Discover the top global PEM electrolyzer OEMs leading the market in quality, innovation, and reliability. Compare suppliers and explore why Hele Titanium Hydrogen is your trusted partner for PEM hydrogen solutions.

Introduction

The race toward a sustainable energy future is driving unprecedented demand for PEM electrolyzers, the technology behind efficient green hydrogen production. According to industry reports, the global hydrogen electrolyzer market is expected to surpass USD 20 billion by 2030, with PEM (Proton Exchange Membrane) systems leading the charge.

For businesses, choosing the right supplier is no longer just about price—it’s about reliability, efficiency, scalability, and long-term ROI. With dozens of OEMs competing globally, identifying the best PEM electrolyzer manufacturers in 2025 is crucial.

This article compares the leading players worldwide, highlights industry trends, and explains why many international buyers trust Hele Titanium Hydrogen as their preferred PEM electrolyzer supplier.

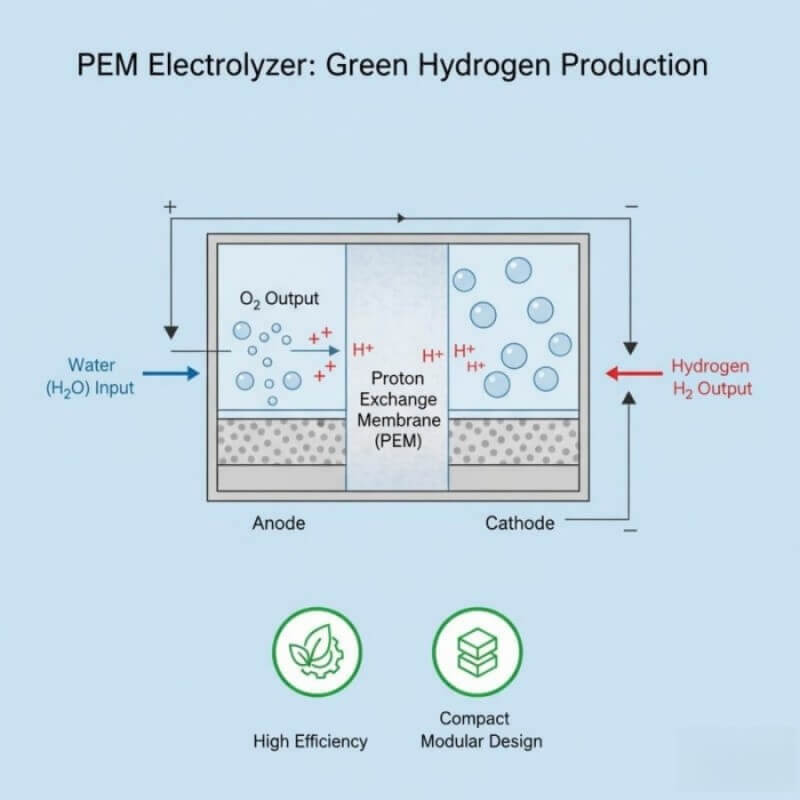

What Is a PEM Electrolyzer and Why It Matters in 2025

A PEM electrolyzer uses a proton-conducting polymer membrane to split water into hydrogen and oxygen. When powered by renewable electricity, it produces green hydrogen—a clean fuel that supports carbon neutrality.

Advantages of PEM technology include:

- High efficiency with low energy consumption.

- Compact and modular designs, ideal for both small- and large-scale projects.

- Rapid response times, making them suitable for fluctuating renewable power sources.

- High-purity hydrogen output (99.999%), essential for sensitive industries.

Applications span across multiple industries:

- Industrial hydrogen supply for steel, glass, and chemicals.

- Hydrogen refueling stations for trucks, buses, and fuel-cell cars.

- Energy storage and grid balancing.

- Off-grid renewable integration for islands and remote areas.

In short, PEM electrolyzers are at the core of the green hydrogen economy—and the manufacturers behind them matter more than ever.

Key Factors Buyers Should Consider When Choosing a PEM Electrolyzer Supplier

When evaluating suppliers, commercial buyers should weigh both technical performance and business practicality. Key factors include:

| Criteria | Why It Matters |

|---|---|

| Performance & Efficiency | Higher efficiency reduces operating costs. |

| Hydrogen Purity | Essential for fuel cells, electronics, and food-grade applications. |

| Durability & Reliability | Longer membrane life and robust materials lower downtime. |

| Scalability | Ability to expand from pilot projects to MW-scale plants. |

| Certifications & Safety | Compliance with ISO, CE, and other global standards ensures safe operations. |

| After-Sales Service | Strong global support reduces risk and keeps systems running. |

| Innovation & R&D | Suppliers with active R&D pipelines stay ahead in cost reduction and efficiency. |

| Cost-Effectiveness & ROI | Competitive pricing plus low operating costs = better business case. |

Best PEM Electrolyzer Manufacturers in 2025 (Supplier Comparison)

Global Leaders (Mega-Scale Projects)

These multinational giants dominate large-scale hydrogen projects:

- Siemens Energy – Known for utility-scale projects and integration with renewable power plants.

- Cummins (Hydrogenics) – Strong presence in North America and Europe, offering MW-class systems.

- ITM Power – A pioneer in large hydrogen hubs, with partnerships in the UK and Germany.

Strength: Proven track records on 100 MW+ projects. Weakness: High upfront costs, longer lead times.

Specialized Innovators (Technology-Driven OEMs)

These suppliers focus on advanced R&D and flexible systems:

- Nel Hydrogen – Scandinavian leader with decades of electrolyzer expertise.

- Plug Power – Focused on hydrogen for mobility and fuel-cell logistics.

- Ballard Power – Strong in PEM technology for transport and clean mobility.

Strength: Cutting-edge R&D, strong innovation. Weakness: Limited cost competitiveness at scale.

Emerging Asian Suppliers (Competitive & Fast-Moving)

This group is gaining global attention for cost efficiency, modular solutions, and export readiness. Among them:

- Hele Titanium Hydrogen (China)

- Overview: A professional OEM and wholesale supplier of PEM water hydrogen generators.

- Product Portfolio: Ranges from compact lab-scale units to MW-class industrial electrolyzers.

- Strengths:

- ISO-certified production.

- Modular designs suitable for scaling.

- Competitive pricing without compromising quality.

- Global export capabilities with fast delivery.

- Strong after-sales technical support.

- Why Choose: Ideal for buyers seeking reliable, cost-effective PEM solutions with responsive service.

Other emerging suppliers in Asia are following similar trends, but Hele Titanium Hydrogen distinguishes itself with advanced titanium-based stack designs, durability, and custom solutions for B2B buyers.

Market Trends & Future Outlook for PEM Electrolyzers

- Falling Costs – New catalysts and membranes are reducing overall system costs.

- Government Support – Subsidies, hydrogen hubs, and clean energy policies are driving adoption.

- Industrial Adoption – Steel, ammonia, and chemical industries are leading large-scale hydrogen demand.

- Digitalization – Smart monitoring, AI-based controls, and predictive maintenance are becoming standard.

Outlook: By 2030, PEM electrolyzers will expand from niche projects to mainstream infrastructure, with capacity scaling into hundreds of gigawatts globally.

Case Studies of PEM Electrolyzer Deployments

- Steel Industry Decarbonization (Europe): Siemens Energy installed a 10 MW PEM electrolyzer to replace coal-derived hydrogen, reducing emissions by thousands of tons annually.

- Hydrogen Mobility (US): Plug Power’s PEM systems power fleets of hydrogen trucks and forklifts, cutting logistics emissions.

- Off-Grid Renewable Integration (Asia): Hele Titanium Hydrogen supplied modular PEM units for a solar-powered island project, providing clean energy independence at a competitive cost.

FAQs

Q1: What criteria determine the best PEM electrolyzer manufacturers?

A1: Efficiency, durability, certifications, after-sales service, and cost-effectiveness are key.

Q2: How does PEM differ from other electrolyzer types?

A2: PEM offers faster response, compact design, and higher purity compared to alkaline or solid oxide systems.

Q3: What’s the lifespan of a PEM electrolyzer?

A3: Typically 5–10 years before major stack replacement, depending on use and supplier quality.

Q4: Can PEM electrolyzers scale for industrial hydrogen needs?

A4: Yes—today’s top suppliers offer systems from 100 kW pilot units up to 100 MW+ installations.

Q5: Why do buyers choose Hele Titanium Hydrogen?

A5: Competitive pricing, reliable ISO-certified quality, modular designs, and responsive global service.

Why Choose Hele Titanium Hydrogen?

At Hele Titanium Hydrogen, we specialize in manufacturing and wholesale supply of PEM water hydrogen generators for global markets.

✅ ISO-certified quality and advanced titanium-based stack technology.

✅ Modular solutions from small-scale to industrial MW-level projects.

✅ Competitive pricing for B2B buyers without sacrificing performance.

✅ Global export support with fast lead times.

✅ Dedicated after-sales service to keep your operations running smoothly.

With years of experience in PEM hydrogen solutions, we’ve helped clients worldwide cut costs, reduce emissions, and adopt green energy at scale.

Conclusion & Call to Action

Choosing the best PEM electrolyzer manufacturers in 2025 requires balancing performance, scalability, support, and cost. Global giants may lead mega-projects, innovators push technology forward, but emerging suppliers like Hele Titanium Hydrogen provide a unique combination of quality, affordability, and flexibility that global buyers are seeking.

👉 Looking for a reliable PEM electrolyzer supplier? Contact Hele Titanium Hydrogen today for specifications, quotations, and partnership opportunities. Let’s power the future of green hydrogen together.

Comparison Tables for B2B Decision-Makers

1. OEM Manufacturer Comparison (Global Leaders vs Emerging OEMs)

| Criteria | Global Leaders (e.g., Nel, Plug Power, Siemens Energy) | Emerging OEMs (e.g., Hele Titanium Hydrogen, Sungrow Hydrogen) |

|---|---|---|

| Technology Maturity | 10+ years experience, proven large-scale deployments | Fast-growing, leveraging new materials & modular designs |

| Price Competitiveness | Higher pricing due to brand reputation & R&D costs | More cost-effective, tailored for competitive B2B supply |

| Customization | Standardized systems with limited flexibility | Flexible, modular design tailored to client needs |

| Lead Time | Longer, due to global demand and complex projects | Faster, agile supply chain with regional manufacturing |

| After-Sales Service | Strong global network, premium service packages | Direct factory support, more personalized technical service |

2. Cost vs Scale Comparison (CAPEX & OPEX Considerations)

| Production Scale | Small Scale (1–5 MW) | Medium Scale (5–20 MW) | Large Scale (20+ MW) |

|---|---|---|---|

| CAPEX (Initial Cost) | Low–Moderate, affordable entry level | Moderate–High, balanced investment | High, requires significant capital |

| OPEX (Operating Cost) | Moderate, depends on efficiency | Lower per kg H₂ due to economies of scale | Lowest per kg H₂, optimal for industrial use |

| B2B Suitability | R&D labs, pilot projects, mobility | Industrial plants, refineries, energy hubs | Utility-scale hydrogen plants, export hubs |

| OEM Leader Example | Hele Titanium Hydrogen (cost-effective) | ITM Power, Sungrow Hydrogen | Nel Hydrogen, Siemens Energy |

3. Performance & Efficiency Metrics

| Metric | High-Efficiency OEMs (e.g., Nel, Siemens) | Cost-Effective OEMs (e.g., Hele Titanium Hydrogen) |

|---|---|---|

| Efficiency | 70–75% | 65–70% |

| Hydrogen Purity | 99.999% | 99.99% |

| Stack Lifespan | 70,000+ hours | 60,000–65,000 hours |

| Maintenance Needs | Low, predictive AI monitoring | Low, simple modular replacement |

| Innovation Focus | Catalyst development, AI-driven control | Titanium stack durability, compact modular design |

4. Buyer-Focused Service Comparison

| Service Criteria | Established Global OEMs | Emerging B2B Suppliers (Hele Titanium Hydrogen) |

|---|---|---|

| Technical Training | Structured, certified programs | On-demand, tailored training packages |

| Warranty Coverage | Standard 2–3 years | Flexible warranties, extendable contracts |

| Delivery Time | 8–12 months (longer for large projects) | 3–6 months (faster, regional sourcing) |

| B2B Contract Options | Fixed, long-term contracts | Flexible MOQs, adaptable to buyer needs |

| Export Support | Strong logistics network | Direct factory-to-buyer exports, lower costs |

5. Innovation & Future-Proofing Comparison

| Innovation Area | Global Leaders (Siemens, Plug Power) | Emerging OEMs (Hele Titanium Hydrogen, Sungrow) |

|---|---|---|

| R&D Investment | Multi-million annual R&D budgets | Focused, efficient innovation pipelines |

| Patent Portfolio | Broad, covering catalysts & membranes | Niche, focusing on titanium PEM stacks |

| Digitalization | AI, IoT, predictive analytics | Modular, smart monitoring add-ons |

| Market Focus | Utility-scale projects, large corporates | SMEs, industrial B2B buyers, regional demand |

Hele Titanium Hydrogen: Your Trusted Hydrogen Generator OEM & Manufacturing Partner

Hele Titanium Hydrogen stands as a reliable and experienced partner in the hydrogen generator OEM supply chain. We specialize in the design, development, and manufacturing of high-performance PEM Water Hydrogen Generators, offering comprehensive OEM & Manufacturing services tailored to your specific needs.

Take the Next Step

Ready to explore the possibilities of partnering with Hele Titanium Hydrogen?

- Browse our Products to see our range of PEM Water Hydrogen Generators.

- Learn more about our Services and how we can support your OEM & Manufacturing needs.

- Contact Us today to discuss your specific requirements.

- Explore our FAQ to get answers to common questions.

- Visit our Blog for the latest insights and updates on hydrogen technology.

Email Us: heletitaniumhydrogen@gmail.com

Phone/WhatsApp: 086-13857402537