PEM water electrolysis hydrogen production system

PEM Electrolyzer System 50Nm³/h

Hele Titanium’s CH-50Nm³/h PEM Electrolyzer is engineered for today’s demanding hydrogen markets, delivering high-purity, low-carbon hydrogen for industrial and renewable energy applications. As a leading solution in proton exchange membrane (PEM) water electrolysis, this system is designed to help businesses achieve decarbonization goals while maintaining operational efficiency and flexibility.

The CH-50Nm³/h PEM Electrolyzer by Hele Titanium offers industrial-scale hydrogen production with 99.999% purity and 4.4 kWh/Nm³ efficiency. Designed for seamless integration with renewable energy sources, this system supports decarbonization in industries like manufacturing, energy storage, and transportation. Compact, scalable, and built for reliability, it’s the optimal solution for sustainable hydrogen infrastructure.

50Nm³/h PEM Water Electrolyzer System

Unlock Clean Hydrogen Production with the CH-50Nm³/h PEM Electrolyzer

Hele Titanium’s CH-50Nm³/h PEM Electrolyzer is engineered for today’s demanding hydrogen markets, delivering high-purity, low-carbon hydrogen for industrial and renewable energy applications. As a leading solution in proton exchange membrane (PEM) water electrolysis, this system is designed to help businesses achieve decarbonization goals while maintaining operational efficiency and flexibility.

Key Features & Advantages

High-Purity Hydrogen Output: Produces 50Nm³/h of hydrogen at 99.999% purity, meeting the strictest standards for fuel cells, semiconductor manufacturing, and other sensitive applications.

Energy-Efficient Operation: Advanced PEM technology ensures low energy consumption—just 4.4 kWh per Nm³ of hydrogen—reducing operational costs and supporting sustainability targets.

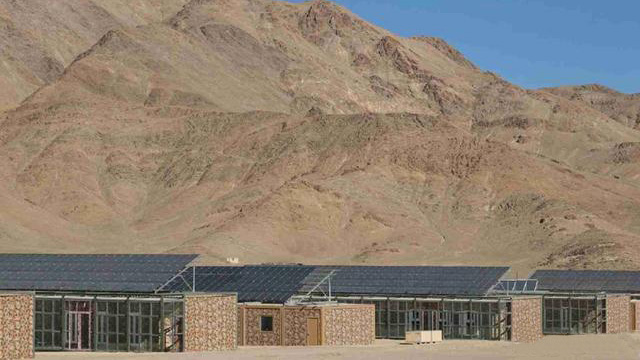

Flexible Integration: Wide load regulation range (5–120%) enables seamless integration with renewable energy sources such as solar and wind, making it ideal for green hydrogen projects and microgrid deployments.

Robust & Reliable: Built with corrosion-resistant titanium anodes and premium components for long service life, stable performance, and minimal maintenance.

Compact, Scalable Design: Space-saving footprint (3000×12000×2700 mm) allows easy installation and future expansion to meet growing hydrogen demand.

Application Areas

Industrial Hydrogen Supply: Perfect for electronics, metallurgy, glass, and chemical industries.

Renewable Energy Storage: Converts surplus solar or wind power into storable, transportable hydrogen.

Hydrogen Refueling Stations: Delivers high-purity hydrogen for fuel cell vehicles and public transportation.

Semiconductor Manufacturing: Supplies ultra-pure hydrogen for critical production processes.

Why Choose Hele Titanium’s CH-50Nm³/h PEM Electrolyzer?

Brand Trust: Hele Titanium is a trusted name in hydrogen technology, known for innovation and quality in PEM electrolyzers.

Sustainability: Support your ESG and carbon reduction initiatives with a zero-emission hydrogen solution.

B2B Focus: Tailored for industrial clients, EPC contractors, and renewable energy developers seeking reliable, scalable hydrogen production.

Optimize Your Hydrogen Supply Chain Today

Contact us to learn how the CH-50Nm³/h PEM Electrolyzer can accelerate your transition to clean hydrogen and give your business a competitive edge in the growing green energy market.

| CH-50Nm³/h PEM Hydrogen Production System | ||

| Parameter | Unit | Value |

|---|---|---|

| Gas production | Nm³/h | 75 |

| Hydrogen production | Nm³/h | 50 |

| Operating temperature | ℃ | 5-70 |

| Hydrogen purity | % | 99.999 |

| Dew point | ℃ | -74 |

| Water quality demand | / | ASTM D1193 Type I deionized water (>10MΩ·CM) |

| Maximum stress | Mpa | 3.5 |

| Supply voltage | V | 380 |

| Water consumption | L/h | 50 |

| Size | mm | 3000×12000×2700 |

| Direct current consumption | kW·h/Nm³H₂ | 4.4 |

| Load regulation range | % | 5-120 |

| Application area | / | Photovoltaic off-grid hydrogen production, wind hydrogen production, cogeneration, semiconductor, multi-energy complementary micro-network and other industrial hydrogen fields |

Hele Titanium Hydrogen Company Profile

Expertise:

Hele Titanium Hydrogen is a leading PEM electrolyzer manufacturer in China, boasting over a decade of specialized experience in designing and producing advanced PEM electrolyzers tailored to meet the unique demands of diverse industries.

Service Scope:

The company offers end-to-end services, from design to large-scale production, ensuring clients receive high-quality, high-performance PEM electrolyzers that support their transition to sustainable energy solutions.

Customization Services:

Hele Titanium Hydrogen provides bespoke solutions, enabling adjustments to electrolyzer stack dimensions and capacity, optimization of operational parameters, selection of appropriate electrode materials and components, configuration of efficient cell structures, and additional system customization options to align with specific client requirements.

PEM Electrolyzer Product Overview

Capacity Range:

The company offers PEM electrolyzers in various capacities, including 0.01-1Nm³/h, 1-10Nm³/h, 10-50Nm³/h, 50-200Nm³/h, as well as compact models (2000-7000ml/min and 300-2000ml/min), catering to applications spanning small-scale laboratories to large industrial operations.

Applications:

These electrolyzers are widely deployed across sectors such as fuel cells, multi-energy hybrid microgrids, power plants, semiconductor manufacturing, hydrogen refueling stations, polysilicon production, chemical industries, optoelectronics, energy storage facilities, power absorption systems, and renewable hydrogen production.

PEM Electrolyzer Operating Principle & Advantages

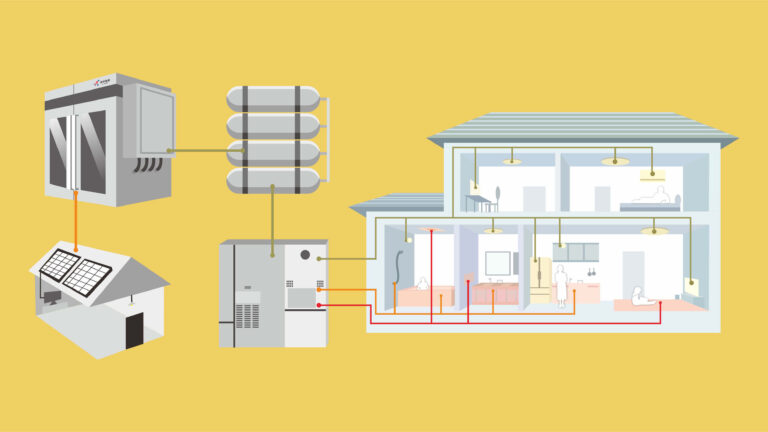

Operating Principle:

PEM electrolyzers generate hydrogen and oxygen through water electrolysis. At the anode, an oxidation reaction produces oxygen, protons, and electrons; protons migrate via the proton exchange membrane to the cathode, where they combine with electrons to form hydrogen gas.

Advantages:

PEM electrolyzers excel in producing ultra-pure hydrogen, operating with high efficiency, and offering rapid response times. They are ideally suited for integration with renewable energy sources (e.g., wind, solar), advancing global decarbonization efforts and enabling the transition to a low-carbon future.

Key Considerations for Selecting PEM Electrolyzers

Hydrogen Production Requirements:

Define required hydrogen volume, purity, and pressure to select the appropriate electrolyzer model.Input Power Specifications:

Evaluate current and voltage requirements to ensure alignment with production scale and application needs.System Design & Configuration:

Assess critical components (e.g., proton exchange membrane, gas diffusion layer, catalyst layer) to guarantee system efficiency and durability.Manufacturer Reputation:

Partner with reputable manufacturers delivering reliable, high-quality electrolyzers and comprehensive after-sales support.Customization Options:

Inquire about tailor-made solutions to address specific operational demands.

Hele Titanium Hydrogen’s Commitment & Strengths

One-Stop Solutions:

Beyond premium PEM electrolyzers, Hele Titanium Hydrogen provides detailed product proposals, seamless logistics, and expert installation assistance.

Strategic Partnerships:

Collaborating with Hele Titanium Hydrogen means gaining a partner dedicated to the success of your hydrogen generation project, offering end-to-end support from design and planning to delivery and installation.

Client-Centric Solutions:

The company delivers customized hydrogen generation solutions for wholesalers, brand owners, manufacturers, suppliers, laboratories, and individual users, accommodating diverse scales and requirements.

Get a Quote

Contact us today for a free quote from one of our sales engineers.

Need more help?

We are here to assist you. We’d love to hear from you!

86-13857402537

86-13857402537

Benefits of our Electrolysers

Mature technology

High efficiency

Compatible with renewable power

Leading performance guarantee

Full maintenance support

Modularity

High purity hydrogen (>99.999%)

Robust materials

Dynamic operation

High pressure (30 bar)

Key Applications of PEM Electrolyzers

PEM electrolyzers are engineered to deliver efficient, high-performance hydrogen production for a wide range of applications. Designed to meet the demands of various sectors, these electrolyzers ensure reliable, sustainable hydrogen generation to support both industrial and environmental goals.

Renewable Energy Integration

Ideal for pairing with renewable sources like solar and wind, enabling the efficient conversion of excess energy into green hydrogen for storage and use.

Hydrogen Production for Industrial Use

Perfect for large-scale production facilities, providing high-purity hydrogen for industrial processes, including fuel cells and chemical manufacturing.

Green Chemical Hydrogen / Storage

Essential for large-scale green chemical production, offering sustainable hydrogen generation and storage solutions for clean chemical processes.

Hydrogenation Stations

Designed for consistent hydrogen supply to hydrogenation processes in industries such as food production, refining, and specialty chemicals.

Common Questions

Most Popular Questions.

PEM waterelectrolysishydrogen production system.

Can be customized according to the needs of professional.

It is a new technology ofnational energy strategy and aworld-leading technology for hydrogen production. Byproton exchange membrane pure water, hydrogen gaswith a purity of up to 99.999% can be rapidly produced

A: Yes, we are a professional manufacturer and our engineers have wide experiences.

Yes, we welcome sample order to test and check quality. Mixedsamples are acceptable. Also accepted OEM/ODM service.

A: Yes, if you have other needs, you can contact us and we would try our best to help you.

A: We cooperated with DHL, UPS, Fedex, EMS, TNT and China Air Post etc. We would recommend to you according to the destination, the quantity and weight. You also can contact your appointed forwarder/agent to arrange shipment.

A: For most products, we provide 6 months warranty. We would give you new one accessories Free of Charge during the guaranty period, or to be negotiated until you are satisfied.

Custom Your PEM Electrolyzer with Easy!

No matter the specific PEM electrolyzer requirements you have, our vast expertise enables us to produce it for you. Notably, as we create our own raw materials, we have the advantage of delivering superior quality control and more competitive pricing compared to our worldwide competitors.

LEAVE A MESSAGE

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.