Source Certified PEM Electrolyzers on heletitaniumhydrogen.com: B2B Playbook for Fast, Safe Procurement

A practical guide to vetting PEM electrolyzer OEMs, validating certifications, comparing efficiency specs, and closing secure, on‑platform purchases—built to prevent scams and accelerate RFQs on heletitaniumhydrogen.com.

Why this guide matters

Buying a PEM electrolyzer is a high‑stakes decision: efficiency, degradation, and lifetime hours drive total cost of ownership and financing confidence. This guide translates technical benchmarks into a step‑by‑step sourcing process on heletitaniumhydrogen.com so procurement teams can shortlist suppliers faster, verify compliance, and execute secure, milestone‑based transactions.

What serious buyers evaluate

- Key metrics: prioritize system energy efficiency in kWh/kg H2, current density and cell voltage, stack vs. system lifetime, outlet pressure, and hydrogen purity; normalize across offers.

- Durability proof: request degradation per 1,000 hours at rated current density and traceable acceptance test records to validate lifecycle assumptions.

- Integration fit: map duty cycle, pressure, compression, and purity requirements to downstream equipment and OPEX.

Why source via heletitaniumhydrogen.com

- Verified OEMs and documents: supplier identity, factory/audit proofs, and certifications on file reduce supplier risk and accelerate internal approvals.

- Competitive price discovery: multi‑vendor RFQs, structured negotiation, and centralized messaging compress clarification loops and shorten procurement cycles.

- Secure payments: on‑platform protections with milestone payments preserve recourse and align cash flow with performance acceptance.

- Support and audit trail: SLA‑backed escalation plus message/file histories simplify compliance and dispute resolution.

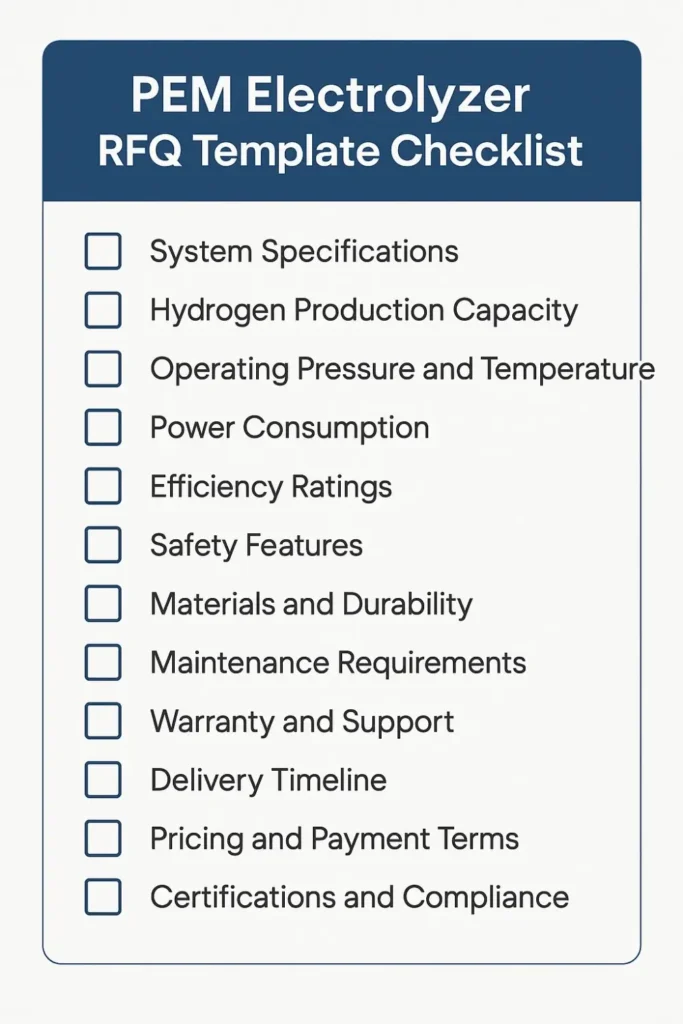

Technical buying checklist

- Performance acceptance: hydrogen output, system efficiency $$kWh/kg H2$$, current density/voltage, and guaranteed acceptance points tied to payment milestones.

- Compliance and safety: CE/UL where applicable, pressure‑vessel codes, serial‑numbered certificates, and third‑party test reports; define verification steps pre‑award.

- Evidence package: installed base, customer references, acceptance tests (FAT/SAT), and degradation curves at rated conditions.

- Warranty and service: spare‑parts SLAs, remote diagnostics, response times, and performance guarantees aligned to operating hours and duty cycle.

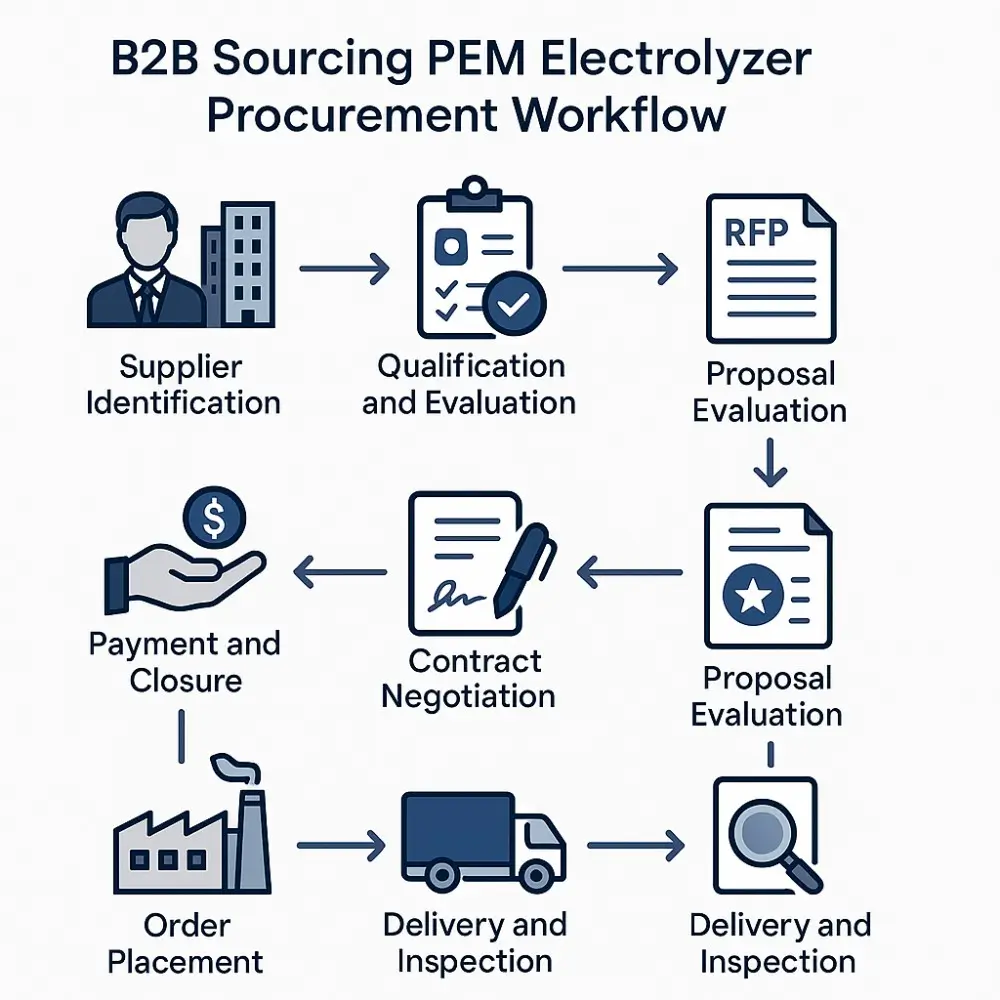

Step‑by‑step: sourcing on heletitaniumhydrogen.com

- Profile setup: specify capacity range, duty cycle, outlet pressure, grid constraints, delivery terms, and acceptance tests to improve quote quality and comparability.

- Search and filter: use structured terms such as “PEM electrolyzer 1–10 Nm³/h,” “CE‑certified,” “high‑pressure outlet,” and “low kWh/kg” to narrow relevant listings.

- Evaluate listings: normalize datasheets against recognized benchmarks; request missing test data and certifications prior to shortlisting.

- Build the RFQ: include a spec matrix, FAT/SAT criteria, warranty KPIs, Incoterms, delivery milestones, and staged payments aligned to acceptance tests.

- Negotiate and close: tie final payments to measured efficiency and output at agreed points; execute via secure on‑platform instruments.

Fraud prevention and safe contracting

- Credential verification: cross‑check legal registrations, factory locations, serial‑linked certificates, and third‑party reports; keep the audit trail within the platform.

- Payment hygiene: maintain milestone payments on‑platform; avoid direct wires to protect dispute mechanisms and chargeback options.

- Contract essentials: define performance KPIs, delivery penalties, confidentiality/IP, spare‑parts SLAs, and clear acceptance procedures; involve counsel for high‑value orders.

Case snapshot

A buyer standardized an RFQ for a 20 Nm³/h PEM system using efficiency and degradation acceptance points, enabling apples‑to‑apples comparison across vendors. The structured RFQ and milestone‑based payments reduced TCO and shortened lead time through clearer acceptance tests and faster decision cycles.

Market and pricing context

PEM electrolyzer demand is expanding with improved efficiency and cost trajectories; policy support and multi‑sector adoption increase the importance of early OEM engagement and standardized acceptance testing to secure production slots and budget certainty.

FAQs

- What is a good system efficiency in kWh/kg H2?

Use benchmarks and normalize for operating point and purity to compare offers fairly; avoid single‑point specs without conditions.

- How to confirm CE/UL and pressure‑vessel compliance quickly?

Check declarations, serial‑numbered certificates, third‑party lab reports, and consistency between nameplates and documents.

- Which FAT/SAT tests belong in the contract?

Include electrical, flow, pressure, purity, noise, safety, and performance verification steps tied explicitly to payment milestones.

CTA

Get benchmark‑referenced quotes from verified OEMs today—submit an RFQ or request a curated shortlist on heletitaniumhydrogen.com to accelerate sourcing and protect project outcomes.

Hele Titanium Hydrogen: Your Trusted Hydrogen Generator OEM & Manufacturing Partner

Hele Titanium Hydrogen stands as a reliable and experienced partner in the hydrogen generator OEM supply chain. We specialize in the design, development, and manufacturing of high-performance PEM Water Hydrogen Generators, offering comprehensive OEM & Manufacturing services tailored to your specific needs.

Take the Next Step

Ready to explore the possibilities of partnering with Hele Titanium Hydrogen?

- Browse our Products to see our range of PEM Water Hydrogen Generators.

- Learn more about our Services and how we can support your OEM & Manufacturing needs.

- Contact Us today to discuss your specific requirements.

- Explore our FAQ to get answers to common questions.

- Visit our Blog for the latest insights and updates on hydrogen technology.

Email Us: heletitaniumhydrogen@gmail.com

Phone/WhatsApp: 086-13857402537