Trusted industrial hydrogen generator manufacturers matter for supply security and cost. Learn how to evaluate PEM electrolyzer OEMs, compare suppliers, and request tailored quotes from Hele Titanium Hydrogen.

1. Introduction

Finding the right industrial hydrogen generator manufacturers is a strategic decision for any business that depends on reliable, high-purity hydrogen — from chemical plants and electronics fabs to food-processing firms and hydrogen-refuelling stations. This buyer’s guide is written for procurement managers, plant engineers, and purchasing directors who need to evaluate suppliers, compare technologies, and fast-track a safe, cost-effective on-site hydrogen solution.

In the sections that follow you’ll get: clear evaluation criteria, a benchmarking snapshot of major global vendors, and a practical sourcing playbook that highlights why specialized OEMs — such as Hele Titanium Hydrogen — are frequently the best choice for wholesale PEM electrolyzer supply, OEM manufacturing, and export projects.

2. Why Businesses Choose On-Site Hydrogen Generation

Cost savings & lifecycle economics

Buying compressed hydrogen or cylinders carries recurring transport, handling, and margin costs. On-site generation converts many of those recurring costs into a capital investment and predictable OPEX — improving long-term TCO (total cost of ownership). For businesses with steady or growing demand, this often becomes the most economical option.

Reliability, uptime & supply security

Dependence on third-party deliveries introduces supply-chain risk: weather delays, logistics bottlenecks, and supplier outages. On-site PEM systems create independence and control — crucial when hydrogen is part of a continuous manufacturing process.

Safety & reduced logistics risk

Generating hydrogen on demand reduces the need to store large volumes of compressed gas on-site or schedule frequent cylinder swaps. That lowers handling risk and simplifies permit and safety management.

Green hydrogen & ESG alignment

When paired with renewable electricity, PEM electrolysis becomes a pathway to green hydrogen — an increasingly important element of corporate ESG commitments and regulatory incentives.

3. How to Evaluate Industrial Hydrogen Generator Manufacturers

When sourcing industrial hydrogen generator manufacturers, buyers should evaluate beyond sticker price. Use the checklist below.

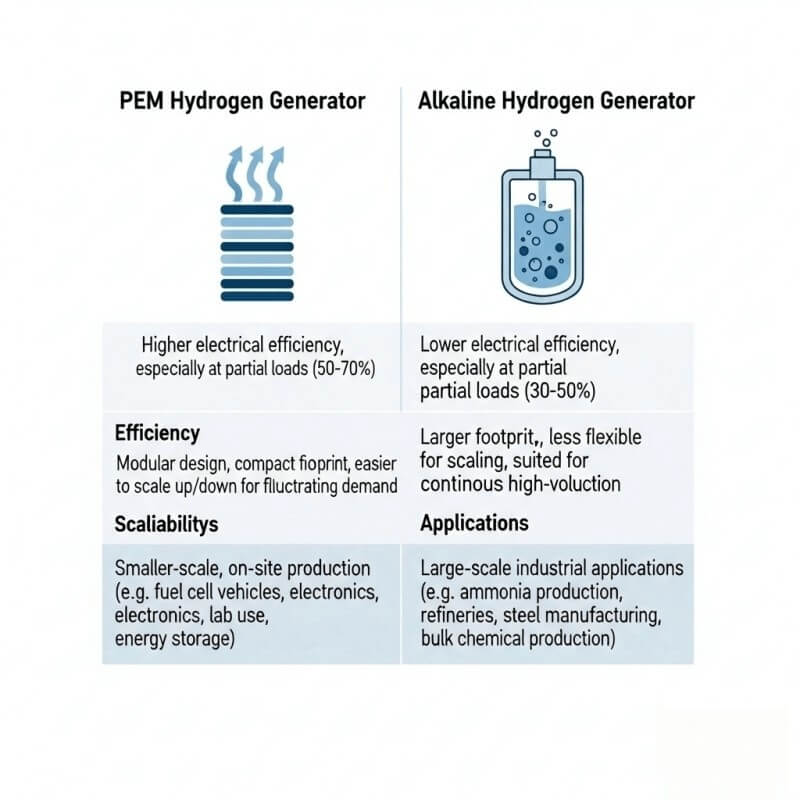

Technology: PEM vs Alkaline

- PEM (Proton Exchange Membrane): fast ramp rates, compact footprint, very high purity (suitable for fuel cells, semiconductors), typically higher CAPEX but lower footprint and easier integration with variable renewables.

- Alkaline: lower CAPEX at larger scale, mature technology for bulk hydrogen, but larger footprint and slower dynamics. For high-purity industrial uses and modular installations, PEM is often the preferred choice.

Capacity, modularity & scalability

Confirm the manufacturer offers modular systems that scale (stack + module approach) — this lowers replacement risk and lets you grow capacity in step with demand.

Certifications & compliance

International buyers should verify compliance with CE, ISO (e.g., ISO 9001 quality), pressure-vessel standards (ASME where applicable), and export documentation. Ask for test reports and factory inspection records.

After-sales, service & spare parts

Fast availability of spare stacks, local partner networks, remote monitoring options, and clear SLAs are essential. Confirm mean time to repair and parts lead times for the region you operate in.

B2B sourcing details

Ask about MOQ for wholesale hydrogen generator orders, lead times for production and shipping, OEM manufacturing/machine customization options, and standard payment terms (L/C, T/T). A responsive export team and experience with customs paperwork reduces delivery risk.

4. Benchmark: Top Global Manufacturers (What They Mean for Buyers)

Large global firms are useful benchmarks: they demonstrate the high-end of performance, project execution, and full-service delivery.

- Linde — Global reach, strong project and service network; often chosen for integrated gas supply and engineering projects.

- Air Liquide — Deep R&D and project experience in large green hydrogen initiatives.

- Nel Hydrogen / Proton OnSite heritage — Specialist electrolyser engineering; well-known for a range of electrolyser technologies.

- ITM Power — Noted for modular PEM stacks and systems suitable for distributed power applications.

- Cummins / Hydrogenics — Known for energy-systems integration and industry-level support.

What buyers should note: big vendors often have premium pricing and longer lead times, but they offer scale, warranties, and a global support footprint. For many B2B buyers the sweet spot is a capable specialist OEM that offers competitive pricing, customization, and fast export support — without sacrificing quality.

5. Rising & Cost-Effective B2B Partners (Where Specialized OEMs Add Value)

Smaller and mid-sized OEMs fill crucial gaps for industrial buyers:

- Customization: Tailored skid designs, integration kits, and control logic that match your plant’s processes.

- Faster lead times: Less complex internal procurement allows quicker turnarounds.

- Competitive wholesale pricing: Lower overheads translate to better unit pricing for bulk orders.

- OEM partnerships: Co-branding, private-labeling, and contract manufacturing options for distributors.

This is the space where Hele Titanium Hydrogen operates: combining PEM expertise with export readiness and B2B commercial flexibility.

6. Hele Titanium Hydrogen — PEM OEM & Wholesale Supplier Spotlight

Company profile & export positioning

Hele Titanium Hydrogen is positioned as a specialist OEM PEM electrolyzer supplier focused on industrial on-site hydrogen generation. We serve international buyers seeking wholesale hydrogen generator supply, OEM customization, and project-grade support for installation and commissioning.

Core product lines

- Industrial PEM water electrolyzers (modular, 0.5–X Nm³/hr per module — scalable to customer demand).

- Skid-mounted turnkey packages: power cubicle, water treatment, gas drying and basic compression options.

- OEM & private-label manufacturing: custom stacks, control software integration, and mechanical packaging to buyer specifications.

(If you’d like, we can insert a detailed spec table per model in the final article.)

Key differentiators

- PEM specialization: stacks optimized for high purity (>99.99%) and fast response to variable renewable power.

- Wholesale & OEM capacity: competitive MOQs and pricing for distributors and integrators.

- Export and compliance experience: done projects across multiple continents with standard export paperwork and customs facilitation.

- Flexible commercial terms: warranty and spare-parts packages; training and commissioning included in many offers.

Anonymized case study (for buyer trust)

Client: Large Asian specialty chemicals plant (anonymized) Scope: Supply and commission of a modular PEM system for on-site feed gas at plant pressure; included water polishing and remote monitoring. Result: The client eliminated cylinder deliveries, improved process uptime, and consolidated hydrogen costs into a predictable fixed and variable spend. The project included a 12-month performance guarantee and a spare-parts kit on site.

Note: specific performance metrics are available upon request and are included in our RFQ package.

Certifications & quality assurance

Hele’s manufacturing follows international quality protocols; our systems are supplied with test certificates, factory acceptance testing (FAT) reports, and CE/ISO documentation for export. (Buyers may request copies during the tender stage.)

Commercial terms (typical)

- MOQ & lead time: competitively low MOQs for wholesale buyers; lead times depend on module count and custom options.

- Payment: standard export terms (T/T deposit with balance on delivery / L/C options by negotiation).

- Warranty & support: parts and workmanship warranty plus optional extended support contracts.

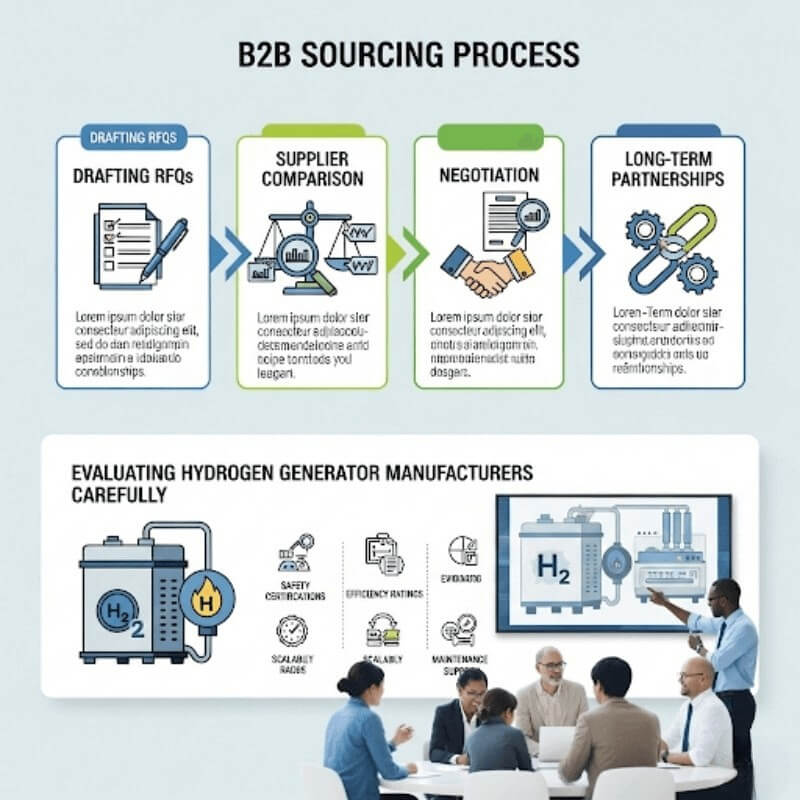

7. B2B Sourcing Playbook — RFQ, Evaluation Matrix & Negotiation Tips

What to include in an RFQ

- Required hydrogen flow (Nm³/h or Nm³/day), operating pressure, desired purity (ppm of O₂, dew point), power availability (kW), water source quality, footprint constraints, and desired delivery schedule.

- Request FAT and SAT acceptance criteria, warranty terms, and spare-part lists.

Supplier evaluation matrix (simple)

Score each supplier 1–5 on: Price, Technology fit, Service & spare parts, Certifications & compliance, Delivery & logistics risk. Weight the categories based on your priorities (e.g., Service 30%, Price 25%).

Negotiation priorities

- Include spare stacks and a small consumable kit in the base contract.

- Negotiate lead times for spare parts and on-site training.

- Secure performance guarantees (e.g., hydrogen purity and uptime) tied to acceptance tests.

8. Integration, Installation & Aftercare — Practical Buyer Checklist

Site requirements

- Electrical: stable grid or renewable source sizing, power quality protections.

- Water: de-ionized/ultra-pure water or on-skid water treatment.

- Ventilation & safety: hydrogen detection, ventilation ducts, isolation distances.

- Foundations & footprint: skid mounting, load ratings, and access for service.

Commissioning & training

- Commissioning should include pressure and leak tests, performance runs, and operator training. Request a DQ/FAT/SAT package in the RFQ.

Aftercare & SLA

- Ask about remote monitoring, predictive maintenance, and response times for critical spares. Consider a tiered SLA with guaranteed MTTR for critical components.

9. Future Trends That Affect Sourcing Decisions

Green hydrogen is becoming mainstream

Buyers should plan for renewable integration. PEM’s flexibility makes it ideal for pairing with solar or wind.

Modularity & containerized systems

Faster deployment, repeatable builds, and lower installation risk favor modular PEM systems for distributors and industrial integrators.

Policy & incentives

Many regions now offer incentives for green hydrogen projects — factor national incentives into your ROI model when preparing the RFQ.

10. FAQs — Practical Answers for B2B Buyers

Q1: What purity can I expect from PEM electrolyzers? A: PEM systems typically deliver ultra-high purity hydrogen (>99.99%), suitable for fuel cells, semiconductor processes, and specialty chemical synthesis. Confirm vendor test certificates in the RFQ.

Q2: What typical lead times should I budget for? A: Lead times vary by capacity and customization but plan a baseline of several weeks to a few months. Specialist OEMs often offer faster turnaround than global giants.

Q3: Do I need water purification for PEM systems? A: Yes—PEM requires high-quality water. Many suppliers offer on-skid water polishers as part of the package or recommend RO + DI systems.

Q4: How are warranties and spare parts commonly handled? A: Standard warranties cover parts and workmanship (often 12 months) with optional extended plans. Negotiate spare stack delivery lead times and consider a local spare kit.

Q5: What export and customs documents should I expect? A: Typical documentation includes commercial invoice, packing list, certificate of origin, FAT reports, and CE/ISO certificates. Request these early in the procurement process.

Q6: Can the electrolyzer be integrated with renewables? A: Absolutely—PEM is well suited to variable power input, but proper power electronics and control logic are required for efficient operation.

Q7: What payment terms are typical for wholesale orders? A: Common terms include 30–40% T/T deposit at order, balance on shipment or acceptance, or an irrevocable L/C for international buyers. Terms are negotiable for large volume orders.

11. Conclusion & Strong CTAs

Selecting the right industrial hydrogen generator manufacturers impacts cost, uptime, and your company’s sustainability goals. For many B2B buyers the best solution is a balance: the reliability and credentials of established names combined with the flexibility, price competitiveness, and export readiness of specialist OEMs.

Hele Titanium Hydrogen offers modular PEM electrolyzers, OEM manufacturing, and wholesale supply tailored to industrial buyers. If you’re evaluating suppliers, we invite you to:

- Request a tailored RFQ response — tell us flows, pressure, purity, and timeline.

- Download our spec sheet & RFQ template (ask our export team for the PDF).

- Get a free ROI/Payback estimate for on-site hydrogen vs delivered supply — share your current hydrogen costs and volumes.

- Schedule a technical call with our export engineers to review integration and compliance requirements.

Send your RFQ or inquiry via our website contact form or message our export team directly to receive: a detailed quotation, FAT plan, and anonymized case studies that match your industry.

Hele Titanium Hydrogen: Your Trusted Hydrogen Generator OEM & Manufacturing Partner

Hele Titanium Hydrogen stands as a reliable and experienced partner in the hydrogen generator OEM supply chain. We specialize in the design, development, and manufacturing of high-performance PEM Water Hydrogen Generators, offering comprehensive OEM & Manufacturing services tailored to your specific needs.

Take the Next Step

Ready to explore the possibilities of partnering with Hele Titanium Hydrogen?

- Browse our Products to see our range of PEM Water Hydrogen Generators.

- Learn more about our Services and how we can support your OEM & Manufacturing needs.

- Contact Us today to discuss your specific requirements.

- Explore our FAQ to get answers to common questions.

- Visit our Blog for the latest insights and updates on hydrogen technology.

Email Us: heletitaniumhydrogen@gmail.com

Phone/WhatsApp: 086-13857402537