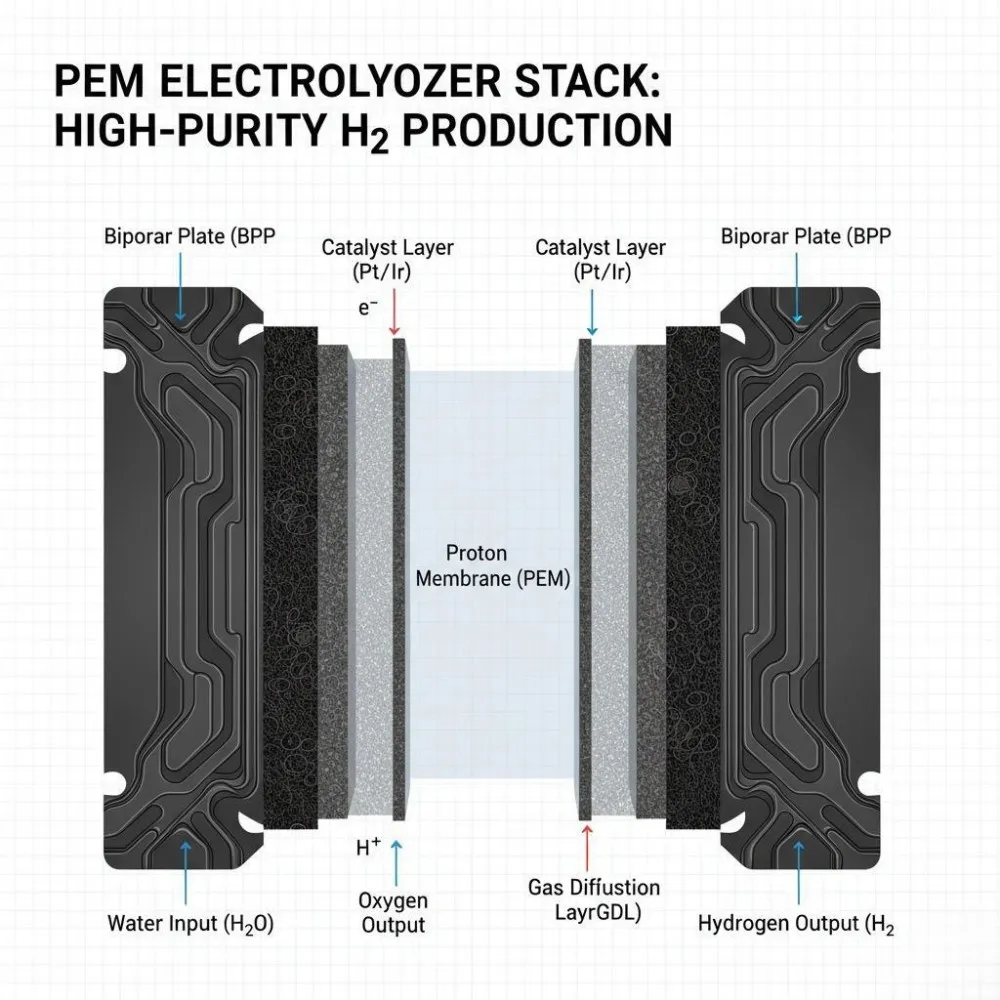

The global commitment to decarbonization has firmly cemented green hydrogen as a cornerstone of the future energy matrix. At the critical intersection of renewable energy and industrial processing lies the Proton Exchange Membrane (PEM) electrolyzer. Prized for its dynamic response and production of high-purity hydrogen, PEM technology is essential for projects seeking seamless integration with intermittent power sources like wind and solar.

For sophisticated B2B buyers—including project developers, EPC firms, and hydrogen generator suppliers—the success of high-stakes projects depends on moving beyond standardized equipment and partnering with a dedicated PEM Electrolyzer OEM for a custom PEM solution.

This comprehensive B2B Buyer’s Guide leverages deep industry expertise and Google E-E-A-T principles to provide the critical framework for the strategic purchase of hydrogen production equipment, ensuring your investment translates into predictable performance, optimized TCO, and superior system integration.

I. The Strategic Imperative of Custom PEM

The sheer pace of renewable energy deployment demands hydrogen electrolysis equipment manufacturers that can meet power intermittency challenges head-on. The hydrogen electrolyzer market is valued at over $1.75 Billion in 2025, driven by the need for reliable, flexible industrial zero-emissions electrolyzer providers.

Hydrogen’s New Frontier: Why PEM is B2B Procurement’s First Choice

- Green Hydrogen Procurement’s Paradigm Shift: The market is shifting from generic products to bespoke water electrolysis systems. High-value projects require partners capable of co-designing the system to meet constraints in footprint, pressure, or control systems. This expertise is the hallmark of a true PEM Electrolyzer OEM and wholesale supplier.

- PEM Technology’s Exclusive Competitive Edge:

- Dynamic Load Following: The solid membrane allows PEM units to ramp up and down in sub-second timeframes, directly maximizing the capture of curtailed renewable energy, a non-negotiable factor for optimized electrolyzer efficiency.

- Ultra-High Purity: PEM inherently produces hydrogen purity exceeding 99.999%, essential for sensitive industrial processes and hydrogen mobility applications where high-purity hydrogen is critical.

- High Output Pressure: PEM systems deliver hydrogen at high pressure (≥30 bar), significantly reducing the need for expensive downstream compression—a crucial factor in lowering the overall electrolyzer pricing.

- Dynamic Load Following: The solid membrane allows PEM units to ramp up and down in sub-second timeframes, directly maximizing the capture of curtailed renewable energy, a non-negotiable factor for optimized electrolyzer efficiency.

🌟 Early Call-to-Action (CTA): Stop settling for off-the-shelf limits. Inquire Today to discuss your required capacity, pressure, and complex integration interfaces with our specialized PEM engineering team. We are ready to transition your specs into a custom PEM electrolysis solution.

II. Procurement Fundamentals: Defining PEM Specifications and Customization Needs

A successful B2B purchase is rooted in technical alignment. The following metrics must be rigorously defined to optimize the Total Cost of Ownership (TCO).

Commercial Specifications: Matching Performance to ROI

| Specification | Unit | Competitive Target (2026 DOE Target) | Impact on TCO and Project Success |

|---|---|---|---|

| Energy Consumption / Efficiency | kWh/kg H2 | ≤48 kWh/kg (≥69% LHV) | 70-80% of LCOH is OpEx. Lower consumption directly reduces hydrogen production cost. |

| System Pressure (Output) | bar | ≥30 bar | Eliminates $100-$300/kW in downstream compression CapEx. |

| Average Degradation Rate | mV/kh | ≤2.3 mV/kh | Extends lifetime from 40,000 h to 80,000 h, vital for stack longevity. |

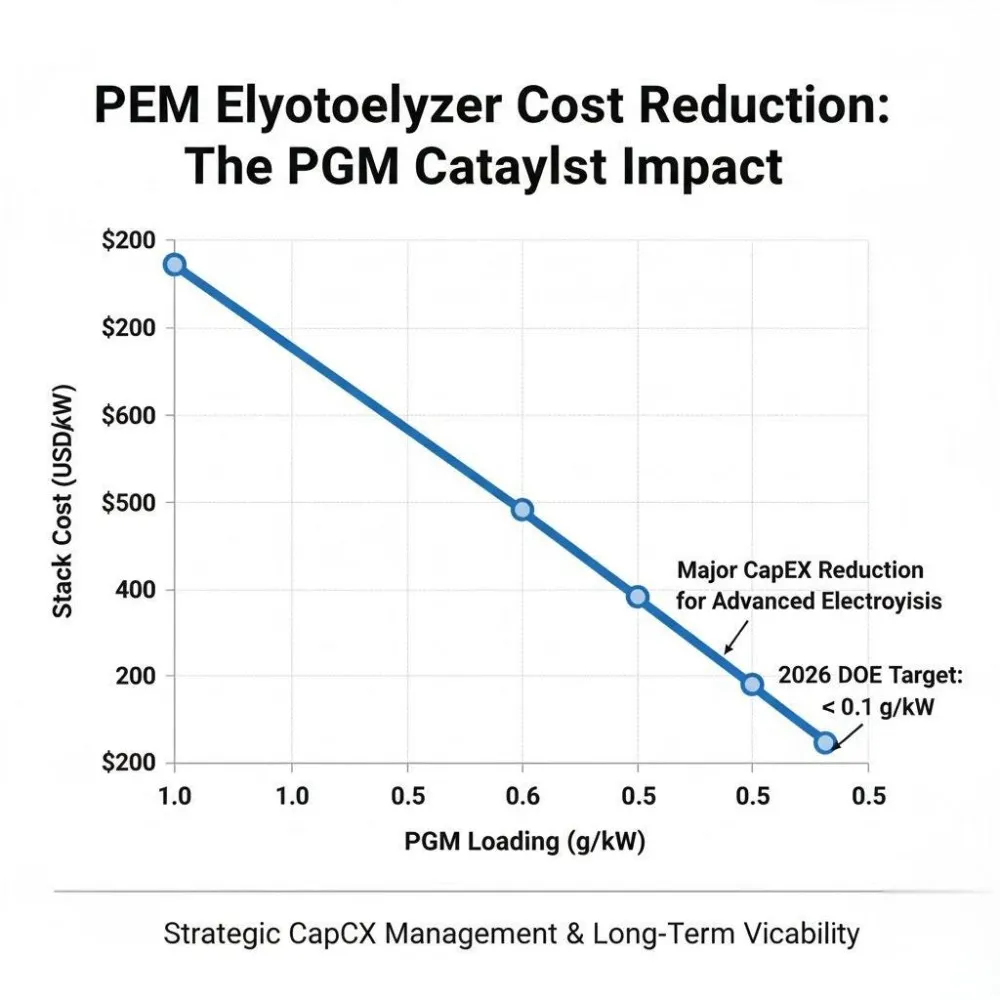

| Iridium Loading (PGM) | g/kW | ≤0.1 g/kW | Directly impacts stack electrolyzer pricing and residual PGM recovery value. |

OEM-Centric Customization Requirements

This is the key step that maximizes value when you buy hydrogen electrolyzer systems.

- Custom BOP Integration: The Balance-of-Plant (BOP) accounts for $\mathbf{\sim 35%}$ of equipment cost. A custom OEM optimizes BOP design (e.g., thermal management, purification) to minimize footprint and reduce installation cost.

- Control Interface Standardization: Define the exact PLC/HMI requirements to ensure seamless inclusion into existing operational technology (OT) networks. An OEM ensures SCADA/DCS compatibility from the design phase, mitigating costly integration delays.

- Modularization for Scaling: Your hydrogen production capacity must be scalable. Modular,5 MW containerized solutions are ideal for phased investment and rapid expansion into large-scale hydrogen production without system redesign.

III. Technology Deep Dive: The PEM Advantage and TCO Analysis

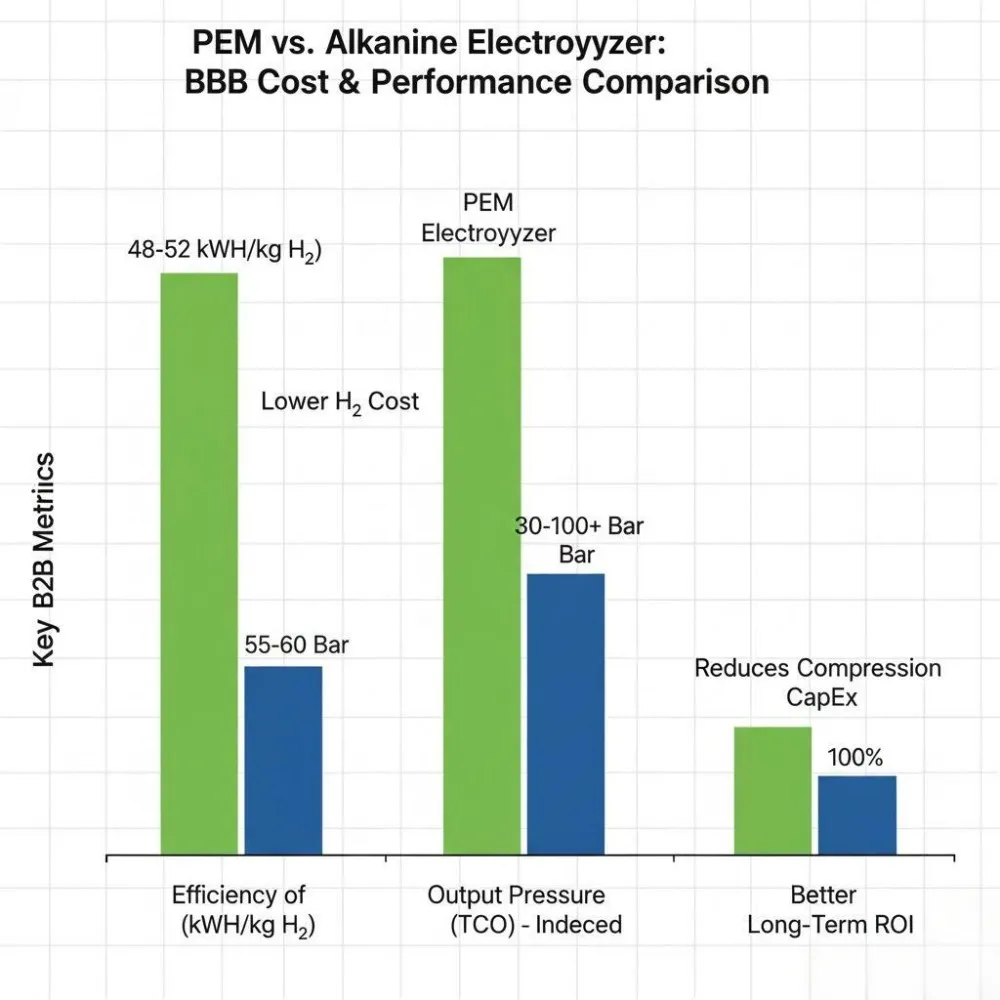

The strategic choice between PEM electrolyzer and alkaline electrolyzer technology must be grounded in performance and long-term financial viability.

###PEM vs. ALK: A Cost and Performance Comparison

| Feature | PEM Electrolyzer (Proton Exchange Membrane) | Alkaline Electrolyzer (AEL) | Strategic Decision Rationale |

|---|---|---|---|

| Dynamic Response | Superior (≤1 second) | Poor (Minutes/Hours) | Essential for capturing volatile renewable energy. |

| Purity Output | High (≥99.999%) | Moderate (≤99.8%) | Reduces CapEx on downstream purification equipment. |

| Power Density | High | Lower | Provides a smaller, more adaptable electrolyzer footprint. |

| Installed CapEx | Higher (∼$2,550/kW in 2025) | Lower (∼$2,300/kW in 2025) | CapEx difference is offset by lower long-term OpEx and reduced BOP cost. |

Capital Cost Reduction via OEM Innovation

While the initial CapEx for a PEM system may be 10-15% higher than a comparable alkaline unit, innovative hydrogen electrolysis equipment manufacturers are closing this gap:

- PGM Strategy: OEMs are aggressively reducing the stack’s dependency on Iridium, targeting loadings below 0.1 g/kW. This innovation is key to lowering the uninstalled capital cost (1,000/kW status → $250/kW target) and making PEM a leader in the next generation.

- Integrated Design: By co-optimizing the stack and BOP in a standardized, modular design, OEMs can achieve a 40-60% reduction in Total Installed Cost (TIC) compared to fragmented, custom-engineered projects. This integration is vital for the advanced electrolysis market.

Case Study Insight: A recent 10 MW wind integration project selected a custom PEM unit over an alkaline alternative. Although the PEM CapEx was 12% higher, its superior dynamic response provided a 15% increase in total captured wind energy over five years, vastly improving the project’s financial ROI.

IV. B2B Due Diligence: Evaluating PEM OEM Supplier E-E-A-T

When selecting hydrogen electrolyzer suppliers, vetting must focus on verifiable proof of capability, aligning with Google’s E-E-A-T principles (Experience, Expertise, Authoritativeness, Trustworthiness).

Supplier Selection Framework: Vetting PEM OEM E-E-A-T

- 1. Expertise and Innovation Track Record (E-E-A-T)

- R&D Commitment: Verify the supplier’s investment in advanced electrolysis through active patents in catalyst development and membrane durability. A credible supplier will provide data from Accelerated Stress Tests (AST) under dynamic cycling conditions.

- Core Component Control: Vertical integration (control over MEA and bipolar plate manufacturing) indicates higher quality control and stability—essential for a reliable hydrogen electrolyzer manufacturer.

- R&D Commitment: Verify the supplier’s investment in advanced electrolysis through active patents in catalyst development and membrane durability. A credible supplier will provide data from Accelerated Stress Tests (AST) under dynamic cycling conditions.

- 2. Trustworthiness and Global Compliance

- Certifications: Require adherence to the highest international standards: ISO 9001:2015 (Quality), ISO 45001 (Safety), CE Mark, and specific regional approvals (e.g., UL Certification for North America) to ensure safety and quality for hydrogen production equipment.

- Transparency: Demand verifiable Case Study Footers detailing system size, technology type, and location, showcasing true Experience as a provider of industrial zero-emissions electrolyzer providers.

- Certifications: Require adherence to the highest international standards: ISO 9001:2015 (Quality), ISO 45001 (Safety), CE Mark, and specific regional approvals (e.g., UL Certification for North America) to ensure safety and quality for hydrogen production equipment.

- 3. Customization and Scale-Up Capacity

- Flexible MOQ: A true OEM partner offers flexible Minimum Order Quantities (MOQ), supporting pilot projects as well as high-volume wholesale supplier contracts.

- Logistics Framework: Assess their capacity to fulfill multi-year contracts and their robust logistics framework for global delivery.

- Flexible MOQ: A true OEM partner offers flexible Minimum Order Quantities (MOQ), supporting pilot projects as well as high-volume wholesale supplier contracts.

🔥 Early Call-to-Action (CTA): Verify our E-E-A-T credentials now. Request our full ISO compliance matrix and latest performance test reports to begin your strategic purchase evaluation.

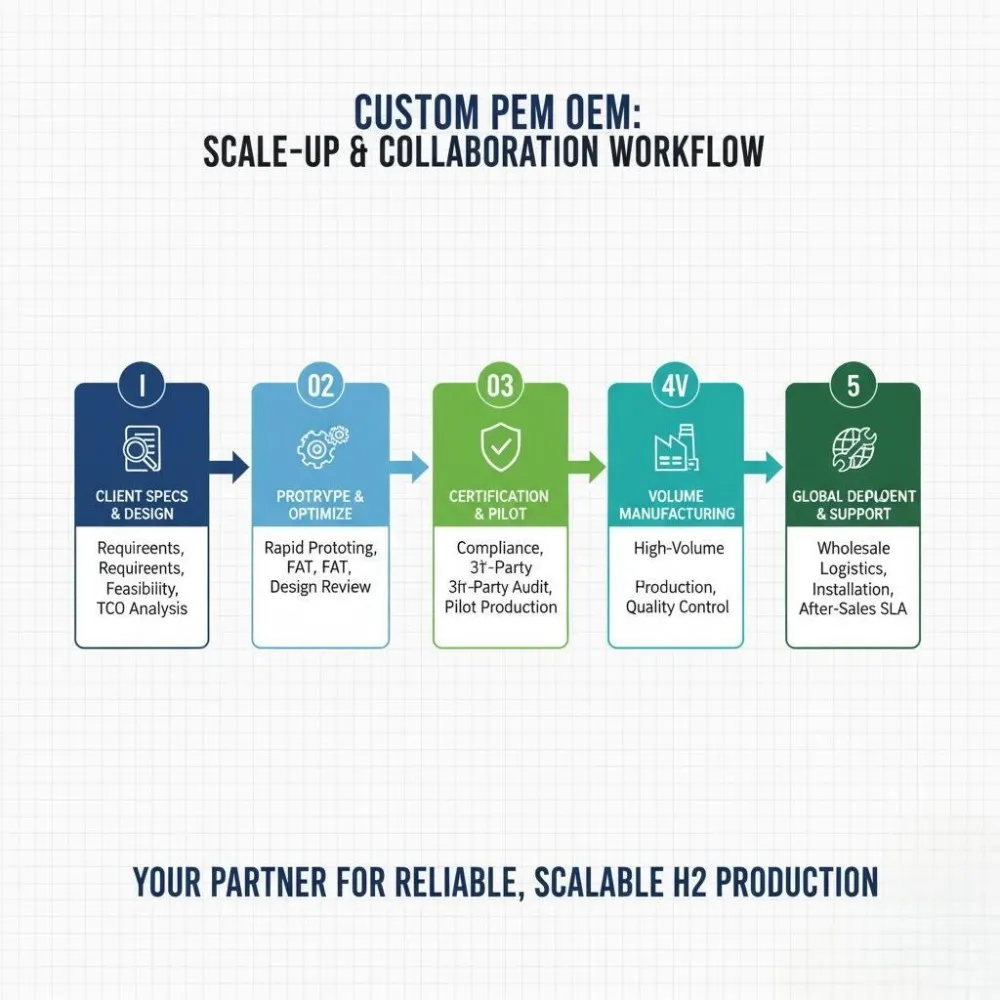

V. Strategic Collaboration: The PEM OEM Partnership Model

For multi-million dollar hydrogen production equipment contracts, the collaboration model is a critical asset. Our OEM model minimizes client risk and accelerates time-to-market and scale-up.

The OEM Collaboration Life Cycle: From Spec to Scale

| Phase | Deliverables from Dedicated PEM OEM | B2B Buyer Advantage |

|---|---|---|

| I. Concept & Scoping | Proprietary System Matchmaking; Feasibility studies; Iridium recovery plan (a crucial CapEx offset). | De-risked initial investment; Optimized hydrogen production capacity for the site. |

| II. Prototype & Vetting | Rapid Prototype Manufacturing; Certified FAT (Factory Acceptance Testing) report; Precise P&ID review. | Faster time-to-market; Verified performance against hydrogen electrolyzer specifications. |

| III. Volume Production | Supply chain transparency; JIT (Just-In-Time) delivery logistics; Wholesale pricing for scaled purchase orders. | Cost-competitive scaling; Reliable supply chain for continuous deployment. |

Warranty and After-Sales Support

A robust Service Level Agreement (SLA) is non-negotiable for water electrolysis systems suppliers.

- Uptime Guarantee: Demand remote monitoring and a guaranteed response time, adhering to 99.998% uptime standards.

- PGM Recycling: A defined, closed-loop process for precious metal recovery is essential for realizing the residual value of the stack, directly improving the project’s final ROI.

VI. Market Outlook & Future-Proofing Your Purchase

Future Validation: Trends and Investment Security

- Policy-Driven Acceleration: Government initiatives (e.g., U.S. IRA, EU Hydrogen Bank) are rapidly maturing the market. Investment now locks in low-cost supply ahead of the expected 98.14% market CAGR.

- Next-Generation Technology: Stay focused on advanced electrolysis by partnering with OEMs actively researching non-PGM catalysts (e.g., AEM, next-generation electrolyzer design) to hedge against future commodity price volatility.

Authoritative Data for Investment Benchmarking

The following data points, derived from U.S. DOE targets, provide the critical benchmarks for securing a high-performing system in the hydrogen application space:

| Key Target (US DOE 2026) | Status (2025 Estimate) | Strategic PEM Investment Implication |

|---|---|---|

| System CapEx | $250/kW | Target investment benchmark for large-scale hydrogen production. |

| Degradation | ≤2.3 mV/kh | Confirms 80,000 h lifespan, optimizing LCOH. |

| LCOH | $2.00/kg H2 | Achievable only with ≤48 kWh/kg efficiency and low-cost electricity. |

VII. Conclusion: Securing Your Custom PEM Electrolysis Solution

The path to commercial viability in green hydrogen is through high-performance, custom-engineered PEM electrolyzer solutions. Your strategic partner must be a dedicated PEM Electrolyzer OEM with proven expertise in stack innovation, global certification, and seamless system integration.

By adhering to a rigorous E-E-A-T-based vetting process and leveraging our wholesale supplier expertise, you ensure your hydrogen production equipment purchase is not just an expense, but a secure, long-term asset ready for the global scale-up.

🔥 Final Call-to-Action: Ready to secure your competitive edge and move from concept to certified prototype? Send us your system specifications today to initiate a rapid design and quotation process for your custom PEM electrolyzer project. Contact our engineering team now to transition from concept to certified prototype.

The SUpplier below offers B2B buyers a valuable, in-depth look at the technology and complex supply chain behind PEM electrolyzers, supporting the “Expertise” pillar of their due diligence: Inside a PEM Electrolyser: Hydrogen, Tech & Supply Chain.

Key Factors to Consider When Choosing Hydrogen Electrolyzer Suppliers

Selecting the right hydrogen electrolyzer supplier can determine the long-term success of your hydrogen project. Here’s what to evaluate:

Production Capacity and Scalability

Ensure the supplier can meet your project’s capacity—whether it’s a small 5 MW pilot or a 500 MW industrial-scale installation.

Technology Type and Efficiency Levels

Choose suppliers offering advanced electrolyzer technologies that align with your energy sources and cost targets.

After-Sales Service, Warranty, and Technical Support

Reliable suppliers offer maintenance contracts, remote monitoring, and 24/7 technical support.

Compliance with Global Standards and Certifications

Look for ISO, CE, and IEC certifications that ensure safety and quality standards are met.

Industrial and Commercial Applications

Hydrogen electrolyzers are used in diverse sectors, including:

- Fuel cell vehicles and hydrogen fueling stations

- Steel and chemical manufacturing

- Renewable energy storage systems

- Power-to-gas and synthetic fuel production

Common Challenges in Hydrogen Electrolyzer Procurement

- Supply Chain Bottlenecks: Delays in critical materials like membranes and catalysts.

- Cost Fluctuations: Variations in raw material pricing can affect system cost.

- Integration Complexity: Matching hydrogen output with renewable energy input efficiently.

Best Practices for Partnering with Hydrogen Electrolyzer Suppliers

Establish long-term partnerships for stability and innovation.

Use performance-based contracts to ensure accountability.

Leverage digital procurement tools for transparent comparisons and documentation.

Frequently Asked Questions (FAQs)

1. What are the main types of hydrogen electrolyzers?

PEM, Alkaline, and Solid Oxide are the three main types, each suited to different applications.

2. How do I choose the best hydrogen electrolyzer supplier?

Evaluate their experience, technology, scalability, and after-sales support.

3. Are hydrogen electrolyzers expensive?

Costs are decreasing due to innovation and scale, though large systems still require significant investment.

4. Which regions have the most hydrogen electrolyzer manufacturers?

Europe and Asia currently lead, followed by North America.

5. Can I integrate electrolyzers with solar or wind energy?

Yes, PEM electrolyzers are particularly well-suited for renewable integration.

6. How can I ensure product quality?

Always choose suppliers with global certifications and proven project references.

Hele Titanium Hydrogen: Your Trusted PEM electrolyzer OEM & Manufacturing Partner

Hele Titanium Hydrogen stands as a reliable and experienced partner in the PEM electrolyzer OEM supply chain. We specialize in the design, development, and manufacturing of high-performance PEM Water Hydrogen PEM electrolysis system, offering comprehensive OEM & Manufacturing services tailored to your specific needs.

Take the Next Step

Ready to explore the possibilities of partnering with Hele Titanium Hydrogen?

- Browse our Products to see our range of PEM Water Hydrogen production equipment.

- Learn more about our Services and how we can support your OEM & Manufacturing needs.

- Contact Us today to discuss your specific requirements.

- Explore our FAQ to get answers to common questions.

- Visit our Blog for the latest insights and updates on hydrogen technology.

Email Us: heletitaniumhydrogen@gmail.com

Phone/WhatsApp: 086-13857402537