1. Introduction to High-Capacity Hydrogen Generation

Hydrogen is rapidly becoming the backbone of clean industrial processes. With global emphasis on decarbonization and energy resilience, the demand for high-capacity, efficient hydrogen generators is surging.

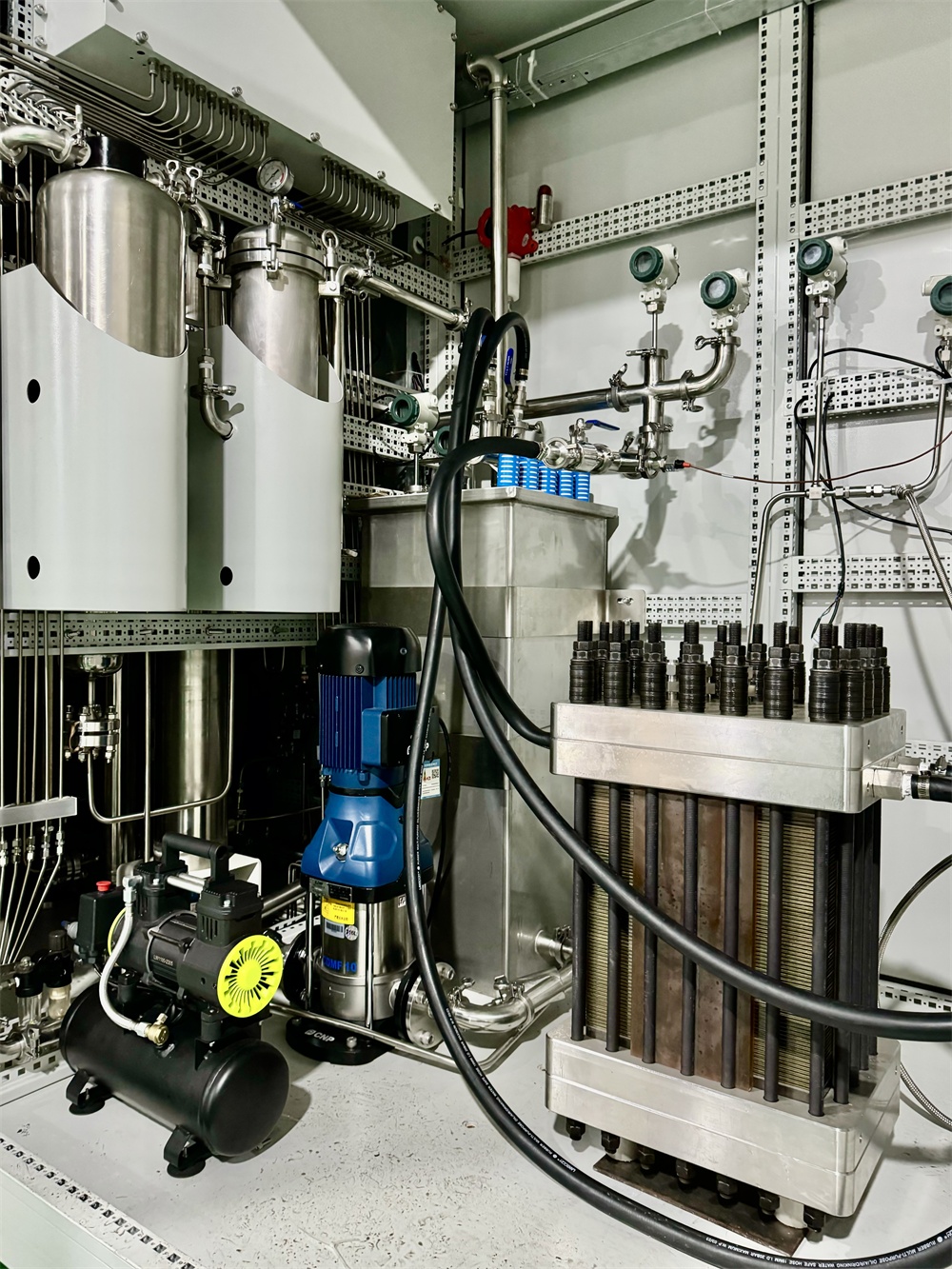

Enter the 5000ml PEM electrolyzer from Hele Titanium Hydrogen—a cutting-edge solution built for continuous, scalable hydrogen production across industrial and commercial environments.

2. Key Applications of 5000ml PEM Electrolyzers

- Industrial hydrogenation in petrochemical and food processing

- Scientific laboratories and R&D facilities

- Energy storage systems integrating renewables

- Hydrogen fueling for commercial vehicle fleets

- Semiconductor manufacturing requiring ultra-pure gases

3. Advantages of PEM Technology in Large-Scale Generators

- High Purity Output: >99.999% hydrogen

- Compact Design: Saves valuable floor space

- Fast Response: Adapts quickly to power fluctuations

- Low Maintenance: Fewer moving parts and robust membranes

- Green Integration: Seamlessly connects with solar and wind sources

4. System Components & Technical Specifications

Core Components

- PEM Electrolysis Stack (Titanium construction)

- High-Efficiency Power Supply Unit

- Intelligent Gas/Liquid Separation System

- Dual-Stage Purification Module

- Smart Control System with Remote Monitoring

Technical Specifications

| Feature | Specification |

|---|---|

| Hydrogen Production | 5000 ml/min (5 L/min) |

| Power Consumption | ≤ 4.8 kWh/Nm³ |

| Operating Pressure | 30–35 bar |

| Hydrogen Purity | >99.99% |

| Cooling System | Integrated air/water cooling |

| Footprint | Compact modular design |

| Certifications | CE, ISO, optional ATEX compliance |

5. Efficiency & Performance Optimization

- Energy Usage Optimization: Lower kWh/Nm³ = higher efficiency

- Thermal Management: Temperature control stabilizes gas output

- Flow Rate Regulation: Adapts to varying hydrogen demand

- Renewable Sync: Supports dynamic loads from solar/wind

6. Maintenance & Operational Best Practices

Daily Checks

- Confirm water levels and flow

- Check operating temperature and pressure

Routine Maintenance

- Inspect membranes monthly

- Clean/replace catalyst material every 6–12 months

- Monitor gas purity sensors

Water Requirements

Use deionized or ultrapure water to prevent contamination.

Preventive Checklist

- Software update schedule

- Valve and pump functionality tests

- Leak detection inspections

7. Cost Analysis & ROI Considerations

Upfront Costs

Investment typically includes:

- Electrolyzer unit

- Installation and integration

- Safety and monitoring systems

Operational Expenditure

- Electricity consumption

- Water supply

- Minimal consumables (membranes, catalyst)

ROI Estimation

Payback period ranges from 2 to 5 years, depending on usage volume, electricity pricing, and hydrogen resale/displacement.

8. Selecting the Right 5000ml PEM Electrolyzer

Why Choose Hele Titanium Hydrogen?

- Proven track record in industrial electrolysis systems

- Robust titanium construction for longevity

- Full technical support and post-sale service

- Configurable automation options and IoT monitoring

Purchase Considerations

- Validate hydrogen demand: Ensure 5 L/min meets your operational need

- Check certification: CE, ISO, and ATEX as applicable

- Assess integration needs: Power source, gas handling, etc.

- Request detailed quote and delivery timeline

9. Future Trends in Industrial Electrolysis

- Next-Gen PEM Materials: Enhanced durability and performance

- AI & IoT Monitoring: Predictive maintenance and load balancing

- Green Hydrogen Certification: For eco-conscious buyers

- Government Subsidies: Tax credits, green energy incentives

10. Conclusion & Next Steps

The Hele Titanium Hydrogen 5000ml PEM electrolyzer stands out as a reliable, high-performance hydrogen generation solution. Designed for industrial-grade use, it delivers on purity, efficiency, and low operational complexity.

✅ Get a Quote Now

Take the next step toward clean hydrogen integration:

- Contact Hele Titanium Hydrogen for a Quote

- Email: sales@heletitaniumhydrogen.com

- Call: 086-13857402537

Frequently Asked Questions (FAQs)

Q1: What industries benefit most from a 5000ml PEM electrolyzer?

Industries such as petrochemical processing, renewable energy storage, laboratories, and semiconductor manufacturing benefit from this unit’s high purity and stable output.

Q2: Is the Hele Titanium Hydrogen model easy to install?

Yes. The system features a plug-and-play modular design and comes with full installation support.

Q3: Can it run on solar or wind power?

Absolutely. The unit is optimized to handle intermittent energy inputs and can be fully integrated into renewable power infrastructures.

Q4: How often does the system require maintenance?

With proper operation, only minor monthly inspections are needed. Annual checks of membranes and catalysts are typically sufficient.

Q5: Does the system include remote monitoring features?

Yes, smart IoT modules allow remote performance tracking, alerts, and firmware updates.