Inside the Hydrogen Generator OEM Supply Chain: A Manufacturer’s Perspective.

Explore the hydrogen generator OEM supply chain with Hele Titanium Hydrogen. Discover key manufacturing hubs, quality standards, and how our PEM technology delivers superior OEM solutions.

Introduction

The hydrogen economy is gaining momentum globally, with Proton Exchange Membrane (PEM) water electrolysis emerging as the preferred technology for clean hydrogen production. As industries pivot to green energy, the hydrogen generator OEM supply chain becomes a strategic focal point for businesses seeking scalable, efficient, and customizable solutions.

At Hele Titanium Hydrogen, we specialize in OEM and manufacturing services that support global B2B partners with state-of-the-art hydrogen generator components and systems. This article reveals how we structure our supply chain, maintain superior quality, and deliver excellence from design to delivery.

The Hydrogen Generator OEM Ecosystem

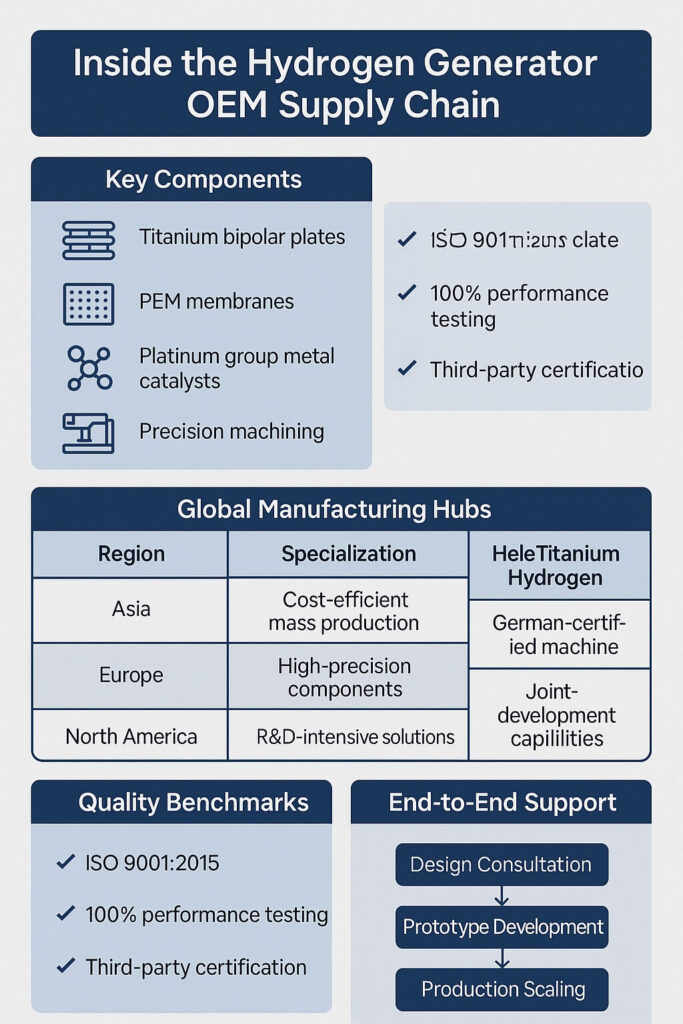

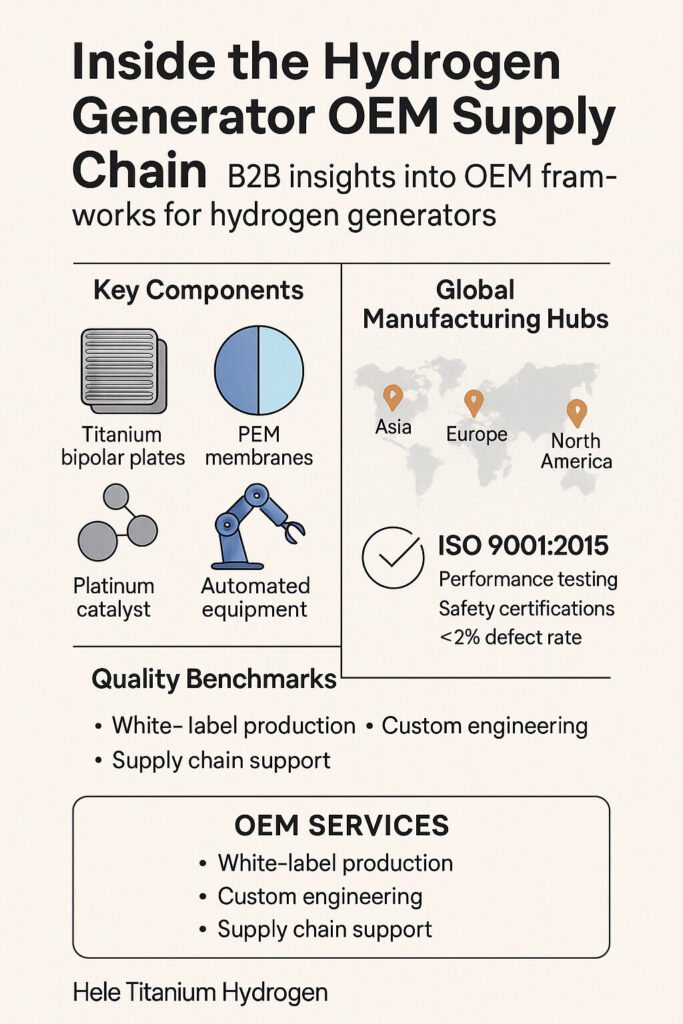

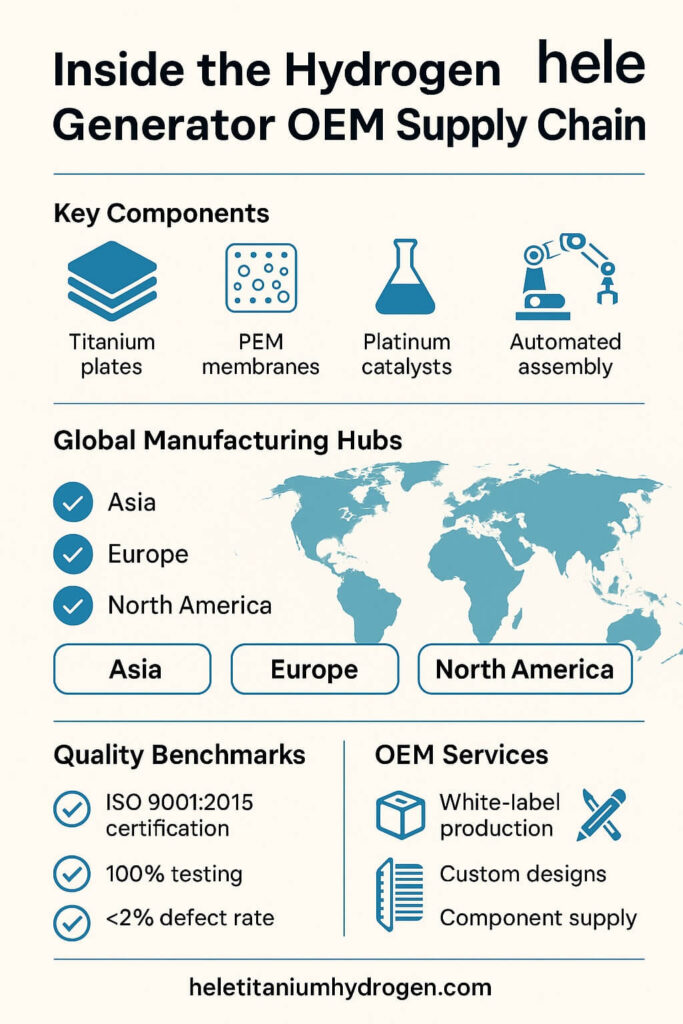

1. Key Components in the Supply Chain

To deliver reliable hydrogen generation, we use only high-quality, traceable components:

- Titanium Bipolar Plates – corrosion-resistant, precision-etched for optimal flow.

- PEM Membranes – sourced from top suppliers like Dupont for durability and efficiency.

- Platinum Group Metal Catalysts – high-performance materials for consistent electrolysis.

- Custom Machining – CNC systems enable micro-level precision.

- Automated Assembly Systems – streamline mass production and reduce error rates.

Our GuangZhou-based facility integrates directly with Tier 1 material vendors, enabling control over sourcing, scheduling, and pricing.

2. Global Manufacturing Hubs

| Region | Specialization | Hele’s Advantage |

|---|---|---|

| Asia | Cost-effective mass production | GuangZhou factory enables volume scaling with precision control |

| Europe | High-spec component engineering | German-grade machining for tight tolerance requirements |

| North America | Innovation & R&D | OEM co-development with energy startups and research labs |

3. Quality Benchmarks in OEM Production

Quality is non-negotiable. Our OEM supply chain includes:

- ISO 9001:2015 certified production workflows

- 100% performance validation before shipment

- Third-party certifications (CE, UL in progress)

- <2% defect rate across all production runs

Every part we deliver carries a Certificate of Conformance and material traceability report.

Why Partner with Hele Titanium Hydrogen?

Technical Superiority

Our engineering innovations provide long-lasting, efficient PEM hydrogen solutions:

- Titanium flow plates with 50,000+ hour lifespan

- Dynamic pressure adjustment tech to handle variable loads

- 5% higher efficiency than standard industry products

Supply Chain Advantages

- 60-day lead time for standard OEM orders

- Flexible MOQs starting at 50 units

- Full in-house R&D team for tailored solutions

End-to-End OEM Support

From blueprint to batch shipment, you have one point of contact—us.

Common OEM Partnership Models

We offer flexible partnership models for every stage of your product cycle:

- White Label Manufacturing

- Full rebranding support

- Custom performance metrics

- Component Supply Agreements

- Bipolar plates

- PEM stacks and subsystems

- Technology Licensing

- Titanium coating IP

- Smart control systems for automation

“Our recent OEM partnership with a German renewables firm cut their sourcing cost by 35%, thanks to our smart material optimization.” – Hele Engineering Team

Navigating OEM Supply Chain Challenges

Modern supply chains face volatility, but we’re built to adapt.

How Hele Mitigates Risks

- Dual sourcing on all critical components

- 3-month raw material buffer stock

- Blockchain tracking of component batches for end-to-end transparency

This enables us to guarantee on-time delivery, even during market disruptions.

The Future of Hydrogen Generator OEM Supply

We’re actively investing in the next generation of hydrogen technology:

- AI-driven predictive maintenance

- Modular PEM generator designs

- Green hydrogen certification support

Our R&D division collaborates globally to keep your products ahead of regulatory and technological shifts.

Frequently Asked Questions (FAQs)

Q1: What’s the MOQ for OEM hydrogen generator units?

A: We offer flexible MOQs starting at 50 units depending on configuration.

Q2: Can you develop custom PEM electrolyzers based on our specifications?

A: Absolutely. Our engineering team will co-design and prototype according to your requirements.

Q3: How do you ensure quality across every order?

A: Each unit undergoes three levels of testing and comes with a full performance report and traceability certificate.

Q4: Do you provide international logistics support?

A: Yes. We offer door-to-door international logistics via air or sea with full tracking.

Q5: Is your titanium coating process patented?

A: Yes. Our proprietary titanium surface treatment ensures ultra-long durability and is available under license.

Q6: What lead times can we expect?

A: For most standard OEM orders, lead time is 60 days. Custom projects may vary.

Call to Action: Let’s Build the Future Together

Are you ready to optimize your hydrogen generator OEM supply chain with a proven, globally trusted partner?

👉 Request a technical brochure or proposal

📞 WhatsApp/Phone: +86-13857402537

📧 Email: heletitaniumhydrogen@gmail.com