Engineer Your Lab’s Gas Supply: Custom OEM PEM Electrolyzer Solutions for Peak Performance

The pursuit of groundbreaking research and the maintenance of rigorous quality control demand absolute precision in every element of a modern laboratory. At the heart of this precision is the quality and consistency of your gas supply, and for countless critical applications, that means ultra-pure hydrogen.

Introduction: Beyond Off-the-Shelf – The Strategic Advantage of Custom PEM Solutions

The critical challenge many world-class laboratories, research institutions, and OEM instrument manufacturers face is the inherent compromise of relying on traditional, inflexible hydrogen supply methods.

Traditional methods introduce risks:

- Hydrogen Cylinders: They pose significant safety risks, require constant handling and replacement, and the purity can never be guaranteed at the point of use due to potential wall and valve contamination. This inconsistency is the enemy of analytical precision.

- Off-the-Shelf Generators: While safer, standard generators often provide flow rates, pressure ranges, or purity levels that are “close enough,” but not perfectly tailored to highly specialized analytical equipment like high-end Gas Chromatography (GC) systems or cutting-edge Fuel Cell R&D rigs.

This is why 99.999% pure hydrogen is not a luxury, but a necessity for precision experiments. Impurities, even in trace amounts, can lead to baseline noise, drift, and fundamentally corrupt research and analytical results.

As a leading OEM PEM electrolyzer manufacturer, we don’t just supply equipment; we engineer custom, on-demand gas solutions. Our approach transforms lab operations by providing a reliable, safe, and perfectly tailored source of hydrogen that maximizes instrument performance and guarantees the integrity of your data. When your application demands specific parameters, choosing to purchase or buy a Custom PEM Electrolysis Solution is a strategic investment in the future of your research.

1. Why Top Laboratories Are Switching to PEM Electrolysis Technology?

The shift from cylinders and bulk supply to on-site generation is driven by overwhelming safety, operational, and financial advantages. Within the on-site generation space, Proton Exchange Membrane (PEM) Electrolysis has become the gold standard for laboratory-grade purity.

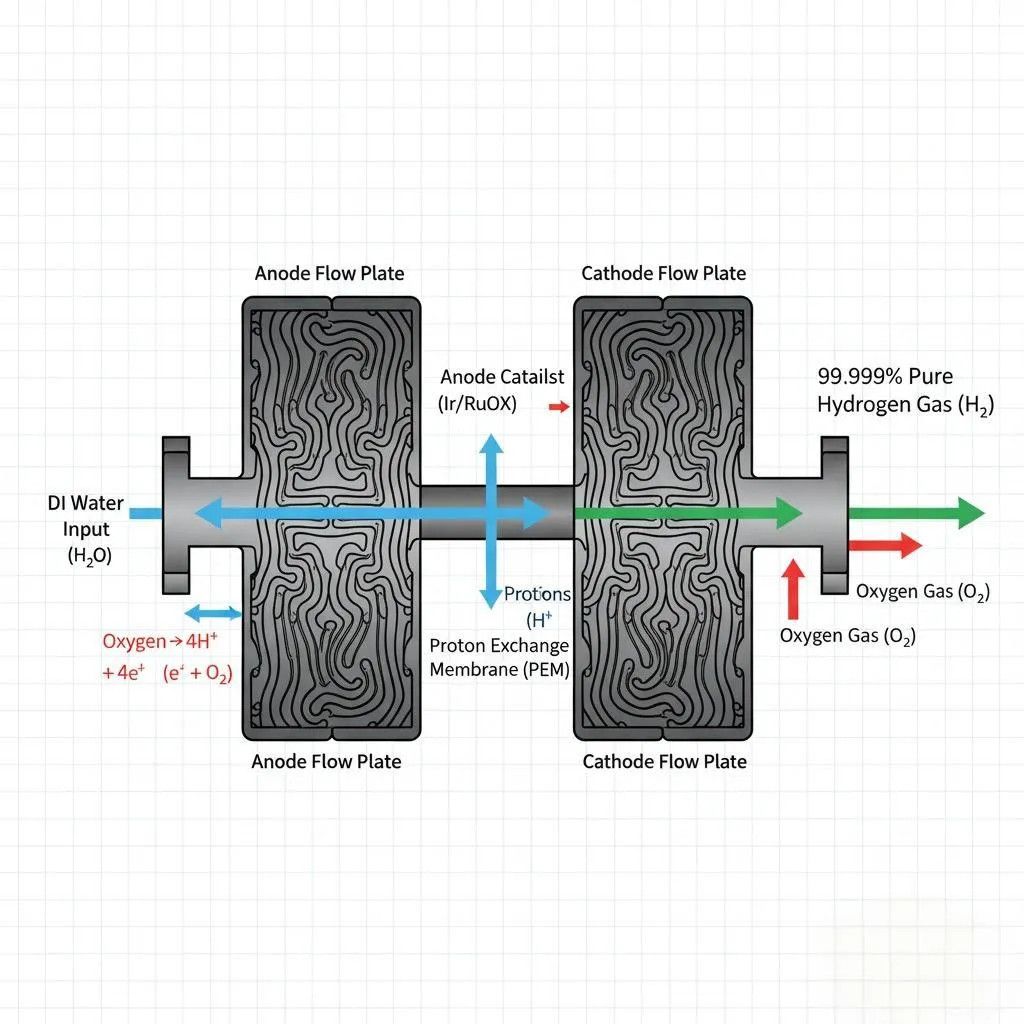

PEM Electrolysis Fundamentals

PEM electrolysis works by using an innovative solid polymer electrolyte (the membrane) to separate hydrogen and oxygen. Water is introduced on the anode side, where an electrical current splits it into oxygen, protons H+, and electrons. The protons travel through the high-selectivity PEM to the cathode, where they combine with electrons to form gaseous hydroge H2.

This process is inherently superior for two key reasons:

- Science Behind Ultra-Pure Hydrogen: The membrane itself acts as a physical barrier, ensuring that the produced hydrogen is nearly bone-dry and free from carryover lye (caustic) that can plague alkaline systems, resulting in an output that is 99.999% pure or better.

- Operational Flexibility: PEM systems are highly dynamic, capable of quick start-up and immediate response to changes in demand, providing true on-demand hydrogen generation critical for intermittent laboratory use.

The Ultimate Showdown: PEM vs Traditional Methods

| Feature | PEM Hydrogen Generator (On-Site) | Hydrogen Cylinders (Bulk Supply) | Alkaline Electrolyzers (Older Gen) |

|---|---|---|---|

| Purity (Typical) | > 99.999% | < 99.995% (Risk of Wall/Valve Contam.) | < 99.99% (Risk of KOH Carryover) |

| Safety | Low pressure, small volume, auto-shutdown | High-pressure, large volume, explosion risk | Requires handling of corrosive lye |

| Cost | Low long-term Total Cost of Ownership (TCO) | High recurring rental/refill costs | High maintenance and lower efficiency |

| Operational Flexibility | On-demand, responsive, automated | Requires scheduled delivery/replacement | Slower response, less dynamic load range |

The on-demand hydrogen advantage means no more supply logistics, cylinder storage fees, or the labor costs associated with continuous replacement. It represents a significant upgrade in safety and operational efficiency, making it the clear choice for laboratories looking to buy or purchase a long-term gas solution.

2. Behind the Scenes: Engineering Laboratory-Grade PEM Hydrogen Generators

To achieve the precise, reliable performance required by sensitive analytical equipment, a laboratory-grade PEM generator must be built on a foundation of exceptional engineering and component quality.

Core Component Excellence

The key to high purity and longevity lies in the materials and design of the core cell stack:

- Membrane Electrode Assembly (MEA) Selection: We customize the MEA—the heart of the electrolyzer—based on the client’s duty cycle and required purity specifications. Selecting the correct membrane thickness and catalyst loading is crucial for both power efficiency and durability.

- Catalyst Optimization: Customization extends to the catalyst (typically platinum group metals) to optimize the system for maximum efficiency and an extended lifespan, minimizing long-term replacement costs.

- Advanced Purification Systems: To ensure that final output reaches the crucial 99.999% pure hydrogen mark, our systems incorporate advanced, multi-stage filtration and drying systems to remove trace moisture and any minor residual impurities, often exceeding standard industry specifications.

Precision Engineering for Laboratory Precision

A laboratory-grade generator is not simply an industrial unit scaled down; it is a precision instrument designed to integrate seamlessly with highly sensitive equipment:

- Flow and Pressure Control Systems: We engineer systems with precise output capabilities ranging from 0 to 1000 mL/min (or higher for R&D applications) with an accuracy of ±1%. This highly stable flow is essential for applications like GC carrier gas, where flow fluctuations directly impact retention times and peak area integration.

- Smart Monitoring & Safety: Our units include sophisticated safety redundancy protocols, including internal leak detection, auto-shutdown mechanisms, and remote operation capabilities. Compliance with standards like ISO 16110 and NFPA is built-in, not bolted on.

- Instrument Compatibility: We provide full software and hardware compatibility with leading analytical instrument brands, ensuring smooth integration and the ability to link the generator’s status directly to the analytical software.

3. Your Applications, Our Solutions: How Custom PEM Generators Empower Research

The need for customizability stems directly from the diversity of high-precision lab applications, where one-size-fits-all simply fails.

Gas Chromatography (GC) Applications

Hydrogen is widely used in GC as a carrier gas and as fuel for Flame Ionization Detectors (FID).

- Purity Impact: The purity of the hydrogen directly affects the GC’s baseline stability and detection limits. Trace oxygen or moisture acts as a poison, reducing column life and increasing background noise. Our 99.999% pure hydrogen generator eliminates this risk.

- Custom Flow Rates: We design systems to perfectly match the combined flow needs of multiple detectors (e.g., FID, TCD) and carrier gas requirements, optimizing the efficiency of the entire GC lab.

Fuel Cell Research & Development

Fuel cell R&D requires a consistently high-volume and high-purity source of hydrogen for rigorous testing and simulation.

- Reliable Supply: We offer custom wholesale PEM electrolyzer supplier solutions that provide the high-flow, high-pressure output necessary for advanced fuel cell testing and stack development, ensuring uninterrupted operation.

- Catalyst Research: For researchers working with highly sensitive catalysts, we can customize purity thresholds to ensure the generated gas meets specific, non-standard impurity limits, supporting the most demanding catalyst research.

Pharmaceutical Synthesis & Calibration Standards

Consistency and regulatory compliance are non-negotiable in the pharmaceutical industry.

- Meeting GMP Compliance: Our generators are designed to meet stringent Good Manufacturing Practice (GMP) requirements. On-site generation eliminates the audit trail complexity of managing external gas supplies.

- Consistency Assurance: The on-demand, stable purity is critical for creating consistent H2/N2 calibration standards and maintaining uniformity across synthesis batches.

University Research & Quality Control Labs

For multi-user, multi-application environments, flexibility and scale are key.

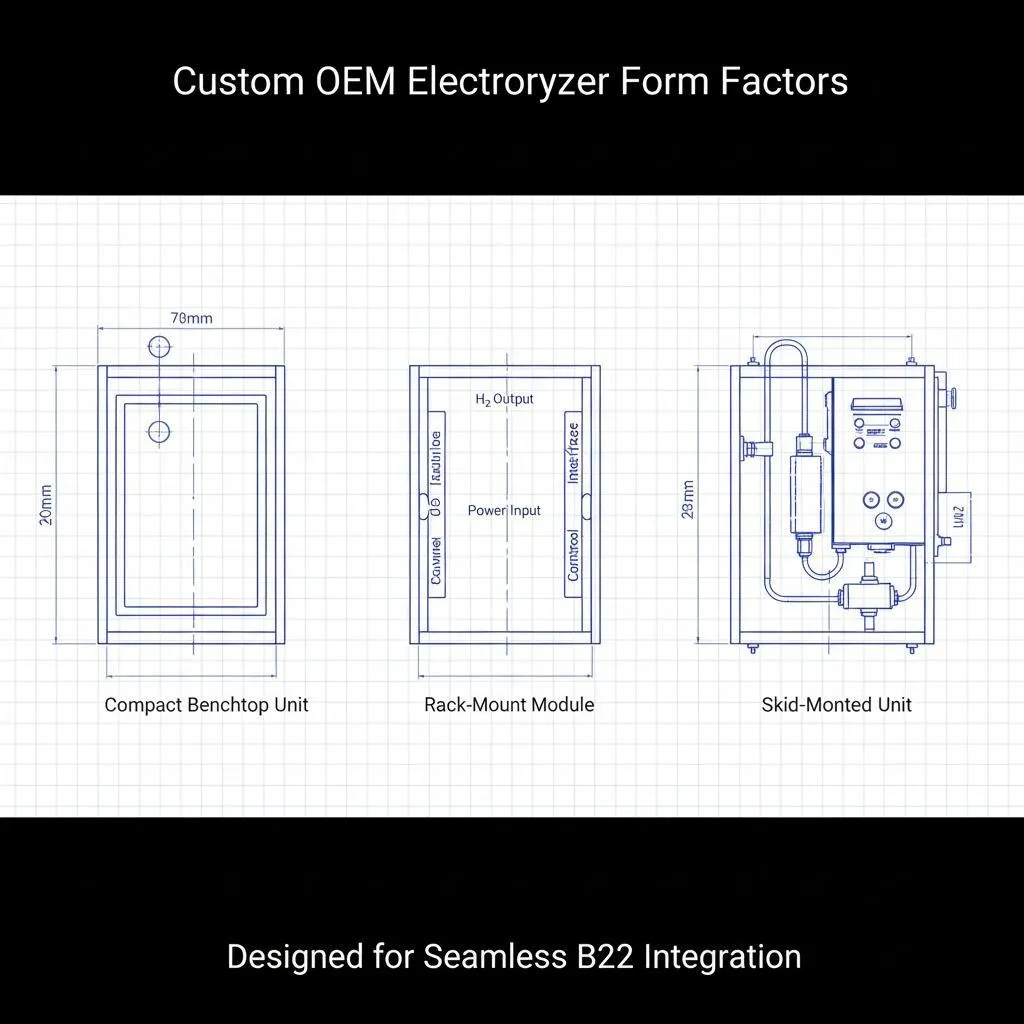

- Compact Design: We offer custom PEM electrolysis solutions in a compact form factor for space-constrained university labs, allowing high-purity gas to be generated precisely where it’s needed.

- Modular Scalability: Our OEM approach allows for modular scalability. Labs can start with a smaller unit and easily add capacity later, future-proofing their purchase against growing research needs.

4. OEM & Collaboration: When Standard Products Don’t Meet Your Unique Needs

For leading analytical instrument companies, integrators, and large-scale research programs, a standard product simply won’t suffice. You need a manufacturing partner who can integrate a hydrogen solution into your own product or facility design.

We’re Manufacturing Partners, Not Just Suppliers

Our strength lies in our role as a dedicated PEM electrolyzer OEM. We function as an extension of your engineering team, specializing in the design and wholesale PEM electrolyzer supplier of core components or fully finished, branded generators.

The OEM advantage is clear: it allows you to bring a custom, high-purity hydrogen solution to market faster or integrate it into your R&D framework without significant internal R&D investment.

Customization Capabilities Showcase

The power of a truly custom solution is realized across critical parameters:

- Flow Rate and Pressure Customization: Beyond standard settings, we can engineer output specifications for non-standard pressure needs (e.g., 10 bar to 20 bar) and specific, high-demand flow profiles.

- Purity Grade Customization: For ultra-sensitive applications, we can provide systems capable of 99.9999% (UHP) purity by adding specialized polishing systems to meet unique impurity thresholds.

- Form Factor and Integration Customization: Need the generator to fit within a specific cabinet, bench space, or machine housing? Our engineers can adapt the physical design, cooling, and venting mechanisms.

- Software and Communication Protocol Adaptation: We customize the HMI (Human-Machine Interface), onboard software, and communication protocols (e.g., Modbus, Ethernet/IP) to ensure seamless data exchange with your internal control systems.

Success Story: Custom PEM Electrolysis Solution in Action

Case Study: Solving Unique Challenges for a Global Environmental Testing Lab

A leading global testing laboratory required a hydrogen generator to be permanently integrated into a mobile, containerized analysis unit for remote fieldwork. The unit had strict dimensional and weight limits, and required a robust anti-vibration build.

Our Custom Solution: We designed a ruggedized, vibration-dampened OEM PEM electrolyzer solution, reducing the standard footprint by 30% and integrating a custom water recirculation and cooling system that performed reliably across extreme temperature variations.

Quantifiable Benefits Delivered: The client was able to deploy their mobile lab 50% faster than expected, eliminating the logistical burden and safety risks of transporting H2 cylinders to remote sites, leading to an estimated 40% reduction in annual gas supply costs.

5. The Smart Choice: Key Decision Factors for Laboratory PEM Generator Procurement

Making the choice to buy or purchase a custom PEM generator requires a detailed assessment of needs and manufacturer capabilities.

Defining Your Requirements

Before you engage a supplier, define the core parameters of your application:

- Purity Specifications: Will 99.999% suffice, or do you require 99.9999% for highly specialized work? Refer to standards like ASTM D7649 for guidance.

- Flow Rate and Pressure: Determine the peak and average flow rate needed across all connected instruments, and the exact output pressure required to avoid regulator issues.

- Safety and Compliance Needs: Ensure the generator meets international standards such as ISO 16110 (Hydrogen generators using water electrolysis) and local fire codes like NFPA.

Evaluating Manufacturer Capabilities

The best product comes from the best partnership. Evaluate your PEM electrolyzer OEM based on:

- Technical Expertise & R&D Investment: Look for manufacturers with a demonstrated commitment to internal research and development, showing the technical depth to deliver on custom requirements.

- OEM Experience and Customization Flexibility: Can the manufacturer provide verifiable examples of past, complex OEM projects? Customization is a measure of technical confidence.

- Quality Systems and Certifications: Demand proof of quality control systems (e.g., ISO 9001) and relevant product safety certifications (e.g., CE, UL).

- After-Sales Support and Service Network: A generator is a long-term investment. Ensure the manufacturer has a robust global service network to minimize downtime.

Total Cost of Ownership (TCO) Analysis

When comparing a PEM hydrogen generator vs cylinder cost comparison, the TCO clearly favors the on-site generation route.

- Generator vs. Cylinder Cost: While the initial purchase price of a generator is higher, the ongoing costs of cylinder rental, gas purchase, shipping, and labor for change-outs quickly eclipse this investment.

- Long-Term Operational Cost Savings: The primary running cost is electricity and periodic water replenishment. Over a typical 5-year lifespan, a PEM generator delivers significant savings.

- ROI Calculation Framework: We provide a clear framework to calculate your Return on Investment (ROI), often demonstrating a payback period of 18 to 36 months, making the decision to buy a custom unit a clear financial winner.

6. Beyond the Product: Comprehensive Support Ecosystem

A high-quality generator is just one part of the solution; expert support ensures peak performance from day one.

Seamless Installation & Integration

Our commitment to you extends through the entire lifecycle of the product:

- Professional Installation Guidance: We provide detailed, professional guidance to ensure the unit is installed correctly, respecting all ventilation and safety requirements.

- Integration with Existing Equipment: Our technical teams specialize in ensuring seamless integration with your existing analytical instruments, including proper piping, pressure regulation, and communication setup.

Training & Compliance Support

Knowledgeable users are safe, efficient users:

- Comprehensive Operator Training Programs: We offer hands-on training to your team on the safe operation, basic troubleshooting, and preventive maintenance of the unit.

- Safety Protocols and Best Practices: We help you establish and maintain safety protocols, ensuring compliance with local gas handling and high-purity gas generation best practices.

Ongoing Maintenance & Optimization

- Preventive Maintenance Schedules: We offer customizable service contracts and preventative maintenance schedules to maximize uptime and extend the lifespan of the MEA.

- Remote Diagnostics and Support Capabilities: Our advanced units are equipped with remote diagnostics, allowing our engineers to quickly assess and troubleshoot issues, minimizing costly service calls and downtime.

7. Future Vision: PEM Technology Evolution and Your Long-Term Investment

Choosing an OEM PEM electrolyzer manufacturer like us means investing in a technology partner who is constantly innovating.

Emerging Trends in PEM Technology

Our continuous R&D ensures your generator is ahead of the curve:

- Smart Monitoring and IoT Integration: We are integrating advanced Internet of Things (IoT) sensors for real-time performance tracking, predictive maintenance alerts, and seamless integration into laboratory informatics systems (LIMS).

- Enhanced Efficiency and Reliability: Our ongoing work focuses on developing next-generation MEAs that offer higher current density and energy efficiency, further reducing the TCO.

Ensuring Your Investment is Future-Proof

- Upgrade Paths and Technology Refresh Options: We provide clear pathways for upgrading your system with new components or features as technology evolves, protecting your original purchase decision.

- Scalability for Future Research Needs: Our modular design philosophy ensures that your current generator can be supplemented or upgraded to meet rising demand, allowing your hydrogen supply to grow alongside your research.

Conclusion & Compelling Call to Action

The integrity of your research, the safety of your personnel, and the efficiency of your budget depend on a high-quality, reliable hydrogen supply. By choosing a custom OEM PEM electrolyzer solution, you gain:

- Ultra-Pure Hydrogen > 99.999% purity: Guaranteeing the highest quality results for your most sensitive analytical instruments.

- Unmatched Customization Capability: Leveraging our OEM PEM electrolyzer manufacturer expertise to perfectly tailor flow, pressure, and form factor to your unique laboratory and product integration needs.

Standard solutions not meeting your unique research requirements?

Don’t compromise your data integrity with off-the-shelf equipment. Partner with the experts who can engineer the gas supply solution your laboratory deserves.

Contact our engineering team today to discuss tailored PEM electrolysis solutions for your laboratory.

Request Your Custom Quote

Schedule a Technical Consultation

Let our experts help you design the perfect hydrogen solution for your specific applications and take the strategic step to buy or purchase the ultimate in laboratory gas reliability.

Frequently Asked Questions (FAQs)

1. PEM Technology & Purity

What is the typical hydrogen purity our PEM electrolyzers deliver?

Our custom-engineered PEM electrolyzers deliver 99.999% (Grade 5.0) pure hydrogen H2 as standard, primarily through the superior separation capability of the Proton Exchange Membrane (PEM) and advanced drying systems. For highly specialized applications like semiconductor or sensitive research, we offer customization up to 99.9999% (Grade 6.0) purity by integrating advanced polishing filters.

How does PEM purity compare to traditional hydrogen cylinders?

While cylinders may start with high purity, their consistency is often compromised by cylinder wall degradation, valve contamination, or moisture buildup, particularly as the pressure drops. On-site PEM hydrogen generation ensures stable, guaranteed purity at the point of use > 99.999% with zero risk of external contamination, which is vital for maintaining GC baseline stability.

What is the main byproduct of PEM electrolysis and how is it managed?

The only byproduct is oxygen O2 gas, which is safely separated from the hydrogen by the PEM. It is vented directly to the atmosphere from the back of the unit. The process is clean, using only deionized water and electricity.

2. Operational & Technical Requirements

What water quality is required to operate the PEM generator?

Our PEM systems require Deionized (DI) water to protect the membrane and and catalyst. We recommend ASTM Type I (resistivity of >10 MΩ-cm) or, at minimum, ASTM Type II (≥1 MΩ-cm) water purity. We can supply integrated DI water purification systems if you do not have a dedicated lab source.

What flow rate and pressure ranges can you customize?

As an OEM PEM electrolyzer manufacturer, we customize output based on your specific instrument needs. We offer tailored systems for lab use with flow rates typically ranging from 100 mL/min up to 1000 mL/min (or higher for R&D industrial scale), with custom pressure output up to 20 bar to account for long distribution lines or high-pressure application requirements.

What are the maintenance requirements?

Maintenance is minimal compared to cylinder logistics. It typically involves annual replacement of the deionizer cartridge/filter and periodic replenishment of the DI water reservoir. Our preventative maintenance schedules are designed for maximum uptime and can be supported by remote diagnostics.

How fast is the start-up time for a PEM generator?

PEM technology offers a highly dynamic response. Our generators provide on-demand hydrogen with a rapid start-up, often reaching full purity and pressure within minutes, making them ideal for intermittent or batch-based laboratory operations.

3. Safety & Procurement (B2B/Wholesale)

Are on-site PEM hydrogen generators safe?

Yes, significantly safer than high-pressure cylinders. PEM generators produce H2 on demand and store only a minimal, low-pressure inventory (well below NFPA safety limits). Our systems feature multi-stage safety redundancy, including continuous leak detection, automatic shutdown, and controlled venting, ensuring compliance with standards like ISO 16110.

What is the Total Cost of Ownership (TCO) advantage over cylinders?

While the initial investment (upfront purchase price) is higher for the generator, the TCO is dramatically lower. The generator eliminates recurring costs like cylinder rental, delivery fees, and labor for change-outs. Most laboratories see a Return on Investment (ROI) within 2 to 3 years due to operational savings.

What is our process for OEM/Wholesale inquiries?

Our OEM process begins with a detailed technical consultation to define your custom specifications (flow, purity, form factor, and communication protocols). This is followed by a design phase, prototype testing, certification support, and scalable manufacturing, solidifying us as your trusted wholesale PEM electrolyzer supplier.

Hele Titanium Hydrogen: Your Trusted PEM electrolyzer OEM & Manufacturing Partner

Hele Titanium Hydrogen stands as a reliable and experienced partner in the PEM electrolyzer OEM supply chain. We specialize in the design, development, and manufacturing of high-performance PEM Water Hydrogen PEM electrolysis system, offering comprehensive OEM & Manufacturing services tailored to your specific needs.

Take the Next Step

Ready to explore the possibilities of partnering with Hele Titanium Hydrogen?

- Browse our Products to see our range of PEM Water Hydrogen production equipment.

- Learn more about our Services and how we can support your OEM & Manufacturing needs.

- Contact Us today to discuss your specific requirements.

- Explore our FAQ to get answers to common questions.

- Visit our Blog for the latest insights and updates on hydrogen technology.

Email Us: heletitaniumhydrogen@gmail.com

Phone/WhatsApp: 086-13857402537