High-Purity PEM Water Electrolyzers for Scalable Green Hydrogen Production

Are You Looking for High-Performance PEM Electrolyzers?

Hele Titanium specializes in manufacturing PEM Electrolyzers, delivering tailored solutions for green hydrogen production. Designed for efficiency and reliability, these advanced electrolyzers support industries in achieving decarbonization goals. Compliant with international standards, Hele Titanium’s products are trusted globally for applications in renewable energy, industrial processes, and hydrogen fueling stations.

High-Efficiency PEM Hydrogen Generators – Offering a hydrogen production range of 0.5-1 Nm³/h.

These systems produce 99.999% ultra-pure hydrogen, engineered for peak efficiency. Featuring cutting-edge load-following technology, they automatically adjust production to meet real-time demand, ensuring unparalleled performance and energy optimization.

PEM Electrolyzer Systems – Delivering hydrogen production from 1 to 10 Nm³/h for industrial-scale applications.

Engineered to produce 99.999% ultra-pure hydrogen, these systems prioritize maximum efficiency. Equipped with advanced load-following technology, they seamlessly adapt production to real-time demand, ensuring exceptional performance.

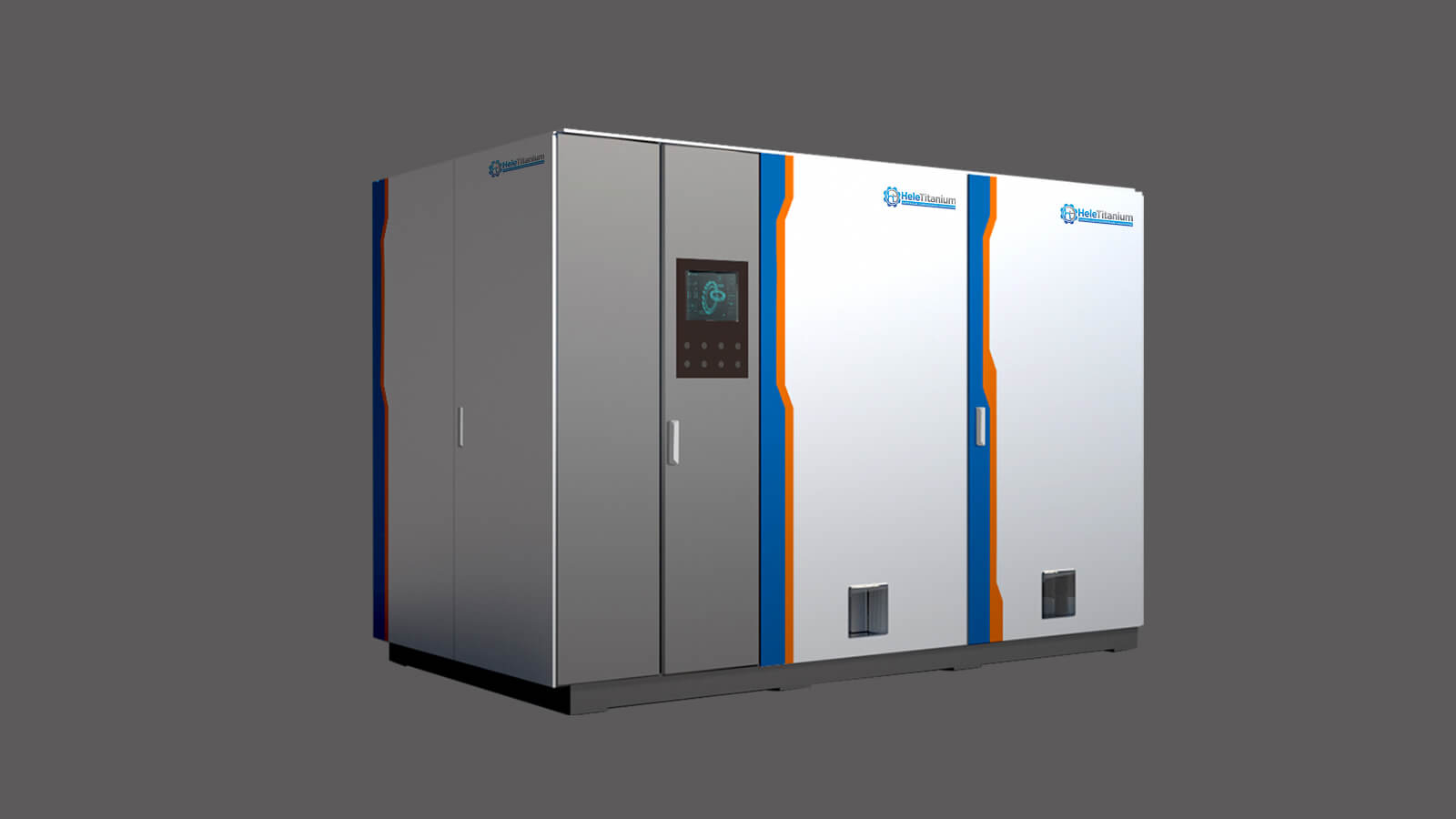

High-Capacity PEM Electrolyzer Systems – Designed for hydrogen production from 10 to 50 Nm³/h

These systems produce 99.999% ultra-pure hydrogen, engineered for optimal energy efficiency. With advanced load-following technology, they continuously adjust output to meet real-time demand, making them ideal for large-scale industrial applications.

Ultra-High Capacity PEM Electrolyzer Systems, ranging from 50 to 300 Nm³/h

Engineered for large-scale industrial and commercial applications, these systems deliver 99.999% ultra-pure hydrogen with exceptional energy efficiency. Customizable for ISO container integration, they provide a scalable, space-saving solution for diverse needs.

Precision PEM Electrolyzers for Lab Testing, ranging from 0 to 4000 ml/min

These compact and efficient systems are ideal for research, prototyping, and small-scale testing. Engineered for high purity (99.999% hydrogen), ensures reliable, repeatable results with minimal energy consumption, making it the perfect choice for advanced R&D and scientific experiments.

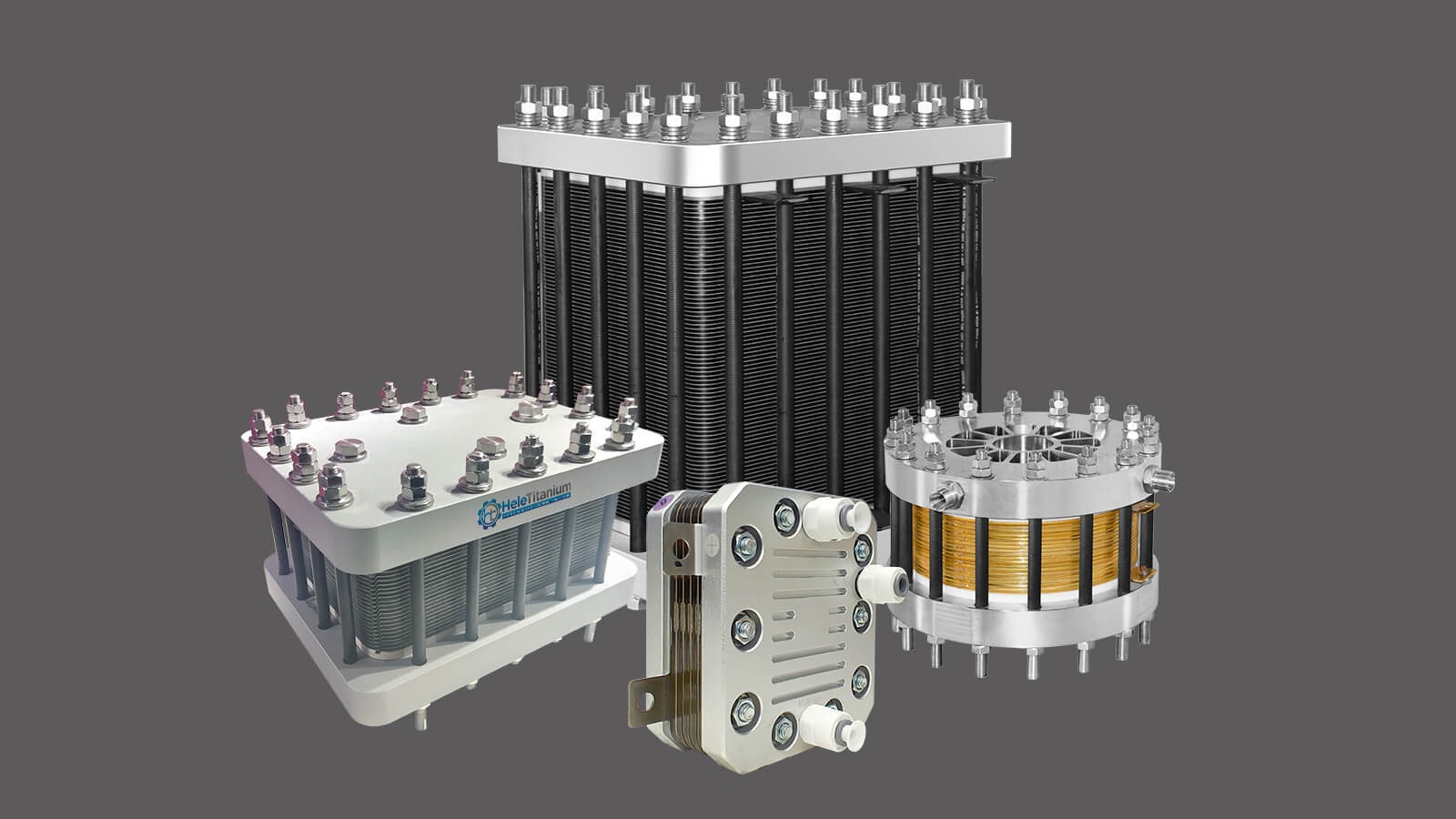

Versatile Hydrogen Production Solutions, ranging from 60 ml/min to 200 Nm³/h.

We provide a comprehensive range of PEM Electrolyzer stacks, tailored to meet the diverse needs of both industrial and research applications. Customizable, reliable, our stacks are the ideal solution for everything from R&D to large-scale hydrogen production, offering versatility across sectors.

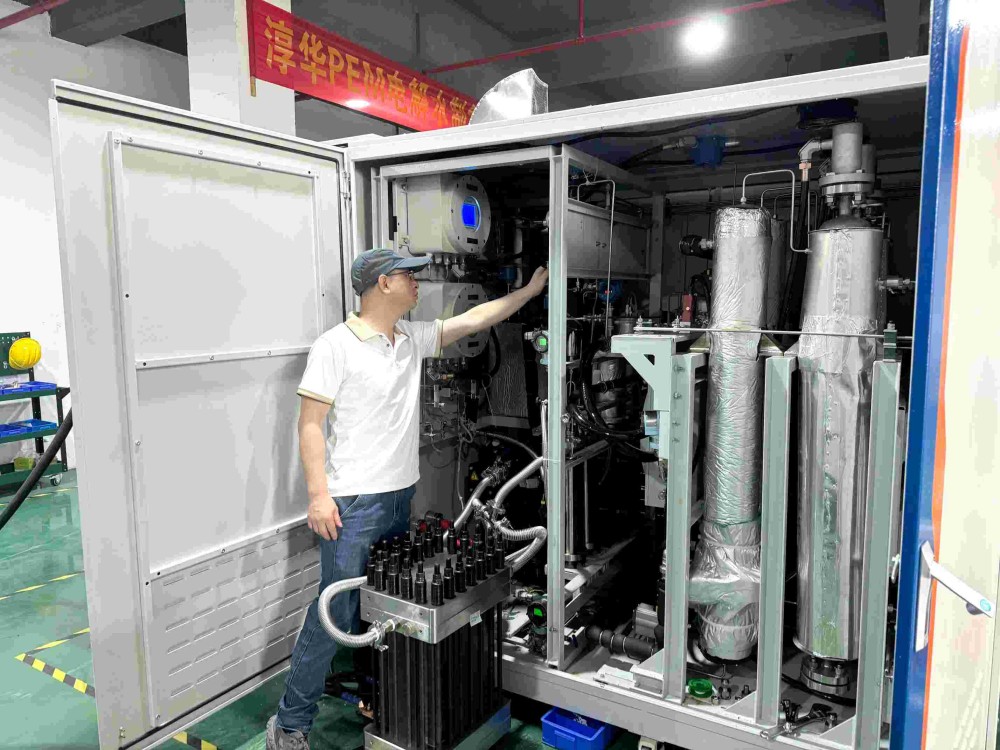

PEM water electrolysis hydrogen production system

Need Assistance?

Reach out for expert advice and information on how we can support your hydrogen solutions.

Customized Solutions for Hydrogen Technology and PEM Electrolyzers

At Hele Titanium, we specialize in delivering advanced titanium solutions tailored for the hydrogen energy sector, with a particular focus on Proton Exchange Membrane (PEM) electrolyzers. Our expertise and infrastructure ensure that B2B clients in hydrogen production receive components and assemblies that meet the highest standards of performance, durability, and efficiency.

- Titanium Machining: Precision milling, drilling, and boring with CNC machines.

- Titanium Fabrication: Expert welding, bending, and folding techniques.

- Titanium Forming: Advanced hot & cold forging and extrusion.

- Surface Treatments: Polishing, anodizing, and etching for aesthetics and durability.

- Assembly & Inspection: Joining techniques and rigorous quality checks.

- Custom Titanium Components: Bolts, medical implants, and aerospace parts.

- Titanium Finishing: Powder coating and galvanizing for protection.

- Specialized Alloys: Unique alloy formulation and heat treatments.

More Than Just a Titanium Supplier

At Hele Titanium, we pride ourselves on being more than a mere titanium supplier. Our commitment to excellence, coupled with cutting-edge technology and an experienced team, sets us apart in the titanium industry. Explore our core services:

Precision Manufacturing

Harnessing advanced tools and techniques, we ensure that each product meets the stringent standards of quality and craftsmanship.

Custom Machining

Our expertise extends to tailored machining services, be it threading or bend machining, tailored to fit your unique specifications.

State-of-the-Art Milling

With our top-tier milling processes, we transform raw titanium into high-quality products suitable for diverse applications.

Comprehensive Consultation

Our seasoned team collaborates with you, offering insights and guidance throughout the manufacturing journey to achieve optimal results.

Titanium Solutions: Customized for Each Step of the Supply Chain

Leveraging our specialized solutions and industry expertise, we are equipped to tackle the distinct challenges across your entire supply chain, helping your business succeed in today’s competitive market.

- For Wholesalers: Wholesalers require substantial inventory, competitive pricing, and reliable quality. With our extensive resources and advanced production capabilities, we deliver high-quality titanium products at highly competitive market prices..

- For Contractors: Contractors face specific project requirements and demanding timelines. We offer customized solutions and flexible manufacturing to support the successful completion of every project..

- For Brand Stewards: Brand leaders seek unique products, cohesive branding, and uncompromising quality. Backed by our expert team, we manufacture titanium solutions that consistently reflect your brand’s standards and integrity..

- For Distributors: Distributors prioritize consistent inventory, diverse product selection, and fast delivery. With our extensive titanium portfolio and robust logistics network, we guarantee prompt and dependable shipments..

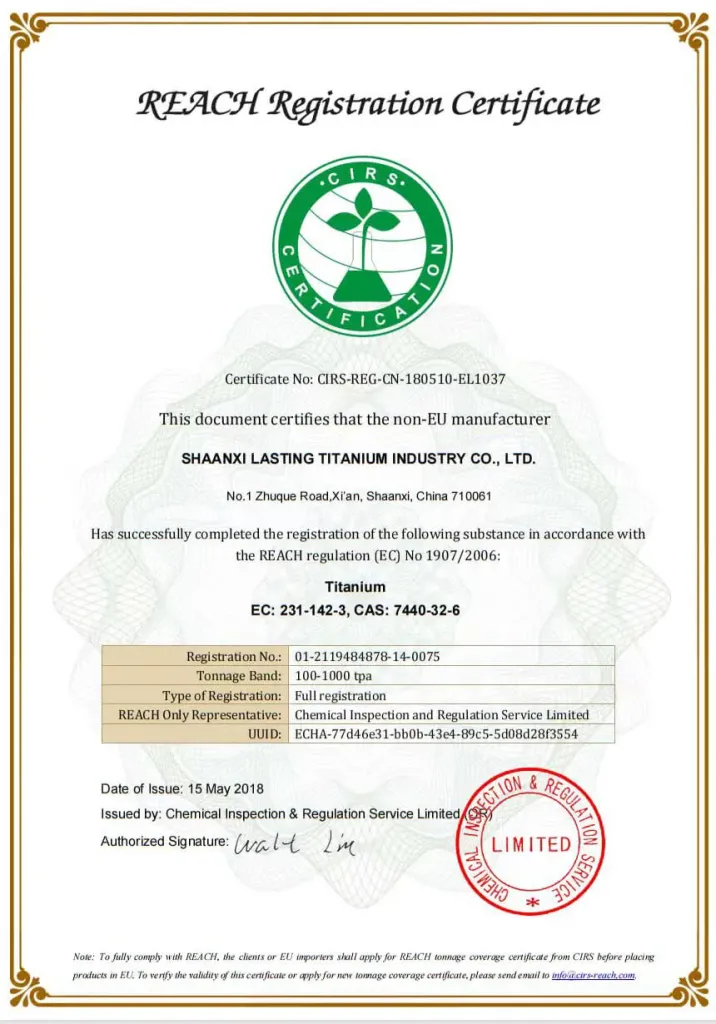

PEM Electrolyzer Manufacturer Hydrogen Production Solution Certificates bureau

PEM Electrolyzer Manufacturer Hydrogen Production Solution Certificates hpi

PEM Electrolyzer Manufacturer Hydrogen Production Solution Certificates cirs

PEM Electrolyzer Manufacturer Hydrogen Production Solution Certificates iso9001

The Industry-Leading Buyer’s Guide to PEM Electrolyzers

When choosing a Proton Exchange Membrane (PEM) electrolyzer for hydrogen production, it’s crucial to consider the main factors that impact performance and long-term efficiency. With their exceptional hydrogen purity, high efficiency, and rapid response, PEM electrolyzers are perfectly suited for renewable energy systems, industrial processes, and mobility solutions.

This guide walks you through key factors like system efficiency, material quality, durability, and maintenance, helping you achieve dependable hydrogen production and lower total ownership costs.

Table of Contents

What is a PEM Electrolyzer?

A Proton Exchange Membrane (PEM) electrolyzer is an advanced technology that efficiently generates clean hydrogen by splitting water into hydrogen and oxygen through electrolysis. Its core component, the proton exchange membrane, enables precise ion transfer and selective hydrogen production.

With the global shift toward renewable energy, PEM electrolyzers have become essential for green hydrogen generation. They are recognized for their high efficiency, rapid response, and adaptability, making them ideal for energy storage, transportation, and renewable energy integration. By delivering a cleaner and more sustainable hydrogen solution, PEM electrolyzers are driving decarbonization and supporting the transition to a low-carbon economy.

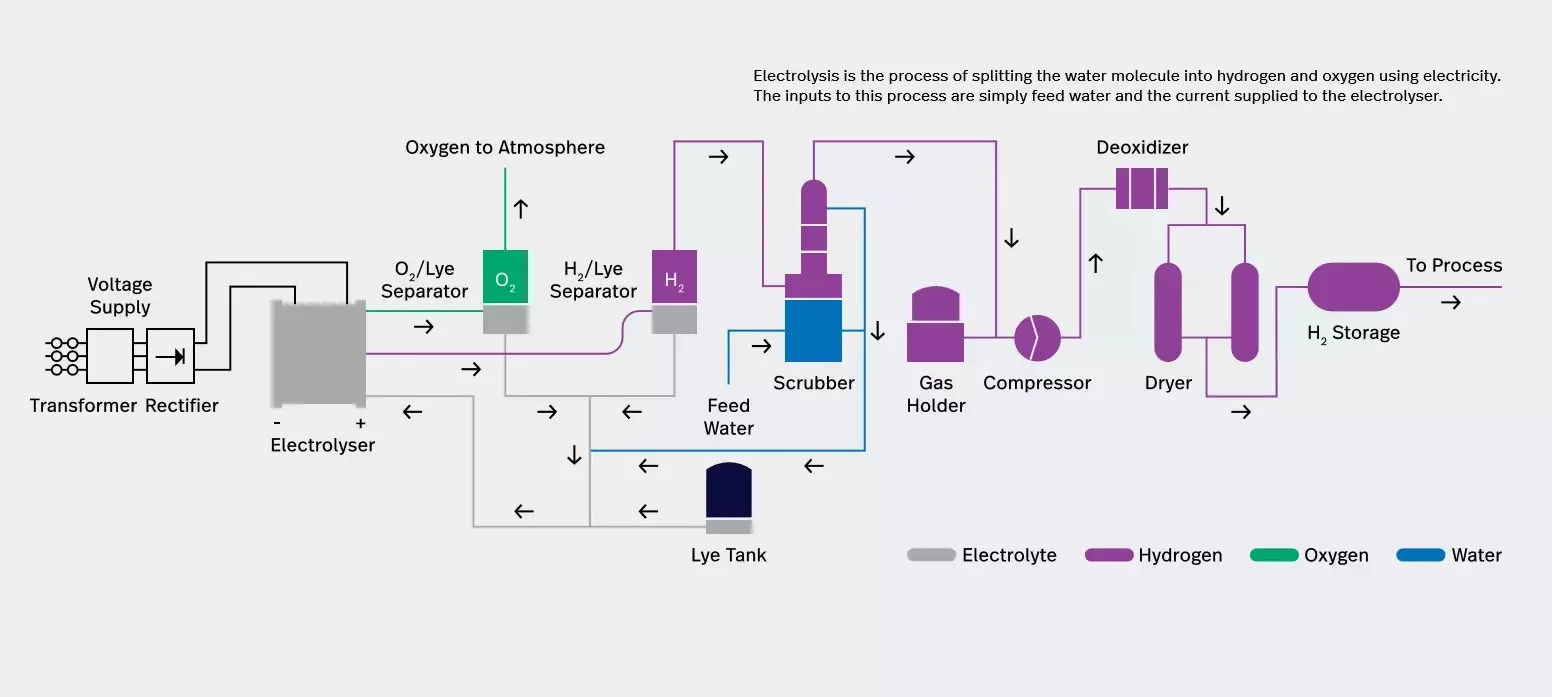

PEM Electrolyzer Working Principle: Easy to Understand

A Proton Exchange Membrane (PEM) electrolyzer operates by splitting water into hydrogen and oxygen through a series of electrochemical reactions. Here’s how the process works step by step:

1. Water Supply

A steady flow of water enters the electrolyzer through a dedicated inlet. This water serves as the feedstock, which will be separated into hydrogen and oxygen gases during the electrolysis process.

2. Anode Reaction (Oxidation)

At the anode, the applied electric current splits water molecules (H₂O) in an oxidation reaction, producing:

Oxygen gas (O₂)

Positively charged hydrogen ions (protons, H⁺)

Electrons (e⁻)

The overall anode reaction is represented by:

2H₂O → O₂ + 4H⁺ + 4e⁻

3. Proton Exchange Membrane (PEM)

The proton exchange membrane, positioned between the anode and cathode, selectively permits only protons (H⁺) to pass through while blocking electrons. Driven by the applied voltage, these protons migrate through the membrane toward the cathode.

4. Electron Flow

Electrons (e⁻) generated at the anode cannot pass through the membrane and instead travel through an external circuit. This movement creates an electric current as electrons flow from the anode to the cathode, completing the electrical circuit.

5. Cathode Reaction (Reduction)

At the cathode, hydrogen ions (H⁺) arriving via the membrane combine with electrons (e⁻) from the external circuit. This reduction reaction produces hydrogen gas (H₂):

4H⁺ + 4e⁻ → 2H₂

6. Gas Separation and Collection

As the process continues, hydrogen gas (H₂) accumulates at the cathode, while oxygen gas (O₂) is released at the anode. The system efficiently separates and collects both gases for use in energy storage, fuel cells, and a variety of industrial applications.

This entire process enables the efficient and clean production of hydrogen, supporting sustainable energy solutions and industrial needs.

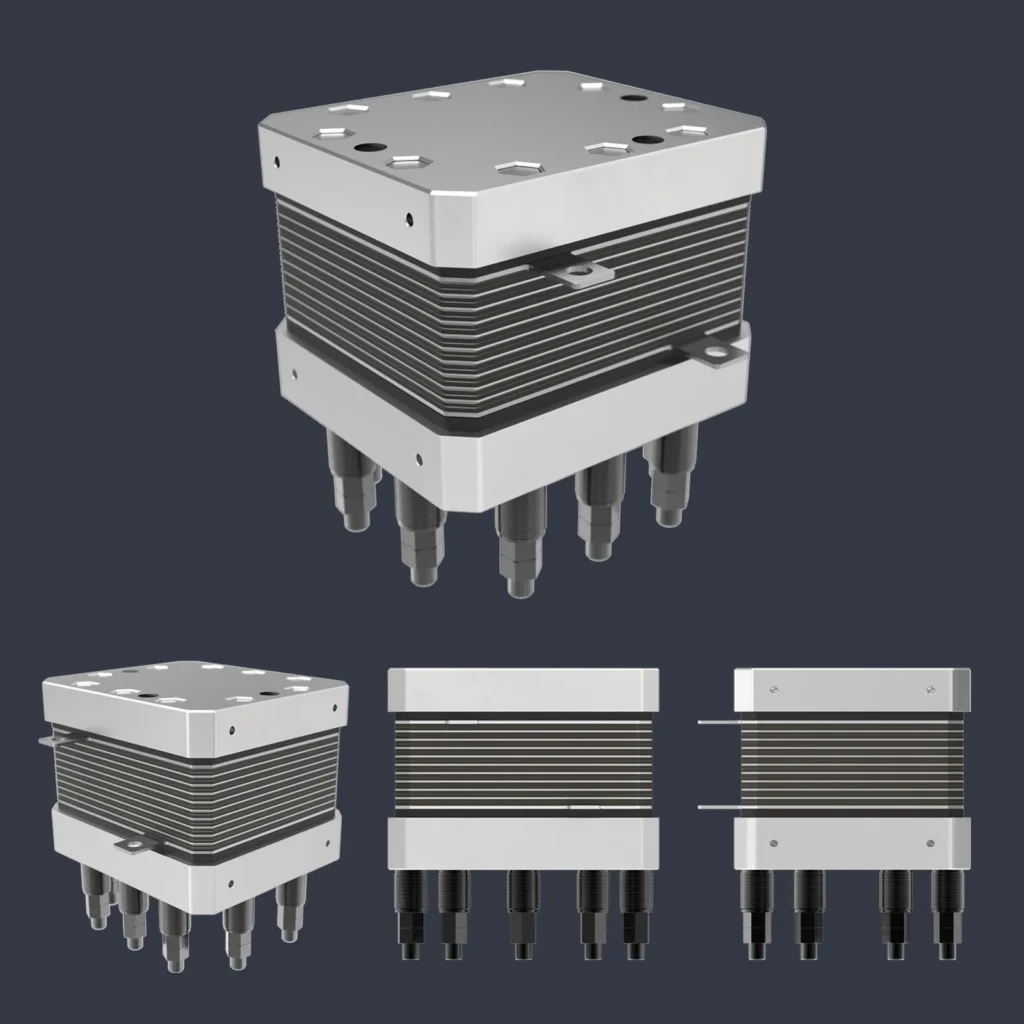

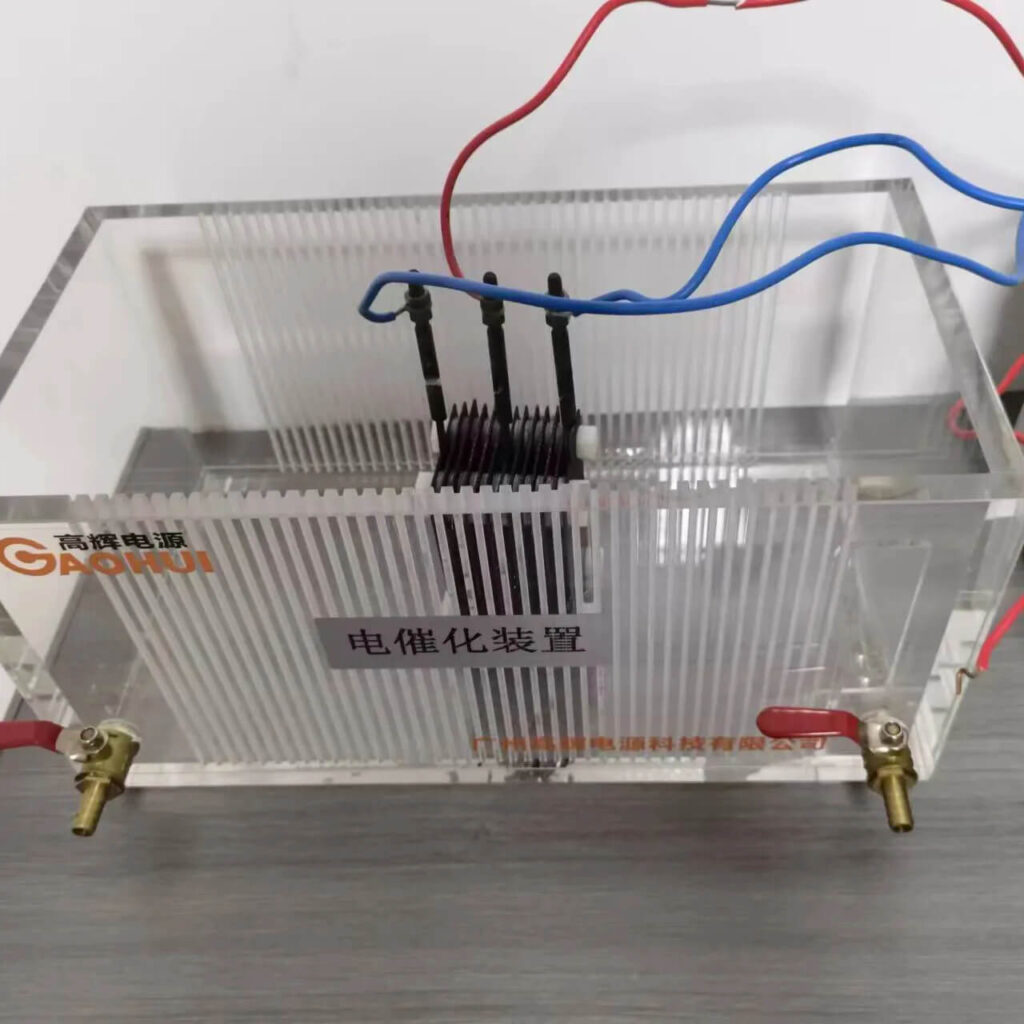

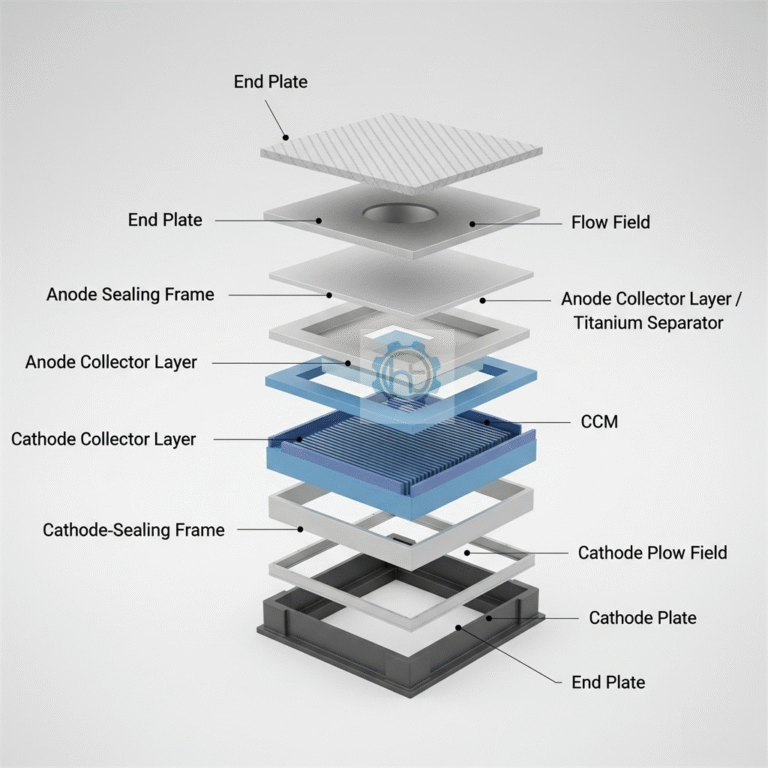

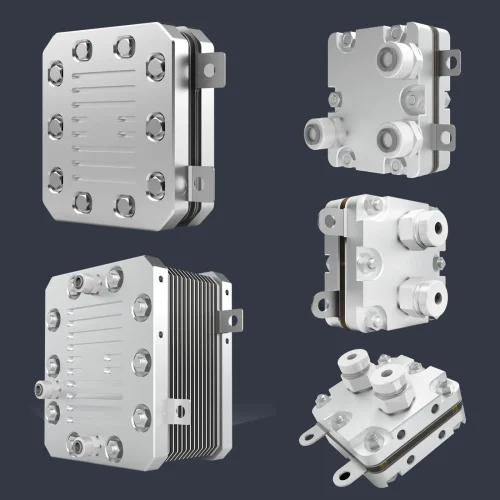

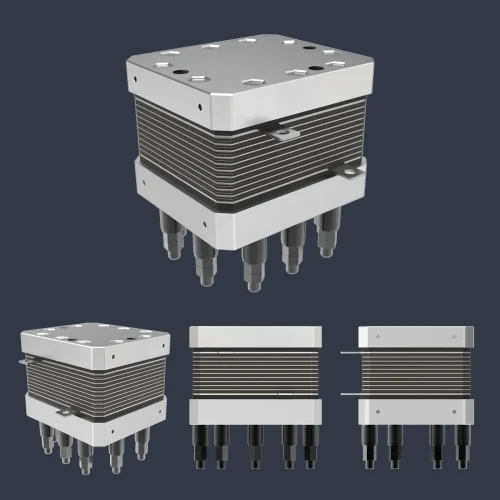

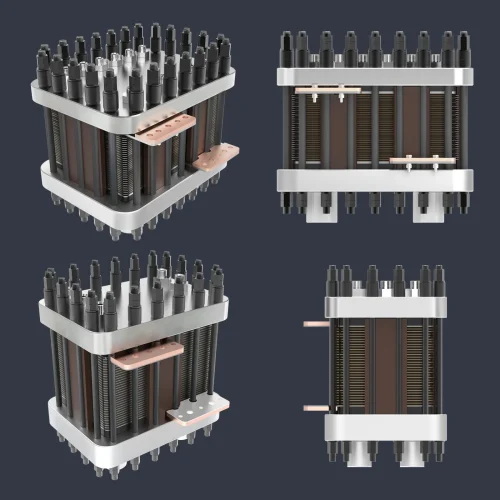

PEM Water Electrolyzer Stack: Core Elements and Design

At our company, we engineer and produce high-performance PEM water electrolyzer stacks, prioritizing quality, efficiency, and long-term reliability. Central to our design is a premium Proton Exchange Membrane (PEM) imported from the United States, ensuring optimal hydrogen production efficiency. Our stacks feature a single-layer architecture, with each precisely crafted component enhancing the system’s overall performance.

Key Components of Our PEM Electrolyzer Stack

Cathode Plate:

Serves as the foundation of the cathode side, providing robust structural support and ensuring uniform current distribution.

Cathode Sealing Frame:

Creates a reliable seal around the cathode chamber, effectively preventing leaks and maintaining stable system operation.

Cathode Chamber:

Houses the cathode-side reaction where hydrogen gas is produced, enabling efficient gas separation and collection.

Cathode Collector Layer:

Gathers and channels electrons to the reaction zone, boosting the overall efficiency of hydrogen generation.

CCM (Catalyst-Coated Membrane) Membrane Electrode:

As the core of the electrolyzer, this catalyst-coated membrane electrode drives electrochemical reactions, separates the anode and cathode processes, and selectively allows protons (H⁺) to pass while blocking gases and electrons.

Anode Collector Layer:

Collects electrons from the anode side and returns them to the external circuit, completing the electrochemical cycle.

Anode Chamber:

Supports oxygen gas production and ensures its safe collection and controlled release.

Anode Sealing Frame:

Secures the anode chamber with a tight seal, preventing any gas or liquid leakage during operation.

Anode Plate:

Provides structural support for the anode side and efficiently conducts electricity to the reaction area.

Titanium Separator:

Placed between layers, this high-grade titanium separator optimizes ion and gas flow while preserving stack integrity over prolonged use.

Titanium End Plate:

The terminal component, designed with dedicated channels for air and water, ensures optimal distribution within the stack and features positive and negative terminals for electrical connections at both the cathode and anode ends.

Stack Design and Lifespan

Meticulous material selection and precise assembly are fundamental to the performance and durability of our PEM electrolyzer stacks. By incorporating corrosion-resistant titanium in critical components and utilizing high-efficiency catalysts, our stacks are engineered for exceptional reliability, delivering a service life of up to 10 years.

The stack features a multi-layered design—much like a “multi-decker sandwich”—with the cathode, anode, and membrane as its core layers. This structure, combined with advanced materials and engineering, enables efficient water splitting into hydrogen and oxygen, ensuring clean hydrogen production for a wide range of industrial and energy applications.

Our PEM electrolyzer stacks provide a robust, efficient, and sustainable hydrogen solution, purpose-built to meet the stringent requirements of the evolving hydrogen economy.

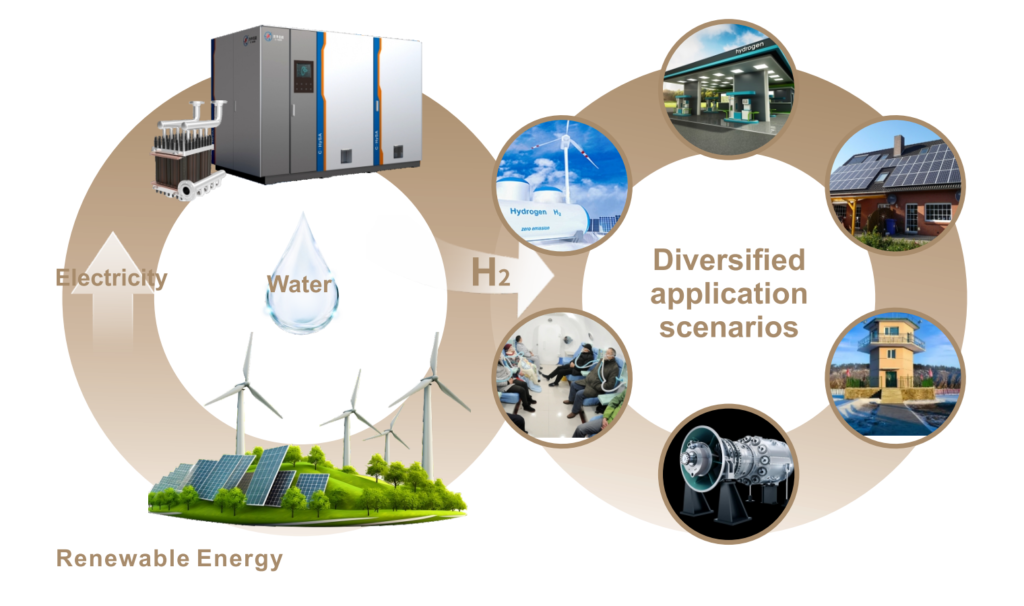

Key Benefits of Using PEM Electrolyzers

PEM electrolyzers deliver significant advantages, especially when integrated with renewable energy sources such as wind, solar, or hydropower. Here are the primary benefits of utilizing PEM electrolyzers:

Zero-Emission Green Hydrogen Production

When powered by renewable sources, PEM electrolyzers generate green hydrogen with no emissions. This clean hydrogen is pivotal for global sustainability initiatives and serves as a foundation for the transition to a low-carbon future.Enabling Green Ammonia and Methanol Synthesis

Green hydrogen from PEM electrolyzers is essential for producing green ammonia and methanol—key chemicals for sustainable agriculture, chemical manufacturing, and shipping. These applications help industries significantly lower their carbon footprint and meet stringent environmental targets.High-Efficiency Energy Storage

PEM electrolyzers offer an efficient method for large-scale energy storage. Hydrogen can be stored under pressure and utilized when needed, providing much greater storage capacity than conventional batteries. This makes PEM electrolyzers ideal for capturing surplus renewable energy and supplying it during periods of high demand.

Rapid Response and Operational Flexibility

PEM electrolyzers excel with their swift response times and the ability to adjust hydrogen output in real time according to demand. This adaptability makes them ideal for integration with variable renewable energy sources like wind and solar, ensuring stable and efficient operation in dynamic energy environments.

Highly Scalable and Versatile Solutions

PEM electrolyzers are designed for scalability, seamlessly expanding from small-scale energy storage to large-scale industrial deployments. Their versatility supports a broad spectrum of applications, including:

– Fuel cell-powered transportation

– Grid energy storage and stabilization

– Industrial processes that require clean hydrogen

By offering efficient, clean, and easily scalable hydrogen production, PEM electrolyzers are essential to driving green energy progress and supporting the global shift toward a sustainable, low-carbon economy.

Main Types of Electrolyzers for Hydrogen Production

Hydrogen production via water electrolysis is a well-established technique that utilizes electrical energy to separate water into hydrogen and oxygen. This method is vital for producing clean, emissions-free hydrogen, supporting a wide range of industrial applications. In an electrolyzer, electrochemical reactions take place at two electrodes—the anode and the cathode—yielding hydrogen at the cathode and oxygen at the anode.

There are three primary types of electrolyzers used for hydrogen generation, each with unique features and operating principles: Proton Exchange Membrane (PEM) Electrolyzers, Alkaline Electrolyzers, and Solid Oxide Electrolyzers. These technologies vary in their electrolyte composition, operating temperature, and efficiency, making them suitable for diverse application scenarios.

Alkaline Hydrogen Generator

Alkaline electrolyzers represent one of the most mature and widely adopted technologies for hydrogen production. They use an alkaline electrolyte—typically potassium hydroxide or sodium hydroxide—and operate efficiently at temperatures between 70°C and 80°C. Electrodes crafted from nickel-molybdenum alloys drive the electrolysis process, effectively splitting water into hydrogen and oxygen.

Key Features:

A diaphragm, often made from asbestos, separates hydrogen and oxygen gases to maintain product purity.

These systems deliver high efficiency, with rates ranging from 62% to 82%, and can generate gas at pressures between 0.1 MPa and 3.0 MPa.

Alkaline electrolyzers are highly cost-effective, featuring low capital investment and operational costs.

While alkaline hydrogen generators offer significant economic advantages, they do face challenges such as lye loss, corrosion, and higher energy consumption compared to PEM electrolyzers. Nevertheless, they remain a leading solution for large-scale hydrogen production, particularly in industries where minimizing initial costs is a priority.

PEM Hydrogen Generator

PEM electrolyzers use a proton exchange membrane made from a perfluorosulfonic acid that ensures excellent chemical stability and high proton conductivity. This solid polymer electrolyte allows for the selective passage of protons while preventing the transfer of electrons, making the process safer and more efficient.

Key components in a PEM electrolyzer include:

- The proton exchange membrane

- Positive and negative catalytic layers

- Gas diffusion layers

- Terminal plates

These components form the membrane electrode assembly (MEA), which is the core site of material transfer and electrochemical reactions. The structure and materials used in the MEA significantly impact the electrolyzer’s performance, efficiency, and lifespan.

PEM hydrogen generators are known for their ability to produce high-purity hydrogen on demand, making them ideal for industrial processes, fuel cell applications, and energy storage solutions. The technology operates efficiently at moderate temperatures (60°C to 80°C), which contributes to its wide adoption across multiple sectors.

Solid Oxide Electrolyzers

Solid oxide electrolyzers are an advanced hydrogen production technology that operates at significantly higher temperatures, typically between 800°C and 1,000°C. This elevated temperature range enables superior electrochemical efficiency and overall system performance, positioning solid oxide electrolyzers as a promising option for efficient hydrogen generation.

Unlike PEM and alkaline electrolyzers, which rely on liquid or polymer electrolytes, solid oxide electrolyzers use a solid ceramic electrolyte. The high operating temperature allows the system to utilize both electrical and thermal energy to split water molecules, thereby reducing the total energy input required.

Despite their efficiency advantages, solid oxide electrolyzers face several challenges:

The extreme operating temperatures accelerate material degradation, necessitating the use of highly robust and stable components.

The limited availability of materials that can endure such harsh conditions complicates large-scale implementation.

High manufacturing costs and system complexity have slowed the widespread adoption of solid oxide electrolyzers.

Efforts are underway to enhance the durability and cost-effectiveness of solid oxide electrolyzers, which could unlock new opportunities, especially in sectors demanding high-efficiency hydrogen production.

Summary of Electrolyzer Types

PEM Electrolyzers:

Utilize a solid polymer membrane and operate at moderate temperatures (60°C to 80°C). They deliver high hydrogen purity and efficiency, making them ideal for industries that require on-site hydrogen generation.Alkaline Electrolyzers:

Employ a liquid alkaline electrolyte and function at slightly higher temperatures (70°C to 80°C). While they are highly cost-effective, they face challenges such as corrosion and lye loss.Solid Oxide Electrolyzers (SOECs):

Operate at elevated temperatures (800°C to 1,000°C), offering superior efficiency but also presenting challenges related to material stability and large-scale deployment.

Selecting the most suitable electrolyzer depends on factors like required hydrogen output, operational conditions, available energy sources, and specific industry needs. Each technology offers unique advantages and limitations, and ongoing innovations in electrolysis are paving the way for more efficient, scalable solutions to support global green hydrogen production.

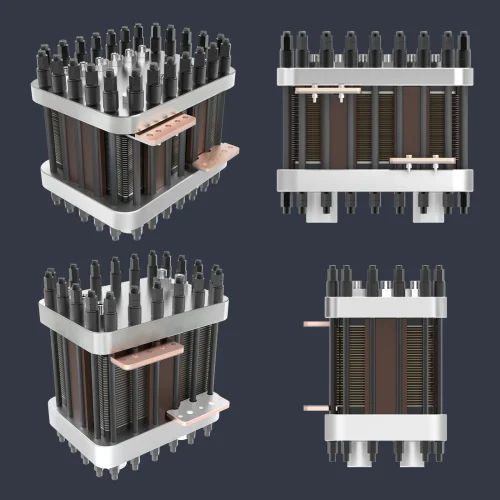

High-Performance PEM Electrolyzer for Scalable Hydrogen Production

With deep industry expertise and a strong commitment to advancing hydrogen technology, Hele Titanium stands as a premier manufacturer of PEM electrolyzers in China. Our high-quality, dependable, and cost-effective PEM electrolyzers are trusted by clients worldwide to address a wide range of hydrogen production needs.

Since our inception, we have focused on continuous innovation in PEM electrolysis, delivering solutions recognized for their outstanding efficiency, durability, and performance. Hele Titanium sets the industry standard by providing robust, energy-efficient PEM electrolyzers for industrial, transportation, and energy storage applications.

Scalable and Flexible Solutions

Our comprehensive product lineup is designed to match your specific hydrogen production requirements:

MW-Class Large PEM Electrolyzers: Ideal for high-capacity industrial hydrogen production.

Medium-Sized PEM Electrolyzers: Perfect for scalable and adaptable applications.

Small and Medium-Sized PEM Electrolyzers: Offer flexible and efficient solutions for mid-range hydrogen needs.

Small PEM Electrolyzers: Compact units for on-site hydrogen generation.

Whether you require large-scale hydrogen production or modular, smaller-scale solutions, Hele Titanium delivers flexible, customizable options that ensure both reliability and efficiency. As your trusted partner in the hydrogen economy, we are dedicated to supporting your transition to clean energy and sustainable operations.

Small Size PEM Electrolyzer

Rated Hydrogen Production: 60–5000 mL/min

Hydrogen Pressure: 0.5–0.8 MPa

Hydrogen Purity: >99.99%

Rated Input Current: 22–28A

Our small-size PEM electrolyzers deliver high-purity hydrogen (>99.99%) at flow rates up to 5000 mL/min, providing a reliable and efficient solution for a variety of applications. These compact units are highly customizable, allowing you to select the optimal configuration for hydrogen production rates between 60 and 5000 mL/min.

Key Applications:

Gas Chromatography (GC): Supplying fuel and carrier gas

ELCD (Electrolytic Conductivity Detector): Reaction gas supply

ED (Atomic Emission Spectroscopy Detector): Reaction gas supply

Hydrogen-Rich Water Machines: Consistent, high-purity hydrogen generation

Designed for maximum versatility, our PEM electrolyzers are ideal for both scientific and industrial environments where ultra-pure hydrogen is essential. With customizable options and low maintenance requirements, they offer the perfect combination of performance, reliability, and convenience for a wide range of specialized applications.

Small and Medium-Sized PEM Electrolyzers

Rated Hydrogen Production: 0.2–1 Nm³/h

Hydrogen Pressure: 0.1–3.5 MPa

Hydrogen Purity: >99.99%

Rated Power Consumption: ≤4.4 kWh/Nm³

Water Consumption: 1 kg/h

Our small and medium-sized PEM electrolyzers are engineered to deliver high-purity hydrogen (>99.99%) at production rates ranging from 0.2 to 1 Nm³/h. Each system can be tailored to your specific requirements, ensuring optimal performance for your application.

Typical Applications:

Hydrogen-rich water generators

Hydrogen absorption devices

Laboratory hydrogen supply

Mobile hydrogen stations

Combining compact design with energy efficiency and reliable operation, these PEM electrolyzers provide a flexible and robust solution for both industrial and personal hydrogen production needs. Customizable configurations further enhance their versatility, making them ideal for a broad spectrum of uses.

Medium-Size PEM Electrolyzer

Rated Hydrogen Production: 1–10 Nm³/h

Hydrogen Pressure: 3.5 MPa

Hydrogen Purity: >99.99%

Rated Power Consumption: <4.4 kWh/Nm³

Water Consumption: 3 kg/h

Our medium-size PEM electrolyzers are designed to deliver ultra-high purity hydrogen (>99.99%) at production rates from 1 to 10 Nm³/h. Each system is fully customizable to meet your specific operational requirements, providing both flexibility and efficiency across a variety of applications.

Typical Applications:

Fuel cell systems

Multi-energy complementary microgrids

Power generation plants

Semiconductor manufacturing

Engineered for reliability and superior performance, our PEM electrolyzers offer scalable, energy-efficient hydrogen solutions tailored to the diverse needs of industrial and energy sectors.

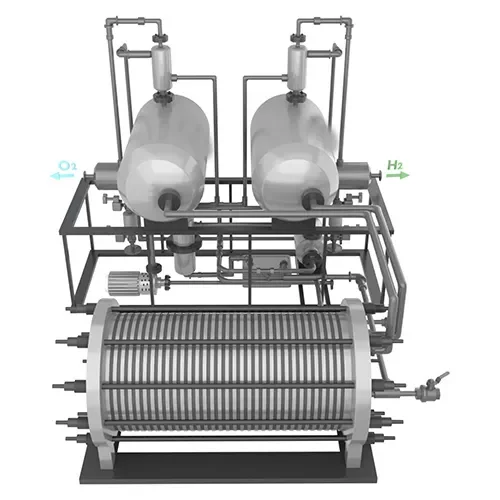

MW-Class PEM Electrolyzer

Rated Hydrogen Production: 50–300 Nm³/h

Hydrogen Pressure: 3.5 MPa

Hydrogen Purity: >99.99%

Rated Power Consumption: <4.5 kWh/Nm³

Water Consumption: 60 kg/h

Our MW-class PEM electrolyzers are engineered for high-capacity, industrial-scale hydrogen production, delivering up to 300 Nm³/h of ultra-pure hydrogen (>99.99%). With customizable output ranges from 50 to 300 Nm³/h, these systems are tailored to meet the unique requirements of large-scale operations, ensuring maximum efficiency and reliability.

Key Applications:

Photovoltaic off-grid hydrogen generation

Wind-powered hydrogen production

Cogeneration and combined heat & power systems

Semiconductor manufacturing

Multi-energy complementary microgrids

Other demanding industrial hydrogen applications

Purpose-built for large industrial environments, our MW-class PEM electrolyzers provide robust, energy-efficient hydrogen solutions that seamlessly integrate with renewable energy sources and support high-demand production processes.

PEM Electrolyzer Solutions for Industry

PEM (Proton Exchange Membrane) electrolyzers are highly versatile, enabling efficient and sustainable hydrogen production for a broad spectrum of industrial applications. Here are some of the primary industrial uses:

Industrial Hydrogen Generation:

PEM electrolyzers are the preferred choice for producing high-purity hydrogen across a diverse range of industries. Key applications include:

Hydrogen Generators: Delivering reliable, on-demand hydrogen for industrial and commercial processes, ensuring consistent quality and supply.

Hydrogen Water Machines: Powering the health and wellness sector with efficient production of hydrogen-enriched water, meeting growing consumer demand.

Hydrogen Absorption Equipment: Supporting advanced scientific and medical devices that require precise hydrogen absorption for specialized procedures.

On-Site and Distributed Hydrogen Production:

PEM electrolyzers excel in small-scale, on-demand hydrogen generation, offering flexibility and efficiency for localized applications such as:

Hydrogenation Units: Enabling tailored hydrogen production for specific industrial processes, reducing logistics and operational costs.

Multi-Energy Microgrids: Integrating seamlessly into microgrid systems to optimize energy management and enhance overall system efficiency.

Pharmaceutical Production: Providing a reliable hydrogen source for pharmaceutical applications, supporting innovation and regulatory compliance.

Hydrogen Fueling Infrastructure:

PEM electrolyzers are essential to the development of hydrogen fueling networks across various transportation sectors, enabling clean and efficient hydrogen production for diverse vehicle types.

Cars, Trucks, and Buses:

Supporting hydrogen fueling stations that cater to electric mobility and heavy-duty vehicles, PEM electrolyzers ensure reliable, high-purity hydrogen supply for sustainable transportation.Other Transportation Markets:

Delivering scalable and eco-friendly fueling solutions for hydrogen-powered vehicles in public transit, commercial fleets, and emerging transport sectors.

Choose PEM electrolyzers to power your hydrogen fueling infrastructure with efficiency, reliability, and sustainability. Contact us to explore customized solutions that drive your business towards a greener future.

Renewable Energy Integration:

PEM electrolyzers play a crucial role in advancing renewable energy applications by efficiently converting and storing clean energy. Key sectors benefiting from this technology include:

Power-to-Gas:

Harnessing surplus renewable electricity from solar and wind sources, PEM electrolyzers convert excess power into hydrogen, enabling long-term energy storage and grid balancing.Power-to-Industry:

Integrating renewable energy into large-scale hydrogen production, PEM electrolyzers support industrial decarbonization efforts by providing clean hydrogen for various processes, significantly reducing carbon footprints.

Leverage PEM electrolyzer technology to optimize your renewable energy assets, enhance sustainability, and drive cost-effective, scalable hydrogen solutions. Contact us to tailor a renewable energy integration strategy that meets your business goals.

Key Factors for Selecting the Right PEM Electrolyzer

When evaluating a PEM electrolyzer for high-efficiency hydrogen production, it’s essential to consider key factors that guarantee the solution aligns with your operational requirements and business objectives:

Hydrogen Production Requirements:

Begin by clearly defining your hydrogen production targets—including desired output volume, purity, and pressure. This clarity ensures you select a PEM electrolyzer precisely matched to your operational needs.Input Power Specifications:

Assess the required input current and voltage for the electrolyzer. Make sure the system’s energy demands align with your production scale and application, optimizing both performance and energy efficiency.System Configuration and Design:

Examine the electrolyzer’s overall design and key components, such as the proton exchange membrane, gas diffusion layers, and catalyst layers. A robust, well-engineered system is critical for achieving long-term efficiency and reliability.Manufacturer Credibility:

Choose a manufacturer with a proven track record for delivering high-quality, dependable PEM electrolyzers. Look for strong warranties, comprehensive technical support, and responsive after-sales service to maximize your investment.Customization Options:

Consider whether your application requires tailored solutions—such as specific control systems, modular configurations, or integration with existing infrastructure. A manufacturer offering flexible customization can help you achieve optimal results for your unique business requirements.

- Customization capabilities in PEM electrolyzers are essential for meeting diverse hydrogen production requirements. Manufacturers that offer tailored solutions empower clients to optimize system performance, efficiency, and reliability, ensuring the electrolyzer is perfectly matched to specific application needs. By prioritizing customization, you can achieve scalable and flexible hydrogen production that supports your operational goals. Hele Titanium, as a professional PEM electrolyzer manufacturer, delivers a comprehensive range of customizable products—from small-scale units to MW-class large electrolyzers—designed to serve a wide array of industrial and energy applications.

Hele Titanium: Your Strategic B2B Partner for Titanium-Based PEM Electrolyzers

Choosing the right PEM electrolyzer supplier is a pivotal decision for enterprises advancing in the hydrogen economy. At Hele Titanium, we specialize in serving B2B clients who demand high-efficiency, robust, and scalable hydrogen solutions. Our deep industry expertise and commitment to innovation ensure that your business benefits from reliable technology, tailored support, and a competitive edge in the evolving hydrogen market.

Ready to Explore PEM Electrolyzer Solutions?

Contact us today to discuss how our advanced PEM technology can power your sustainable energy goals.

LEAVE A MESSAGE

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.