Looking for tailor-made hydrogen electrolyzer designs? Hele Titanium Hydrogen delivers custom hydrogen electrolyzer solutions designed to optimize efficiency, lower costs, and meet your exact industry needs.

Introduction: Why Custom Hydrogen Electrolyzer Solutions Matter Today

Global demand for green hydrogen is accelerating at a record pace. According to the International Energy Agency (IEA), hydrogen demand could grow sixfold by 2050, with green hydrogen accounting for the majority of future production. From powering heavy industries to fueling zero-emission transport, hydrogen is no longer just a vision—it’s a business opportunity.

At the heart of this transformation are hydrogen electrolyzers, the core technology that splits water into hydrogen and oxygen using electricity. While off-the-shelf models exist, industries with unique operational challenges—from steel manufacturing to renewable energy storage—are increasingly looking for custom hydrogen electrolyzer solutions tailored to their specific requirements.

As a trusted PEM hydrogen generator manufacturer and wholesale supplier, Hele Titanium Hydrogen specializes in designing and delivering tailored electrolyzer systems that maximize performance, reduce operating costs, and integrate seamlessly into diverse industrial applications.

👉 If your business is considering hydrogen adoption, now is the time to explore how customized electrolyzer solutions can unlock long-term value.

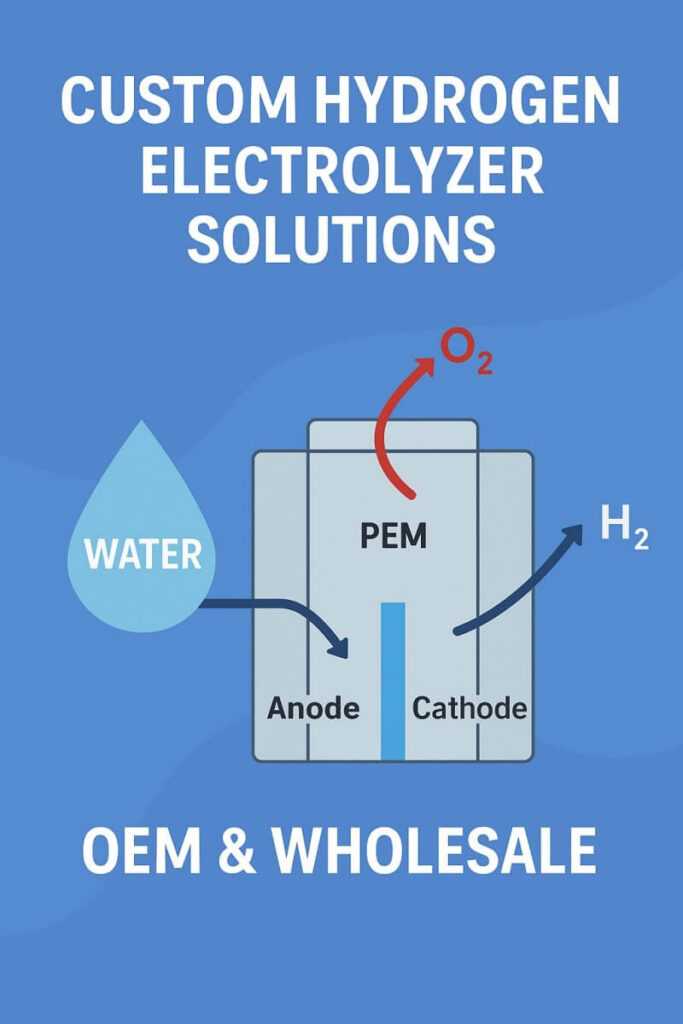

What is a Hydrogen Electrolyzer and How Does it Work?

A hydrogen electrolyzer is a system that uses electricity to split water (H₂O) into hydrogen (H₂) and oxygen (O₂). The hydrogen produced can then be stored, transported, or used as clean fuel.

Main Types of Electrolyzers

- Alkaline Electrolyzers – Mature, cost-effective, but slower in response and less flexible.

- Proton Exchange Membrane (PEM) Electrolyzers – High efficiency, compact design, fast response; ideal for integration with renewables.

- Solid Oxide Electrolyzers (SOE) – Operates at high temperatures, promising efficiency but still in development.

- Anion Exchange Membrane (AEM) Electrolyzers – Emerging technology combining some benefits of alkaline and PEM.

At Hele Titanium Hydrogen, our expertise lies in PEM water hydrogen generators, a technology renowned for high efficiency, compact design, and ability to adapt to fluctuating renewable power sources.

The Business Case for Custom Hydrogen Electrolyzer Solutions

While standard electrolyzers offer a one-size-fits-all approach, they often fail to meet the unique operational needs of industries. Custom solutions, on the other hand, are engineered to align with exact technical, financial, and sustainability goals.

Meeting Industry-Specific Demands

- Transportation & Mobility: Fleet operators need fast-response systems that can fuel hydrogen vehicles efficiently.

- Chemical & Industrial Production: Large-scale hydrogen demand for ammonia, methanol, and steel requires high-capacity, durable systems.

- Renewable Energy Storage: Custom electrolyzers designed to work with intermittent solar and wind power ensure consistent hydrogen output.

Improving Efficiency & Sustainability

Tailored solutions optimize operating parameters—temperature, pressure, and power density—resulting in:

- Higher hydrogen production rates

- Lower energy consumption per kilogram of hydrogen

- Improved system lifetime

Long-Term Cost Benefits

Though initial investment may be higher, custom electrolyzer solutions deliver long-term value by:

- Reducing operational expenses

- Extending lifespan through better material selection

- Offering higher ROI through optimized efficiency

👉 Investing in customized hydrogen systems isn’t just a sustainability move—it’s a strategic business decision.

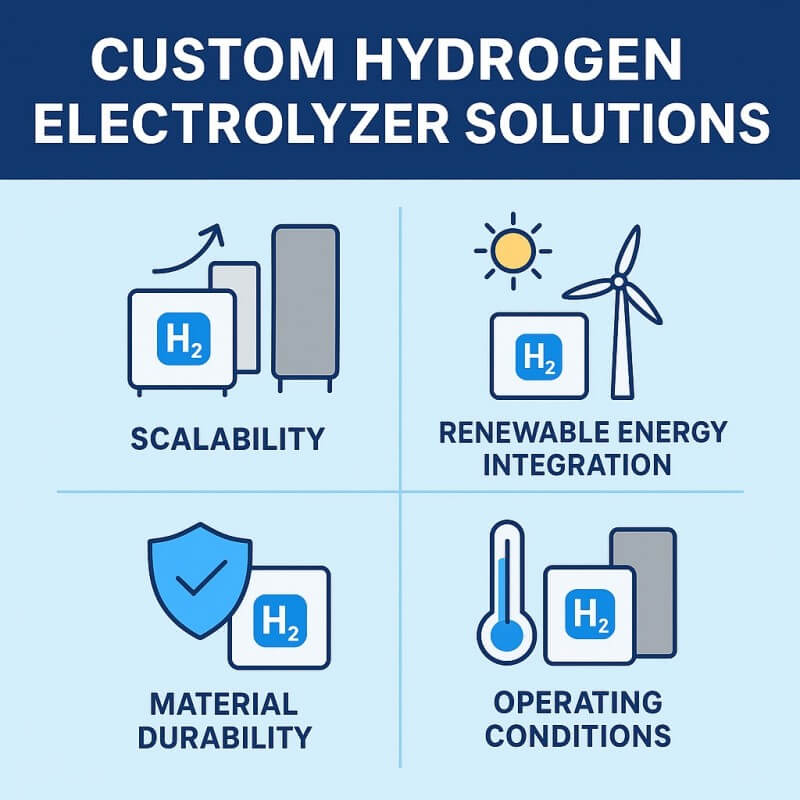

Key Considerations When Choosing Custom Electrolyzers

Scalability & Modular Design

Industries evolve, and so should your hydrogen infrastructure. Custom solutions can be designed as modular systems, allowing businesses to expand capacity as demand grows.

Renewable Energy Integration

Hydrogen electrolyzers often operate in tandem with solar, wind, or hydro. Custom systems can be engineered to:

- Handle fluctuating input power

- Store excess renewable energy

- Operate with hybrid grid + renewable setups

Material Durability & Lifetime

For PEM electrolyzers, advanced materials such as titanium are critical for withstanding high-pressure, corrosive environments. Hele Titanium Hydrogen uses premium-grade titanium and advanced PEM membranes, ensuring durability, reliability, and reduced maintenance.

Operating Conditions & Safety Standards

Different environments require different solutions:

- High-temperature zones need heat-resistant materials.

- Remote or offshore facilities demand compact, ruggedized systems.

- Compliance with ISO, CE, and industry-specific safety standards is non-negotiable.

The Customization Process: From Consultation to Commissioning

At Hele Titanium Hydrogen, customization isn’t just a product feature—it’s a complete process designed around the customer’s goals.

Initial Consultation & Feasibility Study

- In-depth discussions to understand hydrogen demand, site conditions, and integration needs.

- Feasibility analysis covering energy costs, hydrogen output targets, and scalability options.

Engineering & Prototyping

- Advanced CAD modeling and simulations.

- Prototype development to validate efficiency and durability under real-world conditions.

Manufacturing Excellence

- State-of-the-art production with strict quality control (QC).

- Use of titanium components and advanced PEM technology for superior performance.

Installation & Training

- On-site installation by technical experts.

- Operator training to ensure smooth handover.

Ongoing After-Sales Support

- Preventive maintenance programs.

- Spare parts supply and performance monitoring.

- Technical upgrades to keep systems future-ready.

👉 When you partner with Hele Titanium Hydrogen, you don’t just buy an electrolyzer—you gain a long-term technology partner.

Case Studies: Custom Hydrogen Electrolyzer Solutions in Action

Steel & Heavy Industry

A leading steel producer integrated a custom PEM electrolyzer solution to decarbonize its production line. Result:

- 30% reduction in CO₂ emissions

- Lower hydrogen costs compared to external supply

- Scalable system designed for future capacity expansion

Renewable Energy Storage

A remote wind farm required hydrogen storage to balance power fluctuations. A modular PEM electrolyzer designed by Hele Titanium Hydrogen allowed:

- 24/7 green hydrogen production

- Stable backup power supply

- Reduced dependence on fossil fuels

Hydrogen Mobility

A logistics company operating a fleet of hydrogen trucks adopted a customized solution for on-site hydrogen fueling. Benefits included:

- Fast refueling times

- Lower operational costs vs. traditional fuels

- Enhanced reliability for long-haul operations

How to Select the Right Partner for Hydrogen Electrolyzer Solutions

The right partner determines project success. Here’s what to look for:

Proven Expertise & Global Experience

Choose a supplier with successful track records across industries and geographies. Hele Titanium Hydrogen has delivered systems worldwide with a focus on PEM technology.

Advanced PEM Technology

As specialists in PEM hydrogen generators, we ensure higher efficiency, faster response, and better renewable integration.

Compliance & Certifications

Ensure suppliers meet international certifications (ISO, CE) and industry regulations for safety and quality.

Reliable B2B Support

A true partner offers OEM/ODM services, rapid response, and ongoing technical support to help your business grow.

👉 Hele Titanium Hydrogen is ready to be your trusted partner in custom electrolyzer solutions.

The Future of Custom Hydrogen Electrolyzer Solutions

The future is moving toward:

- Higher efficiency PEM systems with lower costs

- Integration with AI and IoT for smart hydrogen production

- Scaling up to gigawatt-level plants for global hydrogen supply

Custom solutions will remain at the center of this growth, empowering industries to transition toward sustainable and profitable energy models.

Frequently Asked Questions (FAQs)

1. What is the typical cost of a custom hydrogen electrolyzer solution?

Costs vary depending on scale, technology, and customization, but tailored solutions typically lower long-term operational expenses.

2. How long does it take to deliver and install a custom electrolyzer?

On average, lead times range from 3–6 months, depending on project complexity.

3. Can a custom PEM electrolyzer be integrated with existing renewable power systems?

Yes, PEM technology is highly compatible with solar, wind, and hybrid grids.

4. What certifications should I look for in a hydrogen electrolyzer supplier?

Look for ISO, CE, and compliance with local safety and environmental regulations.

5. How scalable are custom electrolyzer systems?

They can be designed as modular units, allowing businesses to expand production over time.

6. What kind of after-sales support does Hele Titanium Hydrogen provide?

We offer installation, training, maintenance, spare parts, and lifetime technical support.

Conclusion & Call to Action

The transition to green hydrogen is no longer optional—it’s a business imperative. Custom hydrogen electrolyzer solutions offer the flexibility, efficiency, and cost-effectiveness that industries need to thrive in a sustainable future.

At Hele Titanium Hydrogen, we combine world-class PEM technology, advanced manufacturing, and B2B expertise to deliver tailor-made solutions that fit your exact requirements.

🔗 Learn more about hydrogen technologies at the International Energy Agency (IEA).

Hele Titanium Hydrogen: Your Trusted Hydrogen Generator OEM & Manufacturing Partner

Hele Titanium Hydrogen stands as a reliable and experienced partner in the hydrogen generator OEM supply chain. We specialize in the design, development, and manufacturing of high-performance PEM Water Hydrogen Generators, offering comprehensive OEM & Manufacturing services tailored to your specific needs.

Take the Next Step

Ready to explore the possibilities of partnering with Hele Titanium Hydrogen?

- Browse our Products to see our range of PEM Water Hydrogen Generators.

- Learn more about our Services and how we can support your OEM & Manufacturing needs.

- Contact Us today to discuss your specific requirements.

- Explore our FAQ to get answers to common questions.

- Visit our Blog for the latest insights and updates on hydrogen technology.

Email Us: heletitaniumhydrogen@gmail.com

Phone/WhatsApp: 086-13857402537