Looking for reliable industrial PEM water electrolyzers for large-scale hydrogen production? Explore top manufacturers, key applications, cost factors, and how Hele Titanium Hydrogen delivers advanced, cost-effective solutions for your commercial needs.

Introduction

The global hydrogen economy is accelerating at an unprecedented pace. According to industry reports, the green hydrogen market is projected to exceed $100 billion by 2030, fueled by global efforts to decarbonize industries, power generation, and transportation. At the heart of this transformation lies industrial PEM water electrolyzers—advanced systems that split water into hydrogen and oxygen using renewable electricity.

Unlike traditional electrolysis methods, PEM (Proton Exchange Membrane) electrolyzers deliver higher efficiency, faster response times, and compact design, making them the preferred choice for industrial-scale hydrogen production.

This article serves as a comprehensive commercial guide to industrial PEM water electrolyzers. We’ll explore how they work, their applications, top global manufacturers, and the critical factors businesses must consider before investing. Most importantly, we’ll introduce how Hele Titanium Hydrogen, a professional manufacturer and wholesale supplier, is setting new standards in performance, durability, and cost-effectiveness.

What Are Industrial PEM Water Electrolyzers?

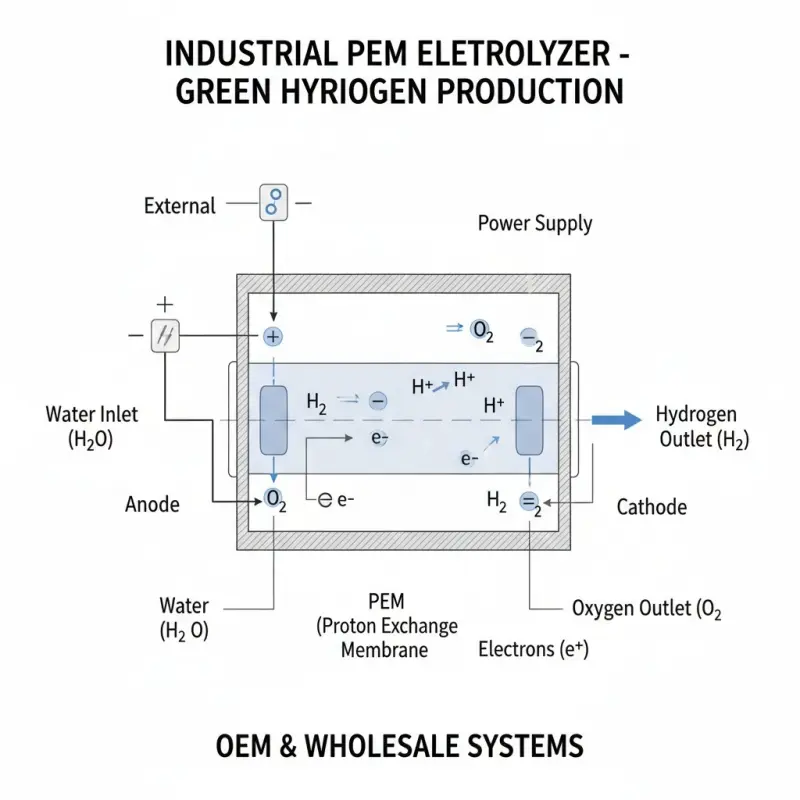

A PEM water electrolyzer uses a polymer electrolyte membrane to conduct protons while serving as an insulator for electrons. When electricity flows through the system, water molecules split at the anode into oxygen, electrons, and protons.

The protons pass through the membrane to the cathode, where they combine with electrons to form hydrogen gas.

Simplified reaction:

- Anode (Positive Electrode): H₂O → O₂ + 4H⁺ + 4e⁻

- Cathode (Negative Electrode): 4H⁺ + 4e⁻ → 2H₂

Key Advantages Over Alkaline and Solid Oxide Electrolyzers

- ✅ High current density – Generates more hydrogen in less space.

- ✅ High purity hydrogen – Suitable for sensitive applications like fuel cells and electronics.

- ✅ Dynamic response – Handles variable renewable energy sources such as wind and solar.

- ✅ Compact design – Ideal for industries with limited installation space.

- ✅ Pressurized operation – Produces hydrogen at higher pressures without extensive compression needs.

In short, PEM electrolysis offers the flexibility and scalability that today’s industrial hydrogen users demand.

Why Businesses Choose PEM Technology

For commercial hydrogen producers, time, efficiency, and reliability are everything. Industrial PEM electrolyzers are increasingly chosen over alkaline alternatives because they:

- Provide On-Demand Hydrogen – Rapid start-up and shut-down make PEM perfect for intermittent renewable integration.

- Offer Long-Term Reliability – Modern PEM stacks, especially those with titanium-based components, withstand demanding industrial cycles.

- Ensure Higher Return on Investment (ROI) – Efficiency improvements and reduced maintenance costs lower the lifetime cost of hydrogen production.

- Support Decarbonization Goals – Companies can meet government carbon reduction mandates by integrating green hydrogen into their operations.

Key Applications of Industrial PEM Water Electrolyzers

Industrial PEM electrolyzers are versatile, serving multiple industries and applications:

1. Hydrogen Production for Industrial Use

- Ammonia & Methanol: Used as feedstock for fertilizers and chemicals.

- Steelmaking: Replacing carbon-intensive blast furnace methods.

- Petroleum Refining: Desulfurization and hydrogenation processes.

2. Power-to-Gas (P2G)

- Grid Balancing: Storing excess renewable power in the form of hydrogen.

- Pipeline Injection: Mixing hydrogen into natural gas infrastructure.

3. Transportation & Mobility

- Fueling Stations: Hydrogen refueling for cars, buses, trucks, and trains.

- Shipping & Aviation: Supporting zero-emission fuels like e-fuels and SAF.

4. On-Site Hydrogen Generation

- Laboratories & R&D Centers: Supplying high-purity hydrogen.

- Electronics & Glass Industry: Hydrogen for controlled processes.

Case Example: In Europe, several steel plants are already replacing coke ovens with hydrogen-powered direct reduction plants, significantly cutting CO₂ emissions.

Global Leaders in Industrial PEM Water Electrolyzers

While Hele Titanium Hydrogen leads with innovative titanium PEM solutions, it’s important to recognize global players shaping the market:

- Nel Hydrogen (Norway): Long history in hydrogen with scalable PEM systems.

- ITM Power (UK): Specializes in large-scale PEM electrolyzers for renewable integration.

- Siemens Energy (Germany): Offers complete energy transition solutions with PEM technology.

- Plug Power (USA): Expanding from fuel cells into industrial electrolysis.

- McPhy Energy (France): Known for high-pressure PEM systems.

- Cummins/Hydrogenics (Canada): Offers diverse electrolyzer technologies, including PEM.

👉 While these companies dominate headlines, Hele Titanium Hydrogen offers a strong, cost-competitive alternative, particularly for businesses seeking reliable supply chains and custom solutions.

Hele Titanium Hydrogen – A Trusted Partner in PEM Electrolysis

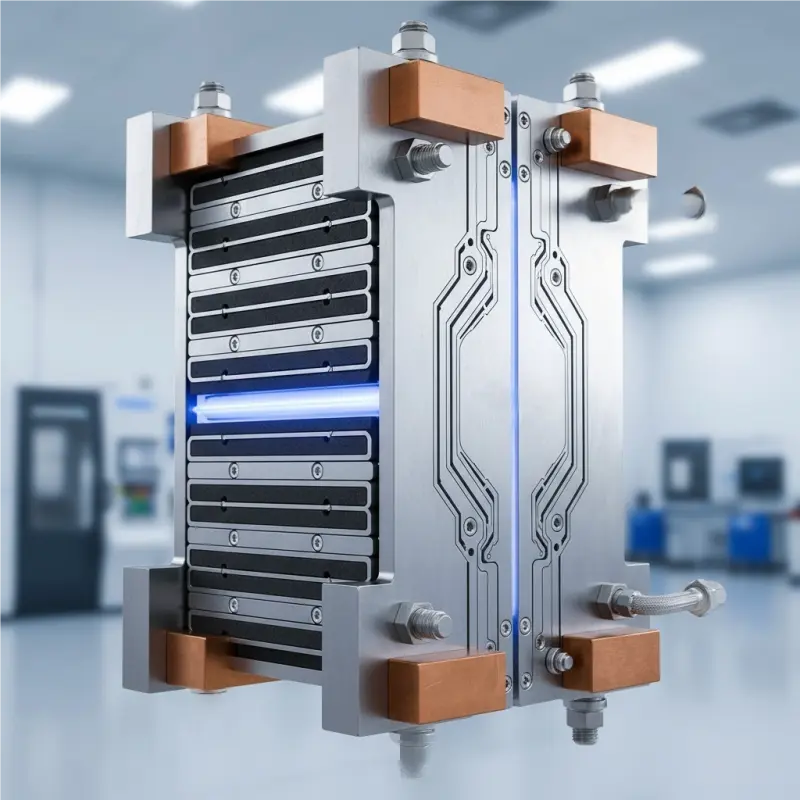

At Hele Titanium Hydrogen, we specialize in designing and manufacturing industrial PEM water electrolyzers with a focus on:

- Titanium PEM Cells: Corrosion-resistant, longer lifetime, reduced maintenance.

- High Purity Hydrogen Output: Meeting strict requirements for sensitive industries.

- Modular & Scalable Systems: From small labs to multi-MW industrial projects.

- Competitive Pricing: More cost-effective than European suppliers without compromising quality.

- Global Supply Capability: Exporting to diverse markets with timely delivery.

- Certified Manufacturing: Compliance with international safety and performance standards.

Our goal is to help businesses transition to green hydrogen profitably while ensuring long-term reliability.

How to Choose the Right Industrial PEM Water Electrolyzer

When selecting a system, decision-makers should consider:

- Hydrogen Output Capacity – Does it match current and future demand?

- Efficiency (kWh/kg H₂) – Lower energy consumption reduces operating costs.

- Hydrogen Purity Levels – Critical for fuel cell and chemical applications.

- Operating Pressure – Can reduce or eliminate costly compression steps.

- Durability & Materials – Titanium stacks extend service life vs. coated alternatives.

- Scalability – Modular units allow easy expansion.

- Integration with Renewables – Ability to handle variable solar/wind power.

- Cost & ROI – Consider both capital cost and lifetime operating expenses.

- Supplier Support – After-sales service, spare parts, and technical assistance.

👉 Asking these questions ensures that businesses choose a solution optimized for performance and profitability.

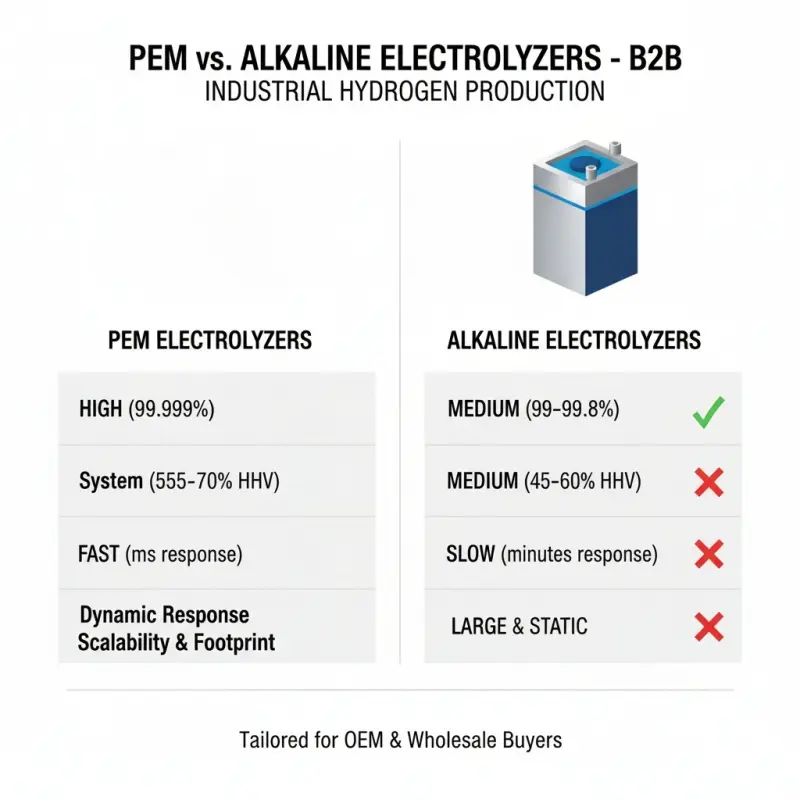

Technical Comparison: PEM vs. Alkaline Electrolyzers

| Feature | PEM Electrolyzers | Alkaline Electrolyzers |

|---|---|---|

| Hydrogen Purity | Very high | Moderate |

| Start-up Time | Seconds to minutes | Hours |

| Footprint | Compact | Larger |

| Efficiency | Higher (60–70%) | Lower (50–60%) |

| Renewable Integration | Excellent | Limited |

| Durability | Higher with titanium | Lower, requires frequent maintenance |

👉 For industries prioritizing scalability, purity, and renewable compatibility, PEM is the superior choice.

Cost Considerations & ROI of PEM Electrolyzers

While initial capital costs of PEM electrolyzers may be higher than alkaline, the total cost of ownership is often lower due to:

- Reduced maintenance requirements

- Higher energy efficiency

- Lower compression costs (due to higher operating pressure)

- Extended lifespan with titanium-based systems

On average, businesses can expect an ROI within 5–8 years, depending on electricity costs and hydrogen demand.

Emerging Trends and Future Outlook

The future of industrial PEM water electrolyzers is promising:

- Scaling to Gigawatt Projects: Global hydrogen hubs are moving from MW to GW capacity.

- AI-Powered Optimization: Predictive maintenance and efficiency tuning.

- Cost Reductions: Economies of scale and material innovations driving down prices.

- Policy Support: Subsidies and tax incentives accelerating adoption worldwide.

PEM electrolysis is poised to become the backbone of the global green hydrogen economy.

Frequently Asked Questions (FAQs)

1. What is the cost of an industrial PEM electrolyzer per MW? Costs vary by supplier and scale but typically range from $800–$1,200 per kW installed capacity.

2. How pure is the hydrogen produced? PEM electrolyzers produce >99.99% pure hydrogen, suitable for fuel cells and sensitive industries.

3. What industries benefit most from PEM electrolysis? Steel, chemicals, energy storage, refineries, mobility, and electronics are top adopters.

4. How long is the delivery lead time from manufacturers? Hele Titanium Hydrogen typically delivers within 8–12 weeks, depending on order size.

5. How does PEM electrolysis compare to alkaline in maintenance? PEM requires less frequent maintenance, especially when using titanium stacks.

6. Can PEM electrolyzers be integrated with solar or wind systems? Yes. PEM is highly flexible, making it ideal for variable renewable energy inputs.

Conclusion & Call-to-Action

Industrial PEM water electrolyzers are no longer niche technology—they’re central to the world’s transition toward green hydrogen. Businesses that adopt PEM systems gain access to efficient, reliable, and scalable hydrogen production while positioning themselves for long-term sustainability.

At Hele Titanium Hydrogen, we deliver next-generation PEM electrolyzers with titanium durability, modular design, and competitive costs, ensuring that our partners achieve both technical excellence and commercial advantage.

👉 Contact us today to request specifications, customization options, and wholesale pricing for your industrial PEM electrolyzer needs.

🔗 Recommended Resource: International Energy Agency – The Future of Hydrogen

Comparison: Hele Titanium Hydrogen vs. Leading PEM Electrolyzer Manufacturers

| Feature | Hele Titanium Hydrogen (China) | Nel Hydrogen (Norway) | ITM Power (UK) | Siemens Energy (Germany) |

|---|---|---|---|---|

| Core Technology | PEM electrolyzers with titanium-based stacks for durability and corrosion resistance | Large-scale PEM & alkaline solutions | Focus on large-scale PEM plants | Integrated energy solutions including PEM |

| Hydrogen Purity | >99.99% (ultra-pure) | 99.9%+ | 99.9%+ | 99.9%+ |

| Stack Lifetime | 15+ years (titanium cell plates extend lifespan) | 10–12 years | 10–12 years | 10–12 years |

| Operating Pressure | Up to 3.0 MPa (high-pressure direct output) | 1.3–2.0 MPa | 1.3–2.0 MPa | 1.5–2.0 MPa |

| System Scalability | Modular systems from 5 Nm³/h to 1,000+ Nm³/h | MW to GW projects | Large-scale GW projects | Primarily MW to GW projects |

| Integration with Renewables | Excellent – rapid response time (seconds) | Excellent | Excellent | Excellent |

| Manufacturing Capacity | Flexible production with fast delivery (8–12 weeks) | Long lead times (6–12 months) | Long lead times (6–9 months) | Long lead times (9–12 months) |

| Customization | High – tailored to customer requirements | Limited (standardized models) | Medium | Medium |

| After-Sales Support | Dedicated engineering support, spare parts, training | Global support centers | Global support centers | Global support centers |

| Capital Cost | Competitive – 20–30% lower than European suppliers | High | High | High |

| Ideal Customers | Industrial plants, labs, refineries, mobility projects seeking cost-effective yet durable solutions | Utility-scale hydrogen hubs | Utility-scale renewable hydrogen projects | Energy companies with integrated renewable projects |

Key Takeaways for Buyers

- Durability Advantage: Hele Titanium Hydrogen uses titanium PEM stacks, extending system lifetime and reducing maintenance costs.

- Cost-Effectiveness: Our systems are typically 20–30% more affordable than European competitors, with no compromise on quality.

- Faster Delivery: While global brands often have long wait times (6–12 months), Hele Titanium Hydrogen delivers in just 8–12 weeks.

- Flexibility: We serve both mid-scale and large-scale customers, unlike competitors who focus mainly on utility-scale mega-projects.

- Custom Solutions: We provide tailored electrolyzer systems for different industries, whereas many global suppliers only offer standard models.

👉 This positions Hele Titanium Hydrogen as the smart, cost-efficient, and reliable partner for businesses that want high-quality industrial PEM water electrolyzers without the inflated costs or long lead times of European suppliers.

Hele Titanium Hydrogen: Your Trusted Hydrogen Generator OEM & Manufacturing Partner

Hele Titanium Hydrogen stands as a reliable and experienced partner in the hydrogen generator OEM supply chain. We specialize in the design, development, and manufacturing of high-performance PEM Water Hydrogen Generators, offering comprehensive OEM & Manufacturing services tailored to your specific needs.

Take the Next Step

Ready to explore the possibilities of partnering with Hele Titanium Hydrogen?

- Browse our Products to see our range of PEM Water Hydrogen Generators.

- Learn more about our Services and how we can support your OEM & Manufacturing needs.

- Contact Us today to discuss your specific requirements.

- Explore our FAQ to get answers to common questions.

- Visit our Blog for the latest insights and updates on hydrogen technology.

Email Us: heletitaniumhydrogen@gmail.com

Phone/WhatsApp: 086-13857402537