Introduction: The Efficiency Imperative in Today’s Hydrogen Economy

The global hydrogen economy is entering a new growth phase. According to the International Energy Agency (IEA), hydrogen demand could quadruple by 2050, with green hydrogen playing a pivotal role in decarbonizing industries, power generation, and transportation. Yet, one major challenge remains: producing hydrogen cost-effectively and at scale.

This is where high-efficiency PEM stacks come into play.

PEM (Proton Exchange Membrane) technology has emerged as a leading solution for both hydrogen production (electrolysis) and hydrogen utilization (fuel cells). However, efficiency is the key differentiator that separates commercially viable projects from pilot programs. The higher the efficiency of a PEM stack, the more hydrogen you achieve per kilowatt of electricity consumed—a factor that directly impacts project ROI and environmental credentials.

This comprehensive guide explores how high-efficiency PEM stacks are reshaping the hydrogen landscape, delves into the latest technological advancements, showcases real-world applications, and explains why partnering with a proven OEM manufacturer like Hele Titanium Hydrogen is critical for scaling your operations faster and smarter.

Understanding PEM Stack Technology

How PEM Electrolysis & Fuel Cells Work

At its core, a PEM stack is a sophisticated electrochemical device. It can operate in two primary modes:

- Electrolysis Mode: Using electricity (ideally from renewable sources) to split purified water (H₂O) into high-purity hydrogen and oxygen.

- Fuel Cell Mode: Recombining hydrogen with oxygen from the air to generate electricity, with water and heat as the only byproducts.

Both processes are enabled by the Proton Exchange Membrane, a remarkable polymer film that selectively allows protons (H⁺) to pass through while blocking gases. This precise separation is the key to the technology’s high efficiency and purity.

Key Components of a High-Performance PEM Stack

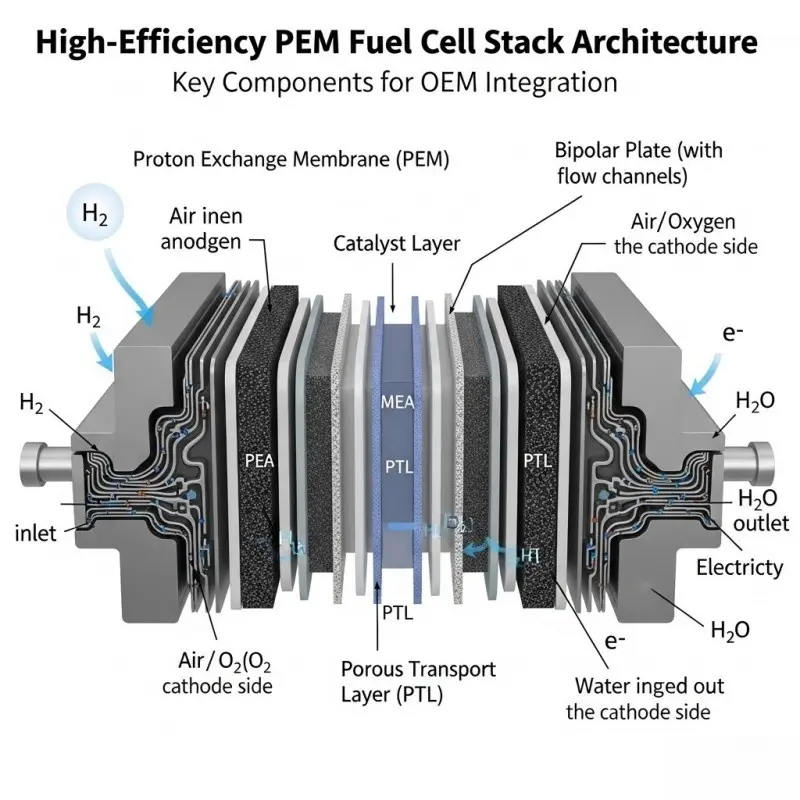

A stack is a meticulously engineered assembly of individual cells. Understanding its core components is essential for any B2B buyer:

- Membrane Electrode Assembly (MEA): The heart of the stack where the electrochemical reactions occur. Its quality dictates performance.

- Bipolar Plates (BPPs): Often made of coated titanium, these plates distribute gases and water, conduct electrical current, and manage heat.

- Porous Transport Layers (PTL): These facilitate the uniform diffusion of reactants to the catalyst layers.

- Seals, Gaskets, and End Plates: This hardware provides structural compression and ensures gas-tight sealing for safe, high-pressure operation.

The efficiency of this entire assembly is governed by factors like operating temperature, pressure, and proper membrane hydration.

Defining “High Efficiency”: Metrics That Matter for Your Bottom Line

In a B2B context, “efficiency” must translate into tangible financial and operational advantages. Here are the key metrics to scrutinize:

- Energy Consumption (kWh/kg H₂): The ultimate business metric. Lower is better, as it directly reduces your largest operational expense: electricity.

- Voltage Efficiency (%): Measures how close the stack operates to the theoretical minimum voltage. Higher percentages mean less energy is wasted as heat.

- Current Density (A/cm²): A measure of output per unit area. Higher current density allows for more compact, power-dense, and cost-effective stacks.

- Degradation Rate (%/1000 hrs): Indicates longevity. A lower rate means a longer operational lifespan and a better return on investment.

The Performance Gap: Standard vs. High-Efficiency

The difference in performance is stark and has major financial implications.

- Conventional PEM stacks often operate with 60-70% efficiency, consuming 50-55 kWh of electricity per kg of hydrogen.

- Hele Titanium Hydrogen’s high-efficiency stacks push this boundary, achieving over 75% efficiency and driving energy consumption below 45 kWh/kg.

This leap in performance can reduce hydrogen production costs by up to 25%, a critical step in making green hydrogen cost-competitive with fossil fuels, as projected by analysts like BloombergNEF.

Is your system underperforming? An inefficient stack could be costing you thousands in hidden energy expenses. Download our free ‘PEM Stack Performance Audit Checklist’ to identify critical areas for improvement.

Breakthrough Innovations Driving Next-Generation PEM Stacks

The superior performance of modern PEM stacks is the result of relentless innovation in materials science and precision engineering.

Next-Generation Membrane Materials

While Perfluorosulfonic Acid (PFSA) membranes remain the industry standard, they are now being manufactured with reinforced composite structures for enhanced mechanical stability and longer life under dynamic conditions.

Catalyst Advancements & Electrode Optimization

The high cost of platinum group metals (PGMs) is a known challenge. Innovations focus on nanostructured catalysts that create a larger active surface area, allowing for significantly less platinum and iridium usage without sacrificing performance or durability.

Intelligent Bipolar Plate and Flow Field Design

Advanced computational fluid dynamics (CFD) modeling allows for the design of optimized serpentine and interdigitated flow fields within the bipolar plates. These intricate patterns ensure uniform distribution of reactants, eliminating performance-killing “hot spots” and maximizing the output of every square centimeter of the MEA. Using corrosion-resistant titanium-based plates is crucial for longevity.

Superior Thermal & Water Management

An efficient stack is a cool stack. Integrated cooling channels and advanced humidification strategies are vital for maintaining stable operating temperatures and optimal membrane hydration, which directly extends the stack’s lifespan and ensures consistent high performance.

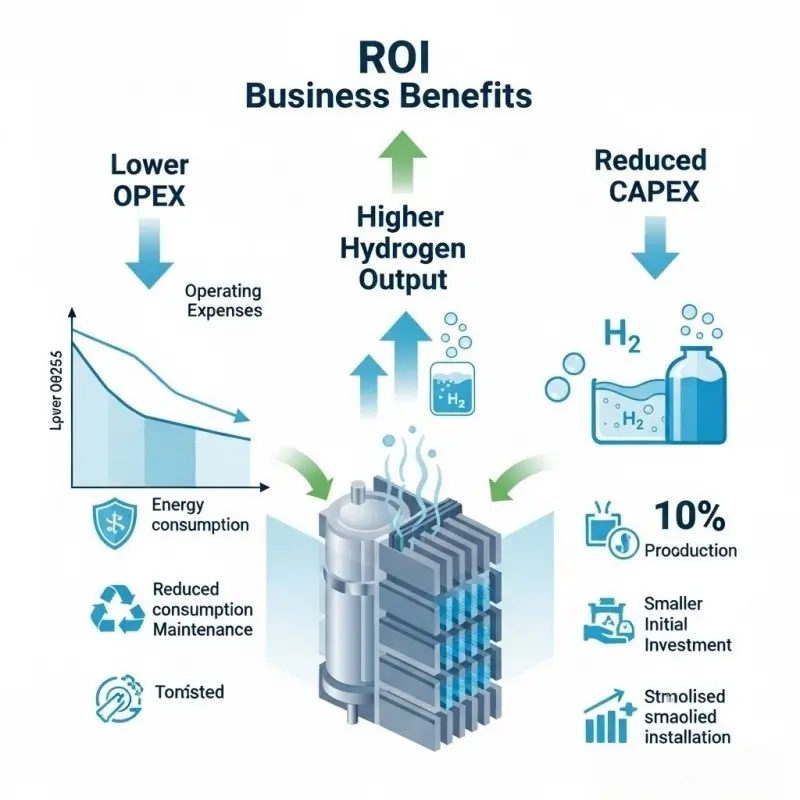

The Business Case: Advantages of High-Efficiency PEM Stacks

Investing in high-efficiency technology is a strategic decision that delivers compounding returns.

Maximize Hydrogen Output & Lower OPEX

The primary advantage is producing more hydrogen for the same energy input. When electricity can account for up to 70% of green hydrogen’s production cost, a 10% gain in stack efficiency can cut overall hydrogen costs by up to 15%, dramatically improving project profitability.

Improve Durability, Reliability & ROI

Enhanced materials and optimized thermal management directly contribute to longer stack lifetimes, with modern stacks now rated for 60,000 to 80,000 operating hours. This reduces replacement cycles, minimizes downtime, and strengthens the overall return on investment.

Meet ESG Goals & Qualify for Incentives

By consuming less electricity per kilogram of hydrogen, high-efficiency stacks reduce the project’s overall carbon footprint (even when using grid electricity). This helps companies meet stringent ESG (Environmental, Social, and Governance) targets and often makes them eligible for green energy subsidies and tax credits available in regions like the EU, USA, and South Korea.

Ready to see the numbers for your project? The financial impact of efficiency is too important to guess. Request a complimentary Total Cost of Ownership (TCO) analysis from our engineering team and we’ll model the potential savings.

Applications Driving Global Market Growth

High-efficiency PEM stacks are the enabling technology for a growing number of applications.

Green Hydrogen Production from Renewables

Solar and wind are variable energy sources. The rapid response time of high-efficiency PEM stacks allows them to capture excess energy during peak production times, making them the ideal choice for grid-scale renewable energy storage projects.

Fuel Cell Electric Vehicles (FCEVs)

In transportation, especially for heavy-duty trucks and buses, efficiency translates directly to longer range and lower fuel consumption. Automakers are increasingly adopting these advanced stacks to improve vehicle performance and user experience.

Stationary & Backup Power Solutions

For critical infrastructure like data centers, hospitals, and telecommunications towers, reliable power is non-negotiable. PEM fuel cells provide quiet, emission-free, and instantaneous backup power, ensuring 100% uptime.

Decarbonizing Heavy Industry

Industries like steel manufacturing, ammonia production, and chemical refining are major consumers of hydrogen. Integrating on-site, high-efficiency PEM electrolysis allows them to replace fossil-fuel-based hydrogen, significantly reducing their carbon footprint.

Why Partner with Hele Titanium Hydrogen?

Choosing a supplier is a long-term commitment. Hele Titanium Hydrogen is not just a component vendor; we are a dedicated OEM & Manufacturing partner.

Proven Expertise in PEM Technology

With decades of focused experience, we possess deep expertise in stack design, materials science, and manufacturing optimization for large-scale hydrogen solutions.

OEM & Custom Manufacturing Capabilities

We specialize in providing PEM Water Hydrogen Generators and custom-engineered stack solutions. Our engineering-led approach means we can adapt stack design to meet the specific power, footprint, and integration requirements of your project, whether for industrial, transport, or energy storage applications.

Global Supply Chain & Uncompromising Quality

Our robust global supply chain and adherence to international quality standards (ISO 9001) ensure that we deliver reliable, high-performance products on schedule. Every stack undergoes rigorous quality assurance and performance testing before shipment.

Dedicated After-Sales Support

Our partnership extends beyond delivery. We provide our global clients with comprehensive technical support, integration guidance, training, and spare parts availability to ensure the long-term success of their projects.

Don’t navigate the complex procurement process alone. Download our comprehensive ‘B2B PEM Stack Vendor Evaluation Guide’ for a detailed framework.

Frequently Asked Questions (FAQs)

1. What is the typical life cycle of a high-efficiency PEM stack? Modern stacks from expert manufacturers are designed for longevity, typically lasting 60,000–80,000 operating hours depending on the application and operating conditions.

2. How exactly do high-efficiency stacks reduce hydrogen costs? They directly lower electricity consumption, which is the largest operational expense (OPEX). A 15-20% reduction in energy use translates to a significant decrease in the final cost per kilogram of hydrogen produced.

3. Are there government incentives for adopting this technology? Yes. Many regions, including the EU (Green Deal), USA (Inflation Reduction Act), Japan, and South Korea, offer substantial subsidies, tax credits, and grants to encourage the adoption of green hydrogen technologies like high-efficiency PEM electrolysis.

4. How do PEM stacks compare to alkaline electrolyzers? While alkaline technology is mature, PEM stacks offer higher current density (more compact), a faster response time (ideal for renewables), and higher-purity hydrogen output without the need for secondary purification.

5. What is a realistic delivery time for an OEM order? Lead times depend on the scale and level of customization. However, a typical timeframe for OEM delivery is 8–12 weeks from order confirmation.

Conclusion & Your Next Steps

High-efficiency PEM stacks are not an incremental improvement—they are the core enabler of a profitable and scalable hydrogen economy. By delivering more hydrogen per unit of energy, drastically reducing operational costs, and ensuring long-term reliability, they are the key to unlocking widespread adoption across all major industries.

For any organization serious about entering or expanding its footprint in the hydrogen sector, partnering with an experienced and specialized OEM manufacturer like Hele Titanium Hydrogen is the most critical first step. It ensures you build your solution on a foundation of world-class technology, tailored to your needs, and backed by global support.

👉 Take the next step toward a more efficient hydrogen future:

- Browse Our PEM Water Hydrogen Generators

- Explore Our OEM & Manufacturing Services

- Contact Our Engineering Team for a Technical Consultation

Hele Titanium Hydrogen: Your Trusted Hydrogen Generator OEM & Manufacturing Partner

Hele Titanium Hydrogen stands as a reliable and experienced partner in the hydrogen generator OEM supply chain. We specialize in the design, development, and manufacturing of high-performance PEM Water Hydrogen Generators, offering comprehensive OEM & Manufacturing services tailored to your specific needs.

Take the Next Step

Ready to explore the possibilities of partnering with Hele Titanium Hydrogen?

- Browse our Products to see our range of PEM Water Hydrogen Generators.

- Learn more about our Services and how we can support your OEM & Manufacturing needs.

- Contact Us today to discuss your specific requirements.

- Explore our FAQ to get answers to common questions.

- Visit our Blog for the latest insights and updates on hydrogen technology.

Email Us: heletitaniumhydrogen@gmail.com

Phone/WhatsApp: 086-13857402537