Sourcing components for a large-scale hydrogen project? This definitive guide covers PEM stack component selection, system integration, and TCO to de-risk your investment. Partner with an OEM expert.

The global energy transition is no longer a forecast; it’s a multi-trillion-dollar reality unfolding on factory floors and in project boardrooms worldwide. With over 1,000 large-scale hydrogen projects announced globally, representing a staggering $320+ billion investment by 2030, the race to build out megawatt- and gigawatt-scale production facilities is on.

While headlines focus on final investment decisions and offtake agreements, engineers and project managers on the ground know a different truth: the long-term success or failure of these monumental projects often hinges on decisions made at the microscopic level—specifically, within the core components of the Proton Exchange Membrane (PEM) electrolyzer stack.

Choosing the right components is a complex balancing act of performance, longevity, and cost. The wrong choice doesn’t just lead to minor inefficiencies; it can trigger premature stack degradation, unforeseen maintenance costs, and catastrophic budget overruns that jeopardize the entire project’s financial viability.

This guide moves beyond textbook definitions. Drawing on our deep experience as a leading Original Equipment Manufacturer (OEM) of PEM hydrogen generators, we will provide a strategic framework for selecting, procuring, and integrating PEM stack components for megawatt-scale projects. We will delve into the critical trade-offs that every project developer must navigate to ensure reliability, profitability, and performance.

What You’ll Learn in This Guide:

- Critical performance criteria for each core component: the MEA, Bipolar Plates, and GDLs.

- How to shift your procurement focus from initial cost to Total Cost of Ownership (TCO).

- Key system integration challenges and Balance of Plant (BoP) considerations to anticipate.

- A strategic framework for de-risking your component supply chain.

The Strategic Advantage: Why PEM Technology Dominates Large-Scale Projects

Before diving into the components, it’s crucial to understand why PEM technology has become the preferred choice for large-scale green hydrogen projects, particularly those coupled with renewable energy sources. While legacy technologies like Alkaline electrolysis have their place, PEM offers a unique combination of advantages essential for modern energy systems:

- Dynamic Response Rate: PEM electrolyzers can ramp up and down from 0% to over 100% of their nominal capacity in seconds, not minutes. This allows them to perfectly match the intermittent output of solar and wind farms, maximizing hydrogen production and capturing every available electron.

- High Power Density: A PEM stack can produce significantly more hydrogen in the same physical footprint compared to an Alkaline system. For large-scale projects where land and facility costs (CAPEX) are major factors, this compactness is a significant financial and logistical advantage.

- Exceptional Hydrogen Purity: PEM systems inherently produce hydrogen with very high purity (typically 99.999%), often eliminating the need for expensive downstream purification equipment, especially for applications like fuel cell mobility.

These advantages—flexibility, compactness, and purity—make PEM the strategic foundation for the future of the hydrogen economy. However, this high performance is entirely dependent on the quality and synergy of its core components.

The Core Triad: A Deep Dive into Mission-Critical PEM Stack Components

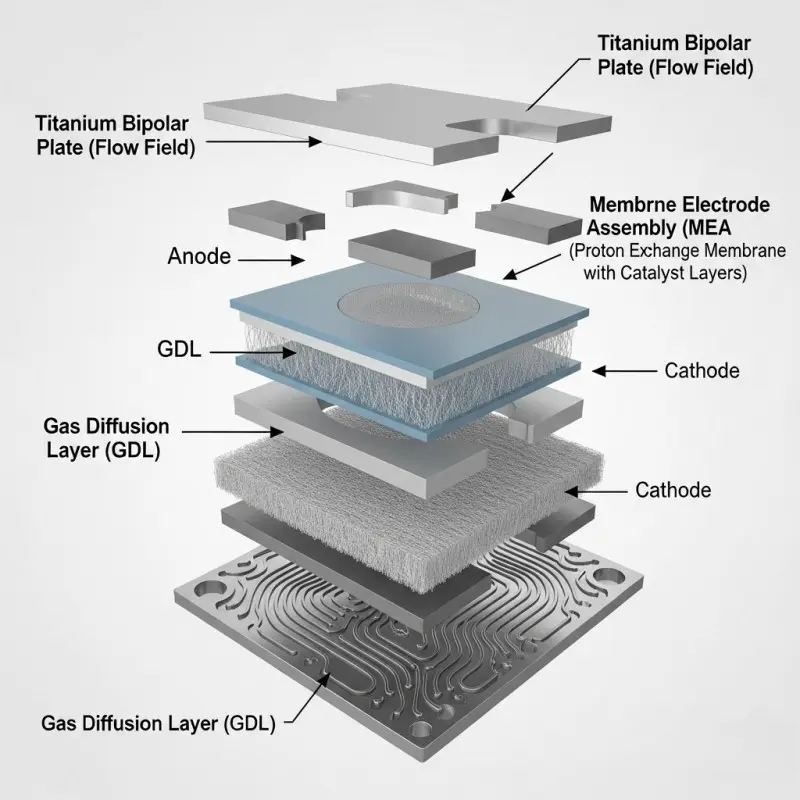

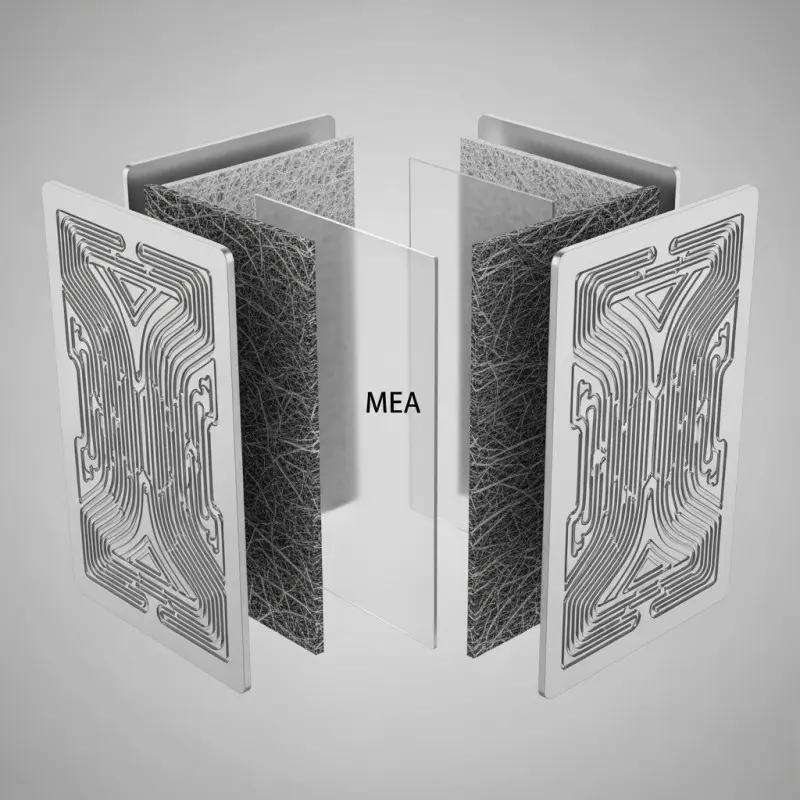

A PEM stack is an electrochemical marvel, a precise assembly of hundreds or even thousands of individual cells. The performance of this entire assembly is dictated by its three most critical components: the Membrane Electrode Assembly (MEA), the Bipolar Plates (BPP), and the Gas Diffusion Layers (GDLs).

A. Membrane Electrode Assembly (MEA): The Engine of Your Project

The MEA is where the electrochemical reaction of splitting water (H2O) into hydrogen (H2) and oxygen (O2) occurs. It is the absolute heart of the electrolyzer. It consists of the proton exchange membrane itself, sandwiched between an anode and a cathode catalyst layer.

- Function & Materials: The solid polymer membrane (commonly Nafion™ or a similar perfluorosulfonic acid material) conducts protons from the anode to the cathode while blocking electrons and gases. The catalyst layers, containing precious metals like platinum and iridium, are where the reactions are facilitated.

- Critical Selection Criteria for Megawatt-Scale:

- Catalyst Loading (mg/cm2): This is the amount of precious metal applied to the membrane. Higher loading generally improves efficiency (lower voltage required to produce hydrogen) but significantly increases cost. For large projects, the key is finding the “sweet spot” that balances the CAPEX of the stack with the long-term OPEX of electricity consumption. Always demand performance curves from your supplier at various current densities.

- Membrane Thickness: A thinner membrane reduces ohmic resistance, improving efficiency. However, it can also increase the risk of gas crossover and be less mechanically robust over a 20-year project lifetime. For high-pressure applications, a thicker, more durable membrane is often a non-negotiable requirement for safety and longevity.

- Degradation Factors: Demand data on the MEA’s performance degradation over thousands of hours of operation. Key metrics include voltage increase over time at a constant current. A supplier should be able to provide clear data on the chemical and mechanical stability of their MEAs under conditions relevant to your project.

B. Bipolar Plates (BPP): The Structural and Conductive Backbone

If the MEA is the engine, the bipolar plates are the chassis, circulatory system, and electrical wiring all in one. These plates are pressed against each side of the MEA, and they perform three crucial functions: they provide structural support for the stack, conduct electricity between adjacent cells, and distribute reactant water and remove product gases via precisely machined flow fields.

- Function & Materials: Traditionally made of graphite, modern high-performance stacks for large projects almost exclusively use metal plates, primarily coated titanium. Titanium offers superior strength, conductivity, and the ability to be formed into very thin plates, which increases the stack’s power density.

- Critical Selection Criteria for Megawatt-Scale:

- Flow Field Design: The pattern machined into the plate’s surface is not arbitrary. It dictates pressure drop, water distribution, and gas removal. An poorly designed flow field can lead to “hot spots,” localized membrane dehydration, or “flooding,” all of which drastically reduce performance and can cause permanent damage to the MEA.

- Corrosion Resistance: This is arguably the single most important factor for stack longevity. In the highly oxidative environment of a PEM cell, an unprotected metal plate will corrode in hours. The quality of the protective coating (often platinum or a corrosion-resistant nitride) on the titanium plate determines the stack’s lifetime. Insist on accelerated lifetime testing data and rigorous quality control documentation from your BPP manufacturer.

- Cost vs. Performance (The TCO Argument): Coated titanium plates have a higher initial cost than graphite or stainless steel. However, their exceptional corrosion resistance, higher conductivity, and durability lead to a significantly longer stack life and higher system efficiency, making them the superior choice when evaluating the Total Cost of Ownership (TCO).

C. Gas Diffusion Layers (GDL): The Unsung Hero of Mass Transport

The GDL is a thin, porous layer positioned between the bipolar plate and the catalyst layer of the MEA. Its role is critical yet often overlooked: it ensures that reactant water can reach the catalyst layer uniformly and allows the produced hydrogen and oxygen gas to escape efficiently.

- Function & Materials: Typically made from carbon paper or carbon cloth, the GDL must be electrically conductive, porous, and mechanically stable under high compression.

- Critical Selection Criteria for Megawatt-Scale:

- Porosity & Hydrophobicity: The GDL’s structure must be carefully engineered. It needs to be hydrophilic enough to allow water in but hydrophobic enough to push product gases out and prevent the catalyst layer from flooding. The correct hydrophobic treatment is essential for stable operation at high current densities.

- Compressive Strength: In a large stack, the components are held under immense pressure (clamping force) to ensure good electrical contact. The GDL must withstand this compression without collapsing, which would restrict gas flow and cripple cell performance.

- Consistency: For a megawatt-scale project using thousands of cells, batch-to-batch consistency of the GDL is paramount. Minor variations in thickness or porosity from one GDL to the next can lead to performance imbalances across the stack, making it difficult to control and reducing overall efficiency. This is where partnering with a manufacturer with stringent quality control, like Hele Titanium Hydrogen, becomes invaluable.

LEAD MAGNET #1 (Mid-Article CTA)

Feeling overwhelmed by the technical details? Download our Free PEM Component Specification Checklist for Project Managers. This practical tool ensures you ask suppliers the right questions and compare components on the criteria that truly matter for large-scale projects.

[Click Here to Download Your Free Checklist]

Beyond the Stack: System Integration & Balance of Plant (BoP) Considerations

A common and costly mistake is to view the PEM stack in isolation. In reality, the stack is the heart of a complex ecosystem—the Balance of Plant (BoP)—which includes power electronics, water purification systems, gas dryers, cooling loops, and control systems. The component choices you make for the stack have direct, cascading effects on the design and cost of your BoP.

- The Stack is Not an Island: Your Bipolar Plate’s flow field design, for example, determines the pressure drop across the stack. A more restrictive design may require a larger, more energy-intensive water pump, increasing your parasitic load and reducing your net system efficiency.

- Compatibility is Key: The efficiency of your MEAs dictates the amount of waste heat generated. This, in turn, determines the required size and capacity of your cooling system. A 5% drop in stack efficiency on a 10MW system means an extra 500kW of heat must be managed, requiring a substantially more robust—and expensive—thermal management system.

- Common Integration Pitfalls: For large-scale stacks, ensuring perfect sealing to prevent gas leaks at high pressures (30 bar or more) is a major engineering challenge. Thermal expansion and contraction over thousands of operational cycles can stress seals and connections. Anticipating these real-world challenges during the design and component selection phase, with guidance from an experienced OEM, can prevent costly downtime and safety incidents later.

A Strategic Procurement Framework: From Component Cost to Total Cost of Ownership (TCO)

For consumer goods, the lowest price often wins. For industrial infrastructure designed to operate for 20+ years, relying on initial unit cost is a recipe for financial disaster. A strategic procurement process for PEM components must be centered on the Total Cost of Ownership (TCO).

TCO provides a holistic financial model for your investment. The simplified equation is:

TCO = Initial Capital Expenditure (CAPEX) + Lifetime Operational Expenditure (OPEX)

- Moving Beyond Unit Price (CAPEX): The initial purchase price of the MEAs, BPPs, and GDLs is just one piece of the puzzle. While important, it must be weighed against its impact on the other variables.

- The Power of Efficiency (OPEX): For an electrolyzer, the single largest operational cost is electricity. A stack built with higher-efficiency MEAs and more conductive BPPs might have a 10% higher CAPEX but could reduce energy consumption by 3%. On a 10MW system operating 8,000 hours a year, that 3% efficiency gain translates into millions of dollars in electricity savings over the project’s life.

- Factoring in Longevity (Degradation & Replacement): Component durability directly impacts TCO. A stack built with cheaper components might degrade faster, requiring a costly full refurbishment or replacement after 40,000 hours instead of the targeted 80,000 hours. This not only doubles the component cost over the project’s life but also incurs significant revenue loss from downtime.

- De-risking Your Supply Chain: In today’s volatile geopolitical climate, supply chain security is paramount. Partnering with an OEM manufacturer with robust production capacity, certified quality control processes (e.g., ISO 9001), and a proven track record provides insurance against delays, inconsistent quality, and supplier instability.

Case Insight: Optimizing a 10MW Green Hydrogen Plant Stack

Let’s consider a practical example:

- Challenge: A project developer was planning a 10MW green hydrogen facility coupled with a solar farm in a coastal, saline environment. Their key objectives were maximizing hydrogen output to meet offtake agreements and ensuring a minimum 20-year operational life with minimal maintenance to ensure bankability.

- Solution & Process: Instead of sourcing the cheapest components, their engineering team adopted a TCO-based approach, working closely with an OEM partner.

- Bipolar Plates: They rejected lower-cost graphite plates, which were susceptible to fracturing, and stainless steel, which had questionable long-term corrosion resistance in the saline air. They specified high-grade coated titanium BPPs for maximum corrosion immunity and durability.

- MEA Selection: They modeled the TCO of two MEA options. Option A had a higher catalyst loading and was 2% more efficient but cost 25% more. Option B had a standard loading. Given the fluctuating nature of their solar power source, the model showed that the extra cost of Option A would not be recovered through efficiency gains. They selected the more cost-effective Option B, confident in its proven 80,000+ hour operational data.

- Outcome: While the initial CAPEX for the stack was 12% higher than a budget-focused alternative, the financial model demonstrated a clear win. The superior durability of the titanium plates extended the projected time to first major refurbishment by 3 years. The optimized system design reduced parasitic loads by 4%. The calculated TCO over the 20-year project lifetime was 15% lower, and the de-risked design was crucial in securing project financing.

Choosing Your Partner: Why a Specialized OEM Manufacturer is Crucial

The case above highlights a critical truth: for projects of this scale, you are not simply buying components; you are investing in a long-term partnership. Sourcing individual parts from multiple vendors—a BPP from one supplier, an MEA from another—creates immense integration risk and leaves you responsible when issues arise.

This is the OEM Advantage. A specialized partner like Hele Titanium Hydrogen provides a vertically integrated solution that mitigates risk and maximizes value.

- Holistic Design: We don’t just sell parts. We engineer components that are designed from the ground up to work in perfect synergy. Our BPP flow fields are optimized for the specific MEAs and GDLs we produce, ensuring predictable, warrantied performance.

- Manufacturing Excellence: We control the entire production value chain, from raw material sourcing to final coating and testing. This end-to-end oversight guarantees the highest levels of quality and batch-to-batch consistency that are absolutely vital for building reliable, multi-megawatt stacks.

- Supply Chain Security: As a direct, large-scale manufacturer, we provide the supply chain stability and transparent lead times that project developers need to adhere to strict construction schedules.

- Collaborative Engineering Support: Our team becomes an extension of yours. We partner with you from the initial design and prototyping phase all the way through to full-scale production, applying our deep expertise to help you avoid common design flaws and integration pitfalls.

LEAD MAGNET #2 (Pre-Conclusion CTA)

Your project’s success is too important for guesswork. Ready to discuss the technical and commercial viability of your component strategy?

[Schedule a No-Obligation Project Discovery Call with Our Senior Engineering Team Today]

The Future is Efficient: Innovations on the Horizon

The world of PEM technology is not static. Hele Titanium Hydrogen remains at the forefront of innovation, constantly exploring next-generation materials and manufacturing techniques. The industry is rapidly advancing in areas like catalyst-coated membranes (CCMs) which integrate the catalyst directly onto the membrane for improved performance, advanced low-cost coatings for BPPs, and the integration of AI-driven monitoring systems for predictive maintenance of stack health.

Conclusion: Build Your Project on a Foundation of Certainty

The success of your multi-million-dollar hydrogen project is fundamentally linked to the strategic selection and integration of its PEM stack components. It is a decision that will impact every key metric of your facility, from construction cost and energy consumption to reliability and long-term profitability.

To build a world-class project, you must move beyond the component price tag. By prioritizing Total Cost of Ownership, deeply understanding the complexities of system integration, and—most importantly—partnering with an experienced OEM manufacturer, you lay a foundation of certainty and performance.

Contact Hele Titanium Hydrogen today to discuss your OEM requirements and get a customized, TCO-optimized quote for your project.

Frequently Asked Questions (FAQ)

1. What is the typical lifetime of a PEM electrolyzer stack?

A high-quality PEM stack, built with durable components like coated titanium bipolar plates, is typically designed for an operational lifetime of 60,000 to 90,000 hours before requiring major refurbishment. The actual lifetime is highly dependent on operating conditions, water quality, and the quality of the core components.

2. How does operating pressure affect component selection?

Higher operating pressures (e.g., 30 bar and above) reduce downstream gas compression costs but put greater mechanical stress on components. This demands thicker membranes in the MEA to prevent gas crossover and robust, non-brittle bipolar plates (like titanium) that can withstand high clamping forces without fracturing.

3. What are the main causes of PEM stack degradation?

Degradation is typically caused by a combination of chemical and mechanical factors. Chemical degradation includes catalyst dissolution or membrane thinning. Mechanical degradation can result from pressure cycles, thermal expansion/contraction, and corrosion of the bipolar plates, which can poison the catalyst layer. A robust design and high-quality materials are the best defense against rapid degradation.

4. What is the cost difference between titanium and graphite bipolar plates?

On a per-plate basis, coated titanium BPPs have a higher initial cost than graphite. However, for large-scale systems, their superior durability, resistance to fracture during assembly and operation, and higher power density often result in a lower Total Cost of Ownership (TCO). The risk of a single cracked graphite plate compromising an entire stack section makes titanium the preferred choice for mission-critical, long-life applications.

Hele Titanium Hydrogen: Your Trusted Hydrogen Generator OEM & Manufacturing Partner

Hele Titanium Hydrogen stands as a reliable and experienced partner in the hydrogen generator OEM supply chain. We specialize in the design, development, and manufacturing of high-performance PEM Water Hydrogen Generators, offering comprehensive OEM & Manufacturing services tailored to your specific needs.

Take the Next Step

Ready to explore the possibilities of partnering with Hele Titanium Hydrogen?

- Browse our Products to see our range of PEM Water Hydrogen Generators.

- Learn more about our Services and how we can support your OEM & Manufacturing needs.

- Contact Us today to discuss your specific requirements.

- Explore our FAQ to get answers to common questions.

- Visit our Blog for the latest insights and updates on hydrogen technology.

Email Us: heletitaniumhydrogen@gmail.com

Phone/WhatsApp: 086-13857402537