I. Introduction

With rising fuel prices and growing concerns over emissions, businesses and fleet managers are exploring alternative technologies to cut costs and stay eco-conscious. Among the emerging solutions, the HHO generator kit—a type of hydrogen fuel generator—is gaining popularity for its potential to enhance vehicle fuel efficiency.

Hydrogen-on-demand systems use water electrolysis to generate HHO gas (a mix of hydrogen and oxygen), which is introduced into the engine to improve combustion.

For enterprise B2B buyers managing large fleets, these systems could translate to significant long-term fuel savings and reduced carbon footprints.

In this article, we’ll break down the components, science, installation, ROI, and legal aspects of HHO generator kits—equipping you with the knowledge to make informed procurement decisions.

II. How HHO Kits Improve Fuel Efficiency

Hydrogen technology might sound futuristic, but its principles are well-established. HHO generators work by converting distilled water into hydrogen and oxygen gases through a process called electrolysis. These gases are then channeled into the vehicle’s air intake.

The Science Behind HHO

When injected into the combustion chamber, the hydrogen component ignites faster than gasoline, leading to more complete combustion. This improved burn helps extract more energy from the same amount of fuel, effectively increasing fuel efficiency.

Key Benefits:

- More complete fuel combustion

- Reduced unburned hydrocarbons

- Cleaner engine operation

- Potential improvement in horsepower

Environmental Impact

By enabling better combustion, hydrogen fuel generators can reduce harmful exhaust emissions, including carbon monoxide and nitrogen oxides. This makes HHO systems a valuable asset for companies aiming to meet sustainability goals.

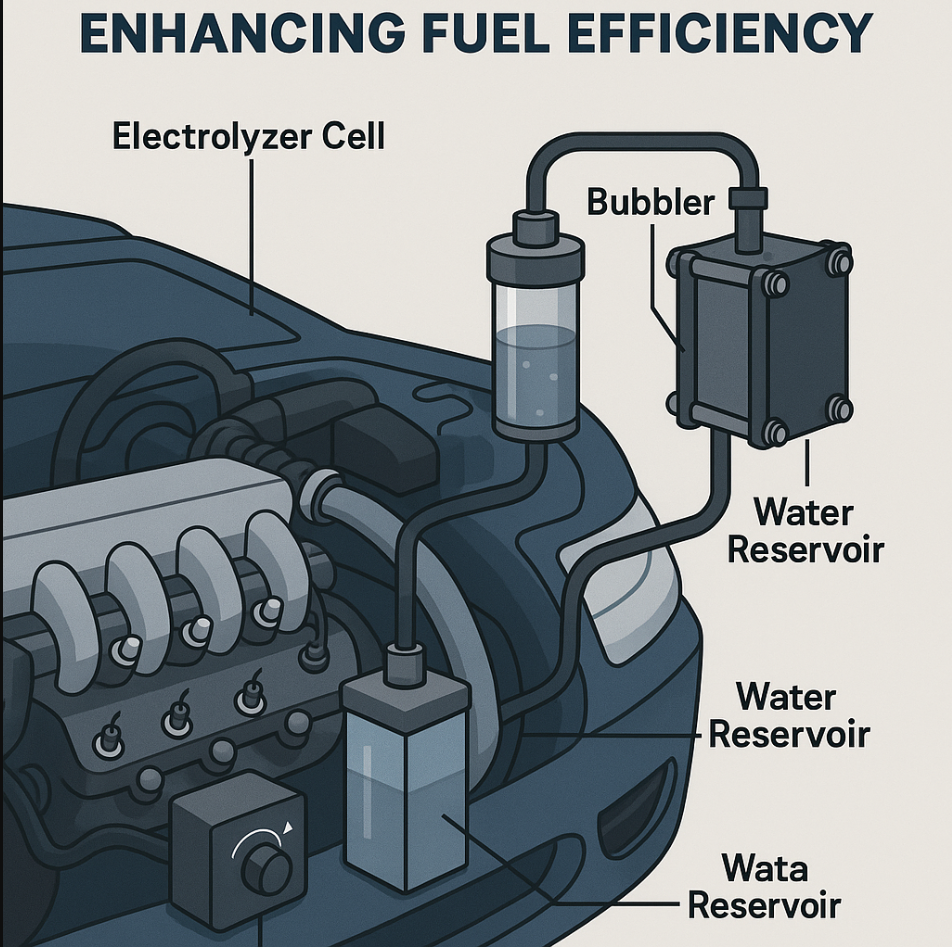

III. HHO Generator Kit Components

An HHO generator kit is more than just a water container with wires. Each part plays a crucial role in producing and delivering hydrogen gas efficiently and safely.

| Component | Function |

|---|---|

| Electrolyzer Cell | Generates HHO gas via electrolysis |

| Water Reservoir | Stores distilled water used in the electrolysis process |

| Bubbler | Acts as a safety barrier to prevent flashback |

| PWM Controller | Regulates voltage and current to optimize gas production |

| Hoses & Fittings | Deliver the gas from the generator to the engine |

| Electrical Wiring | Connects the unit to the vehicle’s battery and ignition system |

Variations in Kit Design

Not all kits are created equal. Higher-end kits feature stainless steel electrodes, advanced bubbler designs, and programmable PWM modules, all contributing to better gas output, stability, and safety.

IV. HHO Generator Kit Installation Process

Installing an HHO system involves mechanical and electrical work, so professional installation is often advised, especially for fleet vehicles.

Basic Installation Steps:

- Mount the Generator: Secure the electrolyzer in a safe location within the engine bay.

- Wire the System: Connect to the vehicle’s power supply using the included wiring harness and fuse.

- Plumb the Gas Line: Route the gas line from the generator to the intake manifold.

- Install the Bubbler: Mount the bubbler between the generator and intake line for added safety.

- Tune and Test: Adjust the PWM to optimize gas production and run tests to ensure no leaks.

Troubleshooting Tips

- Low Gas Output: Check water purity and PWM settings.

- Error Lights: Ensure connections are secure and fuses are intact.

- Backfires: Verify the bubbler is correctly installed to block flashback.

Installing an HHO generator kit is manageable with technical know-how, but professional support ensures long-term safety and system efficiency.

V. Return on Investment (ROI) of HHO Generator Kits

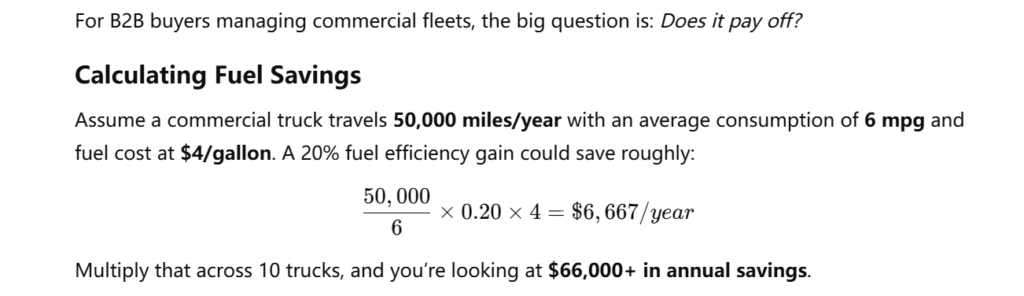

For B2B buyers managing commercial fleets, the big question is: Does it pay off?

Calculating Fuel Savings

Assume a commercial truck travels 50,000 miles/year with an average consumption of 6 mpg and fuel cost at $4/gallon. A 20% fuel efficiency gain could save roughly:

$$ \frac{50,000}{6} \times 0.20 \times 4 = $6,667/year $$

Multiply that across 10 trucks, and you’re looking at $66,000+ in annual savings.

Factors Affecting ROI

- Vehicle type and size

- Driving conditions

- Kit quality and tuning

- Driver behavior

Long-Term Benefits

- Lower fuel costs

- Extended engine life due to cleaner combustion

- Tax incentives for emissions reduction (varies by region)

While results vary, most users see ROI within 6 to 18 months of consistent operation.

VI. Safety Considerations

Hydrogen is highly flammable, so safety cannot be overstated. Fortunately, reputable HHO generator kits include features to mitigate risk.

Built-In Safety Features:

- Flashback Arrestors: Prevent ignition from reaching the generator

- Relief Valves: Release excess pressure

- Water Level Indicators: Prevent dry operation

Best Practices

- Only use distilled water.

- Inspect connections monthly.

- Avoid DIY modifications unless you’re certified.

- Never bypass safety devices.

Proper maintenance ensures the system operates efficiently without compromising vehicle safety.

VII. Product Comparisons: Evaluating HHO Generator Kits

When evaluating kits, don’t just go for the cheapest option. Focus on efficiency, durability, and support.

| Feature | Why It Matters |

|---|---|

| Electrode Quality | Better materials = longer lifespan and more efficient gas production |

| PWM Adjustability | Allows fine-tuning for different engines |

| Documentation | Clear manuals simplify installation and maintenance |

| Warranty | Indicates confidence in product quality |

| Support Availability | Essential for troubleshooting and system optimization |

Types of Kits Available

- Basic DIY Kits: Suitable for hobbyists

- Commercial-Grade Kits: Designed for fleet-level applications

- Plug-and-Play Kits: Require minimal installation time

Always verify certifications and ask for performance testing data when evaluating vendors.

VIII. Regulations and Legal Considerations

While HHO kits can be legally installed in most areas, modifying emissions systems may void manufacturer warranties or violate local regulations.

Key Points:

- Check local laws regarding vehicle emissions and modifications.

- Seek certification from vendors with emissions compliance.

- Understand potential liability if used on public transport or government contracts.

It’s essential to work with certified installers who understand both the technical and legal framework.

IX. Conclusion

HHO generator kits offer a promising route to enhanced fuel efficiency, lower emissions, and long-term cost savings—especially for B2B buyers managing large fleets.

By understanding the science, components, installation, and ROI, businesses can make informed decisions about integrating hydrogen fuel generators into their operations.

Looking to explore further? Consider consulting an energy solutions provider or reaching out to certified installers to assess feasibility for your fleet.

Frequently Asked Questions (FAQs)

1. Are HHO generator kits legal for use in commercial fleets? Legal status varies by jurisdiction. Always check local regulations and emissions laws before installation.

2. How much fuel can I realistically save with an HHO kit? Typical savings range from 10% to 25%, depending on vehicle type, usage, and installation quality.

3. Is it safe to generate hydrogen inside a vehicle? Yes—when using a certified HHO kit with safety features like bubblers, flashback arrestors, and pressure relief valves.

4. Can I install an HHO generator kit myself? DIY installation is possible but not recommended for commercial vehicles. Professional installation ensures optimal safety and performance.

5. Do HHO kits work on diesel engines? Absolutely. Many commercial kits are designed specifically for diesel trucks and heavy-duty applications.

6. Will using an HHO kit void my vehicle warranty? It can. Check with your vehicle manufacturer and local regulations before modifying any engine components.