The global energy transition is not just accelerating; it is here. At the very heart of this transformation lies a critical technology: the Proton Exchange Membrane (PEM) stack. From fuel cells that power the next generation of electric vehicles to advanced electrolyzers producing green hydrogen, PEM stacks are the foundational building blocks of the modern hydrogen economy.

For ambitious international businesses, sourcing high-quality PEM stacks has rapidly evolved from a simple procurement task into a core strategic priority. However, navigating this landscape presents significant challenges: demand is skyrocketing, the supplier market is fragmented, quality standards vary dramatically, and costs can be prohibitive. These hurdles can stall innovation and threaten the viability of large-scale projects.

Fortunately, a proven strategy exists to overcome these obstacles and secure a decisive competitive advantage: bulk purchasing. By strategically buying PEM stacks in large volumes, companies can unlock superior pricing, forge powerful supplier partnerships, and realize substantial long-term ROI gains.

This comprehensive guide will serve as your blueprint for mastering the bulk procurement of PEM stacks. We will cover everything from the fundamental applications and inherent risks to in-depth supplier evaluation, logistical planning, and real-world case studies. Whether you are a fuel cell systems integrator, an electrolyzer manufacturer, or a green hydrogen project developer, this article will equip you with the expert insights needed to make informed, profitable decisions.

👉 First Step to a Secure Supply Chain: Looking for a reliable, world-class PEM stack supplier?

Contact Hele Titanium Hydrogen today to discuss your specific bulk procurement requirements.

What Are PEM Stacks and Why They Matter

Before delving into procurement strategy, it’s essential to understand the technology you are investing in.

Definition & Core Functionality

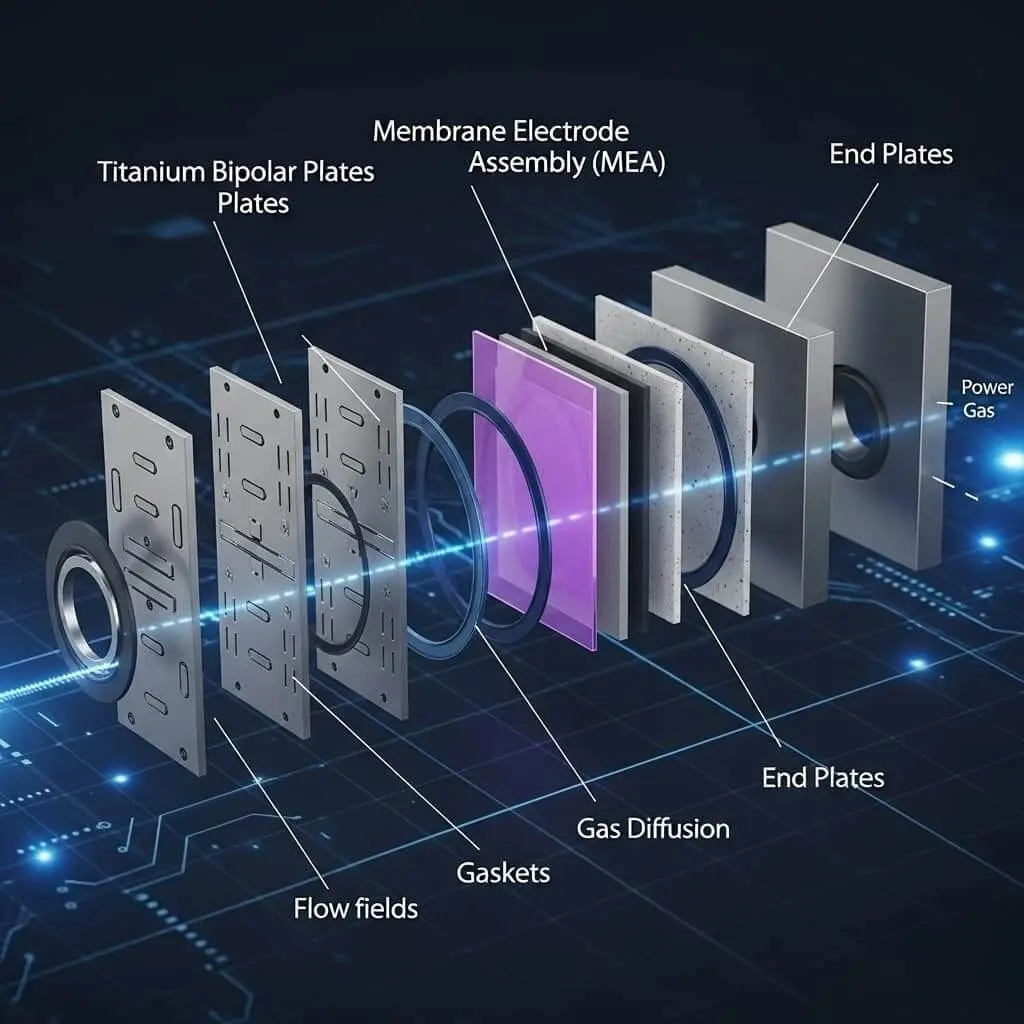

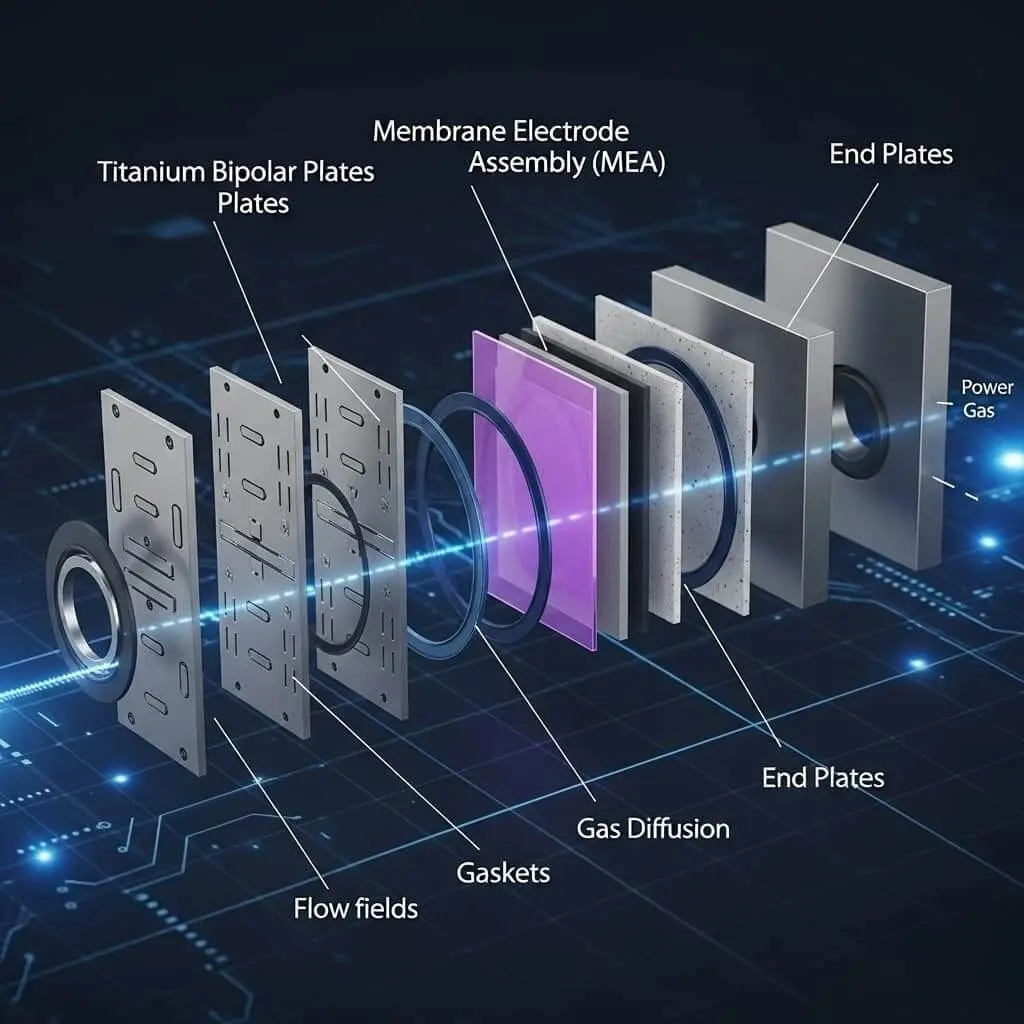

A PEM stack is a precisely engineered device composed of numerous individual fuel or electrolyzer cells, which are stacked together to achieve the desired power output or hydrogen production capacity. The “engine” of each cell is the Proton Exchange Membrane, a remarkable polymer film that allows hydrogen protons (H+) to pass through while blocking electrons and gases. This selective permeability is what facilitates the highly efficient electrochemical reactions that define PEM technology.

Critical Applications Across the Hydrogen Economy

PEM stacks are valued for their versatility and high power density, making them ideal for a range of demanding applications:

- Fuel Cells: They serve as the primary power source in FCEVs (fuel cell electric vehicles), heavy-duty transport, and material handling vehicles. They are also widely used for stationary power plants and as uninterruptible backup energy systems for data centers and hospitals.

- Electrolyzers: In this application, PEM stacks use electricity to split water into pure hydrogen and oxygen, forming the backbone of large-scale green hydrogen production. This process is critical for decarbonizing industry and transportation.

- Other Emerging Uses: The technology is also finding its way into advanced applications in chemical synthesis, grid-scale energy storage, and distributed energy resource systems.

Why Quality is a Non-Negotiable Pillar of ROI

In the world of industrial components, cutting corners on quality is a recipe for failure. Investing in low-grade PEM stacks can have severe and cascading consequences for your business:

- Shortened Lifespan: Substandard materials and poor manufacturing lead to rapid degradation, forcing frequent and costly replacements that destroy your total cost of ownership calculations.

- Reduced Efficiency and Output: Inconsistent catalyst coatings or poorly designed flow fields result in lower efficiency. For an electrolyzer, this means higher electricity costs per kilogram of hydrogen produced; for a fuel cell, it means less power output from the same amount of fuel.

- Catastrophic Safety Risks: A PEM stack is a high-pressure electrochemical system. Poorly sealed gaskets or flawed bipolar plates can lead to gas leaks, creating significant safety hazards in an industrial environment.

The bottom line is unequivocal: sourcing high-quality PEM stacks is the only path to achieving long-term ROI, ensuring reliable performance, and maintaining safe operations.

The Strategic Imperative: Advantages of Buying PEM Stacks in Bulk

Shifting from small, frequent orders to strategic bulk purchasing unlocks a powerful trifecta of financial, operational, and strategic benefits that can redefine your market position.

1. Financial Benefits

- Significant Volume Discounts: This is the most direct benefit. By committing to larger volumes, you enable your supplier to optimize production runs and material sourcing, leading to direct cost savings passed on to you. It’s common to negotiate lower per-unit costs of 15–25% compared to smaller purchases.

- Drastically Reduced Shipping Costs: Consolidating multiple small orders into a single, large shipment allows you to leverage the cost-effectiveness of Full Container Load (FCL) sea freight over Less than Container Load (LCL) or expensive air freight, reducing per-unit logistics costs significantly.

- Enhanced Negotiation Power: As a high-volume customer, you become a priority partner. This gives you powerful leverage to secure favorable payment terms (e.g., Net 30/60), extended warranties, and dedicated after-sales service agreements.

2. Operational Benefits

- Ironclad Supply Chain Reliability: In a market with fluctuating lead times, holding inventory ensures you have a steady, predictable availability of your most critical component, virtually eliminating the risk of production-halting project delays.

- Accelerated Time-to-Market: Having stock in hand means you can begin assembly and deployment immediately, drastically shortening your overall project or product lead times and allowing you to seize market opportunities faster than competitors.

- Simplified Procurement and Logistics: Managing one large order is far more efficient than managing ten small ones. This streamlines your procurement, accounting, and logistics operations, freeing up valuable administrative resources.

3. Strategic Benefits

- Forging a Competitive Advantage: The substantial cost savings unlocked through bulk purchasing can be strategically reinvested into R&D, market expansion, or passed on to customers to gain market share.

- Enabling Confident Scalability: A secured supply of core components gives your business the confidence to scale production aggressively to meet rising demand, without the fear of sourcing disruptions becoming a bottleneck to your growth.

- Long-Term Financial Planning: By negotiating a long-term supply agreement with fixed pricing, you can lock in predictable costs for your PEM stacks, effectively hedging against the notorious price volatility of raw materials like platinum and titanium.

👉 Lead Magnet: See the financial impact for yourself. Download our free Bulk PEM Stack Cost-Savings Calculator to estimate your potential savings.

Navigating the Pitfalls: Risks & Challenges of Bulk Purchases (And How to Mitigate Them)

While the advantages are clear, a successful bulk purchasing strategy is not without risks. Acknowledging and actively mitigating these challenges is what separates successful procurement from a costly mistake.

1. Quality and Performance Risks

- The Risk: The biggest danger of a large order is receiving a batch with inconsistent quality. This can manifest as wide variations in stack performance, the use of counterfeit or substandard materials, or a lack of compliance with essential ISO or CE standards.

- Mitigation Strategy: A multi-pronged approach is essential. Always demand full compliance certifications (ISO 9001), third-party performance testing reports, and raw material traceability documents. Crucially, order and rigorously test a pilot batch or sample unit in your own operating conditions before committing to a full bulk order.

2. Storage and Handling Risks

- The Risk: PEM stacks are not simple components; they are sensitive electrochemical devices that require controlled environments. Exposure to improper humidity or extreme temperatures during storage can degrade the membrane, while physical shock or mishandling during transport can cause micro-cracks and irreversible defects.

- Mitigation Strategy: Before your shipment arrives, ensure you have a clean, climate-controlled facility. Work with your supplier to receive their official storage and handling guidelines and ensure your logistics team is fully trained on these procedures to prevent costly damage.

3. Financial and Market Risks

- The Risk: Bulk orders inherently require a large upfront capital investment, which can strain cash flow. Furthermore, you are exposed to the risk that market prices for raw materials could fall after you’ve locked in your purchase price.

- Mitigation Strategy: To manage cash flow, explore financing solutions or negotiate phased payment terms with your supplier. To hedge against price drops, negotiate long-term price lock contracts that also include clauses for price adjustments if market rates for key materials fall below a certain threshold.

👉 Soft CTA: Validate performance with zero risk. Request a Sample PEM Stack Testing Report from Hele Titanium Hydrogen to see our verified data before you commit.

The Blueprint for Supplier Selection

Finding the right manufacturing partner is the single most important factor in your bulk procurement strategy.

Where to Source Potential Suppliers

- Online B2B Marketplaces: Platforms like Alibaba, Made-in-China, and ThomasNet can be excellent starting points for identifying a wide range of global manufacturers.

- Industry Trade Shows & Expos: Attending premier events like Hydrogen + Fuel Cells Europe or the China Hydrogen Energy Conference allows you to meet suppliers face-to-face, inspect their products, and have deep technical discussions.

- Professional Networks: B2B groups on LinkedIn focused on the hydrogen and fuel cell industries can be a source of valuable referrals and recommendations from industry peers.

Your In-Depth Due Diligence Checklist

Once you have a shortlist, conduct a rigorous vetting process:

- ✔ Verify Certifications and Compliance: Request and validate copies of their ISO 9001 (quality management), ISO 14001 (environmental management), and any region-specific compliance like CE or UL.

- ✔ Demand Quality and Safety Test Reports: A premier supplier will readily provide comprehensive reports on performance, lifespan, degradation rates, and safety testing from their own labs and third-party institutions.

- ✔ Review Customer Case Studies and References: Ask for detailed case studies and speak directly with existing customers to understand their real-world experience with the supplier’s product quality and support.

- ✔ Audit Their Production Facilities: The ultimate step. Schedule a virtual or onsite factory tour to see their manufacturing processes, quality control stations, and overall professionalism for yourself.

Critical Red Flags to Avoid

- Unclear or Vague Product Specifications: A supplier who cannot provide a detailed technical data sheet may not fully understand their own product’s performance limits.

- No Documented Quality Control Process: If they cannot clearly articulate and show you their multi-point QC process, assume it doesn’t exist.

- Poor Communication: Slow response times, evasive answers, or an unwillingness to connect you with technical staff during the sales process are major warning signs.

👉 CTA: Transparency you can see. Contact Hele Titanium Hydrogen today to schedule a factory virtual tour and a supplier verification call with our engineering team.

The Procurement Playbook: Negotiation & Logistics

Negotiating the Best Possible Deal

- Request for Quotation (RFQ): Your RFQ should be incredibly detailed. Include full technical specifications, required quantity tiers, delivery timelines, packaging requirements, and desired warranty terms.

- Strategic Negotiation: Leverage your volume to negotiate beyond price. Push for flexible payment terms (e.g., Letter of Credit, phased payments) and long-term price locks to ensure stability.

- Contract Options:

- One-Off Bulk Purchase: Best for a specific project with well-defined needs.

- Framework Agreement: A longer-term (1–3 year) contract that establishes pricing and terms, allowing you to place recurring orders as needed. This is ideal for ongoing production.

Mastering Logistics & Import Strategy

- Packaging & Shipping: Insist on robust, shock-proof packaging with moisture and corrosion inhibitors to prevent any transit damage. Select the optimal shipping method—typically sea freight for cost efficiency or air freight for urgent needs.

- Customs & Regulations: International trade is complex. It is highly advisable to work with a professional customs broker who understands the import duties, taxes, and documentation requirements for your specific country to ensure smooth, compliant clearance.

- Inventory Management: Implement an inventory management system or software to track your stock levels and use forecasting techniques to predict future demand. This allows you to balance the benefits of bulk purchasing with the costs of holding inventory.

Frequently Asked Questions (SEO-Optimized)

1. What industries benefit most from buying PEM stacks in bulk?

The primary beneficiaries are fuel cell manufacturers, electrolyzer companies, systems integrators, and developers of large-scale green hydrogen projects.

2. How can I verify if a PEM stack supplier is reliable?

A thorough verification includes checking their ISO/CE certifications, requesting third-party sample reports, reviewing detailed customer case studies, and conducting a factory audit.

3. What certifications should PEM stacks have?

At a minimum, look for ISO 9001 for quality management. For specific markets, CE marking is mandatory for the EU, and UL certification is often required for North America.

4. How do I handle customs duties when importing bulk PEM stacks?

The most effective method is to partner with an experienced customs broker. They will handle tariff classifications, duty calculations, and all necessary paperwork to optimize compliance and reduce delays.

5. Can bulk PEM purchases be financed?

Yes, many established global suppliers, including Hele Titanium Hydrogen, offer financing options or flexible payment structures like installment plans for large, qualified orders.

6. What is the typical ROI timeframe for bulk PEM stack procurement?

While it varies, most companies realize a full return on their investment within 12–24 months, driven by lower unit costs, improved operational efficiency, and enhanced market competitiveness.

Conclusion: Forge Your Competitive Edge

In the rapidly expanding hydrogen economy, strategic procurement is no longer a back-office function—it is a competitive weapon. Bulk purchasing of PEM stacks is not just about reducing costs; it’s about securing your supply chain, improving operational efficiency, and maximizing your long-term ROI.

From rigorous supplier selection and risk mitigation to sophisticated contract negotiation and logistics optimization, businesses that adopt and master a structured bulk procurement strategy are the ones that will lead the market. They will build more resilient operations, innovate faster, and ultimately, deliver more value in the clean energy future.

Take the Next Step Toward a Cost-Efficient, Reliable Future

- Contact Hele Titanium Hydrogen today for a personalized consultation on your bulk PEM stack sourcing strategy.

- Request a free technical report on our latest generation of high-performance stacks or schedule your virtual factory tour.

Discover how bulk purchasing PEM stacks lowers costs, secures supply, and maximizes ROI. Trusted OEM & wholesale solutions for fuel cells, electrolyzers & hydrogen production.

Hele Titanium Hydrogen: Your Trusted Hydrogen Generator OEM & Manufacturing Partner

Hele Titanium Hydrogen stands as a reliable and experienced partner in the hydrogen generator OEM supply chain. We specialize in the design, development, and manufacturing of high-performance PEM Water Hydrogen Generators, offering comprehensive OEM & Manufacturing services tailored to your specific needs.

Take the Next Step

Ready to explore the possibilities of partnering with Hele Titanium Hydrogen?

- Browse our Products to see our range of PEM Water Hydrogen Generators.

- Learn more about our Services and how we can support your OEM & Manufacturing needs.

- Contact Us today to discuss your specific requirements.

- Explore our FAQ to get answers to common questions.

- Visit our Blog for the latest insights and updates on hydrogen technology.

Email Us: heletitaniumhydrogen@gmail.com

Phone/WhatsApp: 086-13857402537