The energy sector is experiencing a revolutionary transformation, and hydrogen generators are at the forefront of this change. As industries worldwide grapple with the urgent need for cleaner, more sustainable power solutions, hydrogen technology has emerged as a game-changing alternative that’s reshaping how we think about energy production and storage.

Introduction to Hydrogen Generation Technology

What Are Hydrogen Generators?

Hydrogen generators are sophisticated devices that produce clean hydrogen gas through various methods, with electrolysis being the most prominent. These systems split water molecules into hydrogen and oxygen using electrical energy, creating a clean fuel source that can power everything from industrial facilities to entire power grids.

Modern hydrogen generators have evolved far beyond simple laboratory equipment. Today’s commercial-grade systems are engineered for reliability, efficiency, and scalability, making them viable solutions for large-scale energy applications. The technology has matured to the point where businesses can integrate hydrogen generation directly into their operations, reducing dependence on traditional energy sources while significantly lowering their carbon footprint.

The Science Behind PEM Water Electrolysis

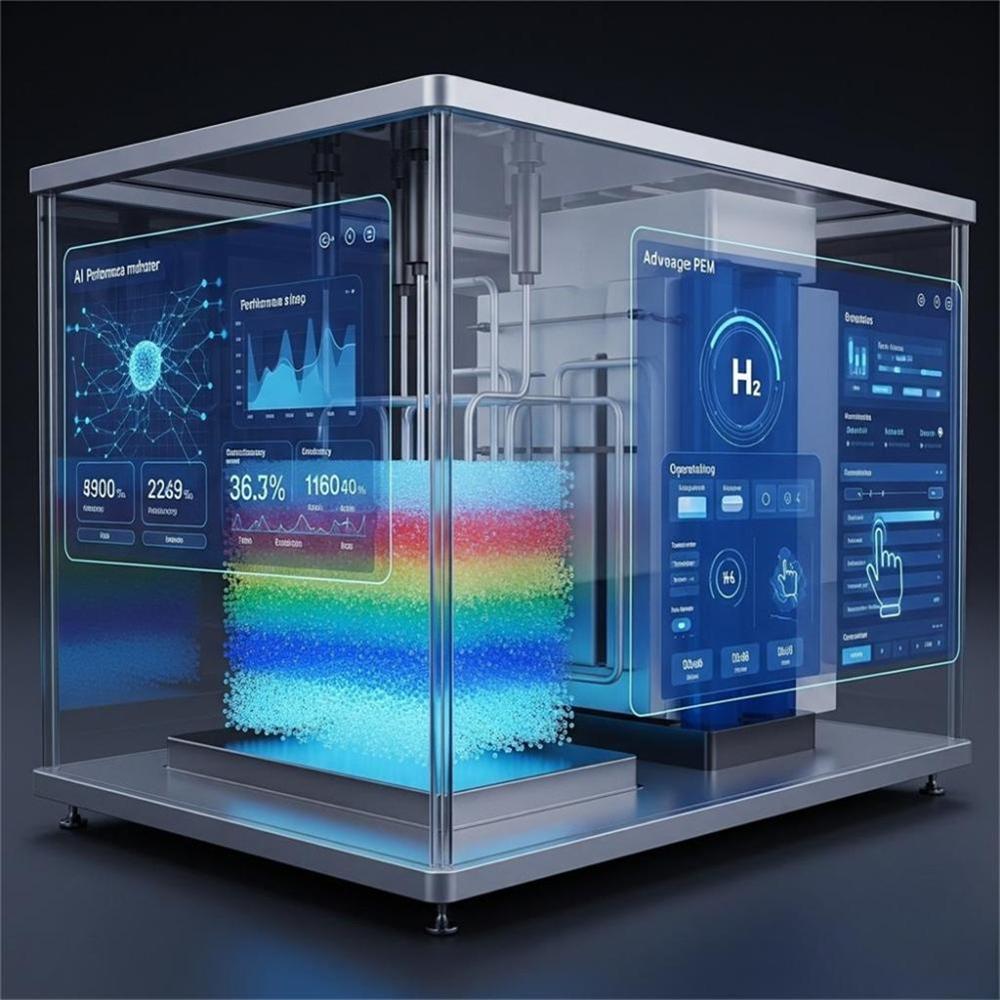

Proton Exchange Membrane (PEM) electrolysis represents the cutting edge of hydrogen generation technology. This process uses a specialized membrane that allows protons to pass through while blocking electrons, creating an efficient pathway for hydrogen production. When electricity is applied to water in a PEM electrolyzer, it separates into hydrogen at the cathode and oxygen at the anode.

What makes PEM technology particularly attractive for energy sector applications is its ability to respond quickly to varying power inputs. This characteristic makes it ideal for integrating with renewable energy sources like solar and wind, where power generation can fluctuate throughout the day. The rapid response capability allows energy companies to convert excess renewable electricity into storable hydrogen fuel during peak production periods.

The Current Energy Landscape and the Need for Change

Traditional Energy Sources and Their Limitations

The global energy sector has long relied on fossil fuels, but this dependence comes with significant drawbacks. Coal, natural gas, and oil-based power generation not only contribute to greenhouse gas emissions but also face volatility in pricing and supply chain disruptions. Energy companies are increasingly recognizing that diversification is not just environmentally responsible—it’s essential for business continuity.

Traditional power plants also struggle with flexibility issues. They can’t easily scale production up or down to match demand fluctuations, leading to inefficiencies and waste. This inflexibility becomes even more problematic as renewable energy sources become more prevalent, creating a need for storage solutions that can bridge the gap between variable supply and consistent demand.

Environmental Impact of Fossil Fuels

The environmental consequences of fossil fuel dependence extend far beyond carbon emissions. Air quality degradation, water contamination, and ecosystem disruption are just some of the collateral effects that energy companies must now factor into their operational planning. Regulatory pressure is mounting globally, with governments implementing stricter emissions standards and carbon pricing mechanisms.

Carbon Emissions and Climate Change

The energy sector accounts for approximately 75% of global greenhouse gas emissions, making it the single largest contributor to climate change. This statistic has put enormous pressure on energy companies to find cleaner alternatives. Hydrogen generators offer a pathway to dramatically reduce these emissions while maintaining the reliable power output that modern society demands.

Hydrogen as a Game-Changer in Energy Production

Why Hydrogen is Called the Fuel of the Future

Hydrogen’s unique properties make it an ideal energy carrier for the modern world. It’s the most abundant element in the universe, it can be produced from various sources including renewable electricity, and when used as fuel, it produces only water vapor as a byproduct. This combination of abundance, versatility, and cleanliness positions hydrogen as a cornerstone of future energy systems.

The energy density of hydrogen is remarkable—it contains about three times more energy per unit mass than gasoline. This characteristic makes it particularly valuable for applications requiring long-duration energy storage or high-power output. Energy companies are discovering that hydrogen can serve multiple roles: as a fuel for power generation, as a storage medium for excess renewable energy, and as a feedstock for various industrial processes.

Clean Energy Benefits of Hydrogen

When hydrogen is produced using renewable electricity through electrolysis, the entire fuel cycle becomes carbon-neutral. This process, known as “green hydrogen” production, represents the ultimate goal for many energy companies looking to achieve net-zero emissions. The hydrogen can then be stored indefinitely without degradation, used immediately for power generation, or transported to where it’s needed most.

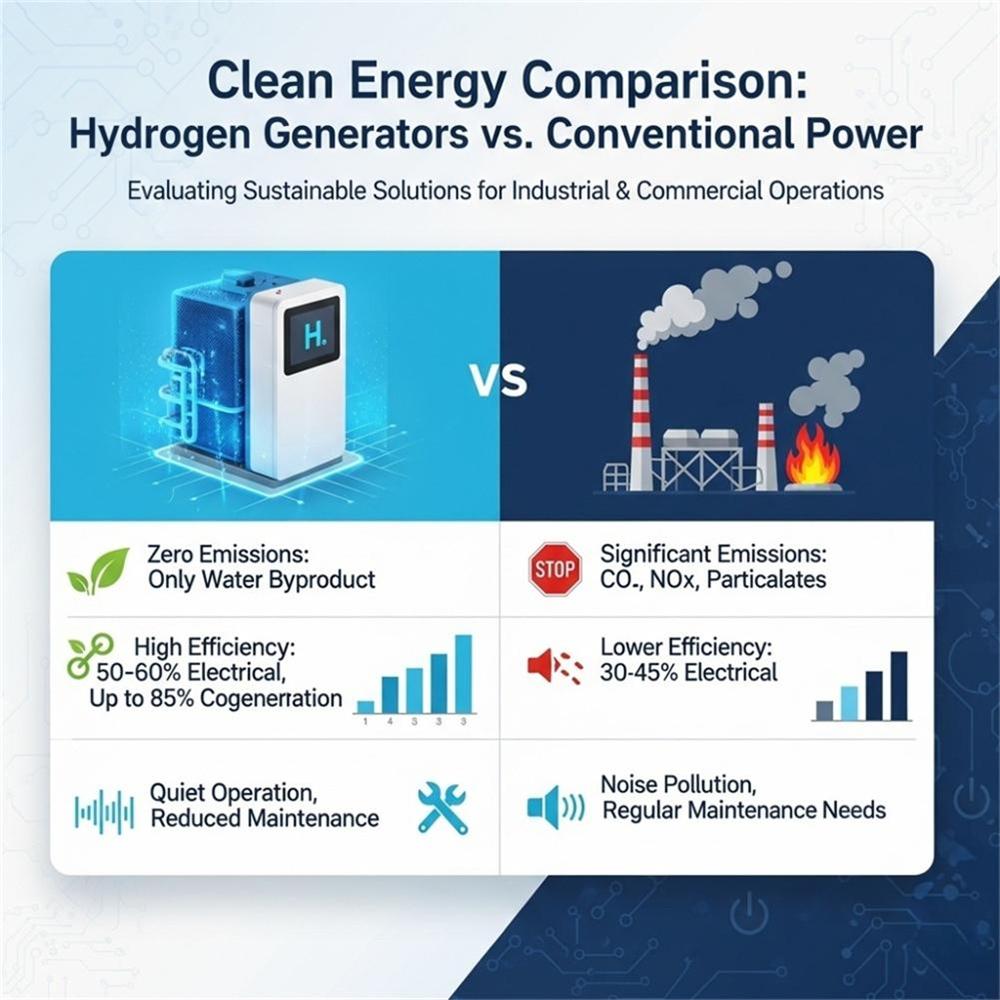

Zero-Emission Power Generation

Hydrogen fuel cells and hydrogen-powered turbines produce electricity with water vapor as the only emission. This zero-emission characteristic is particularly valuable for energy companies operating in urban areas or environmentally sensitive regions where air quality regulations are stringent. The technology allows these companies to maintain their power output while dramatically improving their environmental profile.

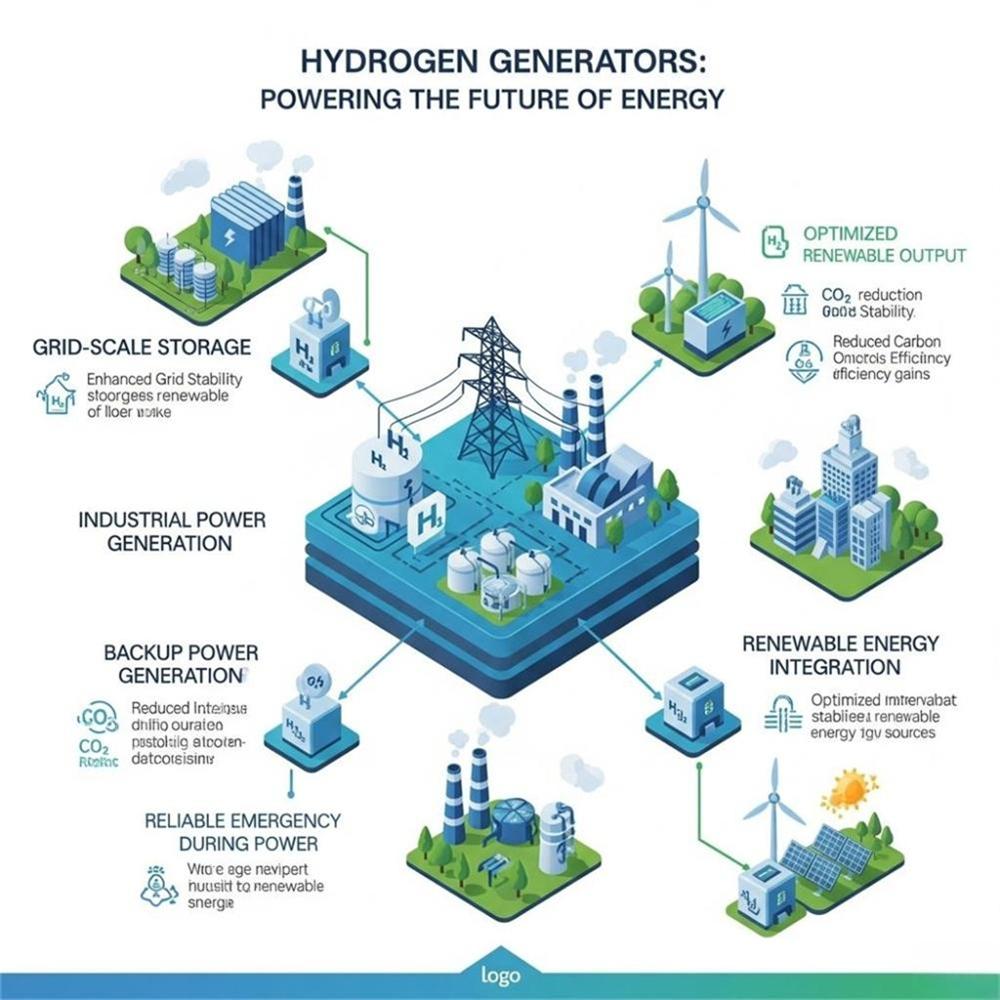

Applications of Hydrogen Generators in the Energy Sector

Industrial Power Generation

Large-scale industrial facilities are increasingly turning to hydrogen generators to meet their power needs. Manufacturing plants, data centers, and processing facilities require consistent, reliable power that traditional renewable sources alone cannot provide. Hydrogen generators bridge this gap by converting excess renewable electricity into storable hydrogen fuel during low-demand periods, then generating clean electricity when it’s needed most.

The scalability of hydrogen generation systems makes them particularly attractive for industrial applications. Facilities can start with smaller systems and expand their hydrogen production capacity as their energy needs grow. This modular approach reduces initial capital investment while providing a clear pathway for future expansion.

Grid-Scale Energy Storage Solutions

One of the most promising applications for hydrogen generators in the energy sector is grid-scale storage. Traditional battery storage systems are limited by capacity and duration constraints, but hydrogen storage can provide long-term energy storage solutions measured in weeks or months rather than hours or days.

Energy companies are deploying hydrogen generators to capture excess renewable energy during peak production periods. This stored hydrogen can then be converted back to electricity during periods of high demand or low renewable generation. The process creates a buffer that stabilizes the grid and maximizes the utilization of renewable energy resources.

Backup Power Systems

Reliability is paramount in the energy sector, and hydrogen generators are proving invaluable as backup power systems. Unlike diesel generators, which require regular maintenance and fuel deliveries, hydrogen systems can operate for extended periods with minimal intervention. They’re particularly valuable for critical infrastructure where power interruptions can have serious consequences.

Emergency Power for Critical Infrastructure

Hospitals, data centers, telecommunications facilities, and other critical infrastructure require uninterrupted power supply. Hydrogen generators provide a clean, reliable backup power solution that can operate for days or weeks without refueling. This capability is especially important in remote locations where fuel delivery might be challenging during emergencies.

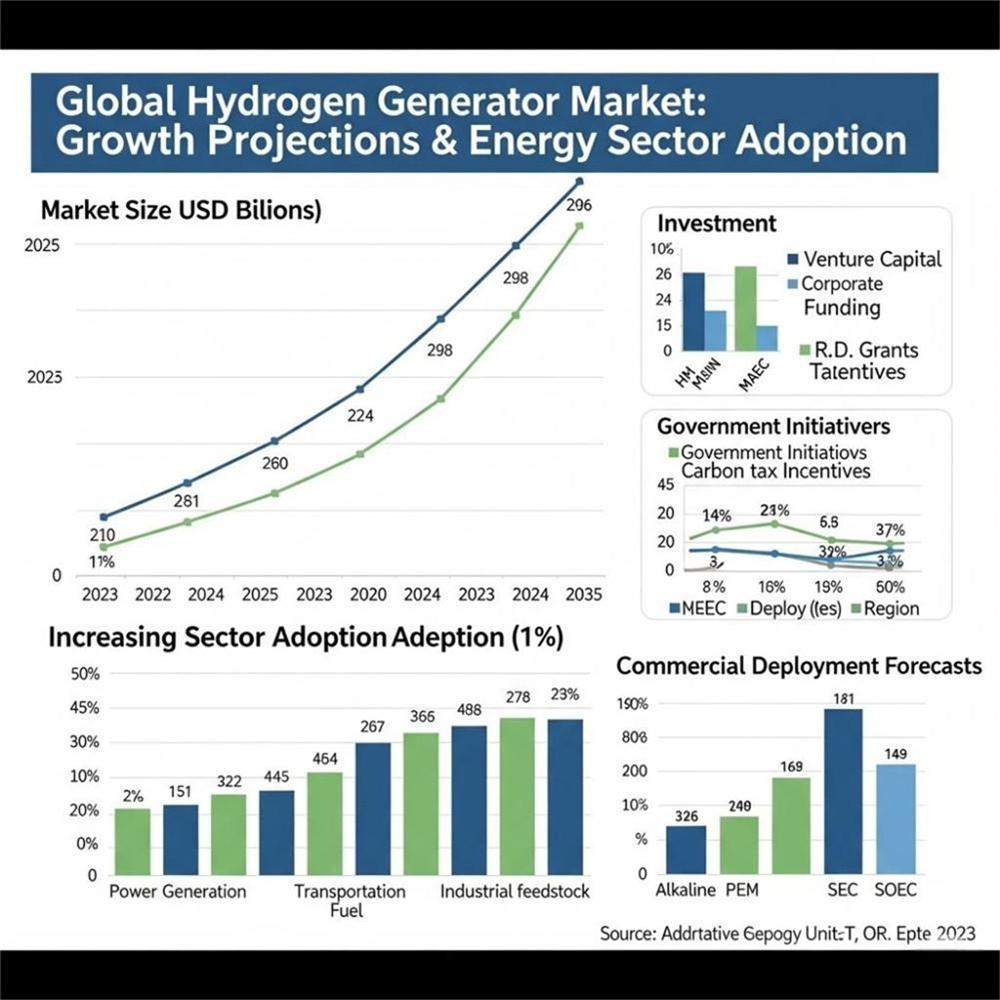

Market Growth and Industry Forecasts

Global Hydrogen Generator Market Size

The hydrogen generator market has experienced explosive growth in recent years, with industry analysts projecting continued expansion through the next decade. Market research indicates that the global hydrogen generation market could reach $200 billion by 2030, driven primarily by energy sector adoption and supportive government policies.

This growth is being fueled by declining equipment costs, improving efficiency, and increasing recognition of hydrogen’s role in decarbonizing the energy sector. Major energy companies are allocating significant portions of their capital expenditure budgets to hydrogen projects, signaling a fundamental shift in industry priorities.

Investment Trends in Hydrogen Technology

Venture capital and private equity investments in hydrogen technology companies have surged, with billions of dollars flowing into the sector annually. Energy companies are not just purchasing hydrogen equipment—they’re investing in hydrogen technology companies, forming strategic partnerships, and developing in-house expertise to position themselves for the hydrogen economy.

Government Initiatives and Policy Support

Governments worldwide are implementing policies that support hydrogen adoption in the energy sector. These include production subsidies, tax incentives, and renewable energy standards that recognize hydrogen as a clean energy solution. The European Union’s hydrogen strategy, the United States’ hydrogen hubs program, and similar initiatives in Asia are creating a favorable policy environment for hydrogen generator deployment.

Technological Advancements in Hydrogen Generation

PEM Technology Improvements

Recent advances in PEM electrolyzer technology have significantly improved efficiency and reduced costs. New membrane materials, advanced catalyst formulations, and optimized system designs have increased hydrogen production rates while extending equipment lifespan. These improvements make hydrogen generators more economically attractive for energy sector applications.

Manufacturing processes for PEM electrolyzers have also been refined, enabling mass production that drives down unit costs. Energy companies can now deploy hydrogen generation systems at price points that make economic sense for a wide range of applications.

Efficiency Gains and Cost Reductions

Modern hydrogen generators achieve electrical-to-hydrogen conversion efficiencies exceeding 80%, representing a significant improvement over earlier systems. These efficiency gains translate directly to lower operating costs and improved return on investment for energy companies. Additionally, the integration of smart control systems allows hydrogen generators to optimize their operation based on electricity prices and demand patterns.

Titanium-Based Electrode Technology

Advanced electrode materials, particularly titanium-based solutions, have revolutionized hydrogen generator performance. Titanium electrodes offer superior corrosion resistance, longer service life, and improved electrical conductivity compared to traditional materials. These advantages are particularly important for continuous operation in industrial energy applications where downtime can be costly.

Case Studies: Real-World Energy Sector Applications

Renewable Energy Integration Projects

Several major energy companies have successfully integrated hydrogen generators into their renewable energy portfolios. These projects demonstrate how hydrogen technology can smooth out the intermittency issues associated with solar and wind power. During periods of high renewable generation, excess electricity is used to produce hydrogen. When renewable output drops, the stored hydrogen is converted back to electricity, maintaining grid stability.

One notable example involves a large utility company that deployed hydrogen generators alongside a wind farm. The system captures excess wind energy during windy periods and stores it as hydrogen. During calm periods, fuel cells convert the hydrogen back to electricity, effectively extending the wind farm’s capacity factor and improving its economic viability.

Industrial Manufacturing Applications

Manufacturing facilities with high energy demands are finding hydrogen generators particularly valuable. A major steel production facility implemented hydrogen generators to provide both process heat and electrical power. The system not only reduced the facility’s carbon footprint but also provided energy cost savings and improved operational flexibility.

The steel plant’s hydrogen system includes multiple generators that can operate independently or in parallel, providing redundancy and scalability. During periods of low steel demand, the generators can produce hydrogen for sale to other industrial customers, creating an additional revenue stream.

Economic Impact and Cost Analysis

Return on Investment for Energy Companies

The economic case for hydrogen generators in the energy sector has strengthened considerably as technology costs have declined and operational benefits have become clearer. Many energy companies report payback periods of 5-7 years for hydrogen generator installations, with some applications achieving even shorter payback periods when environmental benefits and regulatory compliance costs are factored in.

The value proposition extends beyond simple fuel cost savings. Hydrogen generators provide energy companies with greater operational flexibility, reduced regulatory risk, and improved public relations benefits. These factors contribute to the overall return on investment and make hydrogen generators attractive even in markets where the pure economics might be marginal.

Operating Cost Comparisons

When comparing operating costs, hydrogen generators demonstrate competitive advantages over traditional backup power systems and some conventional generation methods. While the initial capital investment is higher than diesel generators, the ongoing fuel and maintenance costs are typically lower. Hydrogen generators also avoid the price volatility associated with fossil fuels, providing more predictable operating expenses.

Maintenance requirements for modern hydrogen generators are minimal compared to combustion-based systems. There are no filters to change, no oil to replace, and no combustion chambers to clean. This simplicity translates to lower maintenance costs and higher system availability.

Challenges and Solutions in Hydrogen Energy Adoption

Infrastructure Development Needs

The widespread adoption of hydrogen generators in the energy sector requires supporting infrastructure development. This includes hydrogen storage facilities, transportation networks, and safety systems. While these infrastructure needs represent a challenge, they also create opportunities for energy companies to develop new business models and revenue streams.

Many energy companies are taking a phased approach to infrastructure development, starting with on-site hydrogen generation and gradually expanding to include storage and distribution capabilities. This approach allows them to gain experience with hydrogen technology while building the infrastructure necessary for larger-scale deployments.

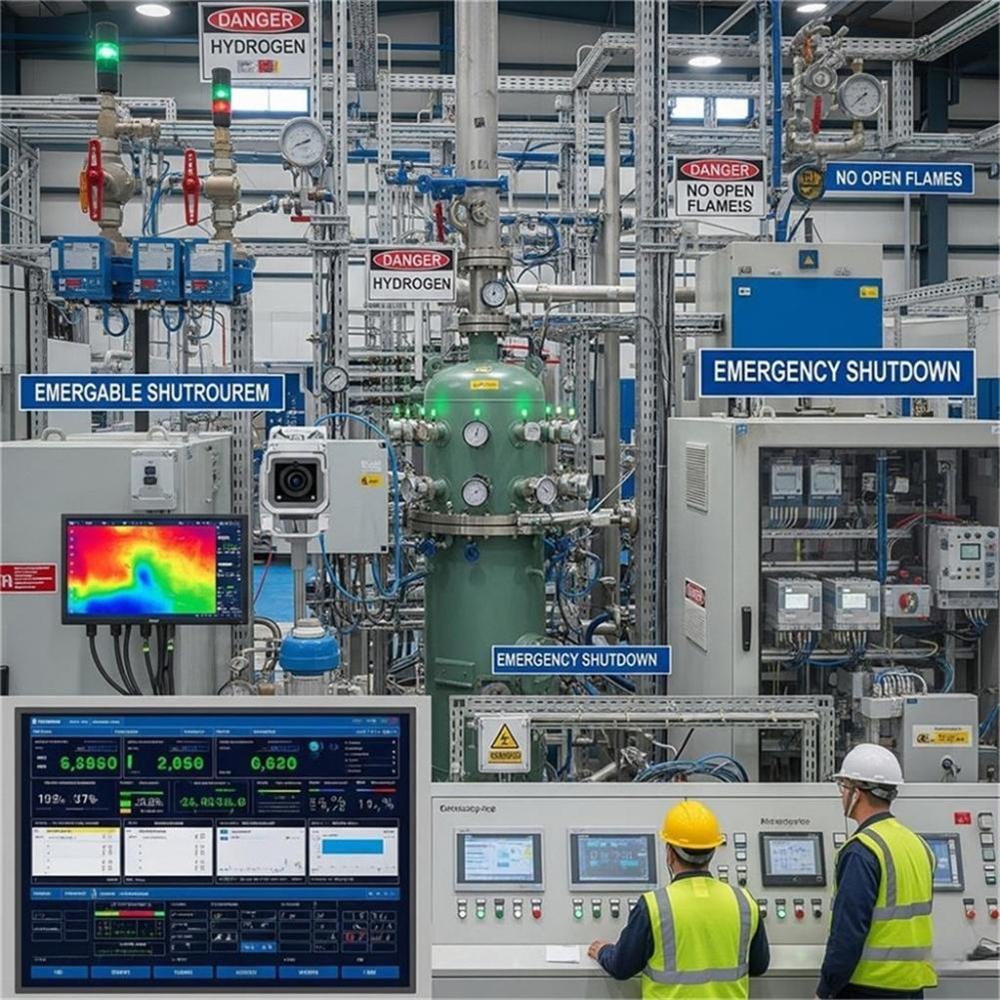

Safety Considerations and Standards

Safety is paramount when working with hydrogen, and the energy sector has developed comprehensive safety protocols and standards for hydrogen generator operation. Modern hydrogen generators incorporate multiple safety systems including leak detection, automatic shutdown procedures, and ventilation requirements. These safety measures ensure that hydrogen systems can operate safely in industrial environments.

Training programs for energy sector personnel have been developed to ensure proper operation and maintenance of hydrogen systems. These programs cover everything from basic hydrogen properties to advanced troubleshooting procedures, ensuring that energy companies have the expertise necessary to operate hydrogen generators safely and effectively.

Future Outlook and Emerging Trends

Next-Generation Hydrogen Technologies

The future of hydrogen generation in the energy sector looks increasingly promising, with several emerging technologies poised to further improve performance and reduce costs. Solid oxide electrolyzer cells (SOEC) technology promises even higher efficiencies than current PEM systems, while advanced materials research is developing new catalysts and membranes that could dramatically reduce equipment costs.

Integration with artificial intelligence and machine learning is also advancing, with smart hydrogen generators that can optimize their operation based on electricity prices, demand patterns, and weather forecasts. These intelligent systems will maximize the economic benefits of hydrogen generation while minimizing operational complexity.

Integration with Smart Grid Systems

The integration of hydrogen generators with smart grid technology represents a significant opportunity for the energy sector. Smart grids can automatically direct excess renewable electricity to hydrogen generators when production exceeds demand, then call upon stored hydrogen for electricity generation when needed. This integration creates a more resilient and flexible energy system.

Blockchain technology is also being explored for hydrogen trading and certification, allowing energy companies to monetize their clean hydrogen production and participate in emerging hydrogen markets. These technological developments will create new business opportunities and revenue streams for energy companies investing in hydrogen technology.

Conclusion

Hydrogen generators are fundamentally transforming the energy sector by providing clean, flexible, and scalable power solutions. As technology continues to advance and costs decline, hydrogen generation is becoming an increasingly attractive option for energy companies seeking to reduce their environmental impact while maintaining operational reliability.

The convergence of environmental regulations, technological advancement, and economic incentives is creating a perfect storm for hydrogen adoption in the energy sector. Companies that embrace this technology early will be better positioned to thrive in the clean energy economy of the future.

For energy companies considering hydrogen generator implementation, the key is to start with pilot projects that demonstrate the technology’s capabilities while building internal expertise. As the hydrogen economy continues to mature, those with early experience will have significant competitive advantages.

The future of energy is hydrogen, and hydrogen generators are the key technology making this future a reality. By investing in hydrogen generation capabilities today, energy companies can secure their position in tomorrow’s clean energy landscape.

Frequently Asked Questions

1. How long do hydrogen generators typically last in commercial energy applications?

Modern PEM hydrogen generators designed for commercial energy applications typically have operational lifespans of 10-15 years with proper maintenance. The stack components may require replacement every 5-7 years depending on usage patterns, but the overall system infrastructure is designed for long-term operation. Regular maintenance and quality water feed can extend system life significantly.

2. What is the efficiency rate of converting electricity to hydrogen in modern generators?

Current PEM hydrogen generators achieve electrical-to-hydrogen conversion efficiencies of 75-85%, with some advanced systems reaching even higher rates. This means that for every 100 kWh of electricity input, approximately 75-85 kWh worth of energy is stored in the produced hydrogen. Efficiency continues to improve as technology advances.

3. Can hydrogen generators operate using renewable energy sources exclusively?

Yes, hydrogen generators are particularly well-suited for operation with renewable energy sources. They can handle the variable power output from solar and wind systems, automatically adjusting production based on available electricity. This makes them ideal for converting excess renewable energy into storable hydrogen fuel.

4. What are the main safety requirements for installing hydrogen generators in energy facilities?

Key safety requirements include proper ventilation systems, hydrogen leak detection equipment, electrical safety systems, and trained personnel. Installation must comply with local codes and standards such as NFPA 2 (Hydrogen Technologies Code). Most modern systems include built-in safety features like automatic shutdown systems and explosion-proof electrical components.

5. How does the cost of hydrogen-generated electricity compare to traditional grid power?

The cost competitiveness of hydrogen-generated electricity depends on several factors including local electricity prices, system utilization rates, and available incentives. In many applications, especially where backup power or long-term storage is required, hydrogen systems provide cost advantages when total lifecycle costs are considered. As technology costs continue to decline, hydrogen is becoming increasingly competitive with traditional power sources.

Please don’t forget to leave a review.

Hydrogen generators—especially PEM‑based systems—are revolutionizing the energy sector by offering cleaner, more efficient, and cost‑effective power solutions. From renewable energy storage to industrial applications and fueling stations, on‑site hydrogen production is disrupting traditional supply models. For customized, robust solutions, Hele Titanium provides advanced hydrogen generators backed by expert support.

Contact Hele Titanium today to explore your energy transformation journey:

📧 heletitaniumhydrogen@gmail.com

📱 WhatsApp: 086‑13857402537

Visit their Contact Us page to get started.