In the relentless pursuit of a sustainable future, industries worldwide are facing immense pressure to decarbonize their operations. At the forefront of this green transformation lies clean hydrogen, a versatile energy carrier poised to revolutionize sectors from steel manufacturing and chemical production to heavy transportation and power generation. The demand for large-scale hydrogen production is soaring, creating an urgent need for efficient, reliable, and environmentally responsible methods.

At Hele Titanium Hydrogen, we are not just witnessing this revolution; we are actively engineering its success. As a professional manufacturer and wholesale supplier, we specialize in advanced industrial PEM water electrolyzers – the cutting-edge technology propelling the green industrial revolution. Our mission is to empower businesses like yours with the proven PEM electrolysis technology required for sustainable, cost-effective, and high-purity hydrogen production.

This comprehensive guide is designed for astute OEM buyers, discerning wholesale customers, forward-thinking procurement teams, and strategic investment decision-makers who recognize the unparalleled potential of green hydrogen. Throughout this article, you will discover the technological superiority of Hele’s solutions, delve into the compelling economics of PEM electrolysis, and understand why partnering with us is a strategic imperative for your long-term success.

1. Unlocking Industrial Scale: Hele’s Advanced PEM Electrolyzer Systems

Imagine a future where your industrial operations are powered by clean, domestically produced hydrogen, reducing your carbon footprint, enhancing energy independence, and fortifying your bottom line. This vision is not a distant dream but a present-day reality, made possible by Hele Titanium Hydrogen’s state-of-the-art industrial PEM water electrolyzer installations.

Our systems represent the pinnacle of large-scale hydrogen production capabilities, meticulously engineered to meet the rigorous demands of continuous industrial operation. When you choose Hele, you’re investing in more than just equipment; you’re acquiring a robust, high-capacity, and seamlessly integrated solution for your hydrogen supply needs.

(Image 1: Professional photograph showcasing a modern industrial PEM water electrolyzer installation in a commercial hydrogen production facility. Features large-scale electrolysis stacks, control systems, and hydrogen processing equipment. Perfect for attracting OEM buyers and wholesale customers seeking proven industrial hydrogen solutions. Demonstrates the scale and sophistication of commercial PEM electrolysis technology for B2B procurement decisions.)

Our installations are designed for commercial hydrogen facilities requiring unwavering reliability and performance. Featuring advanced PLC-based control systems for precise operational management and sophisticated hydrogen processing equipment, Hele’s electrolyzers are built to integrate effortlessly into your existing infrastructure. We deliver proven, industrial-grade electrolysis solutions that ensure high-purity hydrogen output, critical for applications ranging from fuel cells to chemical synthesis.

By providing truly proven industrial hydrogen solutions, Hele Titanium Hydrogen actively attracts OEM buyers and wholesale customers who demand nothing less than excellence. Our systems exemplify the scale and sophistication required for critical B2B procurement decisions, making us the preferred partner for businesses committed to a sustainable and efficient future.

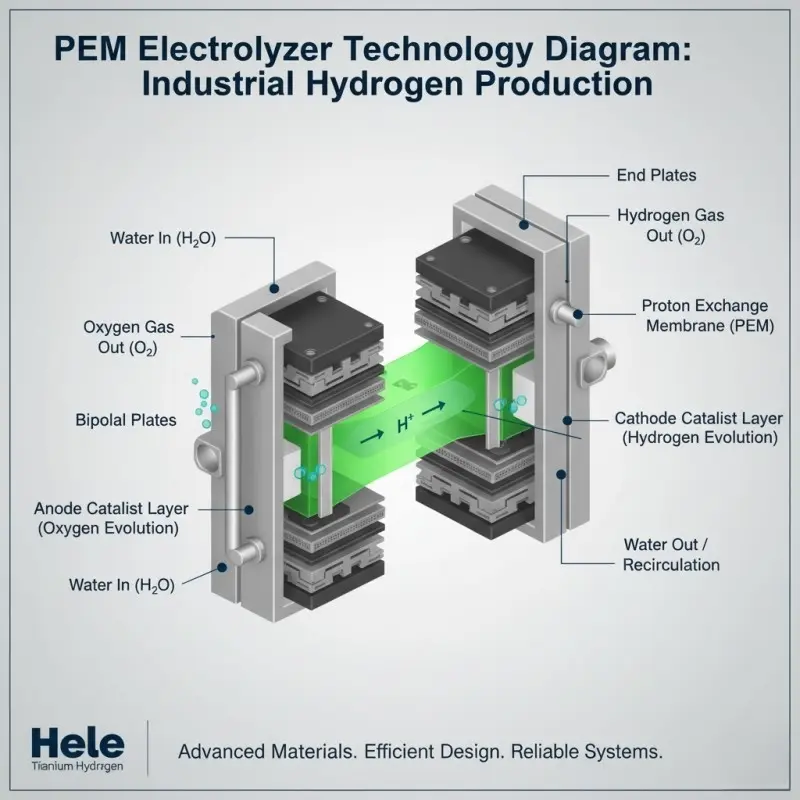

2. The Science Behind the Green: Understanding PEM Electrolyzer Technology

At the heart of every Hele system lies cutting-edge PEM electrolysis technology, meticulously engineered for maximum efficiency, durability, and hydrogen purity. Understanding the fundamental science behind our electrolyzers is key to appreciating their superior performance in demanding industrial environments.

(Image 2: Technical cutaway diagram illustrating PEM electrolyzer core components including proton exchange membrane, catalyst layers, flow fields, and hydrogen separation process. Designed for engineering procurement teams evaluating electrolysis technology options. Highlights advanced materials and efficient design features that appeal to industrial buyers seeking reliable commercial hydrogen systems.)

A Hele PEM electrolyzer utilizes a solid proton exchange membrane (often made from a specialized fluoropolymer material) sandwiched between two electrodes: an anode and a cathode. When deionized water is fed to the anode, and an electrical current is applied, the water molecules split. At the anode, oxygen gas (O₂) and protons (H⁺) are produced. These protons then selectively pass through the proton exchange membrane to the cathode, while electrons travel through an external circuit. At the cathode, the protons recombine with the electrons to form high-purity hydrogen gas (H₂).

Key Components & Their Significance:

- Proton Exchange Membrane (PEM): The core of the technology, facilitating proton transport while preventing the mixing of hydrogen and oxygen gases, ensuring high purity. Our membranes are selected for their durability and high ionic conductivity.

- Catalyst Layers: Typically made of platinum group metals, these layers on either side of the membrane accelerate the electrochemical reactions, maximizing efficiency. Hele utilizes proprietary catalyst formulations for optimal performance and longevity.

- Flow Fields (Bipolar Plates): These precisely engineered plates distribute water to the anode and remove oxygen, while also distributing electrons and collecting hydrogen at the cathode. Hele’s titanium bipolar plates are crucial for corrosion resistance and maintaining system integrity over extended operational cycles.

- Hydrogen Separation Process: Integrated systems efficiently separate the produced hydrogen from water and any residual oxygen, ensuring the high purity levels required for industrial applications.

Our commitment to advanced materials – particularly the use of titanium in critical components – and an efficient design ensures that Hele commercial hydrogen systems offer unparalleled reliability and a significantly extended operational lifespan. This makes our technology particularly appealing to engineering procurement teams evaluating electrolysis technology options, as it promises not only high performance but also robust, long-term operational stability.

3. Strategic Partnership: Why Hele Titanium Hydrogen Stands Out

In a rapidly expanding market for industrial electrolyzer manufacturers, selecting the right partner is paramount. Hele Titanium Hydrogen distinguishes itself through a unique blend of material science, engineering excellence, and an unwavering commitment to customer success. We don’t just supply equipment; we forge strategic partnerships that drive your green hydrogen initiatives forward.

(Image 3: Professional comparison infographic displaying leading industrial PEM electrolyzer manufacturers, their system specifications, capacity ranges, efficiency ratings, and investment costs. Essential visual for procurement managers and engineering teams comparing commercial hydrogen production solutions. Includes Hele Titanium Hydrogen’s competitive positioning for OEM and wholesale partnerships.)

While the market offers various solutions, Hele Titanium Hydrogen’s competitive positioning is defined by several critical advantages:

- The “Hele Titanium Hydrogen” Advantage: Unmatched Durability & Performance: Our commitment to utilizing titanium in critical components isn’t just a naming convention; it’s a testament to our engineering philosophy. Titanium offers superior corrosion resistance compared to other materials, significantly extending the lifespan of our electrolyzer stacks, reducing maintenance frequency, and ensuring consistent high-purity hydrogen output. This translates directly into lower lifecycle costs and greater operational uptime for your facility.

- Precision Engineering & Robust Specifications: Hele’s systems boast leading technical specifications, including optimized capacity ranges, superior efficiency ratings, and exceptional operational stability. We focus on maximizing hydrogen output per unit of energy input, ensuring you get the most value from your investment.

- Customization for Unique Industrial Demands: Unlike one-size-fits-all approaches, Hele specializes in providing custom-engineered solutions. Whether your application involves corrosive environments, high-pressure systems, or requires seamless integration into complex existing process designs, our expert engineering team can tailor a PEM electrolyzer system to your exact specifications.

- Scalability for Future Growth: Our modular designs ensure that Hele commercial hydrogen production solutions are inherently scalable. As your hydrogen demand grows, our systems can be expanded to meet evolving needs, protecting your initial investment and providing flexibility for future growth.

- A Partner for OEM & Wholesale: We actively seek OEM and wholesale partnerships, understanding that long-term success is built on mutual trust and collaboration. Our manufacturing capabilities, quality control, and engineering support are geared towards enabling our partners to deliver superior hydrogen solutions to their end-clients.

For procurement managers and engineering teams meticulously comparing commercial hydrogen production solutions, Hele Titanium Hydrogen offers a distinct and compelling advantage. Our focus on advanced materials, superior efficiency, and long-term operational value positions us as the definitive choice for reliable and sustainable industrial hydrogen.

4. The Business Case for Green Hydrogen: Maximizing Your Investment

Beyond the undeniable environmental benefits, investing in green hydrogen with Hele Titanium Hydrogen delivers significant, measurable financial returns. For CFOs and investment decision-makers, understanding the ROI analysis and cost breakdown is crucial when evaluating large-scale hydrogen production projects. We provide the data-driven insights you need to build a compelling business case.

(Image 4: Data-driven infographic presenting total cost of ownership analysis for industrial PEM electrolyzers including CAPEX, OPEX, payback periods, and financial benefits. Targeted at CFOs and investment decision-makers evaluating large-scale hydrogen production projects. Demonstrates compelling business case for commercial electrolysis technology adoption.)

Our Total Cost of Ownership (TCO) analysis for Hele industrial PEM electrolyzers provides a transparent look at the economic advantages. We consider all critical financial aspects:

- CAPEX (Capital Expenditure): This includes the cost of the electrolyzer system itself, power electronics (rectifiers), water treatment units, hydrogen purification units, and the initial installation and infrastructure development. Hele’s competitive pricing combined with the long lifespan of our titanium-enhanced systems ensures a robust starting point for your investment.

- OPEX (Operational Expenditure): This primarily covers electricity consumption (the largest variable cost), routine maintenance, and consumables. Hele’s high-efficiency PEM technology minimizes electricity usage, while the durability of our components significantly reduces maintenance costs and downtime.

Key Financial Benefits of Investing in Hele PEM Electrolyzers:

- Accelerated Payback Periods: Our systems are designed for optimal economic performance, leading to shorter payback periods and quicker returns on your investment. The rising cost of traditional hydrogen sources and the increasing value of green credentials further enhance this.

- Reduced Energy Costs: By leveraging renewable energy sources to power our electrolyzers, you can insulate your operations from volatile fossil fuel prices, leading to stable and predictable hydrogen production costs.

- Carbon Credit Opportunities: Depending on your region, producing green hydrogen can open avenues for carbon credits or other environmental incentives, further enhancing your project’s financial viability.

- Enhanced Energy Independence: Producing hydrogen on-site reduces reliance on external suppliers, mitigating supply chain risks and offering greater operational control.

- Long-Term Value Creation: The extended lifespan and low maintenance requirements of Hele’s titanium-enhanced systems ensure sustained economic benefits over decades of operation.

Hele Titanium Hydrogen offers a compelling business case for commercial electrolysis technology adoption. Our solutions are not just environmentally sound; they are financially astute, designed to maximize your investment and secure your competitive edge in the evolving energy landscape.

5. Proven Success: Real-World Industrial Applications

Credibility in the B2B sector is built on demonstrable results. Hele Titanium Hydrogen solutions are not theoretical; they are deployed and performing successfully across demanding industrial sectors, proving their reliability and efficiency in real-world conditions. Our industrial hydrogen production case study insights showcase our ability to integrate seamlessly and deliver tangible benefits.

(Image 5: Detailed case study visualization showing successful PEM electrolyzer deployment in steel industry application. Features process flow diagram, performance metrics, and environmental benefits. Builds credibility with industrial buyers by demonstrating proven results in demanding commercial applications. Appeals to procurement teams seeking validated industrial hydrogen solutions.)

While the image highlights the steel industry, a sector aggressively pursuing decarbonization, our PEM electrolyzers are equally impactful in various applications:

- Steel Manufacturing: Integrating green hydrogen as a reducing agent replaces coal and natural gas, drastically cutting carbon emissions in a traditionally high-emission industry. Our systems provide the high-purity hydrogen required for Direct Reduced Iron (DRI) processes.

- Ammonia Production: Green hydrogen is a key feedstock for green ammonia synthesis, critical for sustainable fertilizer production and as a potential clean fuel.

- Chemical & Petrochemical Industries: Supplying high-purity hydrogen for various chemical reactions, hydrogenation processes, and as a utility gas, replacing grey hydrogen sources.

- Refineries: Utilizing green hydrogen for hydrotreating and hydrocracking processes to produce cleaner fuels.

- Power-to-X Applications: Storing excess renewable electricity as hydrogen, which can then be converted back to power, used in industry, or for synthetic fuels.

Key Performance Metrics & Benefits Observed in Our Case Studies:

- High Purity Output: Consistently delivering hydrogen purity exceeding 99.999%, essential for sensitive industrial processes.

- Exceptional Efficiency: Our systems maintain high energy efficiency, translating directly to lower operational costs.

- Outstanding Operational Uptime: Engineered for continuous, reliable operation, minimizing downtime and ensuring consistent hydrogen supply.

- Significant CO₂ Emission Reduction: Directly contributing to your sustainability goals and regulatory compliance by eliminating Scope 1 and Scope 2 emissions associated with traditional hydrogen production.

- Cost Savings: Reducing reliance on purchased hydrogen and capitalizing on the decreasing cost of renewable electricity.

Hele Titanium Hydrogen builds credibility with industrial buyers by showcasing our proven results in demanding commercial applications. For procurement teams seeking validated industrial hydrogen solutions, our case studies offer compelling evidence of our capability and reliability.

6. Comprehensive Solutions: From Concept to Commissioning

Deploying a commercial PEM electrolyzer system requires a holistic approach, far beyond just the core electrolysis stacks. Hele Titanium Hydrogen provides complete, integrated solutions, ensuring a seamless experience from initial design to successful commissioning and ongoing operation. We are your partner for a true turnkey solution.

(Image 6: Technical layout diagram showing complete industrial PEM electrolyzer system including electrolysis stacks, power electronics, water treatment, hydrogen purification, compression, and safety systems. Essential reference for engineering teams planning commercial hydrogen installations. Demonstrates comprehensive solution capability attractive to B2B customers seeking turnkey systems.)

Our approach encompasses all essential commercial PEM electrolyzer system components required for a robust industrial hydrogen production facility design:

- Electrolysis Stacks: The core hydrogen generation units, leveraging our advanced PEM technology and titanium components for unparalleled performance and longevity.

- Power Electronics & Rectifiers: Sophisticated power conversion systems that efficiently convert incoming AC power into the precise DC power required by the electrolyzer stacks, ensuring optimal energy utilization.

- Water Treatment Systems: Critical for preparing the feed water (deionized water) to protect the membrane and catalyst layers, ensuring high purity and extending system life.

- Hydrogen Purification Units: Further processing to remove any trace impurities, guaranteeing the ultra-high purity hydrogen required for sensitive industrial applications.

- Hydrogen Compression Systems: Custom-designed compression units to deliver hydrogen at the required pressure for storage, pipeline injection, or direct process use.

- Advanced Control & Safety Systems: Integrated PLC-based control systems for automated operation, real-time monitoring, and comprehensive safety protocols (including leak detection, emergency shutdowns, and interlocking systems) to ensure secure and reliable operation.

Hele Titanium Hydrogen offers a comprehensive solution capability that is highly attractive to B2B customers seeking turnkey systems. For engineering teams planning commercial hydrogen installations, our detailed layouts and proven component integration serve as an essential reference, simplifying procurement and accelerating project timelines. We handle the complexity so you can focus on your core business.

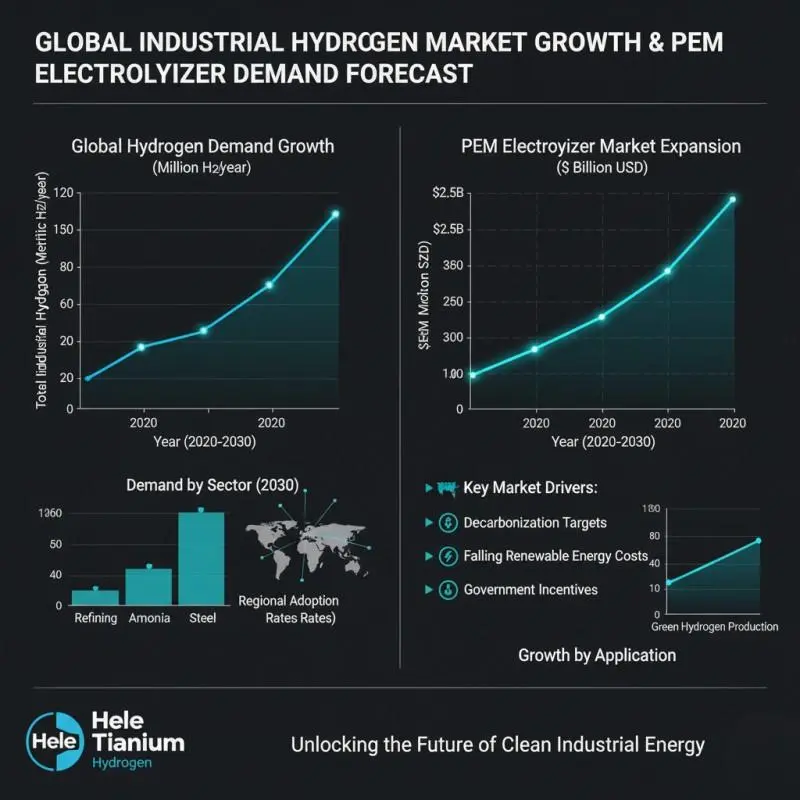

7. Riding the Wave: Global Market Trends & Future Demand

The landscape of industrial energy is undergoing a profound transformation, with industrial hydrogen market growth at its epicenter. Understanding these global market trends and the surging PEM electrolyzer demand forecast is crucial for businesses looking to future-proof their operations and capitalize on new opportunities. Hele Titanium Hydrogen is strategically positioned at the forefront of this expansion.

(Image 7: Professional market analysis chart showing global industrial hydrogen demand growth, regional adoption rates, and PEM electrolyzer market expansion projections through 2030. Supports business case development for industrial buyers and investors. Highlights market opportunities driving commercial electrolysis technology investment decisions.)

The projected global industrial hydrogen demand growth is staggering, driven by a confluence of factors:

- Decarbonization Targets: Governments and corporations worldwide are setting ambitious net-zero targets, making green hydrogen indispensable for heavy industries.

- Falling Renewable Energy Costs: The declining cost of solar and wind power directly makes green hydrogen production more economically viable and competitive.

- Government Incentives & Policies: Supportive policies, subsidies, and regulatory frameworks are accelerating the adoption of commercial applications of green hydrogen.

- Energy Security: On-site green hydrogen production enhances national and corporate energy independence, reducing reliance on volatile fossil fuel imports.

- Technological Advancements: Continuous innovation in PEM technology, including by Hele Titanium Hydrogen, is improving efficiency and reducing costs.

The PEM electrolyzer market expansion projections through 2030 show a robust upward trend, with significant market opportunities across various regions and industrial sectors. This growth underscores the necessity for industrial buyers and investors to integrate commercial electrolysis technology into their long-term strategies.

Hele Titanium Hydrogen offers not just technology, but a strategic partnership to navigate this evolving market. Our solutions are designed to scale with demand, ensuring your operations remain competitive and sustainable as the green hydrogen economy flourishes.

8. Uncompromising Safety & Compliance: Your Peace of Mind

In industrial environments, safety is paramount. When dealing with hydrogen, an uncompromising commitment to the highest safety standards and regulatory compliance is not just an advantage – it’s a non-negotiable requirement. Hele Titanium Hydrogen prioritizes industrial PEM electrolyzer safety standards and ensures our systems meet rigorous compliance certifications for commercial hydrogen production.

(Image 8: Professional diagram highlighting industrial safety standards, compliance certifications, and risk management protocols for commercial PEM electrolyzer installations. Critical information for procurement teams evaluating vendor capabilities and regulatory compliance. Demonstrates commitment to industrial-grade safety standards expected by B2B customers.)

Our dedication to safety is embedded in every stage of design, manufacturing, installation, and operation. Hele’s systems adhere to and often exceed, the most stringent international and regional safety regulations, providing you with absolute peace of mind:

- Global Safety Standards:

- ISO 22734:2019 (Hydrogen Generators): Our electrolyzers are designed and manufactured in accordance with this essential standard for hydrogen generators using water electrolysis.

- IEC 61200-series (Electrolyzer Safety): We follow the comprehensive IEC standards related to the safety of electrolyzers, ensuring electrical, mechanical, and operational safety.

- Local Electrical & Pressure Vessel Codes: Compliance with specific national and regional codes (e.g., ASME, PED, etc.) relevant to the installation site.

- ISO 22734:2019 (Hydrogen Generators): Our electrolyzers are designed and manufactured in accordance with this essential standard for hydrogen generators using water electrolysis.

- Key Certifications & Approvals:

- CE Mark (European Conformity): Demonstrating compliance with health, safety, and environmental protection standards for products sold within the European Economic Area.

- UL (Underwriters Laboratories) Certification: For systems deployed in North America, signifying that products meet specific safety standards.

- TÜV SÜD (System Validation): Independent third-party validation for critical system components and overall system design.

- ATEX / IECEx (Explosion Proof): Where applicable, our systems meet standards for equipment intended for use in potentially explosive atmospheres, crucial for hydrogen handling.

- CE Mark (European Conformity): Demonstrating compliance with health, safety, and environmental protection standards for products sold within the European Economic Area.

- Robust Risk Management Protocols:

- FMEA (Failure Mode and Effects Analysis) & SIL (Safety Integrity Level) Analysis: Proactive identification and mitigation of potential failure modes and assessment of safety system performance.

- HAZID / IHOP Studies: Comprehensive hazard identification and operational analysis during the design phase.

- Emergency Shutdown (ESD) Systems: Redundant and fail-safe ESD systems for rapid and secure system shutdown in abnormal conditions.

- Redundancy & Fail-Safe Design: Implementing design principles that ensure system integrity even in the event of component failure.

- FMEA (Failure Mode and Effects Analysis) & SIL (Safety Integrity Level) Analysis: Proactive identification and mitigation of potential failure modes and assessment of safety system performance.

This robust framework is critical information for procurement teams evaluating vendor capabilities and regulatory compliance. By partnering with Hele Titanium Hydrogen, you are choosing a supplier that demonstrates an unwavering commitment to industrial-grade safety standards – a fundamental expectation of all B2B customers in the industrial sector.

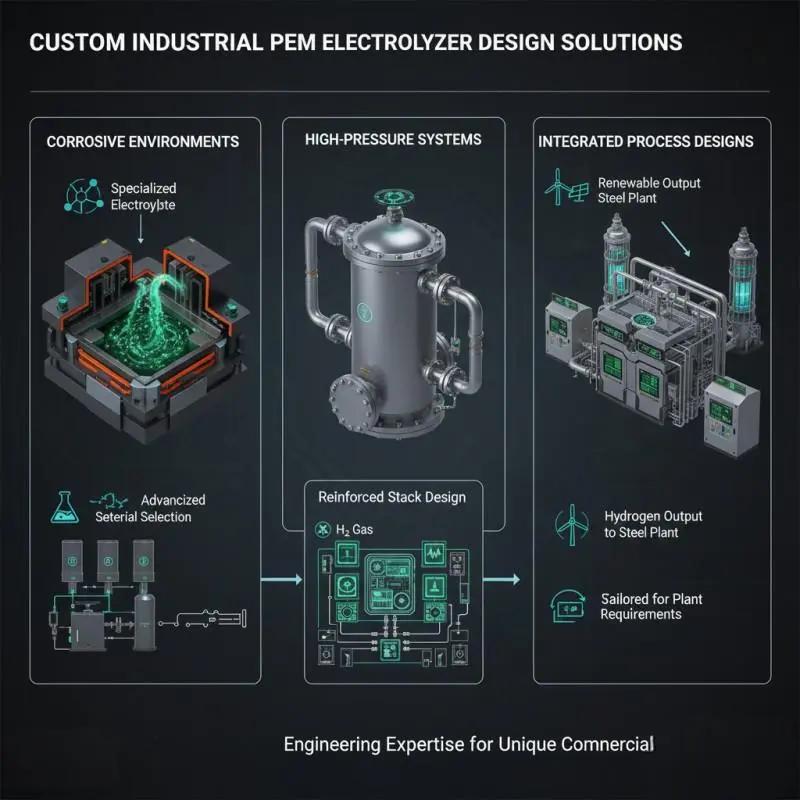

9. The Hele Advantage: Engineering Excellence & Manufacturing Prowess

Our ability to deliver industry-leading industrial PEM water electrolyzers stems directly from our core strengths: unparalleled engineering excellence and a world-class manufacturing infrastructure. Hele Titanium Hydrogen is more than a supplier; we are innovators with a deep understanding of material science and electrochemical processes.

(Image 9: High-quality photograph of Hele Titanium Hydrogen’s modern manufacturing facility showcasing advanced PEM electrolyzer production capabilities, quality control systems, and engineering expertise. Builds trust with potential OEM partners and wholesale buyers by demonstrating manufacturing scale and professional capabilities. Highlights custom engineering and direct factory advantages for B2B customers.)

Our state-of-the-art OEM manufacturing facility is the bedrock of our commitment to quality and innovation. Here’s what sets us apart:

- Advanced Production Capabilities: We utilize precision machinery, automated processes, and advanced fabrication techniques to ensure every component of our PEM electrolyzers meets exacting standards. Our manufacturing scale allows us to efficiently produce units for large-scale hydrogen production projects.

- Rigorous Quality Control Systems: From incoming raw materials (especially our titanium components) to final assembly and factory acceptance testing (FAT), every stage undergoes stringent quality checks. This meticulous attention to detail ensures the reliability and longevity that defines Hele products.

- Deep Engineering Expertise: Our team of electrochemical engineers, material scientists, and process automation specialists are at the forefront of PEM technology development. This engineering expertise allows us to push the boundaries of efficiency and durability.

Beyond our standard product lines, Hele Titanium Hydrogen excels in delivering custom-engineered PEM electrolyzer solutions for the most specialized industrial applications. We understand that every industrial process has unique requirements, and a one-size-fits-all approach is rarely optimal.

. (Image 10: Technical illustration showcasing custom-engineered PEM electrolyzer solutions for specialized industrial applications including corrosive environments, high-pressure systems, and integrated process designs. Appeals to industrial buyers requiring tailored solutions beyond standard offerings. Demonstrates Hele Titanium Hydrogen’s engineering expertise and flexibility for unique commercial requirements.)

Our custom engineering capabilities extend to:

- Corrosive Environments: Designing and fabricating systems with enhanced material selections (e.g., specialized alloys, advanced coatings) to withstand harsh chemical or environmental conditions.

- High-Pressure Systems: Engineering electrolyzers and balance-of-plant components for high-pressure hydrogen output, reducing the need for extensive downstream compression.

- Integrated Process Designs: Seamlessly incorporating our electrolyzers into existing industrial process flows, optimizing energy recovery, heat integration, and overall operational synergy. This is crucial for achieving maximum efficiency in complex manufacturing facilities.

- Space-Constrained Installations: Developing compact, modular designs that maximize hydrogen output in limited footprints, common in urban industrial areas or offshore platforms.

This blend of manufacturing scale, professional capabilities, and custom engineering flexibility builds immense trust with potential OEM partners and wholesale buyers. It highlights the direct factory advantages of partnering with Hele Titanium Hydrogen, offering tailored solutions and expert guidance for unique commercial requirements that standard offerings cannot address.

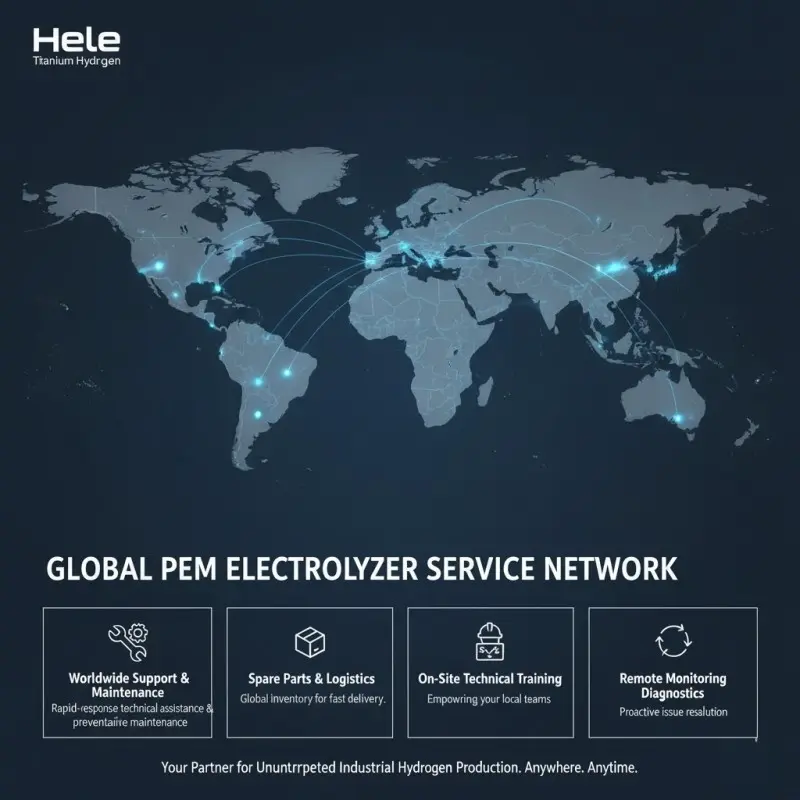

10. Global Reach, Local Support: Hele’s Worldwide Service Network

Investing in industrial PEM water electrolyzers is a long-term commitment. At Hele Titanium Hydrogen, our partnership extends far beyond the point of sale. We understand that continuous, reliable operation is critical for your business, which is why we have established a robust global PEM electrolyzer service network providing comprehensive industrial support and maintenance worldwide for all our commercial hydrogen systems.

(Image 11: World map visualization showing global service network coverage for industrial PEM electrolyzer support, maintenance, and technical assistance. Reassures international B2B buyers about ongoing support availability for commercial hydrogen systems. Demonstrates commitment to customer success and operational reliability expected by industrial procurement teams.)

Our extensive service network is designed to minimize downtime and maximize the operational efficiency of your Hele electrolyzers, wherever you are located:

- Rapid-Response Technical Assistance: Our dedicated support teams are available to provide immediate technical guidance, troubleshooting, and remote diagnostics, ensuring quick resolution of any operational issues.

- Preventative Maintenance Programs: We offer tailored preventative maintenance schedules to optimize system performance, extend equipment lifespan, and prevent costly unplanned outages.

- Global Spare Parts & Logistics: With strategically located inventory hubs, we ensure the swift delivery of genuine Hele spare parts, minimizing lead times and keeping your operations running smoothly.

- On-Site Support & Field Service: Our highly trained and certified field service engineers are available for on-site support, complex repairs, system upgrades, and routine maintenance, bringing expert assistance directly to your facility.

- Operator Training & Empowerment: We provide comprehensive training programs for your operational staff, empowering your teams with the knowledge and skills to confidently manage and maintain your Hele electrolyzer systems.

- Remote Monitoring & Diagnostics: For enhanced proactive support, our systems can be equipped with remote monitoring capabilities, allowing our experts to anticipate potential issues and provide preventative solutions.

This robust global service network effectively reassures international B2B buyers about ongoing support availability for their commercial hydrogen systems. It demonstrates Hele Titanium Hydrogen’s unwavering commitment to customer success and operational reliability – a critical factor for industrial procurement teams making strategic investment decisions. We are your reliable partner, ensuring your green hydrogen infrastructure operates flawlessly for decades to come.

11. Partner with Hele Titanium Hydrogen: Your Future in Green Hydrogen

The global energy transition is here, and green hydrogen is the catalyst for a sustainable industrial future. By partnering with Hele Titanium Hydrogen, you’re not just acquiring leading-edge industrial PEM water electrolyzers; you’re investing in a future of reduced carbon footprint, enhanced operational efficiency, and long-term economic stability. We have meticulously detailed our commitment to:

- Technological Superiority: Through our “Titanium Hydrogen” advantage and advanced PEM electrolysis.

- Proven Performance: Backed by real-world case studies and rigorous testing.

- Financial Advantage: Demonstrating compelling ROI and reduced TCO.

- Uncompromising Safety & Compliance: Ensuring peace of mind for your operations.

- Comprehensive Turnkey Solutions: From custom engineering to global support.

Our expertise as a professional manufacturer and wholesale supplier of PEM water hydrogen generators makes us the ideal partner for your large-scale hydrogen production projects. We understand the complexities of the industrial landscape and are equipped to deliver tailored, high-quality, and reliable solutions that meet your precise requirements.

(Image 12: Professional call-to-action graphic encouraging B2B prospects to request technical consultation, custom quotes, and engineering support for industrial PEM electrolyzer projects. Features clear contact information, response time commitments, and value propositions. Designed to convert website visitors into qualified leads for commercial hydrogen system inquiries.)

Are you ready to elevate your industrial operations with the power of green hydrogen? Are you an OEM looking for a reliable, high-quality component supplier, or a wholesale distributor seeking a partner with proven technology and extensive support? Hele Titanium Hydrogen is poised to be your strategic ally.

We invite you to take the next step towards a sustainable and profitable future.

Request Your Industrial PEM Electrolyzer Consultation and Custom Quote Today!

At Hele Titanium Hydrogen, we make it easy for B2B prospects to access the expertise and solutions they need. Our team is ready to provide:

- Technical Consultation: Engage directly with our electrochemical engineers and material scientists. We’ll discuss your specific operational challenges, hydrogen demand, energy sources, and integration requirements. Our goal is to provide tailored advice and solutions that align perfectly with your project objectives.

- Custom Quotes: Receive a detailed, transparent, and competitive quotation for a Hele industrial PEM water electrolyzer system configured precisely for your facility. We account for all aspects, from system specifications to installation support and long-term service agreements.

- Engineering Support: Leverage our deep engineering expertise to optimize your project design. From feasibility studies to detailed integration plans, our team is here to ensure seamless deployment and efficient operation of your commercial hydrogen production system.

Why Connect with Hele Titanium Hydrogen Now?

- Fast Response: We commit to responding to all industrial inquiries within 24 hours, understanding the fast pace of your business decisions.

- Expert Guidance: Our consultations are not just sales pitches; they are opportunities for you to gain valuable insights from industry leaders.

- Tailored Solutions: We don’t believe in one-size-fits-all. Your solution will be engineered to your precise needs.

- Direct Factory Advantage: Benefit from direct communication, competitive pricing, and efficient project execution as you partner directly with the manufacturer.

Don’t let this opportunity pass you by. The demand for green hydrogen is accelerating, and the time to act is now. Position your business at the forefront of the clean energy transition with Hele Titanium Hydrogen.

Get Started Today!

Visit our Website for more information: www.heletitaniumhydrogen.com

Email us directly for inquiries: sales@heletitaniumhydrogen.com

Or call our dedicated B2B line: 086-13857402537

Hele Titanium Hydrogen: Your Partner for Proven Industrial Hydrogen Solutions.