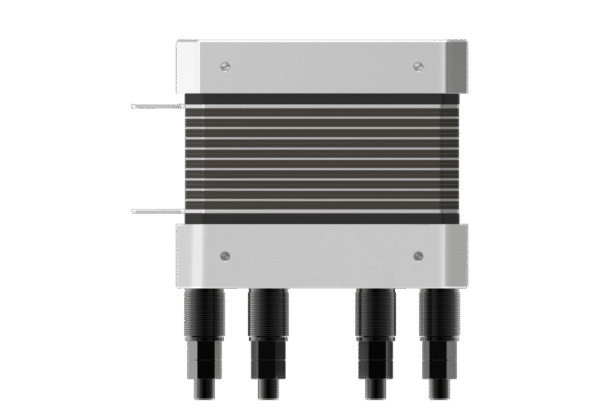

CHL7-7000mL/min PEM Hydrogen Electrolyzer Stack

PEM Hydrogen Electrolyzer Stack 7000mL/min PEM Water Electrolyzer

Reliable, High-Purity Hydrogen Generation for Modern Industries

Experience next-generation hydrogen production with the CHL7-7000mL/min PEM Water Electrolyzer. Engineered for efficiency and reliability, this advanced system delivers clean, high-purity hydrogen to meet the evolving needs of innovative industries.

Application

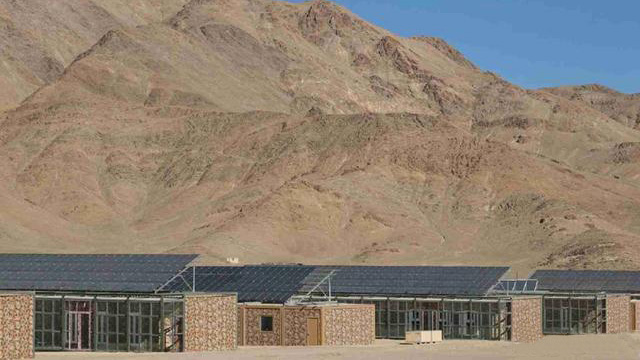

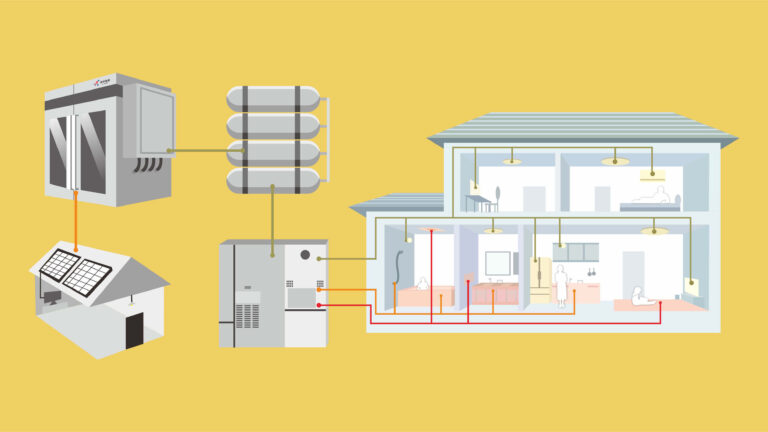

PEM electrolyzers have been commercialized in multiple fields due to their advantages of high efficiency, fast response, and adaptability to fluctuating power sources. Adapt to the intermittency and volatility of wind and solar power, wide power regulation range, industrial decarbonization and chemical raw material substitution, distributed energy and backup power supply

PEM Water Electrolyzer, Hydrogen Production Rate 7000mL/min

Key Features:

Consistent Hydrogen Output: Produces up to 7,000 mL of pure hydrogen per minute (99.99% purity, post-drying) to support continuous operations in laboratories, manufacturing, and energy applications.

Efficient Oxygen Byproduct: Generates 10,500 mL/min of oxygen, maximizing resource utilization.

Low Water Consumption: Uses just 2,300 mL of deionized water per minute, optimizing operational costs and sustainability.

Safe and Compact: Built with robust safety standards, natural water circulation, and a compact footprint (156 × 149 × 220 mm with fittings) for easy integration into your facility.

Flexible Operation: Maintains stable performance across a wide temperature range (25–70°C) and supports constant current operation (80A at 40V) for reliable, on-demand hydrogen supply.

Easy Maintenance: Designed for hassle-free operation, requiring only pure, low-TDS water to protect the advanced proton exchange membrane.

Ideal Applications:

On-site hydrogen production for fuel cell backup power, hydrogenation processes, and semiconductor manufacturing

Renewable energy storage and microgrid integration

Pharmaceutical and electronics industries seeking high-purity gas solutions

Why Choose the CHL7-7000mL/min?

Delivers industry-leading hydrogen purity and efficiency

Compact, reliable, and easy to operate

Supports your transition to cleaner, low-carbon energy solutions

Empower your business with sustainable hydrogen production—choose the CHL7-7000mL/min PEM Water Electrolyzer for performance you can trust.

| CHL7-7000mL/min type PEME | |||

| Parameter | Unit | Value | Notes |

|---|---|---|---|

| Oxygen production | ml/min | 10500 | Hydrogen is mixed with oxygen |

| Hydrogen production | ml/min | 7000 | Pure hydrogen, single out |

| Temperature of circulating water | ℃ | 25-70 | |

| Water consumption | ml/min | 2300 | Pure Water, deionized water |

| Circular manner | / | Natural circulation | |

| Hydrogen purity | % | 99.99 | After drying |

| Water electrolysis method | / | Water electrolysis | Proton exchange membrane electrolysis |

| Maximum stress | Mpa | 3.5 | |

| Anode water TDS | PPM | ≤1 | Recommended ion-exchange resin for circulating water |

| Cathode water TDS | PPM | ||

| Single cell voltage | V | 1.75-2.5 | |

| Constant current | A | 80 | |

| Constant current voltage | V | 40 | |

| Dimensions (without lugs) | mm | 136×135×150 | |

| Dimensions (including lugs and fittings) | mm | 156×149×220 | |

| Weight | kg | / | |

| Application area | Small hydrogen production-hydrogenation machine, fuel cell backup power supply, semiconductor, electron/photoelectron, multi-energy Complementary Independent micro-network, pharmaceutical and other industries on-site hydrogen production. | ||

Hele Titanium Hydrogen Company Profile

Expertise:

Hele Titanium Hydrogen is a leading PEM electrolyzer manufacturer in China, boasting over a decade of specialized experience in designing and producing advanced PEM electrolyzers tailored to meet the unique demands of diverse industries.

Service Scope:

The company offers end-to-end services, from design to large-scale production, ensuring clients receive high-quality, high-performance PEM electrolyzers that support their transition to sustainable energy solutions.

Customization Services:

Hele Titanium Hydrogen provides bespoke solutions, enabling adjustments to electrolyzer stack dimensions and capacity, optimization of operational parameters, selection of appropriate electrode materials and components, configuration of efficient cell structures, and additional system customization options to align with specific client requirements.

PEM Electrolyzer Product Overview

Capacity Range:

The company offers PEM electrolyzers in various capacities, including 0.01-1Nm³/h, 1-10Nm³/h, 10-50Nm³/h, 50-200Nm³/h, as well as compact models (2000-7000ml/min and 300-2000ml/min), catering to applications spanning small-scale laboratories to large industrial operations.

Applications:

These electrolyzers are widely deployed across sectors such as fuel cells, multi-energy hybrid microgrids, power plants, semiconductor manufacturing, hydrogen refueling stations, polysilicon production, chemical industries, optoelectronics, energy storage facilities, power absorption systems, and renewable hydrogen production.

PEM Electrolyzer Operating Principle & Advantages

Operating Principle:

PEM electrolyzers generate hydrogen and oxygen through water electrolysis. At the anode, an oxidation reaction produces oxygen, protons, and electrons; protons migrate via the proton exchange membrane to the cathode, where they combine with electrons to form hydrogen gas.

Advantages:

PEM electrolyzers excel in producing ultra-pure hydrogen, operating with high efficiency, and offering rapid response times. They are ideally suited for integration with renewable energy sources (e.g., wind, solar), advancing global decarbonization efforts and enabling the transition to a low-carbon future.

Key Considerations for Selecting PEM Electrolyzers

Hydrogen Production Requirements:

Define required hydrogen volume, purity, and pressure to select the appropriate electrolyzer model.Input Power Specifications:

Evaluate current and voltage requirements to ensure alignment with production scale and application needs.System Design & Configuration:

Assess critical components (e.g., proton exchange membrane, gas diffusion layer, catalyst layer) to guarantee system efficiency and durability.Manufacturer Reputation:

Partner with reputable manufacturers delivering reliable, high-quality electrolyzers and comprehensive after-sales support.Customization Options:

Inquire about tailor-made solutions to address specific operational demands.

Hele Titanium Hydrogen’s Commitment & Strengths

One-Stop Solutions:

Beyond premium PEM electrolyzers, Hele Titanium Hydrogen provides detailed product proposals, seamless logistics, and expert installation assistance.

Strategic Partnerships:

Collaborating with Hele Titanium Hydrogen means gaining a partner dedicated to the success of your hydrogen generation project, offering end-to-end support from design and planning to delivery and installation.

Client-Centric Solutions:

The company delivers customized hydrogen generation solutions for wholesalers, brand owners, manufacturers, suppliers, laboratories, and individual users, accommodating diverse scales and requirements.

Hele Titanium Hydrogen Generator Overview

The HTH Hydrogen Generator is an advanced device utilizing Proton Exchange Membrane (PEM) technology to produce hydrogen with up to 99.9995% purity. This hydrogen finds extensive applications across various fields, serving as carrier gas and fuel gas for Gas Chromatography (GC), collision gas for ICP-MS, feedstock for hydrogenation reactors, fuel for fuel cells, and calibration gas for emission testing equipment. In laboratory settings, it serves as an ideal alternative to conventional gas cylinders, offering an optimal solution for on-site hydrogen generation.

Operating Principle

The HTH Hydrogen Generation System employs platinum catalysts and Proton Exchange Membrane (PEM) technology to decompose deionized water into its constituent elements. The PEM selectively permits the passage of water molecules and positive ions between compartments while functioning as the electrolyte within the cell, eliminating the need for hazardous liquid electrolytes such as concentrated potassium hydroxide. The PEM water electrolysis process involves the straightforward dissociation of pure deionized water (H₂O) into hydrogen (H₂) and oxygen (O₂), which are separated on either side of the membrane.

Upon application of a DC voltage to the electrolyzer, water is transported to the anode (or oxygen electrode) where it undergoes oxidation, producing oxygen, protons, and electrons. Protons (H⁺ ions) traverse the PEM to reach the cathode (or hydrogen electrode), where they combine with electrons from the external circuit and are reduced to form hydrogen gas. The two electrochemical reactions occurring within the cell are as follows:

Anode Reaction (Oxidation):

2H2O→4H++4e−+O2

Water molecules are oxidized at the anode, generating oxygen gas, protons, and electrons.Cathode Reaction (Reduction):

4H++4e−→2H2

Protons migrating through the PEM combine with electrons at the cathode to produce hydrogen gas.

Get a Quote

Contact us today for a free quote from one of our sales engineers.

Need more help?

We are here to assist you. We’d love to hear from you!

86-13857402537

86-13857402537

Benefits of our Electrolysers

Mature technology

High efficiency

Compatible with renewable power

Leading performance guarantee

Full maintenance support

Modularity

High purity hydrogen (>99.999%)

Robust materials

Dynamic operation

High pressure (30 bar)

Key Applications of PEM Electrolyzers

PEM electrolyzers are engineered to deliver efficient, high-performance hydrogen production for a wide range of applications. Designed to meet the demands of various sectors, these electrolyzers ensure reliable, sustainable hydrogen generation to support both industrial and environmental goals.

Renewable Energy Integration

Ideal for pairing with renewable sources like solar and wind, enabling the efficient conversion of excess energy into green hydrogen for storage and use.

Hydrogen Production for Industrial Use

Perfect for large-scale production facilities, providing high-purity hydrogen for industrial processes, including fuel cells and chemical manufacturing.

Green Chemical Hydrogen / Storage

Essential for large-scale green chemical production, offering sustainable hydrogen generation and storage solutions for clean chemical processes.

Hydrogenation Stations

Designed for consistent hydrogen supply to hydrogenation processes in industries such as food production, refining, and specialty chemicals.

Common Questions

Most Popular Questions.

PEME water electrolysis hydrogen production.

Can be customized according to the needs of professional.

It is a new technology of national energy strategy and aworld-leading technology for hydrogen production. Byproton exchange membrane pure water, hydrogen gas with a purity of up to 99.999% can be rapidly produced

A: Yes, we are a professional manufacturer and our engineers have wide experiences.

Yes, we welcome sample order to test and check quality. Mixedsamples are acceptable. Also accepted OEM/ODM service.

A: Yes, if you have other needs, you can contact us and we would try our best to help you.

A: We cooperated with DHL, UPS, Fedex, EMS, TNT and China Air Post etc. We would recommend to you according to the destination, the quantity and weight. You also can contact your appointed forwarder/agent to arrange shipment.

A: For most products, we provide 6 months warranty. We would give you new one accessories Free of Charge during the guaranty period, or to be negotiated until you are satisfied.

Custom Your PEM Electrolyzer with Easy!

No matter the specific PEM electrolyzer requirements you have, our vast expertise enables us to produce it for you. Notably, as we create our own raw materials, we have the advantage of delivering superior quality control and more competitive pricing compared to our worldwide competitors.

LEAVE A MESSAGE

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.