Explore detailed insights on proton exchange membrane stack price trends and factors. Learn how to compare suppliers, cut costs, and choose the right hydrogen electrolyzer manufacturer for your business.

I. Introduction: Why PEM Stack Prices Matter for B2B Buyers

The hydrogen economy is rapidly transforming industries worldwide. At the heart of this transformation lies the proton exchange membrane (PEM) stack, a core component of hydrogen fuel cells and water electrolyzers. Whether powering fuel cell electric vehicles (FCEVs), supplying backup energy to factories, or enabling on-site hydrogen production, PEM stacks are essential for businesses looking to adopt sustainable energy solutions.

For international buyers and project developers, the proton exchange membrane stack price is a crucial consideration. Understanding how prices are structured, what factors influence them, and how to negotiate with suppliers can mean the difference between an affordable long-term solution and an over-budget investment.

In this article, we’ll provide a comprehensive guide to PEM stack pricing—covering everything from raw materials and manufacturing costs to supplier reputation and bulk order discounts. As a professional hydrogen electrolyzer manufacturer, Hele Titanium Hydrogen brings first-hand insights into how global buyers can save costs and secure reliable PEM stacks.

II. Understanding Proton Exchange Membrane (PEM) Stacks

A. What is a PEM Stack?

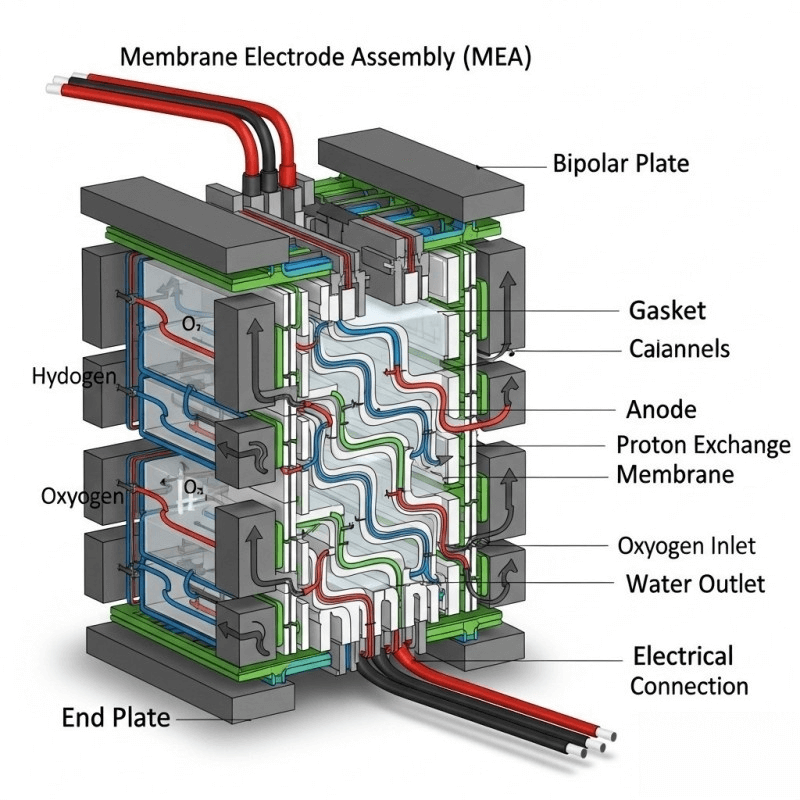

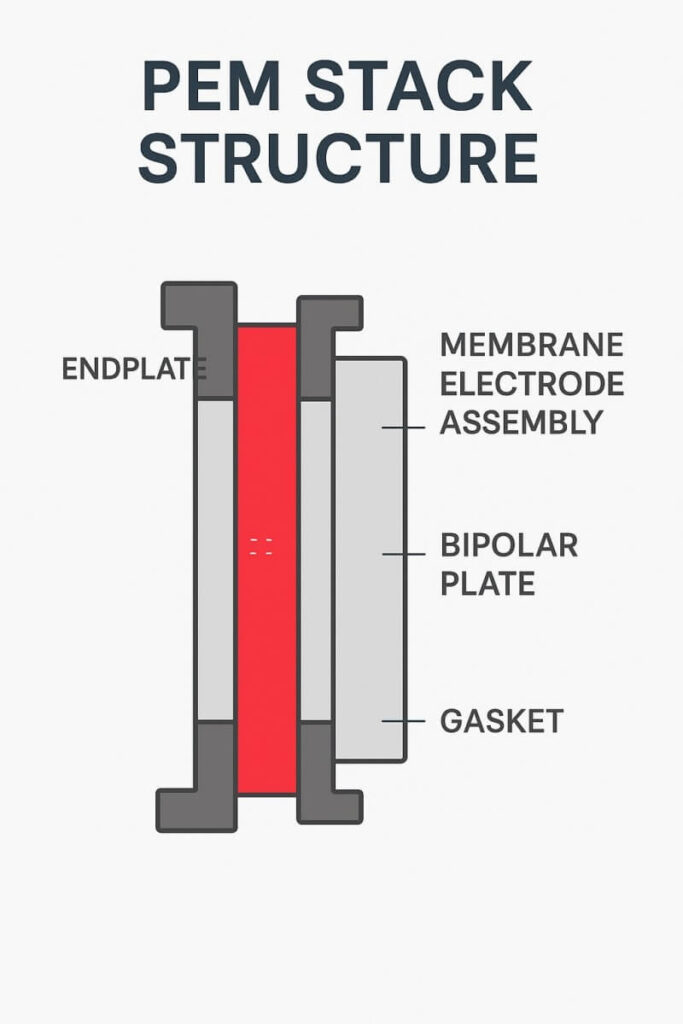

A PEM stack is the “engine” of a hydrogen fuel cell or water electrolyzer. It’s made up of several layers, including:

- Membrane Electrode Assemblies (MEAs): Core layer where the electrochemical reaction happens.

- Bipolar Plates: Distribute gases and conduct current. Materials include graphite, stainless steel, or titanium.

- Endplates & Gaskets: Seal the stack and provide structural support.

Together, these components enable efficient conversion of hydrogen into electricity (fuel cell) or water into hydrogen and oxygen (electrolyzer).

B. How PEM Stacks Work

- At the Anode: Hydrogen molecules split into protons and electrons.

- Through the Membrane: Protons pass through while electrons flow via an external circuit, generating power.

- At the Cathode: Oxygen combines with protons and electrons to form water, releasing clean energy.

C. Applications of PEM Stacks

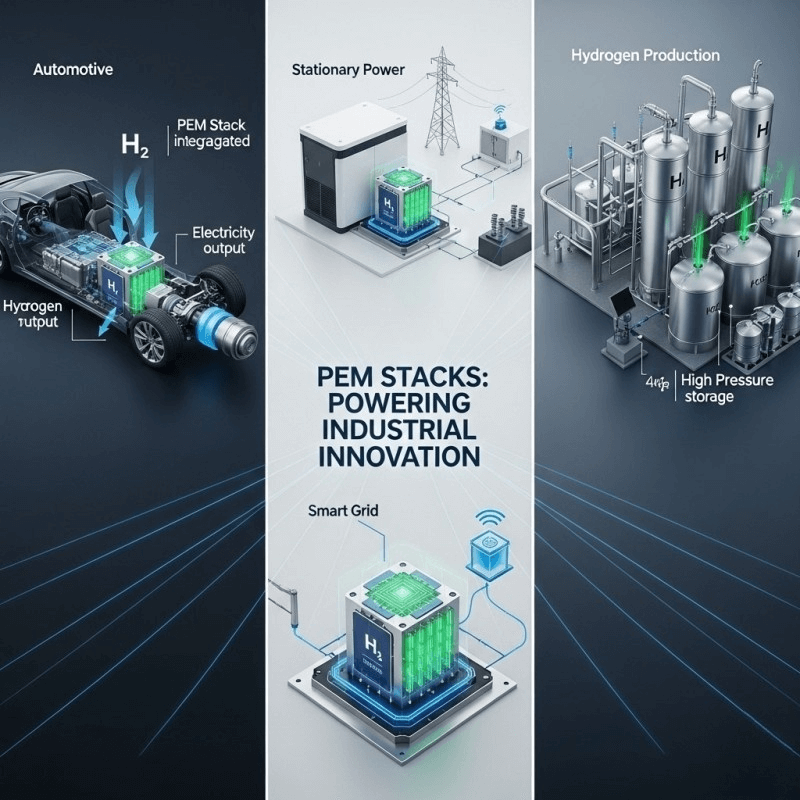

PEM stacks are widely adopted across industries:

- Automotive: Fuel cell vehicles from Toyota, Hyundai, and Honda use PEM stacks.

- Industrial Hydrogen Production: PEM electrolyzers generate hydrogen for factories and refineries.

- Stationary Power Systems: Backup energy for hospitals, data centers, and telecom towers.

- Portable Devices: Military, aerospace, and remote site power solutions.

👉 This broad range of applications drives a wide price variation in PEM stacks, depending on specifications.

III. Key Factors Influencing Proton Exchange Membrane Stack Price

PEM stacks vary significantly in price depending on materials, performance, production, and supplier reliability. Let’s break down the main cost drivers:

A. Materials Used

- Membranes (e.g., Nafion): High proton conductivity but expensive.

- Bipolar Plates: Titanium offers corrosion resistance and long life, but costs more than graphite or steel.

- Catalysts (Platinum/Iridium): Critical for performance; global shortages increase costs.

B. Performance Specifications

- Power Output (W/kW): Higher power stacks demand more robust design.

- Current Density & Efficiency: More efficient stacks cost more upfront but save energy long-term.

- Durability & Lifespan: Commercial buyers prioritize stacks with 30,000+ hours of life.

C. Manufacturing Complexity

- Precision Engineering: MEA and bipolar plate manufacturing require high accuracy.

- Automation vs. Manual: Automated production lowers per-unit cost.

- Quality Assurance: ISO-certified plants cost more to operate but guarantee consistency.

D. Production Volume

- Small Batch Orders: Higher unit cost due to setup and customization.

- Mass Production: Economies of scale drive down cost.

E. Supplier & Brand Reputation

- Established hydrogen electrolyzer manufacturers often charge more but provide long-term reliability, warranty, and global after-sales support.

- Certifications like ISO, CE, and UL add to credibility.

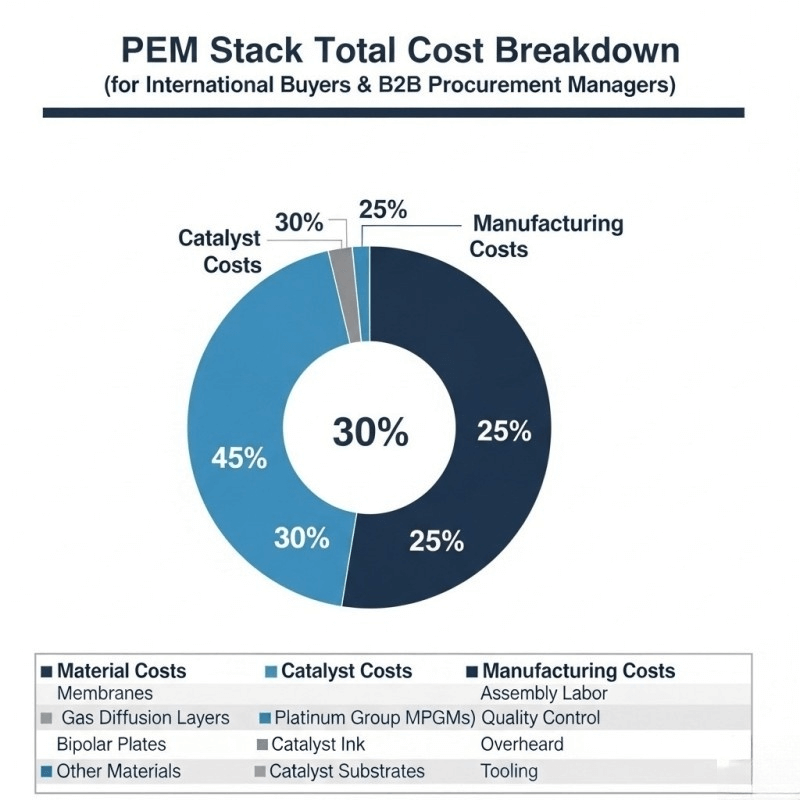

📊 Cost Breakdown Example (Typical PEM Stack):

| Component | Approx. Cost Contribution |

|---|---|

| Membrane Materials | 35–40% |

| Catalysts (Platinum/Iridium) | 25–30% |

| Bipolar Plates | 15–20% |

| Endplates, Seals, Gaskets | 5–10% |

| Assembly & Quality Testing | 10–15% |

IV. Typical Price Ranges of PEM Stacks

PEM stack pricing varies by power output and intended use case.

A. Low-Power PEM Stacks (<1kW)

- Price Range: $500 – $2,000

- Applications: Educational kits, lab use, portable hydrogen generators.

B. Mid-Power PEM Stacks (1–10kW)

- Price Range: $5,000 – $20,000

- Applications: Residential energy storage, telecom towers, light commercial use.

C. High-Power PEM Stacks (10kW+)

- Price Range: $30,000+

- Applications: Industrial hydrogen generators, automotive, large-scale stationary power.

D. Why Prices Vary

- Customization requirements.

- Shipping and tariffs.

- Supplier experience and warranty terms.

👉 Pro Tip: International buyers should factor in logistics and customs duties, which can add 10–25% to the final landed cost.

V. How to Compare PEM Stack Prices Like a Professional Buyer

Buying PEM stacks is not just about comparing unit prices—it’s about evaluating total cost of ownership (TCO).

A. Define Your Business Needs

- Desired power output (kW range).

- Efficiency & lifespan expectations.

- Compliance with regional certifications (CE, UL, ISO).

B. Research Suppliers

- Use industry directories, exhibitions, and hydrogen forums.

- Shortlist manufacturers with OEM/ODM capabilities.

- Review company reputation, certifications, and export experience.

C. Request Quotations (RFQs)

- Include detailed specifications (output, voltage, operating temperature).

- Ask about minimum order quantities (MOQs).

- Clarify lead times and after-sales support.

D. Evaluate Quotations

- Compare price vs. performance metrics (cost per kW).

- Consider service contracts, spares, and warranties.

- Use a cost-benefit matrix to prioritize long-term value.

E. Negotiate Smartly

- Request volume discounts.

- Explore alternative materials to reduce cost.

- Consider multi-year supply agreements for stability.

📥 Lead Magnet Idea: Download Hele Titanium Hydrogen’s “PEM Stack Price Comparison Checklist” to streamline supplier evaluations.

VI. Case Studies: Real-World PEM Stack Price Insights

A. Automotive Fuel Cell Stack

A global automaker sourced 80kW PEM stacks for FCEVs. Initial unit cost: ~$35,000. After scaling production and negotiating long-term supply, costs dropped by 30% over three years.

B. Stationary Hydrogen Generator

A telecom operator invested in 5kW PEM stacks for rural base stations. While upfront cost was ~$8,000 each, the reduced diesel dependency saved $50,000 annually in fuel costs.

C. Portable Hydrogen Device

A defense client purchased 500W PEM stacks for field units. Despite higher unit cost (~$1,200), the lightweight and durability justified the investment compared to traditional batteries.

👉 These examples highlight that the true value of PEM stacks lies in lifecycle savings—not just upfront price.

VII. Future Outlook for PEM Stack Pricing

- Technological Advancements: Cheaper membranes, reduced platinum loading, titanium plate innovations.

- Market Expansion: More hydrogen electrolyzer manufacturers entering the market = stronger competition.

- Government Policies: Subsidies in EU, China, and USA expected to lower effective buyer costs.

- Sustainability: Recycling platinum and membranes may reduce long-term pricing.

VIII. Why Choose Hele Titanium Hydrogen?

As a leading hydrogen electrolyzer manufacturer and bulk PEM stack supplier, Hele Titanium Hydrogen provides:

- OEM/ODM Manufacturing: Tailored solutions for global clients.

- Titanium Expertise: Durable bipolar plates for longer service life.

- Competitive Pricing: Bulk order discounts and flexible supply contracts.

- Global Compliance: ISO-certified production and international export experience.

- Trusted Partnerships: Long-term collaborations with automotive, industrial, and research institutions.

💡 Hele Titanium Hydrogen helps international buyers cut costs without compromising quality—making us the ideal partner for businesses entering the hydrogen economy.

IX. Conclusion

The proton exchange membrane stack price depends on many factors: materials, specifications, production volume, and supplier reliability. For B2B buyers, the smartest approach is to look beyond upfront price and evaluate total ownership cost, long-term durability, and supplier credibility.

By working with experienced suppliers like Hele Titanium Hydrogen, businesses can secure cost-effective, high-performance PEM stacks while enjoying global support and reliable partnerships.

X. Call to Action (CTA)

📌 Ready to compare prices with confidence?

- ✅ Request a Free Quotation from Hele Titanium Hydrogen today.

- ✅ Download our PEM Stack Buyer’s Checklist for supplier comparison.

- ✅ Contact our team to discuss OEM/ODM solutions tailored to your project.

👉 Partner with Hele Titanium Hydrogen and unlock the power of cost-effective, reliable PEM stacks for your hydrogen future.

Hele Titanium Hydrogen: Your Trusted Hydrogen Generator OEM & Manufacturing Partner

Hele Titanium Hydrogen stands as a reliable and experienced partner in the hydrogen generator OEM supply chain. We specialize in the design, development, and manufacturing of high-performance PEM Water Hydrogen Generators, offering comprehensive OEM & Manufacturing services tailored to your specific needs.

Take the Next Step

Ready to explore the possibilities of partnering with Hele Titanium Hydrogen?

- Browse our Products to see our range of PEM Water Hydrogen Generators.

- Learn more about our Services and how we can support your OEM & Manufacturing needs.

- Contact Us today to discuss your specific requirements.

- Explore our FAQ to get answers to common questions.

- Visit our Blog for the latest insights and updates on hydrogen technology.

Email Us: heletitaniumhydrogen@gmail.com

Phone/WhatsApp: 086-13857402537