Discover how PEM hydrogen generator systems revolutionize green hydrogen electrolysis with zero carbon emissions, high efficiency, renewable integration, and future scalability.

1. Introduction

Green hydrogen is fast becoming a transformative solution in the global energy transition. As countries pursue net-zero targets, hydrogen produced via renewable electrolysis is gaining traction in renewables-heavy energy portfolios.

At the heart of this revolution is Proton Exchange Membrane (PEM) technology—a compact, efficient, and responsive electrolysis method. By using water and renewable electricity, PEM electrolyzers produce clean hydrogen without CO₂ emissions.

Key takeaway: This article explores PEM’s environmental benefits, system design, practical applications, and policy framework. Can PEM-powered green hydrogen become the backbone of a zero-emission economy? Let’s dive in.

2. Understanding PEM Electrolysis

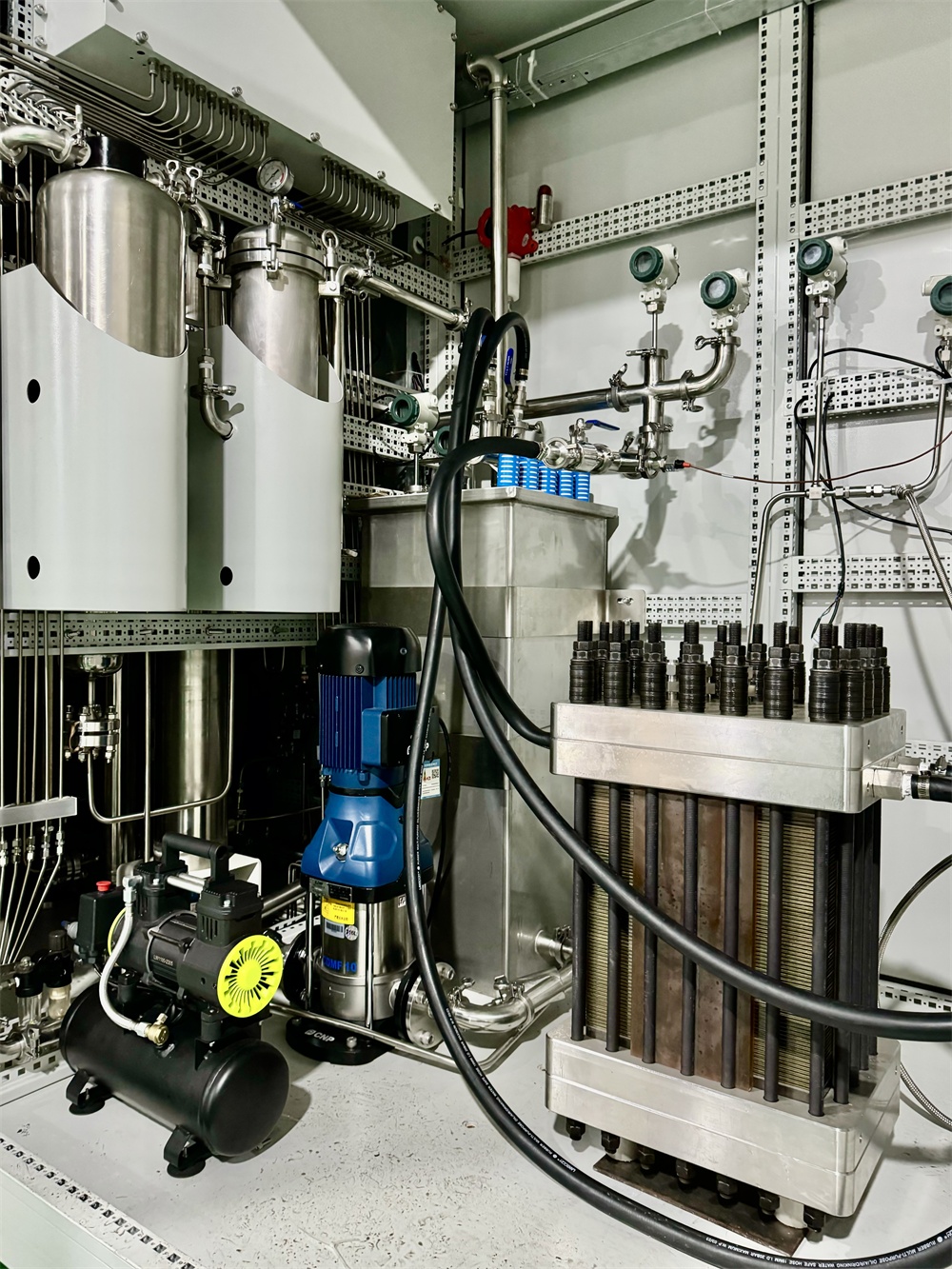

2.1 How PEM Electrolyzers Work

PEM electrolyzers split water into hydrogen and oxygen using a solid polymer membrane. The membrane selectively transports protons while blocking gases, ensuring ultra-pure hydrogen output.

2.2 PEM vs. Alkaline Systems

- Operating dynamics: PEM adjusts output in seconds—ideal for pairing with intermittent renewables.

- Purity levels: PEM produces >99.999% hydrogen, preferred for fuel cells.

- Compact design and quicker response time give it an edge over alkaline alternatives.

2.3 Core Terminology

- MEA (Membrane Electrode Assembly): Key component where water splitting occurs.

- Bipolar plates: Manage current flow and thermal regulation.

- Catalysts: Platinum and iridium speed up reactions.

3. Environmental Benefits of PEM Technology

3.1 Zero CO₂ Emissions

When powered by solar, wind, or hydroelectric energy, PEM electrolysis generates hydrogen with no direct carbon emissions. This aligns perfectly with global net-zero goals.

3.2 High Electrical Efficiency

PEM systems offer 70–80% conversion efficiency, making them one of the most effective hydrogen production methods available—surpassing many alternative technologies.

3.3 Water Efficiency

Advanced PEM electrolyzers greatly reduce water intake. This makes them suitable for deployment in regions where water scarcity is a concern.

3.4 Lifecycle Emission Reductions

According to the International Energy Agency (IEA), hydrogen from renewable electrolysis can cut lifecycle CO₂ emissions by 95% compared to grey hydrogen produced by fossil methods.

4. Key Performance Features of PEM Systems

4.1 Rapid Load-Following

PEM’s ability to ramp within seconds helps balance grid fluctuations, especially when renewables are providing surplus electricity.

4.2 High-Purity Hydrogen

With fuel-cell-grade purity, PEM hydrogen supports applications in transportation (FCVs), electronics, and aerospace.

4.3 Flexibility and Durability

PEM systems can endure daily startups and shutdowns without significant efficiency loss — a crucial characteristic for long-term field deployments.

5. System Design Considerations

5.1 MEA and Catalyst Layers

The MEA includes a Nafion® membrane, catalyst-coated electrodes, and gas diffusion layers. Researchers are working to reduce platinum group metal loading through innovative nano-coating techniques.

5.2 Bipolar Plate Materials

Modern plates are made of titanium or coated stainless steel to ensure conductivity, durability, and corrosion resistance.

5.3 Durability & Lifespan

Membrane degradation and catalyst stability are key challenges. Technologies such as safer water recirculation and improved stack design are extending PEM life to 50,000 hours+.

5.4 Safety & Maintenance

Reliable systems include:

- Pressure relief valves

- Humidity and temperature monitoring

- Purity controls to avoid gas crossover risks

6. Renewable Integration & Energy Storage

6.1 Pairing with Solar and Wind

Due to fast response times, PEM electrolyzers are optimally suited for intermittent sources like solar PV and onshore/offshore wind farms.

6.2 Hybrid Facilities

Projects like the HyDeploy initiative in the UK are blending wind-to-hydrogen systems, helping utilities inject low-carbon hydrogen into existing gas grids.

6.3 Energy Buffering

Hydrogen acts as a form of long-term energy storage, turning excess renewable energy into transportation fuel or industrial feedstock.

7. Real-World Case Studies

7.1 NEOM’s $5B Project (Saudi Arabia)

NEOM plans to produce 650 tons/day of hydrogen using PEM electrolyzers powered by 4 GW of solar and wind—one of the world’s largest green hydrogen initiatives.

7.2 Toyota’s California Stations

Toyota installs PEM-based electrolyzers at its hydrogen fueling stations, supporting Mirai fuel-cell vehicles and demonstrating zero-emission mobility.

7.3 Thyssenkrupp’s Industrial Deployment

Thyssenkrupp is integrating PEM systems into steel plants in Germany, replacing fossil fuels to produce low-carbon steel.

8. Policy & Market Trends

8.1 European Union Initiatives

The EU aims to build 40 GW of electrolyzer capacity by 2030. Supportive policies like the Hydrogen Bank and certification systems are accelerating adoption.

8.2 U.S. Inflation Reduction Act (IRA)

The IRA offers tax credits up to $3/kg for low-carbon hydrogen, promoting PEM systems powered by renewables.

8.3 Global Deployment Models

- China is building hydrogen valleys using combinations of PEM and alkaline systems.

- Europe is constructing hydrogen corridors and cross-border transport capacity.

8.4 Cost Downtrend & Scale

Current costs hover around $1,000/kW. By 2030, economies of scale, R&D, and improved manufacturing aim to reduce this to $500/kW or less.

9. Future Trends & Innovation

9.1 Next-Gen Catalysts

Researchers are exploring non-precious metal catalysts (e.g., nickel, cobalt) to replace or reduce platinum-group usage, dramatically cutting material cost.

9.2 Stack Longevity

New membrane chemistries and thermostable designs are improving stack durability beyond 50,000 operational hours.

9.3 Renewable-to-Synthesized Fuels

Green hydrogen can be combined with captured CO₂ to create synthetic methanol, ammonia, or aviation fuels—advancing circular carbon economies.

9.4 Digital Monitoring & AI

AI-driven monitoring systems enable predictive maintenance, operational flexibility, and performance optimization in real time.

10. Challenges & Next Steps

| Challenge | Key Focus |

|---|---|

| High CAPEX | Reducing PEM system costs through scale and volume |

| Infrastructure Gaps | Expanding hydrogen pipelines & refueling stations |

| Competitive Alternatives | Balancing PEM with solid oxide and alkaline options |

11. Economic Viability & Business Models

11.1 Levelized Cost of Hydrogen (LCOH)

Current green hydrogen prices: $4–6/kg. With utility-scale renewables and improved system efficiency, $1–2/kg is within reach by 2030.

11.2 Revenue Streams

- Hydrogen sales (transport, energy, industrial)

- Grid ancillary services

- Carbon credit markets and renewable energy certificates

11.3 Innovative Models

- On-site hydrogen hubs for industrial energy

- Microgrids blending solar, storage, and PEM

- “Hydrogen as a Service” (HaaS) for industrial consumers

12. FAQs

Q1: What is a PEM electrolyzer?

A device that uses a proton exchange membrane to split water into hydrogen and oxygen, driven by electricity.

Q2: How efficient is PEM electrolysis?

It converts 70–80% of electrical energy into hydrogen, ranking it among the top electrolyzer options.

Q3: What are the environmental benefits?

Zero carbon emissions, minimal water use, and full renewable compatibility make PEM an eco-friendly technology.

Q4: Can PEM scale up industrially?

Yes—current systems are already scaled up to 10s of megawatts, and gigawatt-scale projects are underway.

Q5: How do policies affect adoption?

Incentives like the EU Hydrogen Bank, US tax credits, and carbon pricing fast-track investment and large-scale projects.

13. Conclusion

PEM electrolyzers offer a powerful pathway to clean hydrogen—combining zero emissions, high efficiency, and operational flexibility. Supported by falling costs and robust policy frameworks, PEM technology is now central to global decarbonization efforts.

Call to Action:

- Increase investment in R&D

- Foster cross-sector collaboration

- Enact supportive policy frameworks

Final thought: PEM-powered green hydrogen isn’t an alternative—it’s the future backbone of a carbon-neutral economy.

Green Hydrogen Generation with PEM Technology: Zero-Emission, High-Efficiency Electrolysis for the Future

- Green Hydrogen Generation: Refers to the production of green hydrogen, which is generated through the electrolysis of water powered by renewable energy sources such as solar and wind energy. This process does not emit greenhouse gases and thus represents a clean form of energy.

- PEM Technology: Stands for Proton Exchange Membrane technology, a method employed in hydrogen production via water electrolysis. A proton exchange membrane electrolyzer utilizes a solid polymer electrolyte membrane. Under an applied electric field, water molecules are oxidized at the anode to produce oxygen, while protons are reduced at the cathode to generate hydrogen.

- Zero-Emission: Indicates that no greenhouse gases, particularly carbon dioxide, are emitted during the hydrogen production process, making it environmentally sustainable.

- High-Efficiency Electrolysis: Highlights the high energy conversion efficiency of this technology in the electrolysis process, enabling hydrogen production with relatively low energy input.

- for the Future: Suggests that this green hydrogen production method is forward-looking and aligned with long-term sustainability goals, positioning it as a key player in future energy systems.

Discover how PEM hydrogen generators enable efficient, zero-emission green hydrogen production. Well-suited for applications across the clean energy, industrial, and transportation sectors.

- PEM hydrogen generators: Also known as proton exchange membrane hydrogen generators, these are systems that utilize proton exchange membrane technology for hydrogen generation.

- enable efficient, zero-emission green hydrogen production: Emphasizes the capability of these generators to produce clean hydrogen efficiently, with no harmful emissions during the production process.

- Well-suited for applications across the clean energy, industrial, and transportation sectors: Highlights the broad applicability of this technology. For example, in the clean energy sector, it can serve as a storage solution for intermittent renewable energy; in industry, it supports hydrogen-demanding chemical processes; and in transportation, it provides fuel for hydrogen fuel cell vehicles.

PEM hydrogen generator, green hydrogen electrolysis, PEM electrolyzer, hydrogen fuel cell, renewable hydrogen, zero-emission hydrogen production, sustainable energy

- PEM hydrogen generator: Refers to a proton exchange membrane hydrogen generator, closely related to the “PEM Technology” mentioned in the title, and serves as a core device for green hydrogen production.

- green hydrogen electrolysis: Denotes the process of producing hydrogen through water electrolysis powered by renewable energy, emphasizing its environmental benefits.

- PEM electrolyzer: Short for proton exchange membrane electrolyzer, which is the central component of a PEM hydrogen generator responsible for splitting water into hydrogen and oxygen.

- hydrogen fuel cell: Although not directly discussed in this context, hydrogen fuel cells represent one of the major applications of green hydrogen. They convert hydrogen’s chemical energy into electricity and are widely used in automotive propulsion and decentralized power generation.

- renewable hydrogen: Refers to hydrogen produced using renewable energy sources, distinguishing it from fossil-fuel-derived hydrogen and highlighting its sustainability.

- zero-emission hydrogen production: Reinforces the environmental advantages of this method, as it does not result in any greenhouse gas or pollutant emissions during hydrogen generation.

- sustainable energy: Green hydrogen functions as a sustainable energy carrier, capable of storing and transporting renewable energy, thereby contributing to a more resilient and eco-friendly energy system.