Published by Hele Titanium Hydrogen | Exporting High-Performance PEM Electrolyzers Worldwide

Introduction

As the global economy shifts towards decarbonization, green hydrogen has emerged as a clean, scalable energy carrier that can revolutionize industries and support net-zero goals. Green hydrogen is produced through water electrolysis powered by renewable energy—offering a zero-emissions alternative to fossil fuels.

At the forefront of this revolution is PEM (Proton Exchange Membrane) technology, renowned for its high efficiency, fast response, and compact system design.

At Hele Titanium Hydrogen, we specialize in exporting high-performance PEM electrolyzers engineered to meet industrial and commercial demands. Our systems are trusted by clients worldwide seeking reliable, sustainable hydrogen solutions.

Understanding PEM Technology

How Does PEM Electrolysis Work?

PEM electrolyzers use a solid polymer membrane as the electrolyte. When electricity is applied, water (H₂O) splits into hydrogen (H₂) and oxygen (O₂). The hydrogen gas is collected at the cathode, and oxygen is released at the anode.

Key Advantages of PEM over Alkaline Electrolysis:

- ✅ High Efficiency – Converts electricity to hydrogen with minimal losses.

- ⚡ Rapid Start-Up/Shutdown – Ideal for dynamic renewable energy input.

- 🔋 High Current Density – Delivers more hydrogen in less space.

- 🛢️ High-Pressure Hydrogen Output – Without requiring a mechanical compressor.

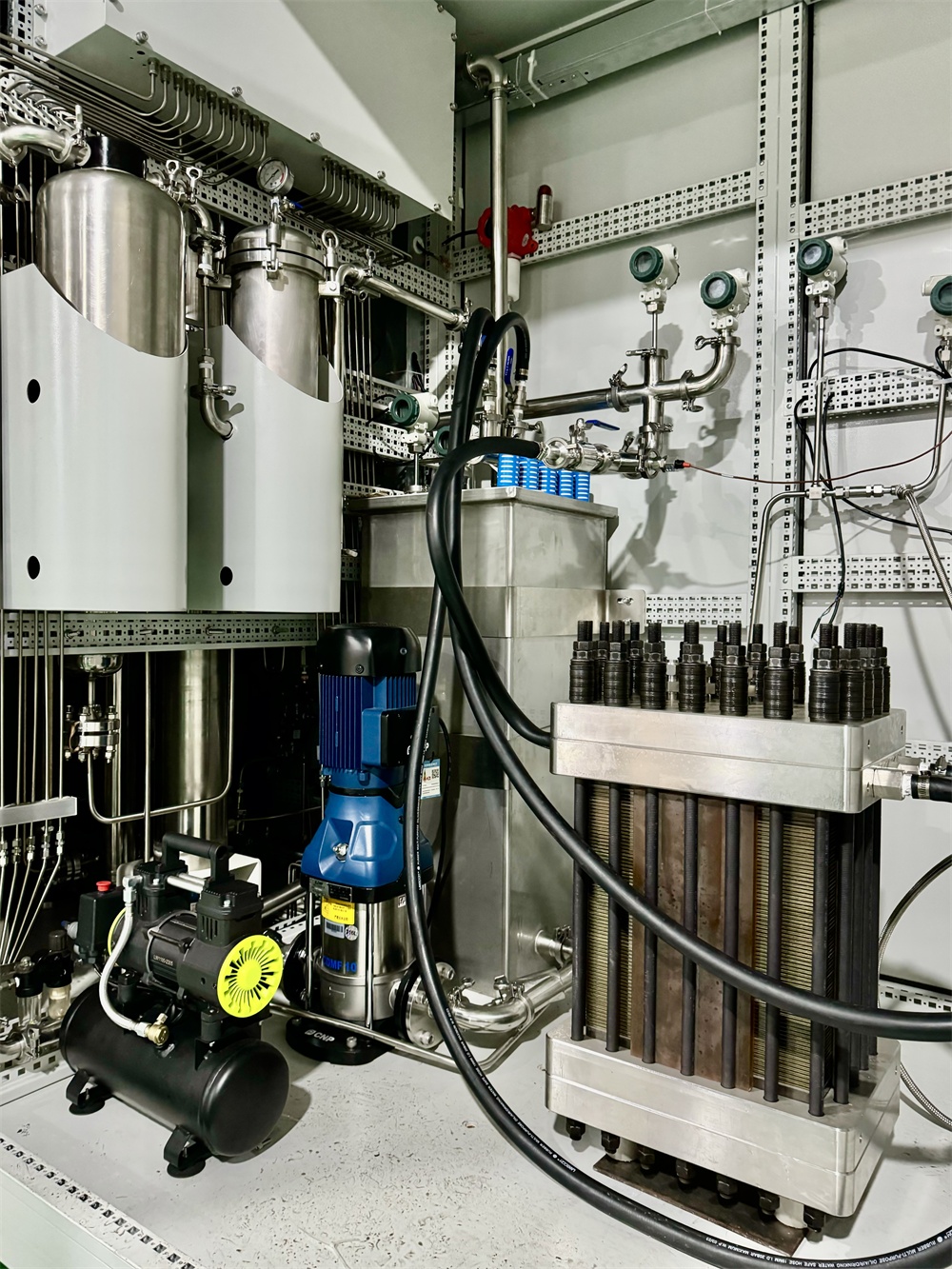

Quality Components, Reliable Output

Our PEM systems are built with premium components, including:

- Durable titanium bipolar plates

- Advanced proton exchange membranes

- High-performance catalysts and electrodes

At Hele Titanium Hydrogen, each unit is designed for long-term durability and consistent efficiency, even in demanding environments.

Environmental Advantages of PEM Technology

Green hydrogen produced via PEM electrolysis is 100% emission-free, making it a cornerstone of global climate strategies.

Key Sustainability Impacts:

- 🌎 Zero CO₂ emissions during production

- 🚚 Fueling clean transportation (buses, trucks, ships)

- 🏭 Decarbonizing industrial sectors (steel, ammonia, refineries)

- 🔋 Storing surplus renewable energy for grid stability

By integrating Hele Titanium Hydrogen’s PEM systems, businesses can reduce carbon footprints, meet ESG goals, and gain compliance with evolving environmental regulations.

System Design Considerations

Designing a PEM green hydrogen generator involves several technical factors:

| Component | Description |

|---|---|

| Power Source | Solar, wind, hydro, or grid-connected |

| Water Quality | Requires purified deionized water |

| Hydrogen Storage | Pressurized tanks or metal hydrides |

| Distribution | Pipelines, cylinders, or direct fuel use |

| Safety Features | Automatic pressure relief, gas detection, cooling system |

Hele Titanium Hydrogen offers custom-engineered PEM electrolyzer systems, tailored to your project size, power source, and storage needs.

Integration with Renewable Energy Sources

PEM electrolyzers are ideal for coupling with intermittent renewable energy sources such as:

- ☀️ Solar PV Systems

- 🌬️ Wind Turbines

- 🌊 Hydropower

They act as a buffer and storage system—converting excess electricity into storable hydrogen.

Applications include:

- Fuel cell EV charging stations

- Hydrogen-powered microgrids

- Hybrid power plants for off-grid areas

Hele Titanium Hydrogen provides seamless integration support for renewable-to-hydrogen projects, enabling decentralized, clean energy ecosystems.

Case Studies

✅ Case 1: 500Nm³/h PEM System in Southeast Asia

Installed at an industrial fuel cell manufacturing site, this system achieved:

- 95% uptime

- 4.9 kWh/Nm³ efficiency

- Zero downtime during seasonal grid fluctuations

✅ Case 2: 200Nm³/h Microgrid Solution in Europe

Coupled with solar panels, our PEM unit ensured uninterrupted power for a rural community, reducing diesel reliance by 70%.

These success stories reflect Hele Titanium Hydrogen’s capability to deliver turnkey hydrogen solutions worldwide.

Policy Implications

Governments worldwide are introducing green hydrogen incentives, including:

- Investment tax credits

- Renewable energy subsidies

- Hydrogen purchase guarantees

- Low-carbon fuel standards

Hele Titanium Hydrogen ensures our products align with international standards (CE, ISO, IEC), helping clients navigate policy requirements and capitalize on subsidies.

Future Trends

The future of PEM electrolysis is bright:

- 📈 Growing demand from mobility, energy, and industrial sectors

- 🔬 R&D in catalyst materials to reduce platinum usage

- 🧪 Development of high-temperature PEM systems

- 🏗️ Gigafactories for electrolyzer mass production

At Hele Titanium Hydrogen, we invest heavily in technology innovation, partnering with universities and labs to develop next-generation PEM systems.

Conclusion

PEM hydrogen generation is clean, efficient, scalable, and ready for global deployment.

Why Choose Hele Titanium Hydrogen?

- 🌱 Industry-leading PEM technology expertise

- ⚙️ Customized system design and integration

- 📦 Reliable export logistics and global support

- 🔒 Strict quality control for long-term performance

🚀 Ready to start your green hydrogen journey?

👉 Contact Hele Titanium Hydrogen for your customized PEM electrolyzer solution.

📘 Visit our Product Page to explore technical specifications and get a free quote today!

Certainly! Here’s a professional FAQ section based on the blog content, optimized for SEO and customer clarity. It can be placed at the end of the blog or on a dedicated FAQ page.

Frequently Asked Questions (FAQ) about PEM Green Hydrogen Generators

1. What is green hydrogen?

Green hydrogen is hydrogen produced by splitting water (H₂O) using electricity from renewable energy sources, such as solar or wind. Unlike grey or blue hydrogen, green hydrogen generation results in zero carbon emissions.

2. How does a PEM hydrogen generator work?

A PEM (Proton Exchange Membrane) electrolyzer uses a solid polymer membrane to separate hydrogen and oxygen in water through electrolysis. When electricity is applied, water molecules split into H₂ and O₂ gases. The hydrogen is collected for use, while oxygen is vented or reused.

3. What are the advantages of PEM technology over alkaline electrolysis?

PEM electrolyzers offer several advantages:

- High energy efficiency

- Fast response and quick start/stop

- High current density in a compact footprint

- High-pressure hydrogen output without compressors

4. What are the main components of a PEM electrolyzer?

Key components include:

- Proton exchange membrane

- Electrodes (anode and cathode)

- Bipolar plates (often made of titanium)

- Catalyst layers

- Power supply and water purification units

5. Is PEM electrolysis suitable for use with solar or wind energy?

Yes. PEM systems respond rapidly to variable power inputs, making them ideal for integration with solar panels, wind turbines, and other renewable energy sources.

6. What industries can benefit from PEM hydrogen generators?

Industries that benefit include:

- Transportation (fuel cell vehicles)

- Industrial processes (steel, ammonia, refining)

- Power generation and microgrids

- Energy storage systems

- Off-grid and remote locations

7. How does Hele Titanium Hydrogen customize its PEM systems?

Hele Titanium Hydrogen offers:

- Tailored system capacities (Nm³/h output)

- Integration with your chosen power source

- Custom hydrogen storage and safety modules

- Engineering support to meet regional standards and site-specific needs

8. Are Hele Titanium Hydrogen’s electrolyzers compliant with international standards?

Yes. Our PEM electrolyzers are manufactured in accordance with major global certifications such as ISO, CE, and IEC, ensuring safety, quality, and export-readiness.

9. Can these systems help companies meet ESG or net-zero goals?

Absolutely. Green hydrogen from PEM systems can dramatically reduce Scope 1 and Scope 2 emissions, helping companies meet ESG commitments, carbon-neutral targets, and sustainability certifications.

10. What support does Hele Titanium Hydrogen provide after purchase?

We provide:

- Technical consultation and design services

- Installation guidance

- Operational training

- Maintenance support

- Remote diagnostics and system updates (on select models)

11. How can I get a quote or more information?

You can contact us directly here or visit our Product Page to explore specifications, request a consultation, or receive a customized quotation for your project.