In the global race toward decarbonization, the hydrogen economy is advancing at an unprecedented pace. With demand for hydrogen expected to surge sevenfold by 2050, industries are shifting from experimental trials to full-scale implementation of hydrogen technologies. From next-generation fuel cell vehicles and maritime shipping to resilient backup power systems and industrial green hydrogen production, the applications are expanding daily. At the core of this technological shift lies a single, critical component: the PEM (Proton Exchange Membrane) stack.

However, in this highly competitive landscape, standard components lead to standard results. For ambitious projects, an off-the-shelf PEM stack is often a source of compromise, creating bottlenecks in performance, durability, and system integration that can jeopardize project success and profitability. True innovation and market leadership demand an engineered solution.

This is where customized PEM stack solutions become a strategic necessity. By moving beyond a one-size-fits-all approach and engineering a stack for a specific application, businesses can unlock unparalleled efficiency, extend operational lifespan, and significantly lower the total cost of ownership.

This comprehensive guide is written for the decision-makers driving the hydrogen future.

Who This Guide Is For:

- OEMs (Original Equipment Manufacturers) seeking a reliable, high-performance PEM stack to integrate into their products and a manufacturing partner who can scale with their needs.

- Project Developers in green hydrogen, maritime, aerospace, and energy sectors who require components that meet stringent performance and reliability targets.

- International Distributors looking to offer their clients a portfolio of superior, application-specific hydrogen fuel cell and PEM electrolyzer solutions.

As a professional manufacturer and wholesale supplier, Hele Titanium Hydrogen provides this guide to illuminate the technical and financial advantages of investing in a custom-engineered fuel cell stack.

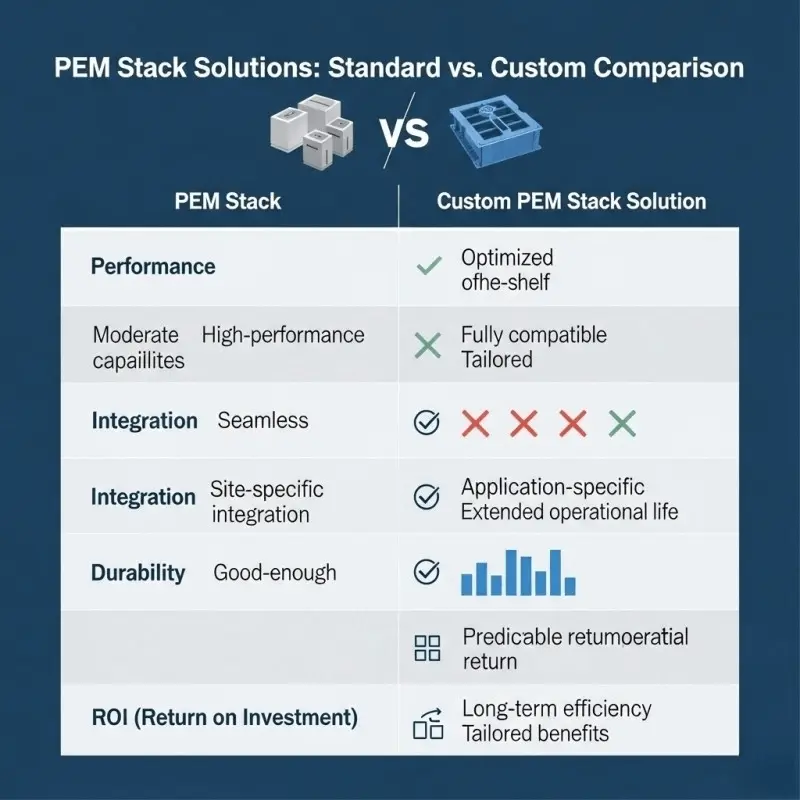

Standard vs. Custom PEM Stacks: A Strategic Comparison

The initial choice between a standard and a custom PEM stack can define a project’s trajectory. Off-the-shelf stacks are convenient for initial prototyping and basic applications, but they are fundamentally a product of compromise, designed for the broadest possible use case rather than for optimal performance in a specific one. For serious B2B applications, these compromises manifest as tangible business risks, including inefficient operation, costly integration challenges, and a shorter lifespan, all of which contribute to a lower return on investment.

A custom PEM stack, by contrast, should be viewed not as a simple component cost but as a long-term strategic investment in your system’s core performance. The difference is stark, as this comparison table illustrates:

| Feature | Standard (Off-the-Shelf) Stack | Custom-Engineered PEM Stack Solution |

|---|---|---|

| Performance & Efficiency | Generic efficiency curve. Performance degrades significantly outside of ideal operating conditions. | Performance Optimization: Precisely tailored to specific current densities, voltage ranges, and dynamic load cycles for maximum efficiency in your application. |

| System Integration | Fixed dimensions and port locations force complex and often costly modifications to the surrounding system architecture. | Application-Specific Fit: Designed to your exact dimensional, weight, and port configuration requirements for seamless “plug-and-play” system integration. |

| Durability & Lifespan | Uses standard materials that may fail prematurely under environmental stressors like corrosion, vibration, or humidity, leading to a shorter lifespan. | Engineered Durability: Material selection is matched to your operational environment (e.g., titanium for maritime, shock-resistant composites for aerospace) to ensure maximum reliability and longevity. |

| Cost Structure | Lower upfront purchase price. | Higher initial design and tooling investment, but a significantly lower Total Cost of Ownership (TCO) due to higher efficiency, reduced maintenance, and longer operational life. |

| Ideal Use Case | Initial R&D, academic research, non-critical applications where performance is secondary to immediate availability. | Mission-critical commercial systems, large-scale industrial projects, and any application where performance, reliability, and long-term ROI are primary business drivers. |

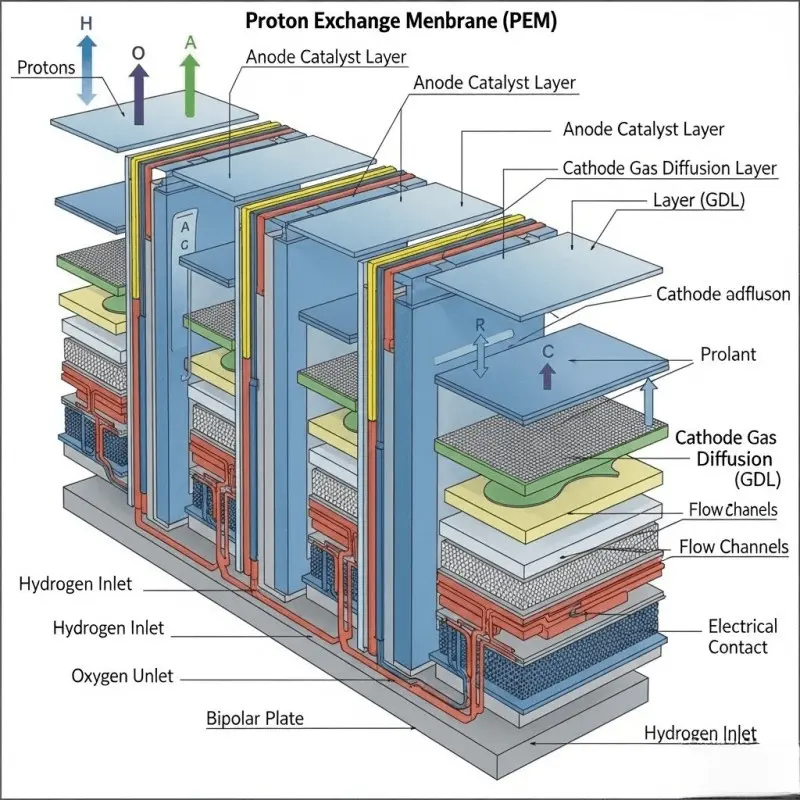

The Engineering Core: A Technical Deep Dive

The superior performance of a custom PEM stack doesn’t come from superficial changes. It’s the result of deep engineering at the component level, optimizing the electrochemical heart of your system. A true custom solution involves a meticulous redesign of the stack’s core elements.

Advanced Materials Science

The operational environment dictates the materials. A standard stack uses materials meant for benign conditions, but specialized applications demand more.

- Bipolar Plates: These plates perform the critical functions of conducting electrons and distributing gases. While standard stacks often use graphite or basic stainless steel, a custom stack allows for superior materials. For maritime applications, we engineer stacks with titanium bipolar plates that offer exceptional corrosion resistance to saltwater, preventing degradation and ensuring a long service life. For aerospace projects, lightweight graphite composites or surface-treated metallic plates are used to achieve the highest possible power-to-weight ratio.

- Membranes and Gaskets: The proton exchange membrane is the core of the cell. We select advanced membranes and sealing systems designed to withstand high pressures for hydrogen production or the specific thermal cycles of a fuel cell in a transportation application, preventing gas leaks and ensuring safe, reliable operation.

Flow Field Design Optimization

The microscopic channels on the surface of the bipolar plates—the flow field—control how hydrogen and oxygen gases are delivered to the catalyst. An poorly designed flow field leads to “flooding” or “starvation,” crippling performance. Using advanced Computational Fluid Dynamics (CFD) modeling, we engineer custom flow field patterns (such as serpentine, parallel, or interdigitated) to ensure uniform gas distribution and effective water management, perfectly matching your system’s operating pressures and flow rates. This optimization is a key driver of the stack’s overall efficiency and power density.

MEA (Membrane Electrode Assembly) Optimization

The MEA is where the electrochemical reaction happens, facilitated by catalyst layers. In a custom PEM stack design, we don’t use a generic MEA. We tailor it. For a high-efficiency PEM electrolyzer operating 24/7, we might optimize the catalyst loading to maximize hydrogen production and minimize degradation over time. For a hydrogen fuel cell in a drone, which needs to respond to rapid changes in power demand, we would design the MEA for fast response and high power output, ensuring the vehicle has the agility it needs. This level of customization ensures the electrochemical engine of your system is perfectly tuned for its mission.

Real-World Applications & Case Study Spotlight

The strategic advantage of custom fuel cell and electrolyzer stacks is most evident in industries where performance is non-negotiable. Customization creates measurable, competitive advantages in these key sectors:

- Aerospace: For unmanned aerial vehicles (UAVs), flying taxis, and future hydrogen-powered aircraft, power-to-weight ratio is everything. Custom-built, lightweight, and compact PEM stacks deliver the high power output needed for propulsion and onboard systems, enabling longer flight times and heavier payloads.

- Maritime: The maritime industry faces intense pressure to decarbonize. Custom-designed, corrosion-resistant PEM stacks are being deployed as auxiliary power units and primary propulsion systems on ferries, cargo ships, and naval vessels, offering a reliable, zero-emission alternative to diesel engines.

- Backup Power Systems: For critical infrastructure like hospitals, data centers, and telecom towers, power outages are not an option. Custom hydrogen fuel cells provide instantaneous, reliable, and long-duration backup power, ensuring operational continuity when the grid fails.

- Green Hydrogen Production: The efficiency of the PEM electrolyzer stack directly impacts the cost of green hydrogen. The International Energy Agency (IEA) projects that PEM electrolyzer capacity will need to grow 25-fold by 2030 to meet climate targets. Custom stacks, optimized for dynamic operation with renewable energy sources like wind and solar, are key to making these projects economically viable and scalable.

Case Study Spotlight: Green Hydrogen Production Challenge: A North American energy integration firm aimed to develop a commercial-scale green hydrogen facility powered by a solar farm. To secure financing, they needed to prove the project’s long-term financial viability by minimizing the levelized cost of hydrogen (LCOH). Their initial tests with off-the-shelf electrolyzer stacks showed efficiency levels that were too low and degradation rates that were too high to meet their target ROI. Solution: They partnered with Hele Titanium Hydrogen in an ODM (Original Design Manufacturer) capacity. Our engineering team conducted a deep analysis of their planned operational profile, including the variable power input from the solar array. We then designed a custom PEM electrolyzer stack featuring high-activity catalysts and an optimized flow field for dynamic efficiency. Result: The custom-engineered stack delivered superior performance under real-world variable power conditions. The client reduced their hydrogen production costs by 15% and projected a stack lifespan that was two years longer than the standard alternative, securing the project’s financing and positioning them as a leader in regional green hydrogen production.

The Partnership Model: Beyond a Supplier Relationship

For complex B2B projects, a simple transactional relationship with a component supplier is insufficient. You need a partner who is as invested in your project’s success as you are. This is the core of our philosophy at Hele Titanium Hydrogen. An OEM/ODM partnership model moves beyond supplying a part to co-creating a solution.

- Dedicated Project Support: From the moment you engage with us, you are assigned a dedicated project manager and engineering contact. This ensures clear, consistent, and responsive communication, eliminating the frustrations of dealing with multiple departments. Your dedicated contact understands your project’s history and goals, providing efficient and knowledgeable support at every stage.

- Collaborative Engineering: We view our engineering team as an extension of yours. We work with your designers and engineers in a collaborative process, sharing insights, solving complex technical challenges together, and ensuring the final stack design integrates perfectly with your broader system.

- Transparent Process: Trust is built on transparency. We provide a clear project roadmap with defined milestones, open communication about progress and challenges, and a shared commitment to your project’s goals. Our aim is to build a long-term relationship founded on mutual success.

Our Transparent 6-Step Customization Process

To ensure a successful outcome and de-risk the development process, we follow a structured, transparent, and client-focused methodology. This journey transforms your specific requirements into a reliable, factory-produced core component for your system.

- Consultation & Requirement Analysis: The process begins with a deep-dive consultation to fully understand your application, performance goals, operational environment, and integration constraints.

- Engineering Design & Simulation: Using sophisticated modeling and simulation tools like CFD and FEA, our engineers design the optimal stack architecture, virtually testing and refining it to meet your specifications before any physical parts are made.

- Prototype Development: We manufacture a functional prototype of your custom stack. This unit is not just a model; it is a fully operational stack built for performance validation.

- Rigorous Testing & Validation: The prototype undergoes a battery of exhaustive tests in our facility to validate every aspect of its performance, from power output and efficiency to durability under simulated operational stresses.

- Mass Production & Quality Assurance: Once the prototype is approved, we transition to factory-scale production under strict ISO 9001 certified quality control processes, ensuring every stack delivered is identical in quality and performance to the validated unit.

- Global Delivery & Ongoing Support: We manage the complexities of international logistics to deliver your order on time, anywhere in the world. Our partnership continues after delivery with ongoing technical support to assist with system integration and lifecycle management.

Addressing Your Key Concerns (Cost & Timelines)

Embarking on a custom engineering project naturally brings up questions about investment and timelines. We believe in addressing these concerns head-on.

“Isn’t customization much more expensive?”

It is true that a custom-engineered PEM stack has a higher initial investment for design, tooling, and prototyping than an off-the-shelf product. However, focusing solely on the upfront price is a critical mistake. The true financial measure is the Total Cost of Ownership (TCO). A custom stack generates a powerful return on investment through:

- Higher Energy Efficiency: Consumes less fuel (for a fuel cell) or less electricity (for an electrolyzer) to achieve the same output, leading to significant operational cost savings over thousands of hours.

- Longer Lifespan: Superior materials and an application-specific design reduce wear and tear, extending the time between costly stack replacements.

- Reduced Maintenance & Downtime: Higher reliability means less time and money spent on maintenance and fewer losses from system downtime.

When you factor in these long-term savings, the custom solution is very often the more financially sound choice for any serious commercial or industrial application.

Wondering what the ROI could be for your project? Download our free ‘Custom PEM Stack ROI Calculator’ (Excel Template) to analyze the numbers for yourself.

“What is the typical lead time for a custom stack?”

The development timeline for a custom stack is longer than buying off-the-shelf, typically spanning several weeks or months depending on complexity. This period includes design, simulation, prototyping, and rigorous testing. While this requires planning, this upfront investment of time is one of the most valuable risk-mitigation strategies you can employ. It ensures that the component you receive is fully validated and fit for purpose, preventing the far more costly and time-consuming delays that arise from trying to integrate an ill-suited standard component late in your project schedule.

De-Risking Your Global Supply Chain

In today’s volatile global market, choosing a manufacturing partner requires more than just technical expertise. It requires confidence in their ability to deliver consistently and reliably. For our international B2B clients, we focus on de-risking the supply chain.

- Factory-Scale Production & Capacity: Our modern manufacturing facility is equipped to handle both specialized, low-volume orders and large-scale, wholesale production runs. This scalability ensures we can grow with you as your market demand increases.

- Rigorous Quality Control (ISO 9001 Certified): Our commitment to quality is unwavering. We operate under strict ISO 9001 quality management standards, with multiple quality control checkpoints throughout the production process. This ensures that every PEM stack that leaves our factory meets the highest international standards of performance and reliability.

- Proven Global Export Experience: We are experts in international trade. Our logistics team has a proven track record of successfully exporting to clients across North America, Europe, and Asia-Pacific. We handle the complexities of packaging, customs, and shipping, ensuring your components arrive safely and on time.

Conclusion: Your Strategic Advantage in the Hydrogen Economy

In the rapidly evolving hydrogen sector, your choice of core components will define your success. Settling for a standard, off-the-shelf PEM stack means settling for average performance, compromised reliability, and a higher long-term cost.

A customized PEM stack solution is more than just a component; it’s a strategic investment in your project’s competitive advantage. It’s the key to achieving the market-leading efficiency, unwavering reliability, and seamless integration necessary to succeed. For B2B buyers, distributors, and OEMs, embracing customization is the most direct path to delivering a superior product and achieving a stronger return on investment.

Start Your Customization Journey with Hele Titanium Hydrogen

As a leading PEM water hydrogen generator manufacturer and OEM/ODM supplier, Hele Titanium Hydrogen is ready to be your trusted partner in innovation. Let’s build a solution engineered for your success.

👉 Take the next step today:

- 📊 [Request a Free Consultation with Our Engineers] to discuss your specific technical challenges and project goals.

- 📥 [Download our Whitepaper: “The ROI of Customized PEM Stacks”] to explore the financial benefits in more detail.

- 📌 [Access a Case Study: How a Client Cut Hydrogen Costs by 15%] to see our expertise in action.

📧 Contact our international team directly at heletitaniumhydrogen@gmail.com or via WhatsApp: +86-13857402537

Hele Titanium Hydrogen – Engineering Customized PEM Stack Solutions for a Sustainable Future.

Hele Titanium Hydrogen: Your Trusted Hydrogen Generator OEM & Manufacturing Partner

Hele Titanium Hydrogen stands as a reliable and experienced partner in the hydrogen generator OEM supply chain. We specialize in the design, development, and manufacturing of high-performance PEM Water Hydrogen Generators, offering comprehensive OEM & Manufacturing services tailored to your specific needs.

Take the Next Step

Ready to explore the possibilities of partnering with Hele Titanium Hydrogen?

- Browse our Products to see our range of PEM Water Hydrogen Generators.

- Learn more about our Services and how we can support your OEM & Manufacturing needs.

- Contact Us today to discuss your specific requirements.

- Explore our FAQ to get answers to common questions.

- Visit our Blog for the latest insights and updates on hydrogen technology.

Email Us: heletitaniumhydrogen@gmail.com

Phone/WhatsApp: 086-13857402537