The global industrial landscape is undergoing a monumental shift. Driven by urgent decarbonization mandates and the pursuit of energy independence, industries worldwide are turning to green hydrogen as a pivotal solution. At the forefront of this revolution are large-scale renewable electrolyzers, transforming renewable electricity into a clean, versatile energy carrier. Hele Titanium Hydrogen stands as a leading manufacturer, dedicated to powering this transition with our advanced large-scale PEM water electrolyzers.

This comprehensive guide delves into the commercial imperative of green hydrogen production, focusing on the unparalleled advantages of PEM electrolysis for industrial-scale projects. We will explore the technical intricacies, economic considerations (CAPEX, OPEX, LCOH), seamless integration strategies, and real-world applications. Discover why Hele Titanium Hydrogen is your ideal partner in building a sustainable, profitable green hydrogen future.

Introduction: The Dawn of Industrial Green Hydrogen – Powered by PEM

The imperative for decarbonizing industry has never been more pressing. From steel and ammonia production to heavy-duty transportation and grid balancing, green hydrogen offers a zero-emission pathway to a sustainable future. Produced by electrolysis technology powered exclusively by renewable energy sources like solar and wind, green hydrogen production is no longer a futuristic concept but a critical, deployable reality.

At Hele Titanium Hydrogen, we envision a world where industrial processes are fueled by clean energy. As a leading PEM electrolyzer manufacturer, we specialize in high-efficiency large-scale PEM water electrolyzers that are specifically engineered to meet the robust demands of industrial hydrogen production. Our mission is to accelerate the global hydrogen economy by providing reliable, scalable, and cost-effective solutions for large-scale hydrogen projects. This article serves as your definitive guide to understanding and implementing megawatt electrolyzer technology for your commercial ventures.

Section 1: Why PEM? Unpacking Large-Scale PEM Water Electrolyzer Technology

While various electrolysis technology types exist, Proton Exchange Membrane (PEM) electrolysis has emerged as a cornerstone for modern green hydrogen projects, particularly when paired with intermittent renewable power. Understanding its core principles and benefits is crucial for any commercial hydrogen project.

1.1 The Hele Titanium Hydrogen Advantage in PEM Electrolysis

A PEM electrolyzer utilizes a solid polymer electrolyte (the membrane) to conduct protons, separating hydrogen and oxygen from water. At the anode, water molecules are split into oxygen, protons, and electrons. The protons pass through the PEM to the cathode, where they combine with electrons to form hydrogen gas. Crucially, the Hele Titanium Hydrogen design incorporates robust titanium components for enhanced durability and performance.

Our PEM Strengths at Hele Titanium Hydrogen:

- High Efficiency & Purity: Hele Titanium Hydrogen’s large-scale PEM electrolyzer systems are engineered for superior energy efficiency, translating directly into lower electrolyzer cost over the project lifespan. They consistently produce high-purity hydrogen (typically >99.999%), which is often required directly by industrial processes, eliminating the need for expensive additional purification steps. This direct purity makes our solutions ideal for critical applications like fuel cells and specialized chemical synthesis.

- Dynamic Response & Load Following: This is a hallmark advantage of PEM technology and a core strength of Hele Titanium Hydrogen’s design. Our systems boast rapid start-up and shutdown capabilities (in seconds to minutes), making them perfectly suited for direct integration with variable renewable energy sources like solar and wind. This agility allows efficient utilization of surplus renewable power, maximizing asset utilization and minimizing curtailment.

- Compact Footprint: For industrial sites where space is a premium, our PEM electrolysis system offers a significantly smaller physical footprint compared to traditional alkaline technologies of equivalent capacity. This compactness facilitates easier integration into existing industrial infrastructure or allows for greater hydrogen production within a limited area.

- Pressurized Hydrogen Output: Hele Titanium Hydrogen’s PEM electrolyzers can produce hydrogen at elevated pressures (e.g., 30 bar), significantly reducing the energy required for downstream compression. This translates into tangible cost savings in capital expenditure (CAPEX) for compressors and ongoing operational expenditure (OPEX) for electricity consumption.

- Water Quality Demands: While PEM electrolyzers require deionized water, our integrated systems include advanced water purification units to ensure optimal performance and extend the lifespan of the membrane electrode assembly (MEA). We work with clients to assess and manage their specific water input requirements.

Comparisons and Context:

While other technologies like Alkaline Electrolyzers (ALK) and Solid Oxide Electrolyzers (SOEC) have their niches, PEM often stands out for modern, flexible large-scale hydrogen projects:

- Alkaline Electrolyzers: Known for their lower CAPEX and mature technology, ALK systems are excellent for base-load, continuous production with stable power sources. However, their slower response times and lower efficiency at partial loads can be a disadvantage when coupled with intermittent renewables.

- Solid Oxide Electrolyzers (SOEC): These offer the highest efficiency potential, especially when integrated with high-temperature industrial waste heat. However, their high operating temperatures and durability challenges mean they are still largely in earlier stages of commercial hydrogen projects compared to PEM or ALK.

For many progressive industrial hydrogen applications demanding responsiveness, high purity, and efficient integration with variable renewables, PEM, as offered by Hele Titanium Hydrogen, is the chosen, leading path.

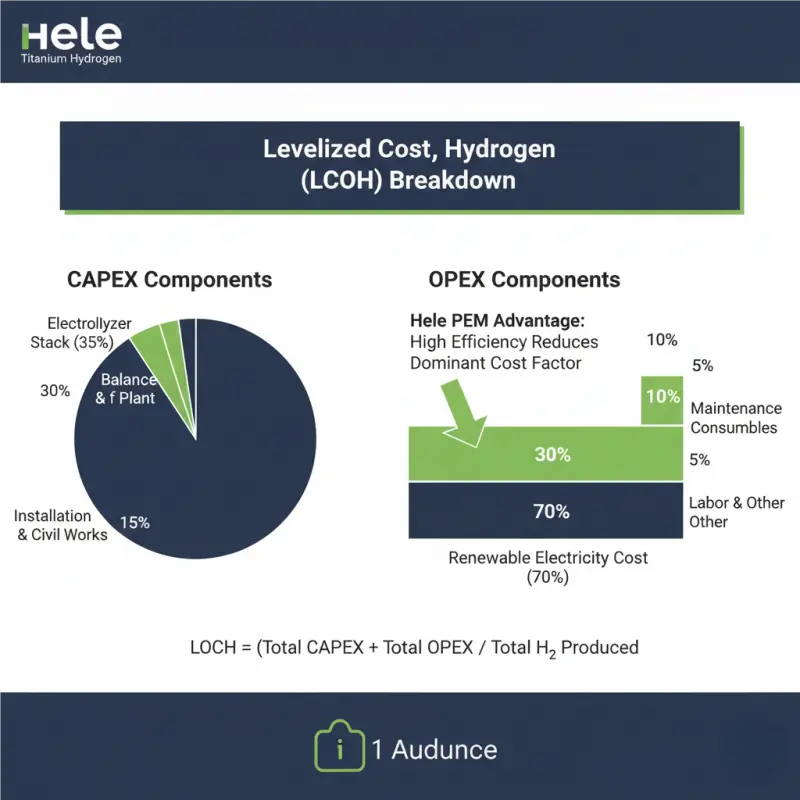

Section 2: The Commercial Imperative: ROI, CAPEX, OPEX, and Levelized Cost of Hydrogen (LCOH) for PEM Projects

Investing in large-scale renewable electrolyzer technology is a significant commercial decision. Understanding the economic drivers—CAPEX, OPEX, and the resulting Levelized Cost of Hydrogen (LCOH)—is crucial for project feasibility and securing a competitive advantage in the burgeoning hydrogen economy.

2.1 Initial Investment (CAPEX) for Hele Titanium Hydrogen PEM Systems

The Capital Expenditure (CAPEX) for a large-scale PEM electrolyzer project encompasses several key components:

- Electrolyzer Stack Cost: This is the core component. While PEM stacks can have a higher initial cost per kilowatt ($/kW) due to the use of precious metals (e.g., platinum, iridium) for catalysts and titanium for flow fields, this is offset by their dynamic capabilities and high hydrogen purity. At Hele Titanium Hydrogen, our robust titanium construction ensures durability, extending stack lifespan and providing long-term value.

- Balance of Plant (BoP) Costs: This includes power conversion units (rectifiers, transformers), gas processing (dryers, compressors), water purification systems, heat management, and sophisticated control systems. Hele Titanium Hydrogen designs these BoP components for optimal integration and efficiency with our PEM stacks.

- Installation & Civil Works: Site preparation, foundations, piping, electrical infrastructure, and structural assembly contribute to the overall CAPEX.

Hele Titanium Hydrogen’s Cost-Effectiveness: We understand that competitive CAPEX is vital. Through continuous R&D, optimized manufacturing processes, and economies of scale, Hele Titanium Hydrogen strives to deliver PEM solutions that offer compelling long-term value. The higher initial cost of precious metals is frequently justified by the superior operational flexibility, high efficiency, and reduced downstream processing requirements of our PEM systems. Global market trends indicate a consistent reduction in electrolyzer cost, making green hydrogen increasingly competitive.

2.2 Maximizing Operational Efficiency (OPEX) with Hele Titanium Hydrogen

Operational Expenditure (OPEX) is often the largest component of the total cost of hydrogen production over a project’s lifetime. Focusing on efficiency is paramount:

- The Dominant Factor: The Cost of Renewable Electricity: This is by far the most significant driver of OPEX. Hele Titanium Hydrogen’s large-scale PEM electrolyzer systems are designed for optimal energy consumption, measured in kWh/kg-H₂. Our high efficiency directly translates into lower electricity bills per kilogram of green hydrogen produced. Strategic sourcing of low-cost renewable energy (solar, wind, hydro) is key.

- Maintenance & Durability: Hele Titanium Hydrogen designs PEM electrolyzers for robust operation and extended lifespan. Our stacks are built for resilience, reducing maintenance frequency. We offer comprehensive maintenance schedules and support services, including preventative measures and component replacement, to ensure maximum uptime and minimal ongoing costs.

- Water Consumption and Treatment Costs: While water is a feedstock, its cost is typically minor compared to electricity. Hele Titanium Hydrogen systems require deionized water, and we provide guidance on effective water treatment solutions to ensure longevity and consistent performance.

- Labor and Monitoring: Modern large-scale hydrogen projects benefit from advanced automation. Hele Titanium Hydrogen’s systems feature sophisticated control systems, reducing the need for extensive on-site labor and enabling remote monitoring.

2.3 Achieving Competitive Levelized Cost of Hydrogen (LCOH) with Hele Titanium Hydrogen PEM

The Levelized Cost of Hydrogen (LCOH) is the ultimate metric for evaluating the economic viability of a green hydrogen project. It represents the total cost to produce one kilogram of hydrogen over the project’s lifespan, accounting for both CAPEX and OPEX.

LCOH Formula: (Total CAPEX + Total OPEX over project life) / Total Hydrogen Produced over project life.

How Hele Titanium Hydrogen PEM Directly Impacts LCOH:

- Superior Efficiency: Our lower kWh/kg-H₂ consumption directly reduces the largest OPEX component.

- Dynamic Response: The ability of Hele Titanium Hydrogen’s PEM electrolyzers to quickly ramp up and down means they can efficiently utilize all available renewable energy, minimizing energy waste (curtailment) and maximizing hydrogen output, thereby lowering the denominator in the LCOH calculation.

- Reduced Downstream Costs: High-purity and pressurized hydrogen output from our systems can reduce or eliminate the need for costly purification and high-pressure compression steps.

- Durability and Uptime: Our robust designs lead to fewer maintenance interruptions and longer operating periods, maximizing hydrogen production over the project’s lifespan.

Interactive Element Suggestion: Curious how electricity price affects your LCOH? Contact Hele Titanium Hydrogen today for a personalized LCOH projection and project feasibility consultation!

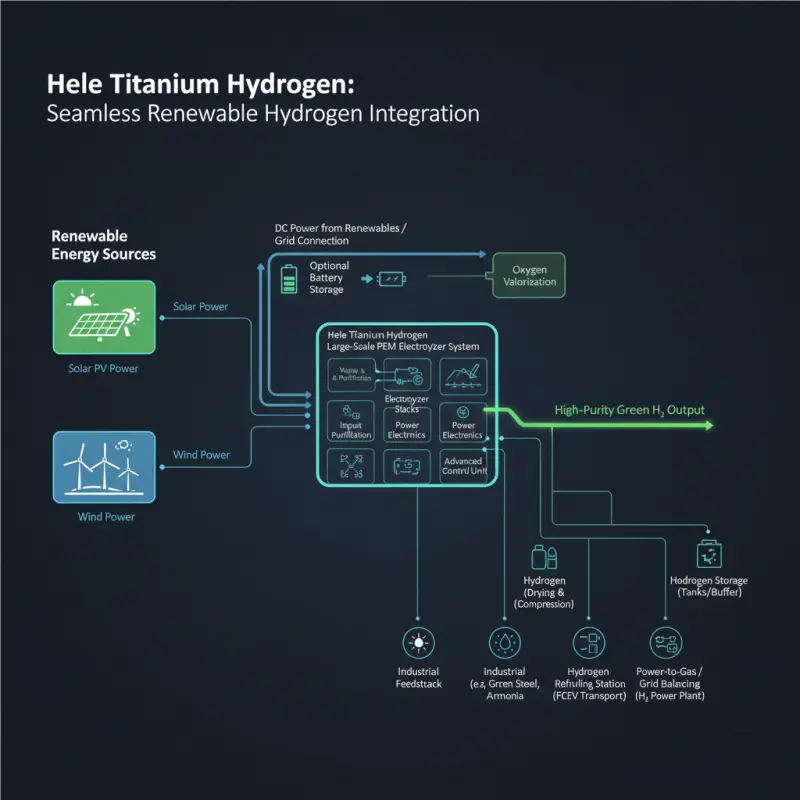

Section 3: Seamless Integration: Designing Your Green Hydrogen Ecosystem with Hele Titanium Hydrogen

A large-scale renewable electrolyzer is not a standalone unit; it’s the heart of a sophisticated green hydrogen production ecosystem. Successful deployment hinges on expert system design and seamless integration with renewable energy sources and downstream processes. Hele Titanium Hydrogen excels in providing these integrated solutions.

3.1 Renewable Power Source Integration

The efficacy of renewable hydrogen production is directly tied to its power source:

- Grid-Connected vs. Off-Grid Designs: Hele Titanium Hydrogen supports both configurations. Grid-connected systems offer stability and can potentially leverage grid services. Off-grid systems, directly coupled with dedicated solar farms or wind parks, provide complete energy independence.

- Managing Intermittency: The inherent variability of solar and wind power demands dynamic electrolyzer response. Hele Titanium Hydrogen’s large-scale PEM electrolyzer technology is uniquely suited for load-following, quickly adjusting hydrogen production to match fluctuating renewable input. This minimizes energy waste and maximizes system efficiency.

- Power Electronics: Robust rectifiers and transformers are essential for converting AC renewable power into the DC power required by our electrolyzers. Hele Titanium Hydrogen ensures that these power electronics are perfectly matched and optimized for MW-scale connection, safeguarding system stability and efficiency.

3.2 Balance of Plant (BoP) Critical Components – Our Integrated Approach

Beyond the electrolyzer stack, the Balance of Plant (BoP) ensures the entire system operates efficiently and safely. Hele Titanium Hydrogen offers integrated solutions for these critical components:

- Water Demineralization System: Water quality is paramount for PEM electrolyzers. We provide and integrate advanced water demineralization systems that deliver the high-purity water required, protecting the membrane and extending the lifespan of the stack.

- Hydrogen Processing:

- Dryers: Essential for removing moisture from the produced hydrogen, preventing corrosion in downstream equipment and ensuring gas purity.

- Compressors: While Hele Titanium Hydrogen’s PEM electrolyzers produce pressurized hydrogen, further compression might be needed for specific storage or pipeline injection. We integrate efficient compression solutions.

- Storage: Depending on project scale and demand profile, hydrogen can be stored in buffer tanks, large pressure vessels, or even salt caverns for long-term hydrogen energy storage.

- Dryers: Essential for removing moisture from the produced hydrogen, preventing corrosion in downstream equipment and ensuring gas purity.

- Oxygen Valorization: Green hydrogen production also yields high-purity oxygen as a byproduct. This oxygen can be a valuable resource for various industrial applications (e.g., medical, welding, steelmaking), offering a potential additional revenue stream for your commercial hydrogen project. Hele Titanium Hydrogen systems are designed to capture and manage this oxygen effectively.

3.3 Intelligent Control Systems and Digitalization

Modern industrial hydrogen facilities demand sophisticated control and monitoring:

- SCADA Systems: Hele Titanium Hydrogen integrates advanced Supervisory Control and Data Acquisition (SCADA) systems, providing comprehensive real-time monitoring, data logging, and remote operational control of the entire electrolyzer plant. This ensures optimal performance, safety, and efficient resource allocation.

- AI and Predictive Maintenance: We embrace digitalization. Our systems can be equipped with AI-driven analytics for predictive maintenance, anticipating potential issues before they become critical failures. This maximizes uptime, extends equipment life, and reduces unscheduled downtime, bolstering the reliability of your renewable hydrogen supply.

- Remote Support and Diagnostics: For international clients, Hele Titanium Hydrogen offers remote diagnostic capabilities and technical support, ensuring prompt assistance and minimizing operational disruptions, regardless of geographical distance.

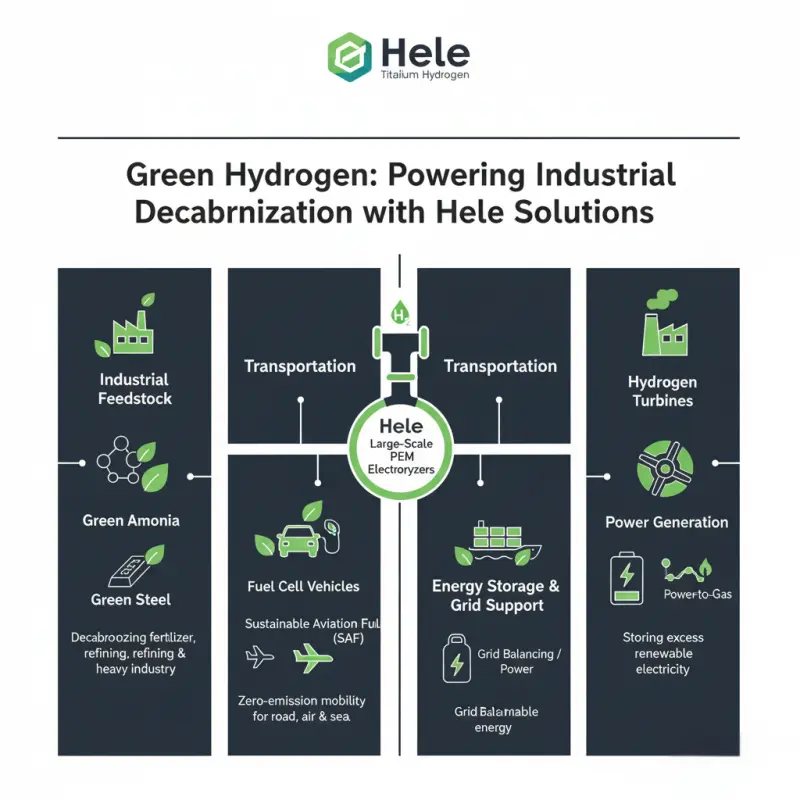

Section 4: Commercial Applications & Case Studies with Hele Titanium Hydrogen

The versatility of green hydrogen produced by large-scale PEM electrolyzers unlocks transformative commercial opportunities across numerous sectors. Hele Titanium Hydrogen solutions are at the forefront of these applications.

4.1 Driving Decarbonization Across Industries

- Industrial Feedstock:

- Green Ammonia Production: Replacing fossil fuel-derived hydrogen in the Haber-Bosch process to produce zero-carbon fertilizer, crucial for sustainable agriculture.

- Green Steelmaking: A paradigm shift in heavy industry, utilizing green hydrogen as a reductant in direct reduced iron (DRI) processes, dramatically cutting CO2 emissions from steel production.

- Green Methanol & Other Chemicals: Producing sustainable chemicals and fuels from green hydrogen and captured CO2 (Power-to-X).

- Green Ammonia Production: Replacing fossil fuel-derived hydrogen in the Haber-Bosch process to produce zero-carbon fertilizer, crucial for sustainable agriculture.

- Transportation:

- Hydrogen Fueling Stations: Supplying hydrogen for fuel cell electric vehicles (FCEVs), particularly heavy-duty trucks, buses, and trains, enabling zero-emission logistics and public transport.

- Sustainable Aviation Fuels (SAF): Green hydrogen is a key component in the synthesis of SAF, decarbonizing the aviation sector.

- Shipping: Powering maritime vessels with hydrogen or hydrogen-derived fuels, reducing emissions from global shipping.

- Hydrogen Fueling Stations: Supplying hydrogen for fuel cell electric vehicles (FCEVs), particularly heavy-duty trucks, buses, and trains, enabling zero-emission logistics and public transport.

- Power-to-X (P2X) & Energy Storage:

- Power-to-Gas: Converting surplus renewable energy into renewable hydrogen for storage in pipelines or dedicated facilities, providing long-term hydrogen energy storage and grid stability.

- Grid Balancing: Hele Titanium Hydrogen’s dynamic PEM electrolyzers can rapidly respond to grid signals, absorbing excess renewable electricity and providing ancillary services to the grid, thus enhancing grid stability and reliability.

- Power-to-Gas: Converting surplus renewable energy into renewable hydrogen for storage in pipelines or dedicated facilities, providing long-term hydrogen energy storage and grid stability.

- Power Generation:

- Hydrogen Turbines: Utilizing stored green hydrogen to generate electricity during peak demand or when renewable sources are unavailable, offering a clean dispatchable power solution.

4.2 Hele Titanium Hydrogen Project Spotlights (Illustrative Examples)

While specific project details may be proprietary, these examples demonstrate the impactful deployment of our large-scale PEM electrolyzer technology:

- Case Study A: 10 MW PEM System for Green Ammonia Facility in Europe

- Description: A leading chemical producer required a reliable source of high-purity green hydrogen to decarbonize its ammonia production. Hele Titanium Hydrogen supplied a modular 10 MW PEM electrolysis system directly coupled with a wind farm.

- Key Outcomes: Achieved consistent production of over 4,000 kg of high-purity hydrogen per day, significantly reducing the facility’s carbon footprint by thousands of tons annually. The dynamic response of the PEM system ensured optimal utilization of intermittent wind power, contributing to a competitive LCOH. The compact design minimized site disruption.

- Description: A leading chemical producer required a reliable source of high-purity green hydrogen to decarbonize its ammonia production. Hele Titanium Hydrogen supplied a modular 10 MW PEM electrolysis system directly coupled with a wind farm.

- Case Study B: 5 MW PEM Unit for Regional Hydrogen Mobility Hub in North America

- Description: A consortium developing a regional hydrogen economy needed a scalable and responsive hydrogen production unit to supply multiple heavy-duty vehicle refueling stations. Hele Titanium Hydrogen delivered a 5 MW PEM water electrolyzer integrated with a solar array and short-term battery storage.

- Key Outcomes: The system demonstrated exceptional flexibility, producing hydrogen to match fluctuating demand and solar availability. Pressurized output reduced downstream compression costs, and the high purity ensured compliance with fuel cell vehicle standards. This project serves as a blueprint for future hydrogen infrastructure development.

- Description: A consortium developing a regional hydrogen economy needed a scalable and responsive hydrogen production unit to supply multiple heavy-duty vehicle refueling stations. Hele Titanium Hydrogen delivered a 5 MW PEM water electrolyzer integrated with a solar array and short-term battery storage.

- Case Study C: Pilot 2 MW PEM for Green Steel Research in Asia

- Description: A major steel producer launched a pilot project to explore green hydrogen-based direct reduced iron (DRI) processes. Hele Titanium Hydrogen provided a dedicated 2 MW PEM system, chosen for its high efficiency and ability to produce the required purity of hydrogen for metallurgical applications.

- Key Outcomes: The electrolyzer has consistently supplied the high-purity hydrogen necessary for research, validating the technical feasibility and paving the way for future large-scale hydrogen projects in the steel sector.

- Why this works: These examples, even if illustrative, demonstrate the real-world application, scale, and benefits achievable with Hele Titanium Hydrogen’s technology. They provide tangible proof of our capabilities.

- Description: A major steel producer launched a pilot project to explore green hydrogen-based direct reduced iron (DRI) processes. Hele Titanium Hydrogen provided a dedicated 2 MW PEM system, chosen for its high efficiency and ability to produce the required purity of hydrogen for metallurgical applications.

Call to Action: Inspired by these possibilities? Discuss your specific industrial application with our experts. Hele Titanium Hydrogen offers tailored green hydrogen solutions designed for your operational needs and sustainability goals.

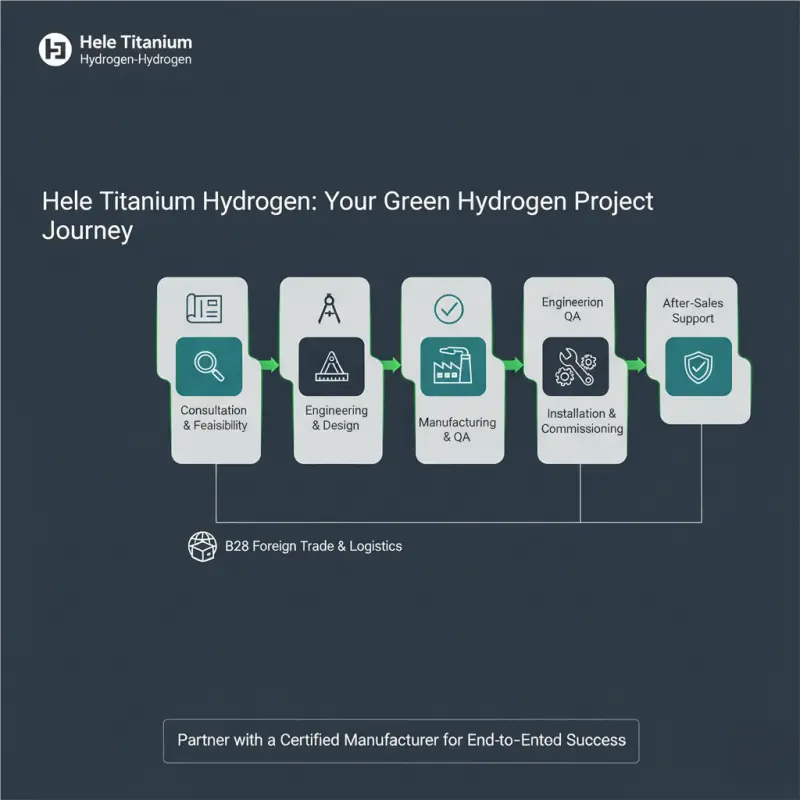

Section 5: Partnership & Project Success: Developing Your Green Hydrogen Future with Hele Titanium Hydrogen

Embarking on a large-scale renewable electrolyzer project requires more than just technology; it demands a trusted partner with proven expertise. Hele Titanium Hydrogen offers end-to-end support, ensuring the success of your commercial hydrogen projects.

5.1 Your Project Journey with Hele Titanium Hydrogen

We guide our clients through every stage of project development:

- Initial Consultation & Feasibility Study: Our team works closely with you to understand your specific requirements, conduct site assessments, analyze energy availability, and develop preliminary project economics.

- Engineering & Design: Leveraging our deep expertise in PEM electrolysis system design, we create optimized solutions, from stack configuration to complete Balance of Plant integration.

- Manufacturing & Quality Assurance: As a dedicated PEM electrolyzer manufacturer, we control the entire production process. Our state-of-the-art facilities ensure that every component, especially our robust titanium-based stacks, meets the highest quality standards.

- Installation Support & Commissioning: We provide expert supervision and technical assistance during installation and commissioning, ensuring smooth start-up and optimal performance.

- After-Sales Service & Maintenance: Our commitment extends beyond delivery. We offer comprehensive after-sales support, including spare parts, remote diagnostics, on-site technical assistance, and preventative maintenance programs to maximize the lifespan and efficiency of your industrial electrolyzer.

- Our Expertise in B2B Foreign Trade: Hele Titanium Hydrogen understands the complexities of international project delivery. We ensure smooth logistics, clear communication, and compliance with global shipping and trade regulations, making us a reliable electrolyzer wholesale supplier for worldwide clients.

5.2 Navigating Regulations & Incentives

The global landscape for green hydrogen is evolving rapidly, with governments introducing significant incentives. While Hele Titanium Hydrogen focuses on technology, we can support clients by providing the necessary technical data and performance metrics required for grant applications, carbon credit schemes, and other regulatory compliance. Understanding policies like the US Inflation Reduction Act (IRA) or the EU Hydrogen Bank can be crucial for project financing.

5.3 Quality, Certifications, and Safety: The Hele Titanium Hydrogen Commitment

At Hele Titanium Hydrogen, our reputation is built on unwavering commitment to quality, safety, and reliability.

- Certifications: We adhere to stringent international standards. Our manufacturing processes are ISO certified, ensuring consistent quality management. Our products comply with relevant safety and environmental directives, including CE certification for European markets, underscoring our commitment to global benchmarks.

- Manufacturing Excellence: Every Hele Titanium Hydrogen PEM electrolysis system undergoes rigorous quality control checks and extensive factory acceptance testing (FAT). We pride ourselves on precision engineering and robust component selection, particularly our proprietary membrane electrode assemblies (MEAs) and corrosion-resistant titanium construction.

- Safety Protocols: Handling hydrogen requires meticulous safety protocols. Our systems are designed with inherent safety features, incorporating robust leak detection, ventilation, emergency shutdown procedures, and pressure management systems. We conduct thorough hazard studies (HAZOP) and provide comprehensive operator training to ensure safe and reliable operation of every green hydrogen generator.

- R&D Investment: Hele Titanium Hydrogen continuously invests in research and development to push the boundaries of electrolyzer efficiency, durability, and electrolyzer cost reduction. Our team of expert engineers and scientists is dedicated to innovation, ensuring our clients benefit from cutting-edge technology.

Partner with Hele Titanium Hydrogen, a certified and trusted China PEM electrolyzer manufacturer. Request our comprehensive technical specifications or inquire about our manufacturing capabilities.

Conclusion: Unlock Your Green Hydrogen Potential with Hele Titanium Hydrogen

The future of industrial energy is green, and large-scale renewable electrolyzers are the engines driving this transformation. Green hydrogen production offers an unparalleled pathway to decarbonization, energy independence, and sustainable profitability for industries across the globe.

Hele Titanium Hydrogen stands ready as your premier partner. Our advanced large-scale PEM water electrolyzers deliver the high efficiency, dynamic response, purity, and reliability demanded by commercial hydrogen projects. From competitive CAPEX and optimized OPEX to seamless integration and comprehensive after-sales support, we provide complete green hydrogen solutions.

Ready to embark on your green hydrogen journey? Whether you are exploring a megawatt electrolyzer for a new facility, scaling up existing renewable hydrogen production, or seeking an expert electrolyzer wholesale supplier, Hele Titanium Hydrogen offers the technology and partnership you need for success.

Contact Hele Titanium Hydrogen today for a personalized consultation, detailed technical specifications, or a customized quote. Let our expert team help you build a sustainable, profitable future.

FAQ Section (Targeting Long-Tail Keywords & “People Also Ask”)

Q: What is the largest electrolyzer project in the world, and what role does PEM play?

A: The scale of large-scale hydrogen projects is rapidly growing, with some planned gigawatt-scale projects globally. While many early large projects have used alkaline technology, PEM is increasingly being deployed in multi-MW to 100MW+ projects due to its dynamic response, which is crucial for integrating with fluctuating renewable energy sources like those at the heart of these massive endeavors. Hele Titanium Hydrogen’s modular PEM systems are designed to scale to these ambitious levels.

Q: How much does a 1 MW electrolyzer cost?

A: The electrolyzer cost for a 1 MW system varies significantly based on technology (PEM vs. Alkaline), specific features, balance of plant components, and supplier. For a large-scale PEM electrolyzer, the CAPEX can range from $1 million to $3 million for the core electrolyzer and associated BoP, excluding installation and ancillary infrastructure. Hele Titanium Hydrogen provides detailed, customized quotes based on project specifications.

Q: How much water does a large electrolyzer use?

A: A large-scale PEM water electrolyzer typically consumes around 9-10 liters of high-purity deionized water per kilogram of hydrogen produced. While this might seem substantial for industrial hydrogen production, in terms of overall industrial water consumption, it is often manageable. Hele Titanium Hydrogen designs efficient water management systems to minimize consumption and ensure optimal system performance.

Q: What is the difference between green, blue, and grey hydrogen?

A: This distinction is crucial in the hydrogen economy: * Grey Hydrogen: Produced from fossil fuels (e.g., natural gas) without carbon capture, emitting significant CO2. * Blue Hydrogen: Produced from fossil fuels with Carbon Capture, Utilization, and Storage (CCUS) technologies to mitigate CO2 emissions. * Green Hydrogen: Produced exclusively through electrolysis technology powered by renewable energy (solar, wind, hydro), resulting in near-zero greenhouse gas emissions. Hele Titanium Hydrogen specializes in green hydrogen generator systems.

Q: How efficient is a commercial electrolyzer?

A: Electrolyzer efficiency is typically measured in terms of electrical energy consumed per kilogram of hydrogen produced (kWh/kg-H₂) or as a percentage relative to the heating value of hydrogen. Modern commercial electrolyzers (both PEM and alkaline) achieve efficiencies between 50-80% (based on Lower Heating Value, LHV), meaning 50-80% of the electrical energy is converted into chemical energy in the hydrogen. Hele Titanium Hydrogen’s large-scale PEM electrolyzers are designed for high efficiency, contributing to a lower Levelized Cost of Hydrogen (LCOH).

Q: What is the typical lifespan of a Hele Titanium Hydrogen PEM electrolyzer stack?

A: With proper operation and maintenance, Hele Titanium Hydrogen’s large-scale PEM electrolyzer stacks are designed for a long operational life, typically 10-15 years, with individual components and MEAs having specified replacement cycles. Our robust titanium construction and advanced materials contribute significantly to this durability, ensuring a strong return on investment for industrial electrolyzer projects.

6. Real-World Challenges and Expert Mitigation Strategies (E-E-A-T Focus)

Deploying large-scale renewable electrolyzers is a complex undertaking with inherent challenges. Hele Titanium Hydrogen leverages its extensive experience and expertise to develop robust mitigation strategies, ensuring the success and reliability of your green hydrogen project. Our proactive approach minimizes risks and maximizes operational efficiency.

Challenge 1: High Capital Costs (CAPEX) for Initial Investment

The upfront investment for large-scale PEM electrolyzer systems, especially those using precious metals, can be substantial. This is often a primary hurdle for new commercial hydrogen projects.

- Expert Mitigation by Hele Titanium Hydrogen:

- Economies of Scale in Manufacturing: As a dedicated PEM electrolyzer manufacturer, our continuous investment in automated production lines and efficient supply chain management allows us to reduce per-unit costs, making electrolyzer cost more competitive for megawatt electrolyzer and multi-megawatt systems.

- Modular & Scalable Design: Our modular PEM systems allow for phased expansion, enabling clients to initially invest in smaller capacities and scale up as demand grows and financial resources become available, optimizing initial CAPEX.

- Long-Term Value Proposition: We emphasize the total cost of ownership (TCO) over initial CAPEX. Our high-efficiency systems lead to significantly lower OPEX (due to reduced electricity consumption) and superior longevity, providing a stronger return on investment (ROI) over the project’s lifespan.

- Support for Financing Structures: While we are not a financial institution, we can provide detailed technical and economic data to support clients in securing government incentives, grants, and project financing, highlighting the robust economics of renewable hydrogen production.

- Economies of Scale in Manufacturing: As a dedicated PEM electrolyzer manufacturer, our continuous investment in automated production lines and efficient supply chain management allows us to reduce per-unit costs, making electrolyzer cost more competitive for megawatt electrolyzer and multi-megawatt systems.

Challenge 2: Intermittency and Variability of Renewable Energy Sources

Renewable energy sources like solar and wind are inherently intermittent, creating challenges for consistent green hydrogen production.

- Expert Mitigation by Hele Titanium Hydrogen:

- Dynamic Load-Following Capability: Our large-scale PEM electrolyzers are specifically designed for rapid start-up, shutdown, and wide operational ranges (e.g., 5-100% load following in seconds). This allows for precise matching of hydrogen production to the fluctuating output of solar or wind farms, maximizing the utilization of renewable energy and minimizing curtailment.

- Hybrid System Integration: We advise on and facilitate integration with short-term battery storage solutions. Batteries can buffer short-term fluctuations, providing a more stable power input to the electrolyzer and enhancing overall system efficiency and reliability.

- Advanced Control Algorithms: Our sophisticated control systems (SCADA) incorporate predictive analytics and smart algorithms to optimize electrolyzer operation in response to real-time renewable energy forecasts and grid conditions, ensuring stable and efficient renewable hydrogen output.

- Dynamic Load-Following Capability: Our large-scale PEM electrolyzers are specifically designed for rapid start-up, shutdown, and wide operational ranges (e.g., 5-100% load following in seconds). This allows for precise matching of hydrogen production to the fluctuating output of solar or wind farms, maximizing the utilization of renewable energy and minimizing curtailment.

Challenge 3: Maintaining Optimal Efficiency at Partial Loads

While PEM electrolyzers offer excellent dynamic response, operating any electrolyzer significantly below its rated capacity can reduce overall efficiency.

- Expert Mitigation by Hele Titanium Hydrogen:

- Optimized Stack Design: Hele Titanium Hydrogen’s PEM stacks are engineered to maintain high efficiency across a broad operating range, minimizing efficiency penalties even during periods of lower renewable energy availability.

- Modular Design for Flexibility: For extremely variable power profiles, a modular approach with multiple electrolyzer units allows individual modules to be shut down or brought online as needed, ensuring that active modules operate closer to their peak efficiency points. This provides greater operational flexibility for industrial hydrogen applications.

- Smart Scheduling: Our control systems can intelligently schedule production runs based on anticipated energy availability and hydrogen demand, ensuring that the electrolyzers operate at their most efficient points as much as possible.

- Optimized Stack Design: Hele Titanium Hydrogen’s PEM stacks are engineered to maintain high efficiency across a broad operating range, minimizing efficiency penalties even during periods of lower renewable energy availability.

Challenge 4: Durability and Lifespan of Electrolyzer Components

The operational environment within an electrolyzer is demanding, and the lifespan of critical components like MEAs (Membrane Electrode Assemblies) is a key concern for large-scale hydrogen projects.

- Expert Mitigation by Hele Titanium Hydrogen:

- Robust Material Selection: We utilize high-quality, corrosion-resistant materials, most notably titanium components, for crucial parts of our PEM electrolyzers. This ensures structural integrity and chemical stability over extended operational periods.

- Proprietary Membrane & Catalyst Technology: Through continuous R&D, we develop and select advanced MEAs and catalysts that offer superior longevity and performance stability under continuous operation.

- Stringent Water Quality Management: Emphasizing and integrating effective demineralization systems helps protect the membrane from impurities, which are a leading cause of degradation.

- Predictive Maintenance & Monitoring: Our advanced control systems enable real-time monitoring of key performance indicators (e.g., cell voltage, temperature, current density). This allows for early detection of potential degradation, enabling proactive maintenance to extend the lifespan of the stack and other components, optimizing electrolyzer efficiency over time.

- Robust Material Selection: We utilize high-quality, corrosion-resistant materials, most notably titanium components, for crucial parts of our PEM electrolyzers. This ensures structural integrity and chemical stability over extended operational periods.

Challenge 5: Developing Robust Hydrogen Infrastructure

The nascent stage of the hydrogen economy means that existing hydrogen infrastructure (storage, pipelines, refueling stations) can be a limitation for some large-scale hydrogen projects.

- Expert Mitigation by Hele Titanium Hydrogen:

- Integrated Solutions & Partnerships: While Hele Titanium Hydrogen focuses on electrolyzer technology, we partner with leading providers of hydrogen storage, compression, and delivery solutions. We can advise clients on integrating our PEM electrolysis system with suitable downstream infrastructure, whether it’s on-site storage, connection to existing pipelines, or development of refueling stations for hydrogen mobility.

- Modular & Scalable Storage Options: We help clients design appropriate on-site storage solutions (e.g., high-pressure tanks, buffer tanks) that match their production capacity and demand profile.

- Focus on Local/Regional Hubs: We advocate for and support the development of localized green hydrogen hubs, where production (from our electrolyzers), storage, and consumption are co-located, minimizing transportation infrastructure needs in the initial stages of hydrogen economy growth.

- Integrated Solutions & Partnerships: While Hele Titanium Hydrogen focuses on electrolyzer technology, we partner with leading providers of hydrogen storage, compression, and delivery solutions. We can advise clients on integrating our PEM electrolysis system with suitable downstream infrastructure, whether it’s on-site storage, connection to existing pipelines, or development of refueling stations for hydrogen mobility.

Challenge 6: Navigating Complex Permitting and Regulatory Landscapes

Developing industrial hydrogen projects often involves navigating intricate local, national, and international environmental and safety regulations.

- Expert Mitigation by Hele Titanium Hydrogen:

- Comprehensive Documentation & Compliance: We provide detailed technical specifications, safety data sheets, and compliance documentation for all our large-scale PEM electrolyzer products, facilitating the permitting process. Our systems are designed to meet international safety standards (CE certification, ISO standards).

- Safety by Design: Hele Titanium Hydrogen prioritizes inherently safe design principles for all components and system layouts, which significantly aids in meeting stringent safety regulations and streamlines environmental impact assessments.

- Technical Support for Approvals: Our engineering team can offer technical input and clarification during regulatory reviews, helping clients address concerns and secure necessary approvals more efficiently.

- Comprehensive Documentation & Compliance: We provide detailed technical specifications, safety data sheets, and compliance documentation for all our large-scale PEM electrolyzer products, facilitating the permitting process. Our systems are designed to meet international safety standards (CE certification, ISO standards).

Call to Action: Don’t let challenges deter your green hydrogen ambitions. Hele Titanium Hydrogen’s experts provide comprehensive project planning and mitigation strategies to de-risk your investment. Contact us for a detailed project risk assessment.

7. Future Trends and Innovations in Large-Scale PEM Electrolyzers

The hydrogen economy is a rapidly evolving landscape, and Hele Titanium Hydrogen is at the forefront of innovation. We are committed to pushing the boundaries of electrolysis technology to make green hydrogen production even more accessible, efficient, and cost-effective for large-scale hydrogen projects.

- Decreasing Electrolyzer Costs:

- R&D in Materials: Ongoing research into reducing the loading of precious metals (platinum, iridium) in PEM catalysts, or developing entirely new, cost-effective catalysts, promises to significantly lower the electrolyzer cost of PEM systems.

- Manufacturing Scale-Up: As demand for large-scale PEM electrolyzer systems grows, mass production techniques and automation in our facilities will continue to drive down manufacturing costs, leading to more competitive pricing for commercial electrolyzer solutions.

- Supply Chain Optimization: Hele Titanium Hydrogen actively works to optimize its global supply chain for raw materials and components, ensuring cost efficiency and reliability.

- R&D in Materials: Ongoing research into reducing the loading of precious metals (platinum, iridium) in PEM catalysts, or developing entirely new, cost-effective catalysts, promises to significantly lower the electrolyzer cost of PEM systems.

- Improved Efficiency:

- Next-Generation Membrane Electrode Assemblies (MEAs): Continuous innovation in membrane materials and stack designs aims to improve current density, reduce overpotentials, and thus increase electrolyzer efficiency (lower kWh/kg-H₂).

- Operating Parameter Optimization: Advanced control strategies are being developed to dynamically optimize operating temperature, pressure, and current density for peak efficiency across various loads and renewable energy input profiles.

- Next-Generation Membrane Electrode Assemblies (MEAs): Continuous innovation in membrane materials and stack designs aims to improve current density, reduce overpotentials, and thus increase electrolyzer efficiency (lower kWh/kg-H₂).

- Integration with Other Technologies:

- Power-to-X (P2X) Synergy: Beyond direct hydrogen use, future trends involve tighter integration of large-scale renewable electrolyzer systems with carbon capture and utilization (CCU) technologies to produce synthetic fuels, chemicals, and even sustainable aviation fuels (SAF).

- Advanced Heat Management: Developing more efficient ways to recover and utilize the waste heat generated during electrolysis can further boost overall system efficiency and create additional value streams for industrial hydrogen facilities.

- Power-to-X (P2X) Synergy: Beyond direct hydrogen use, future trends involve tighter integration of large-scale renewable electrolyzer systems with carbon capture and utilization (CCU) technologies to produce synthetic fuels, chemicals, and even sustainable aviation fuels (SAF).

- Large-Scale Hydrogen Hubs:

- The concept of regional hydrogen hubs is gaining momentum. These are integrated ecosystems where renewable hydrogen production (often from megawatt electrolyzer and gigawatt-scale PEM plants), storage, and various end-use applications (industrial, mobility, power generation) are co-located. Hele Titanium Hydrogen is actively involved in supplying the core electrolysis technology for such visionary projects.

- These hubs foster collaboration between renewable energy developers, hydrogen producers, and industrial off-takers, creating robust hydrogen infrastructure and accelerating the growth of the hydrogen economy.

- The concept of regional hydrogen hubs is gaining momentum. These are integrated ecosystems where renewable hydrogen production (often from megawatt electrolyzer and gigawatt-scale PEM plants), storage, and various end-use applications (industrial, mobility, power generation) are co-located. Hele Titanium Hydrogen is actively involved in supplying the core electrolysis technology for such visionary projects.

- Digitalization and AI:

- Further integration of Artificial Intelligence (AI) and Machine Learning (ML) for predictive maintenance, real-time optimization, and autonomous operation of large-scale PEM electrolyzer plants will become standard, enhancing reliability and reducing OPEX.

Call to Action: Stay ahead of the curve with Hele Titanium Hydrogen. Our commitment to R&D ensures you always have access to cutting-edge PEM electrolysis system technology. Learn more about our innovation pipeline. [Link to R&D / Innovation Page]

8. The Hele Titanium Hydrogen Difference: Why Partner with Us?

Choosing the right partner for your large-scale renewable electrolyzer project is paramount. Hele Titanium Hydrogen offers a unique combination of technical prowess, manufacturing excellence, and unwavering customer support.

- Dedicated PEM Expertise: We specialize exclusively in PEM water electrolyzers, giving us unparalleled depth of knowledge and experience in this specific, high-growth electrolysis technology. Our focus ensures continuous innovation and refinement of our PEM solutions.

- Advanced Titanium Technology: Our name, Hele Titanium Hydrogen, reflects our commitment to using premium materials. Our robust titanium components ensure the longevity, durability, and corrosion resistance essential for industrial hydrogen production in demanding environments.

- Full Lifecycle Support: From initial concept to long-term operation, Hele Titanium Hydrogen provides comprehensive support. Our services include project consultation, engineering design, in-house manufacturing, quality assurance, installation guidance, commissioning, and dedicated after-sales service.

- Proven Track Record: Our growing portfolio of large-scale hydrogen projects demonstrates our capability to deliver reliable and efficient solutions for diverse commercial hydrogen project requirements. We have a clear understanding of the nuances of electrolyzer cost and efficiency.

- Global Reach & B2B Focus: As an experienced China PEM electrolyzer manufacturer and electrolyzer wholesale supplier, we understand the intricacies of international trade. We are committed to building long-term partnerships with B2B buyers worldwide, providing seamless logistics and communication.

- Commitment to Sustainability: We are driven by the vision of a green hydrogen economy. Partnering with Hele Titanium Hydrogen means collaborating with a company deeply committed to sustainable practices and helping you achieve your decarbonization goals.

- Unrivaled Quality & Safety: Our adherence to ISO and CE standards, combined with rigorous internal quality control and safety protocols, ensures that every Hele Titanium Hydrogen large-scale PEM electrolyzer is built to the highest specifications, guaranteeing performance and peace of mind.

Call to Action: Ready to experience the Hele Titanium Hydrogen advantage? Let’s build your green hydrogen future together. [Link to ‘Why Choose Us’ Page or Direct Contact Form]

Conclusion: Unlock Your Green Hydrogen Potential with Hele Titanium Hydrogen

The future of industrial energy is green, and large-scale renewable electrolyzers are the engines driving this transformation. Green hydrogen production offers an unparalleled pathway to decarbonization, energy independence, and sustainable profitability for industries across the globe.

Hele Titanium Hydrogen stands ready as your premier partner. Our advanced large-scale PEM water electrolyzers deliver the high efficiency, dynamic response, purity, and reliability demanded by commercial hydrogen projects. From competitive CAPEX and optimized OPEX to seamless integration and comprehensive after-sales support, we provide complete green hydrogen solutions. We are not just a supplier; we are your strategic partner in navigating the complexities of the hydrogen economy.

Ready to embark on your green hydrogen journey? Whether you are exploring a megawatt electrolyzer for a new facility, scaling up existing renewable hydrogen production, or seeking an expert electrolyzer wholesale supplier, Hele Titanium Hydrogen offers the cutting-edge technology, proven expertise, and dedicated partnership you need for unparalleled success.

Contact Hele Titanium Hydrogen today for a personalized consultation, detailed technical specifications, or a customized quote. Let our expert team help you build a sustainable, profitable future.

Hele Titanium Hydrogen: Your Trusted Hydrogen Generator OEM & Manufacturing Partner

Hele Titanium Hydrogen stands as a reliable and experienced partner in the hydrogen generator OEM supply chain. We specialize in the design, development, and manufacturing of high-performance PEM Water Hydrogen Generators, offering comprehensive OEM & Manufacturing services tailored to your specific needs.

Take the Next Step

Ready to explore the possibilities of partnering with Hele Titanium Hydrogen?

- Browse our Products to see our range of PEM Water Hydrogen Generators.

- Learn more about our Services and how we can support your OEM & Manufacturing needs.

- Contact Us today to discuss your specific requirements.

- Explore our FAQ to get answers to common questions.

- Visit our Blog for the latest insights and updates on hydrogen technology.

Email Us: heletitaniumhydrogen@gmail.com

Phone/WhatsApp: 086-13857402537