilities are often relatively straightforward to retrofit. However, fundamental changes to production capacity, power systems, or structural modifications may require significant system modifications or replacement. It’s best to consult with the original manufacturer or qualified engineering firm to assess retrofit possibilities.

Q: How long does it typically take to implement customization options for OEM hydrogen generators?

A: Implementation timeframes for customization options vary significantly based on complexity and scope. Simple modifications like control system upgrades or monitoring enhancements might be completed in days or weeks. More complex customizations involving structural modifications, safety system integration, or major component changes can require several months from design through implementation. Planning for customization during initial system procurement typically reduces implementation time compared to retrofitting existing systems.

Q: What safety considerations are most important when customizing hydrogen generators?

A: Safety considerations for hydrogen generator customization must address hydrogen’s unique properties including its wide flammability range, low ignition energy, and potential for material embrittlement. Critical safety customizations include appropriate ventilation systems, gas detection and monitoring, emergency shutdown capabilities, and explosion-proof equipment where required. All customizations must comply with applicable safety standards and regulations while addressing site-specific hazards and operational requirements.

Q: How do I determine which customization options provide the best return on investment?

A: Determining optimal customization options requires comprehensive analysis of operational requirements, cost factors, and performance benefits. Start by identifying specific operational challenges or improvement opportunities, then evaluate customization options that address these needs. Consider both direct benefits like reduced energy consumption and indirect benefits such as improved reliability and reduced maintenance. Economic analysis should include initial costs, operational savings, and long-term value over the system’s expected lifetime.

Conclusion

Customization options for OEM hydrogen generators offer unprecedented opportunities to optimize industrial hydrogen production systems for specific operational requirements, environmental conditions, and economic objectives. From basic capacity adjustments to sophisticated control system integration, these modifications enable businesses to maximize their hydrogen generation investment while ensuring safe, reliable operation.

The key to successful customization lies in understanding your specific operational requirements and working with experienced manufacturers who can translate those needs into practical engineering solutions. Whether you’re looking to integrate renewable energy sources, enhance safety systems, or optimize production capacity, the right customization options can transform standard equipment into highly specialized systems that deliver exceptional performance and value.

As hydrogen technology continues to evolve, customization capabilities will only expand, offering even greater flexibility and optimization potential. Investing in properly customized OEM hydrogen generators today positions businesses for long-term success in the growing hydrogen economy while providing immediate operational benefits through improved efficiency, reliability, and safety.