I. The High Stakes of Choosing Your Hydrogen Electrolyzer Partner

The global shift towards green hydrogen solutions is no longer a future prospect; it’s a present-day industrial revolution. For project developers, engineers, and procurement managers, this presents both a monumental opportunity and a critical challenge. The success of multi-million dollar investments in energy storage, industrial feedstocks, and clean transportation hinges on the performance of one core component: the hydrogen electrolyzer. The stakes have never been higher.

Your choice of an OEM PEM electrolyzer supplier is a decision that echoes through every phase of your project, from initial capital outlay to long-term operational efficiency. Partnering with the right manufacturer can accelerate your timeline, enhance your reputation, and maximize your return on investment. Conversely, the wrong choice can lead to a cascade of devastating problems:

- Costly Downtime from underperforming or faulty equipment.

- Safety Hazards stemming from subpar manufacturing and quality control.

- Performance Gaps that prevent you from meeting production targets.

- Project Delays due to unreliable supply chains and non-compliance with international standards.

How, then, do you navigate a crowded global market to find a partner who delivers on their promises? How do you mitigate risk and ensure the bankability of your project?

The answer lies in a globally recognized framework of quality, safety, and trust: ISO certification. This isn’t merely a piece of paper; it’s verifiable proof of a manufacturer’s commitment to excellence.

This guide is designed to be your comprehensive vetting checklist. As a leading, fully-certified manufacturer of PEM electrolyzers for industrial use, Hele Titanium Hydrogen believes in empowering our partners with knowledge. We’re not just here to supply a product; we are here to provide the bedrock of quality and reliability upon which your success in the hydrogen economy can be built.

II. Decoding ISO Certifications: The Non-Negotiable Language of Quality

In the world of international trade and advanced manufacturing, marketing claims are abundant. Words like “high-quality,” “reliable,” and “premium” are used so often they can lose their meaning. So, how does a discerning B2B buyer cut through the noise to find objective proof of a manufacturer’s capability? The answer is ISO certification.

The International Organization for Standardization (ISO) provides a globally recognized framework that forces companies to meet rigorous standards for their processes, safety protocols, and environmental impact. For anyone procuring hydrogen electrolyzers for industrial use, understanding these standards is the first step in effective due diligence.

Think of it as a universal language of trust. When a factory is ISO certified, it signifies that an independent, third-party body has audited their operations and confirmed they adhere to world-class systems. Let’s break down the “big three” certifications that should be non-negotiable for any serious hydrogen OEM manufacturing partner.

ISO 9001:2015 – The Blueprint for Manufacturing Excellence

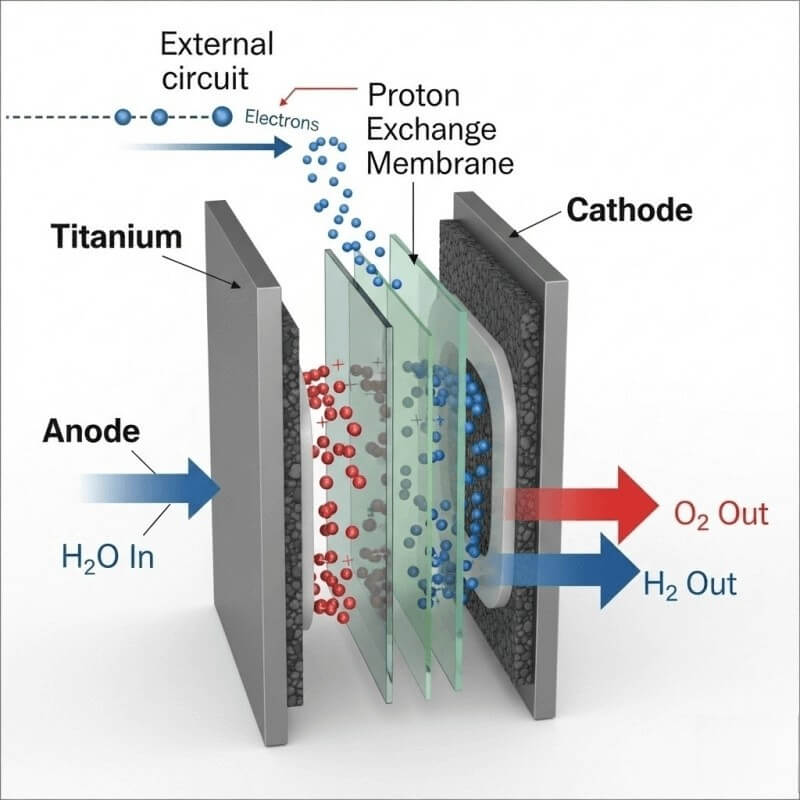

This is the cornerstone of quality. ISO 9001:2015 is not about a simple final inspection of the product; it’s a deep-seated commitment to a process that ensures quality is built-in from the moment raw materials arrive to the moment the finished electrolyzer is crated for shipment.

For a technology as precise as a PEM electrolyzer, this is critical. Here’s what it means in practice:

- Full Material Traceability: A certified manufacturer can trace the exact batch of titanium used for your bipolar plates or the specific lot of platinum-iridium catalyst applied to the proton exchange membrane. This is crucial for performance consistency and any future diagnostics.

- Rigorous Process Control: The efficiency and lifespan of a PEM stack depend on the precise application of pressure and temperature during the bonding of the Catalyst Coated Membrane (CCM). ISO 9001 mandates that these processes are meticulously controlled, documented, and repeatable, eliminating variation and ensuring every stack performs to specification.

- Continuous Improvement: The standard requires a system for identifying and correcting potential issues. This means an ISO 9001 certified partner is constantly refining their methods to build a better, more reliable product for you.

Without ISO 9001, you are essentially gambling on your supplier’s internal, unverified claims. With it, you have proof of a systematic approach to quality that drastically reduces the risk of receiving a substandard wholesale hydrogen generator.

ISO 14001:2015 – A Commitment to Sustainable & Responsible Production

The entire purpose of the green hydrogen solutions industry is to build a cleaner, more sustainable future. It is only logical to demand the same from your manufacturing partners. ISO 14001:2015 is the international standard for Environmental Management Systems (EMS).

For a B2B buyer, this certification signals more than just corporate responsibility; it indicates operational efficiency and foresight:

- Modern & Efficient Operations: Effective environmental management often correlates with reduced waste, optimized energy consumption, and smarter use of resources. This efficiency can translate into a more competitively priced and better-built product.

- Compliance & Risk Reduction: A partner with a certified EMS is less likely to face regulatory penalties or disruptions related to environmental non-compliance, ensuring a more stable and reliable supply chain for your projects.

- Brand Alignment: Partnering with an ISO 14001 certified manufacturer strengthens your own company’s sustainability credentials and aligns your supply chain with the core values of the green hydrogen movement.

ISO 45001:2018 – Prioritizing Safety from the Factory Floor to Your Facility

Hydrogen is an energy carrier that demands the utmost respect for safety. That respect must begin at the point of manufacture. ISO 45001:2018 is the global standard for Occupational Health and Safety Management Systems.

A manufacturer’s commitment to their own team’s safety is a powerful indicator of the meticulous care they put into their products.

- An Ingrained Culture of Safety: This certification proves a manufacturer doesn’t just talk about safety; they have a systematic process for identifying hazards, assessing risks, and implementing controls. This culture permeates everything they do.

- Higher Quality Workmanship: A safe, well-managed working environment leads to a more focused and detail-oriented workforce. When technicians are confident in their safety protocols for handling high-voltage components and testing systems with compressed gases, the quality of their work improves.

- A Safer End Product: The design and manufacturing choices made in a safety-conscious environment inevitably lead to a product that is inherently safer for you to install, operate, and maintain at your own facility.

Together, this trifecta of ISO certifications forms the baseline for a trustworthy OEM PEM electrolyzer supplier. It demonstrates a holistic commitment to quality, sustainability, and safety that is essential for any critical industrial application.

III. Your 5-Point Vetting Checklist for ISO Certified Suppliers

An ISO certificate on a website is a good start, but it is not the finish line. True due diligence requires you to look beyond the logo and probe the real-world application of these quality, environmental, and safety systems. A truly world-class OEM PEM electrolyzer supplier will welcome detailed questions and be proud to demonstrate the robustness of their operations.

Use this five-point checklist during your evaluation process to separate the genuine experts from the mere assemblers.

1. Go Beyond the Logo: Verify the Certificate’s Authenticity and Scope

Any manufacturer can place a certification logo on their marketing materials. Your first step is to verify it.

- Action: Request a full, unredacted copy of their ISO 9001, ISO 14001, and ISO 45001 certificates.

- Verification: Check the certificate number, the date of validity (ensure it’s not expired), and the name of the accredited, third-party certification body (e.g., SGS, TÜV Nord, Bureau Veritas, Intertek).

- Crucial Detail – The Scope: This is the most overlooked step. The certificate’s “Scope of Certification” must be specific to their business. A generic certificate for “metal fabrication” is insufficient. Look for precise wording such as: “The design, development, manufacturing, and sales of Proton Exchange Membrane (PEM) hydrogen electrolyzers.” This confirms their core processes for producing hydrogen electrolyzers for industrial use have been audited.

2. Drill Down on Quality Management (ISO 9001 in Practice)

A certificate proves a quality management system exists. Your job is to test its depth. Ask specific questions that reveal how they live and breathe quality control every day.

- Suggested Questions:

- “Can you walk me through your quality control process for incoming raw materials, specifically the proton exchange membranes and catalysts?”

- “What are your standard procedures for Factory Acceptance Testing (FAT) on a completed wholesale hydrogen generator, and can a representative from our company witness this test?”

- “If a non-conforming component is identified during production, what is your documented procedure for quarantine, analysis, and corrective action?”

3. Assess Their Core Competency in PEM Technology

The market contains many types of electrolyzer technologies. If your project requires high-purity hydrogen, rapid response times, and a compact footprint, you need a PEM specialist. A generalist supplier may not have the deep expertise required for optimal performance and longevity.

- Suggested Questions:

- “What percentage of your company’s R&D budget and engineering resources is dedicated specifically to advancing PEM stack technology?”

- “Can you provide long-term operational data for your PEM stacks, including typical voltage degradation rates ($µV/h$) under various load profiles?”

- “How does your hydrogen OEM manufacturing process ensure the delicate Catalyst Coated Membrane (CCM) is protected from contamination or physical damage during stack assembly?”

4. Evaluate Supply Chain Robustness and Component Traceability

In today’s volatile global market, a manufacturer is only as strong as its supply chain. Delays in critical components can derail your entire project timeline.

- Suggested Questions:

- “How do your ISO 9001 systems ensure full, end-to-end traceability for every critical component within our electrolyzer unit?”

- “What redundancies have you built into your supply chain for key materials like iridium catalyst and Nafion™ membranes to mitigate geopolitical or logistical risks?”

- “Can you provide a certificate of origin for the core components, ensuring they meet international quality and ethical sourcing standards?”

5. Confirm Their Expertise in International Trade and Support

For international B2B buyers, the manufacturer’s responsibilities do not end at the factory gates. Flawless logistics and reliable after-sales support are paramount.

- Suggested Questions:

- “Can you provide case studies or client references from our region (e.g., European Union, United States, APAC)?”

- “What is your standard procedure for expert-grade crating, international shipping, and providing necessary documentation (e.g., CE conformity, Certificate of Origin) to ensure smooth customs clearance?”

- “What is the structure of your after-sales technical support for international clients, including response times, warranty claim processes, and spare parts availability?”

IV. The Hele Advantage: Your Fully Certified PEM Partner

Theory and checklists are essential, but the ultimate goal is to find a manufacturing partner who puts those principles into practice every single day. Hele Titanium Hydrogen was built on the foundation of the standards detailed above. We don’t just pass the audit; we have integrated the ethos of ISO quality, safety, and sustainability into the core of our hydrogen OEM manufacturing process.

Here is how we meet and exceed the criteria of the vetting checklist, providing our global partners with the confidence and peace of mind they need to execute their projects successfully.

1. Uncompromising Quality, Certified and Verified (ISO 9001)

At Hele, our ISO 9001:2015 certification is the backbone of our operation. We welcome scrutiny of our quality systems because we are proud of the rigor they represent.

Our commitment goes far beyond the certificate on the wall. It’s evident in our multi-stage quality control protocol:

- Raw Material Purity Testing: Every batch of titanium for our bipolar plates and every roll of proton exchange membrane undergoes stringent purity and dimensional analysis. We ensure quality before a single component is even made.

- Precision Stack Assembly: Our PEM stacks are assembled in a controlled-environment facility to prevent contamination of the delicate Catalyst Coated Membrane (CCM), ensuring maximum efficiency and operational lifespan.

- Full-System Stress Testing: Every wholesale hydrogen generator we produce is subjected to a continuous 72-hour performance and pressure test before shipment. We provide our clients with a detailed Factory Acceptance Test (FAT) report, guaranteeing the unit you receive performs flawlessly to its stated specifications.

2. Deep Expertise in Advanced PEM Technology

Hele Titanium Hydrogen is not a generalist; we are PEM technology specialists. We believe this focus is essential to push the boundaries of what is possible in green hydrogen solutions. Our R&D is exclusively dedicated to advancing PEM performance, which translates into tangible benefits for our clients:

- Exceptional Purity: Our systems consistently deliver hydrogen at 99.999% purity, suitable for the most demanding applications, including fuel cells and semiconductor manufacturing.

- Superior Efficiency: Through continuous innovation in stack design and catalyst application, we maximize hydrogen output per kilowatt-hour of energy input, directly lowering your operational costs.

- Rapid Response & Wide Turndown Ratio: PEM technology is renowned for its ability to ramp up and down quickly, making our electrolyzers ideal for pairing with intermittent renewable energy sources like solar and wind.

3. Responsible Manufacturing and a Culture of Safety (ISO 14001 & 45001)

Our commitment to the green hydrogen economy is holistic. Our ISO 14001 certified environmental management system ensures we minimize waste and energy consumption in our own operations. Furthermore, our ISO 45001 certification in occupational health and safety creates a culture of meticulous care. This focus on safety on our factory floor translates directly into the robust, reliable design of the hydrogen electrolyzers for industrial use that we ship to your facility.

4. A Proven, Bankable Global Partner

We understand the unique challenges of international trade. Our operational expertise is designed to provide a seamless procurement experience for our B2B partners across the globe.

- Global Logistics Mastery: We have a proven track record of shipping to clients across the European Union, North America, and the Asia-Pacific region. Our logistics team handles all aspects of expert-grade crating and documentation (including CE conformity) to ensure your asset arrives safely and clears customs without delay.

- Transparent Supply Chain: Our ISO 9001 system provides full traceability of all critical components, offering you an unparalleled level of transparency and quality assurance.

- Comprehensive Support: We provide dedicated after-sales technical support, clear warranty terms, and a readily available inventory of spare parts to ensure the long-term success of your operation.

See the Proof: Don’t just take our word for it. Download our latest case study to see how we helped a European industrial client integrate our PEM systems to create a reliable on-site hydrogen supply.

V. The Tangible Benefits: Your ROI with a Certified Partner

Choosing a certified, specialist partner like Hele Titanium Hydrogen isn’t just about mitigating risk; it’s an investment strategy that unlocks significant, measurable advantages for your project and your business. These benefits go far beyond the initial purchase price, impacting your operational efficiency, project timeline, and overall profitability.

Lower Total Cost of Ownership (TCO)

The true cost of an industrial asset is measured over its entire lifecycle. Our ISO 9001-driven manufacturing precision and use of premium materials result in a wholesale hydrogen generator built for longevity and reliability. This translates to:

- Reduced Maintenance Costs: High-quality components and robust assembly lead to fewer breakdowns and less need for unscheduled servicing.

- Maximized Uptime: Reliable performance means your facility remains productive, avoiding the immense costs associated with downtime.

- Longer Equipment Lifespan: Our commitment to quality ensures you get more operational years from your investment, improving its long-term value.

De-Risk Your Investment & Ensure Bankability

Large-scale green hydrogen solutions often require significant capital and stakeholder buy-in. Partnering with a fully certified OEM PEM electrolyzer supplier strengthens your entire project proposal.

- Increased Investor Confidence: Presenting a supply chain backed by internationally recognized ISO certifications demonstrates thorough due diligence and risk management to investors and financial institutions.

- Simplified Project Financing: A bankable project is one with a predictable, low-risk execution plan. Our proven track record and certifications help de-risk the equipment procurement phase, making your project more attractive to lenders.

Accelerate Your Time-to-Market

Delays are the enemy of profitability. Our expertise as a global supplier is geared towards getting you operational faster.

- Seamless Integration: We deliver a fully tested, compliant (e.g., CE marked for Europe) system that is designed for straightforward integration, reducing on-site commissioning time.

- Hassle-Free Logistics: Our deep experience in international shipping and customs documentation prevents costly delays at ports, ensuring your equipment arrives on schedule.

Guarantee Performance & Purity

For your process to work, you need a guaranteed supply of hydrogen at the right purity and flow rate. Our certified processes eliminate performance guesswork.

- Contractual Confidence: The performance specifications on our data sheets are not just targets; they are guaranteed outcomes of a controlled manufacturing process, ensuring you get the hydrogen output (Nm³/hr) and purity (99.999%) you paid for.

- Protect Downstream Equipment: Consistent, ultra-high purity hydrogen protects sensitive downstream applications like fuel cells or specialized industrial catalysts from contamination and damage.

VI. Conclusion: Your Next Step to a Secure Hydrogen Future

In the rapidly expanding hydrogen economy, the difference between a successful, profitable project and a costly failure often comes down to the quality and reliability of its core technology. As we have explored, choosing your PEM hydrogen electrolyzer supplier is one of the most critical decisions you will make. The risks of partnering with an uncertified, unproven manufacturer are simply too great.

ISO certification is more than a logo on a brochure; it is your most reliable indicator of a manufacturer’s commitment to quality, safety, and operational excellence. By using the detailed vetting checklist provided, you can move beyond marketing claims and identify a partner who has a robust, verifiable system for delivering a world-class product.

Hele Titanium Hydrogen embodies this standard. Our identity as a specialized OEM PEM electrolyzer supplier, backed by the trifecta of ISO 9001, 14001, and 45001 certifications, is your assurance of a partnership founded on trust, transparency, and a shared commitment to advancing green hydrogen solutions.

Don’t leave the success of your project to chance. Take the next step with confidence.

Let’s Build Together

Our team of hydrogen technology experts is ready to discuss the specific requirements of your project. Whether you are in the planning stages or ready to procure, we can provide the technical guidance and support you need.

- Request a Personalized Quote: Contact us with your project specifications, and we will provide a detailed, no-obligation quote for a turnkey wholesale hydrogen generator solution.

- Schedule a Technical Consultation: Speak directly with one of our engineers to review your technical challenges and discover how our PEM systems can be optimized for your application.

- Download Our Technical Data Sheets: Access in-depth performance data, specifications, and P&ID documentation for our full range of electrolyzers.

Contact Hele Titanium Hydrogen today. Let’s build the future of clean energy, together.

VII. Frequently Asked Questions (FAQ)

1. What is the most important ISO certification for PEM hydrogen electrolyzers?

While all three (9001, 14001, 45001) are vital signs of a high-quality partner, ISO 9001:2015 (Quality Management) is the most critical for the product itself. It directly governs the precision manufacturing processes essential for the reliability, efficiency, and long lifespan of the highly sensitive PEM stack, which is the heart of the electrolyzer.

2. How can I verify Hele Titanium Hydrogen’s ISO certifications?

We practice full transparency. You can request a copy of our current certificates directly from our team at any time. We will gladly provide the certificate number and the name of the accredited issuing body, allowing for independent verification.

3. Does ISO certification guarantee a lower initial price?

Not necessarily for the upfront capital cost. However, it is a powerful indicator of a lower Total Cost of Ownership (TCO). The superior reliability, reduced maintenance needs, and longer operational life that result from ISO 9001-certified quality control deliver a far greater return on investment over the asset’s lifecycle.

4. Are your hydrogen electrolyzers certified for use in Europe and North America?

Yes. Beyond our ISO process certifications, our hydrogen electrolyzers for industrial use are engineered to meet stringent international product standards. Our systems carry the CE marking, which demonstrates conformity with the health, safety, and environmental protection standards required for the European Economic Area (EEA). We also provide comprehensive documentation to support compliance and smooth importation into North America and other key global markets.

Hele Titanium Hydrogen: Your Trusted Hydrogen Generator OEM & Manufacturing Partner

Hele Titanium Hydrogen stands as a reliable and experienced partner in the hydrogen generator OEM supply chain. We specialize in the design, development, and manufacturing of high-performance PEM Water Hydrogen Generators, offering comprehensive OEM & Manufacturing services tailored to your specific needs.

Take the Next Step

Ready to explore the possibilities of partnering with Hele Titanium Hydrogen?

- Browse our Products to see our range of PEM Water Hydrogen Generators.

- Learn more about our Services and how we can support your OEM & Manufacturing needs.

- Contact Us today to discuss your specific requirements.

- Explore our FAQ to get answers to common questions.

- Visit our Blog for the latest insights and updates on hydrogen technology.

Email Us: heletitaniumhydrogen@gmail.com

Phone/WhatsApp: 086-13857402537