Discover the advantages of high-efficiency PEM hydrogen generator stations for energy storage, transportation, and industrial applications. Learn about technology, design considerations, and future trends shaping the hydrogen economy. High-Efficiency PEM Hydrogen Generator Stations.

I. Introduction

The hydrogen economy is no longer a futuristic dream — it’s a fast-growing market projected to exceed $500 billion by 2050, according to recent energy forecasts. Countries worldwide are investing heavily in hydrogen infrastructure as they look for ways to decarbonize transportation, industry, and energy storage.

At the center of this transformation lies green hydrogen — hydrogen produced without carbon emissions, typically via water electrolysis powered by renewable energy. Among the available technologies, the PEM hydrogen generator station has emerged as a frontrunner for its high efficiency, scalability, and ability to integrate with intermittent renewable sources like wind and solar.

By leveraging Proton Exchange Membrane (PEM) electrolysis, these systems can produce ultra-pure hydrogen on demand, making them a critical enabler of the net-zero energy transition. This article explores how high-efficiency PEM hydrogen generator stations work, their components, performance metrics, applications, and the innovations driving their future.

II. Understanding PEM Technology for Hydrogen Generation

How PEM Electrolysis Works

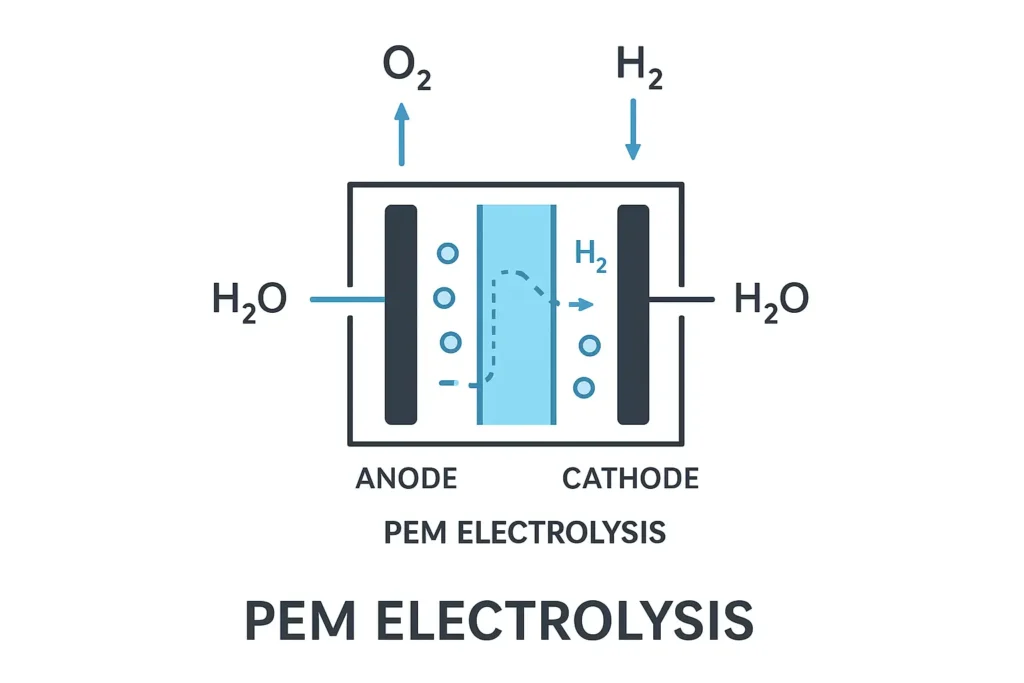

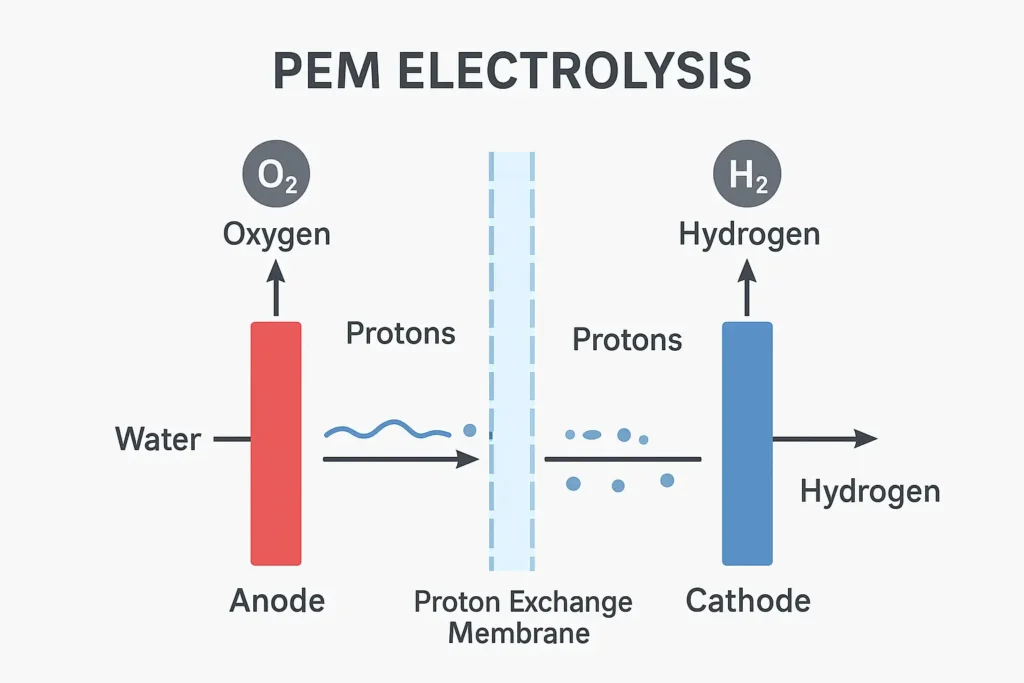

A PEM hydrogen generator station uses a proton exchange membrane to separate water into hydrogen and oxygen using electricity. The core process happens in the electrolyzer stack, which consists of:

- Anode: Where water molecules split into protons, electrons, and oxygen.

- Cathode: Where protons combine with electrons to form hydrogen gas.

- Membrane: A solid polymer that allows only protons to pass through, preventing gas crossover.

The overall reaction: H₂O → H₂ + ½ O₂

Advantages Over Alkaline Electrolysis

Compared to alkaline electrolysis, PEM hydrogen generator stations offer:

- Higher current density & efficiency – more hydrogen per unit of electricity.

- Fast start-up – can ramp up production in seconds.

- Compatibility with renewables – handles fluctuating power inputs without performance loss.

- Compact, modular design – scalable from small fueling stations to large industrial plants.

These benefits make PEM technology a preferred choice for high-efficiency hydrogen production in commercial applications.

III. Key Components and Design Considerations for High-Efficiency PEM Hydrogen Generator Stations

A high-efficiency PEM hydrogen generator station is an integrated system designed for durability, performance, and energy optimization. Key components include:

1. Electrolyzer Stack

- Membrane Electrode Assembly (MEA):

- Catalysts like platinum and iridium enhance reaction rates.

- Membrane properties determine proton conductivity and efficiency.

- Bipolar Plates:

- Often made of coated titanium for corrosion resistance.

- Designed to optimize water and gas transport.

2. Power Supply and Control System

- Rectifiers & Inverters ensure stable DC power.

- Advanced control algorithms adjust voltage and current for peak efficiency.

3. Water Purification System

- Uses reverse osmosis and deionization to achieve the ultra-pure water required for membrane longevity.

- Impurities can damage catalysts and reduce efficiency.

4. Gas Separation & Drying System

- Removes oxygen traces from hydrogen.

- Uses pressure swing adsorption (PSA) or membrane dryers for moisture control.

5. Cooling System

- Maintains optimal operating temperatures to prevent membrane degradation.

- Uses liquid or air cooling depending on system scale.

Design Optimization Factors:

- Operating Pressure – Higher pressures can reduce downstream compression costs.

- Flow Rates – Balanced water and gas flow improve stack life.

- Material Selection – Corrosion resistance boosts longevity and efficiency.

IV. Efficiency Metrics and Performance Analysis

To evaluate a PEM hydrogen generator station, engineers look at several key performance indicators:

Energy Efficiency

- Electrical Efficiency: Ratio of hydrogen’s energy content to total electrical input. Example: 65–75% is typical for high-end PEM systems.

- Faradaic Efficiency: Measures how closely actual hydrogen output matches theoretical yield.

Hydrogen Production Rate

- Measured in Nm³/h or kg/day.

- Directly impacts station sizing for fueling or industrial needs.

Specific Energy Consumption

- kWh/kg H₂ – the lower this value, the better the efficiency.

System Degradation Rate

- Over years of operation, catalysts and membranes lose performance.

- Advanced designs can limit degradation to <1% annually.

Example: A commercial PEM hydrogen generator station producing 1,000 Nm³/h at 70% efficiency can save hundreds of MWh annually compared to older designs.

V. Applications of PEM Hydrogen Generator Stations in Energy Storage

1. Power-to-Gas (P2G)

- Converts excess renewable electricity into hydrogen for storage.

- Hydrogen can be fed into natural gas pipelines or stored in tanks.

2. Hydrogen Fuel Cell Vehicles

- Enables on-site production for fueling stations.

- Eliminates reliance on centralized hydrogen supply chains.

3. Industrial Applications

- Supplies hydrogen for ammonia production, oil refining, and steelmaking.

- Reduces CO₂ emissions in traditionally carbon-heavy sectors.

Case Study: A PEM hydrogen generator station in Germany integrates with a wind farm, producing hydrogen during peak output and fueling a local fleet of fuel cell buses — reducing diesel consumption by 250,000 liters annually.

VI. Future Trends and Innovations in PEM Hydrogen Generator Technology

Advanced Electrode Materials

- Research focuses on reducing platinum group metal use.

- Development of non-precious metal catalysts to lower costs.

Improved Membrane Technology

- High-temperature PEM membranes enhance efficiency.

- Lower gas crossover rates improve safety and purity.

Smart System Integration

- AI-based controllers adjust operation for maximum energy utilization.

- Coupling with solar/wind for fully renewable hydrogen production.

Cost Reduction Strategies

- Scaling production for economies of scale.

- Government subsidies and carbon credits.

Emerging Alternatives

- Anion Exchange Membrane (AEM) electrolysis promises lower material costs while keeping efficiency competitive.

VII. Conclusion

High-efficiency PEM hydrogen generator stations are set to play a central role in the global transition to clean energy. Their ability to produce pure hydrogen quickly, reliably, and sustainably makes them ideal for transportation, industrial use, and large-scale energy storage. As innovation continues, costs will drop, and performance will rise — bringing us closer to a truly green hydrogen economy.

FAQs

1. What is a PEM hydrogen generator station? A facility that uses proton exchange membrane electrolysis to split water into hydrogen and oxygen, producing high-purity hydrogen for fuel and industrial use.

2. Why are PEM hydrogen generator stations considered high efficiency? They operate at high current densities, have quick response times, and can efficiently use fluctuating renewable energy inputs.

3. How much hydrogen can a PEM station produce? Production capacity varies — from small stations making a few kilograms per day to industrial plants producing tons daily.

4. What industries benefit most from PEM hydrogen production? Transportation, chemical manufacturing, steelmaking, and energy storage sectors are key beneficiaries.

5. Can PEM hydrogen stations run on 100% renewable energy? Yes — they are designed to integrate seamlessly with wind, solar, and hydroelectric power sources.

Hele Titanium Hydrogen: Your Trusted Hydrogen Generator OEM & Manufacturing Partner

Hele Titanium Hydrogen stands as a reliable and experienced partner in the hydrogen generator OEM supply chain. We specialize in the design, development, and manufacturing of high-performance PEM Water Hydrogen Generators, offering comprehensive OEM & Manufacturing services tailored to your specific needs.

Take the Next Step

Ready to explore the possibilities of partnering with Hele Titanium Hydrogen?

- Browse our Products to see our range of PEM Water Hydrogen Generators.

- Learn more about our Services and how we can support your OEM & Manufacturing needs.

- Contact Us today to discuss your specific requirements.

- Explore our FAQ to get answers to common questions.

- Visit our Blog for the latest insights and updates on hydrogen technology.

Email Us: heletitaniumhydrogen@gmail.com

Phone/WhatsApp: 086-13857402537