As the global community accelerates efforts toward decarbonization, green hydrogen is emerging as a vital clean fuel for the future. One technology is proving especially effective in making this vision a reality: Proton Exchange Membrane (PEM) electrolysis. Efficient, scalable, and environmentally friendly, PEM hydrogen generators are poised to transform how the world produces and consumes hydrogen.

In this article, we explore the environmental benefits of PEM hydrogen production, key system design considerations, integration with renewables, real-world case studies, and what the future holds. We also highlight how companies like Hele Titanium Hydrogen are innovating to provide customized solutions that support industrial, transportation, and energy applications.

Can PEM technology help your business become a leader in clean energy? Let’s find out.

Understanding PEM Technology: The Backbone of Green Hydrogen

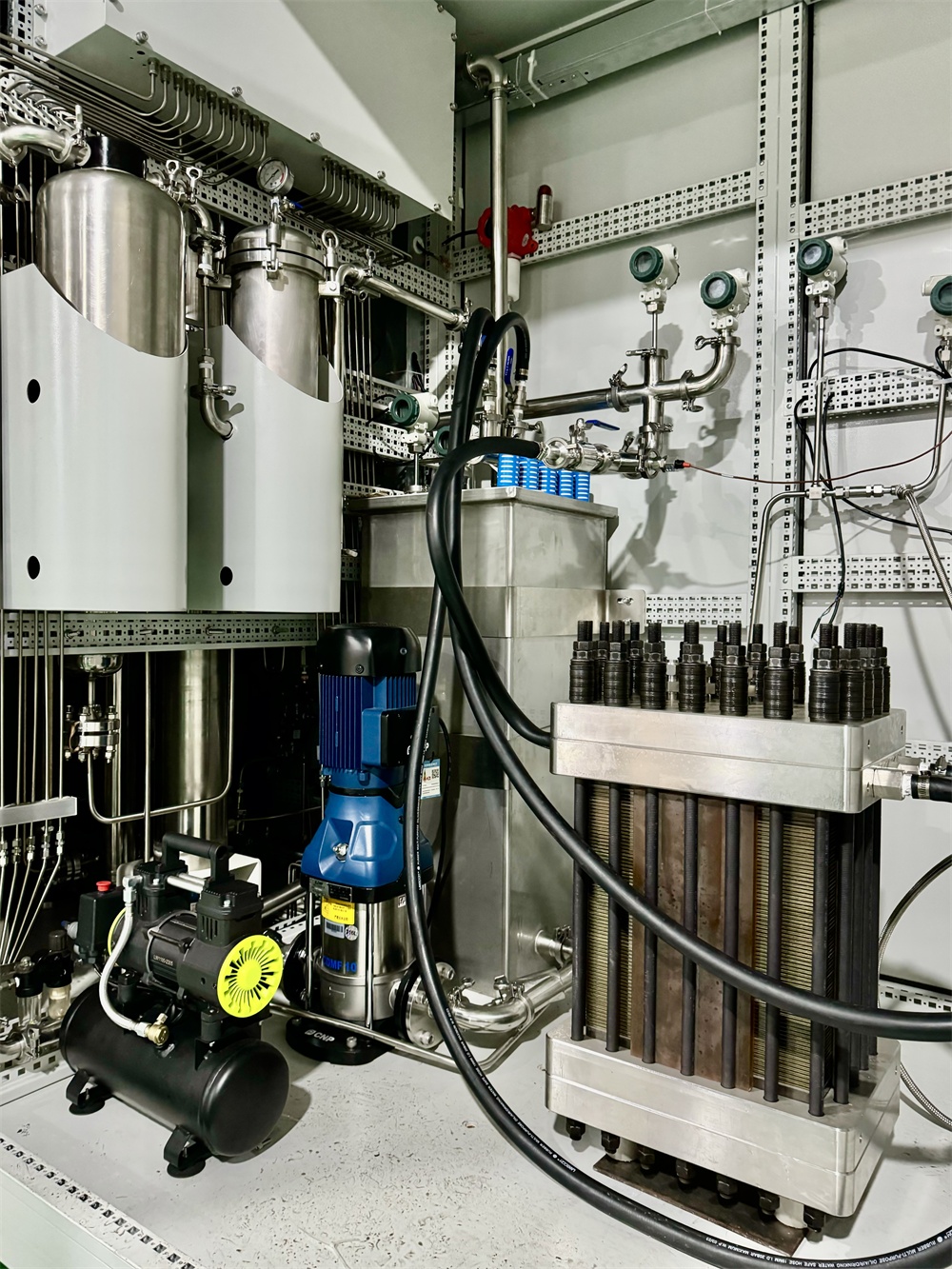

PEM electrolysis is a method of splitting water (H2O) into hydrogen (H2) and oxygen (O2) using electricity. Unlike traditional alkaline electrolysis, PEM systems use a solid polymer membrane to conduct protons from the anode to the cathode. This results in high-purity hydrogen, rapid response times, and compact system architecture.

Key Advantages of PEM Electrolyzers:

- High Efficiency (up to 80%)

- Fast Startup and Shutdown

- High Current Density

- Pressurized Hydrogen Output (eliminates compressors)

- Compact, modular design

Hele Titanium Hydrogen’s PEM systems use advanced membranes, bipolar plates, and electrodes to optimize long-term performance and durability.

Environmental Advantages of PEM Green Hydrogen

Green hydrogen, when produced via PEM electrolysis using renewable electricity, generates zero carbon emissions. This makes it an essential component in global efforts to decarbonize hard-to-abate sectors.

Environmental Benefits:

- No CO2 emissions during hydrogen production

- Low water consumption with efficient recycling

- Supports decarbonization of transportation, industry, and power

- Low life cycle environmental impact

Backed by IEA and DOE reports, PEM systems show one of the best emissions profiles in the industry.

Hele Titanium Hydrogen supports ESG strategies through efficient, scalable PEM solutions.

PEM System Design Considerations

Designing a PEM hydrogen generator system involves several engineering and performance factors:

- Power Integration: AC/DC inverters, renewable compatibility

- Water Purification: Pre-treatment and quality monitoring

- Storage & Distribution: Pressurized tanks or pipelines

- Safety: Real-time monitoring and fail-safe systems

Innovations such as non-noble catalysts and new membrane materials are driving system cost-efficiency. Hele Titanium Hydrogen provides complete design support for scalable and custom-configured PEM installations.

Integration with Renewable Energy Sources

PEM electrolyzers excel when paired with intermittent renewable sources like solar and wind power due to their flexible operating range and fast ramp-up capability.

Popular Applications:

- Solar-to-Hydrogen Systems

- Wind-Hydrogen Hybrids

- Off-grid and Island Microgrids

- Fuel cell integration for mobility and backup power

Hele Titanium Hydrogen customizes PEM systems for hybrid power systems, supporting decarbonization in distributed energy networks.

Case Studies: PEM in Real-World Applications

Global Examples:

- NEOM (Saudi Arabia): $5B PEM-powered green hydrogen plant for global energy export

- Toyota (USA): Hydrogen refueling stations using PEM for FCEV infrastructure

- Thyssenkrupp (Germany): PEM electrolyzers in steel decarbonization

Hele Titanium Hydrogen Projects:

- Microgrid-powered PEM systems in Asia

- Custom off-grid hydrogen production units

- Fuel cell-ready PEM generators for fleet logistics

These examples demonstrate the scalability and versatility of PEM systems in real-world deployment.

Policy and Market Drivers

The global green hydrogen market is rapidly expanding, supported by national strategies and funding initiatives:

- EU Hydrogen Strategy: Targeting 40 GW of electrolysis capacity

- U.S. IRA: $3/kg tax credits for green hydrogen

- China Hydrogen Valleys: Regional government subsidies and innovation hubs

Hele Titanium Hydrogen helps clients align systems with policy requirements, certification processes, and investment incentive programs.

Future Trends and Innovation

Emerging Trends in PEM Hydrogen:

- Low-cost, earth-abundant catalysts

- Modular PEM stacks for distributed hydrogen production

- AI-enhanced system monitoring and diagnostics

- Green hydrogen export using ammonia or LOHC

Hele Titanium Hydrogen is committed to continuous R&D and product innovation to stay ahead of market demands and support large-scale adoption.

Conclusion: Driving the Future of Clean Hydrogen

PEM hydrogen technology offers one of the most effective and scalable pathways to produce green hydrogen. With zero emissions, high efficiency, and renewable compatibility, it is reshaping the energy future.

Hele Titanium Hydrogen is your trusted partner in deploying customized PEM electrolyzers that meet commercial, industrial, and environmental needs.

Ready to transform your energy strategy with green hydrogen?