Introduction to Laboratory Hydrogen Generation

When you’re running sophisticated laboratory experiments, the quality of your hydrogen supply can make or break your research. That’s where laboratory steam reforming hydrogen generators come into play, revolutionizing how research facilities produce this essential gas. These compact powerhouses have transformed laboratory operations by providing on-demand, high-purity hydrogen right at your fingertips.

Why Pure Hydrogen Matters in Research

Think of hydrogen as the lifeblood of modern analytical chemistry. Whether you’re running gas chromatography analyses, conducting fuel cell research, or exploring cutting-edge materials science, the purity of your hydrogen directly impacts your results. Traditional cylinder-based hydrogen supply systems often fall short of delivering the consistent, ultra-pure hydrogen that today’s sensitive instruments demand.

Laboratory steam reforming hydrogen generators address this challenge head-on. Unlike bottled hydrogen that can contain trace impurities from storage and handling, steam-reformed hydrogen achieves purity levels exceeding 99.999%. This isn’t just a number on a spec sheet – it’s the difference between reliable, reproducible results and data that keeps you second-guessing your methodology.

The Evolution of Lab Hydrogen Production

The journey from bulky hydrogen cylinders to sleek, automated generators represents more than just technological advancement – it’s a paradigm shift toward laboratory independence. Remember the days of coordinating cylinder deliveries, managing inventory, and dealing with the safety concerns of storing pressurized hydrogen? Those challenges become obsolete when you install a lab-scale hydrogen generator.

Steam reforming technology, traditionally used in large industrial plants, has been brilliantly miniaturized for laboratory applications. This downsizing doesn’t compromise performance; instead, it concentrates all the benefits of on-site hydrogen production into a laboratory-friendly package.

Understanding Steam Reforming Technology

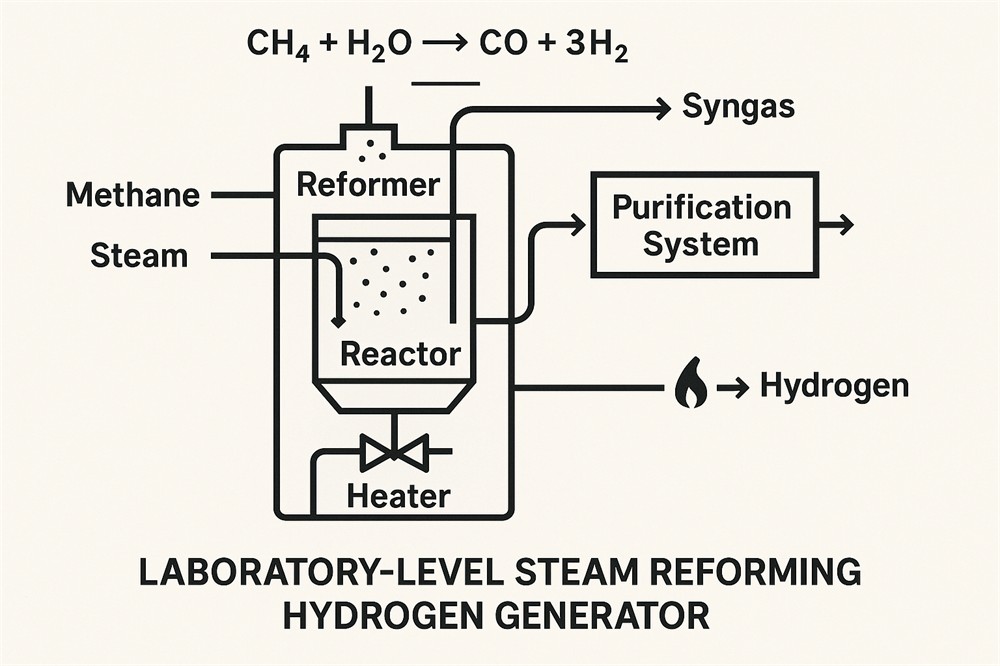

The Chemistry Behind Steam Methane Reforming

At its core, steam methane reforming is elegantly simple yet scientifically sophisticated. The process centers around a fundamental chemical reaction: CH₄ + H₂O → CO + 3H₂. This endothermic reaction requires precise temperature control, typically operating between 700-1000°C, to achieve optimal hydrogen yield.

But here’s where it gets interesting – this isn’t just a one-step process. The initial reforming reaction is followed by the water-gas shift reaction (CO + H₂O → CO₂ + H₂), which maximizes hydrogen production while minimizing carbon monoxide content. Think of it as a two-stage purification process that nature designed for us.

How Laboratory Steam Reformers Work

Laboratory steam reforming hydrogen generators are marvels of engineering miniaturization. They compress industrial-scale technology into compact units that fit comfortably in your lab space. The process begins when natural gas or methane enters the reformer chamber, where it meets superheated steam in the presence of specialized catalysts.

The magic happens in the catalyst bed – a carefully engineered environment where nickel-based catalysts facilitate the reforming reaction. These catalysts are specifically formulated for small-scale applications, offering exceptional activity and longevity even in the demanding stop-start cycles typical of laboratory use.

Temperature and Pressure Requirements

Operating conditions are critical for optimal performance. Laboratory steam reformers typically operate at 3-25 bar pressure, striking a balance between efficiency and safety. The temperature profile is equally important – too low, and the reaction becomes sluggish; too high, and you risk catalyst degradation and equipment stress.

Modern lab-scale units incorporate sophisticated temperature control systems that maintain precise thermal profiles throughout the reformer. This isn’t just about hitting target temperatures – it’s about creating the ideal reaction environment that maximizes hydrogen yield while ensuring long-term reliability.

Catalyst Systems for Small-Scale Applications

The catalyst is the heart of any steam reforming system. Laboratory hydrogen generators use specialized catalyst formulations optimized for the unique demands of research environments. These catalysts must perform reliably across varying load conditions, from continuous operation during extended experiments to intermittent use for routine analyses.

Unlike their industrial counterparts, lab-scale catalysts are designed for easy replacement and minimal downtime. Many systems feature modular catalyst cartridges that can be swapped quickly, ensuring your research schedule isn’t disrupted by maintenance requirements.

Key Features of Research-Grade Hydrogen Generators

Precision Flow Control Systems

When precision matters – and in laboratory work, it always does – flow control becomes paramount. Research-grade hydrogen generators feature sophisticated flow control systems capable of delivering hydrogen at precisely controlled rates, typically ranging from 0.1 to 10 standard liters per minute (SLPM).

These systems employ advanced mass flow controllers that respond instantly to demand changes. Whether you’re running a single GC analysis or supplying multiple instruments simultaneously, the flow control system maintains consistent delivery pressure and flow rate. It’s like having a dedicated hydrogen technician who never takes a break.

Integrated Purification Technologies

Raw reformed hydrogen contains trace amounts of carbon monoxide, carbon dioxide, and unreacted methane. While these concentrations are typically low, they’re unacceptable for sensitive analytical applications. That’s where integrated purification systems earn their keep.

Most laboratory steam reforming hydrogen generators incorporate pressure swing adsorption (PSA) or selective membrane technologies to achieve ultra-high purity levels. PSA systems use molecular sieves to selectively remove impurities, while membrane separators employ selective permeation to isolate hydrogen molecules.

Real-Time Monitoring Capabilities

Modern laboratory hydrogen generators are smart machines that continuously monitor their own performance. Real-time monitoring systems track critical parameters including flow rate, pressure, temperature, and hydrogen purity. This isn’t just data collection – it’s predictive maintenance that prevents problems before they impact your research.

Advanced units feature digital displays and remote monitoring capabilities that allow you to check system status from anywhere in your facility. Some systems even send alerts to your smartphone when attention is required, ensuring you’re always connected to your hydrogen supply.

Safety Interlocks and Detection Systems

Safety isn’t an afterthought in laboratory hydrogen generation – it’s built into every component. Multiple safety interlocks monitor system conditions continuously, automatically shutting down operation if any parameter exceeds safe limits. Gas detection systems provide early warning of any potential leaks, while pressure relief systems prevent over-pressurization.

Think of these safety systems as multiple layers of protection, each providing backup for the others. It’s like having a team of safety engineers watching over your system 24/7.

Laboratory Applications for Steam Reforming Hydrogen Generators

Gas Chromatography Carrier Gas Supply

Gas chromatography represents one of the most demanding applications for laboratory hydrogen. GC systems require ultra-pure hydrogen with minimal trace impurities that could interfere with sensitive detectors. Steam reforming hydrogen generators excel in this application, providing consistent, high-purity carrier gas that enhances chromatographic resolution and detector sensitivity.

The consistent flow and purity characteristics of steam-reformed hydrogen eliminate many of the variables that can affect GC performance. You’ll notice improved baseline stability, enhanced peak resolution, and reduced detector noise – all contributing to more reliable analytical results.

Fuel Cell Research Applications

Fuel cell research demands hydrogen of exceptional purity, as even trace contaminants can poison catalyst surfaces and degrade performance. Laboratory steam reforming hydrogen generators provide the consistent, high-purity hydrogen supply essential for meaningful fuel cell testing and development.

Whether you’re testing proton exchange membrane fuel cells, solid oxide fuel cells, or next-generation hydrogen technologies, on-site hydrogen generation eliminates the variability introduced by cylinder storage and handling. Your research benefits from consistent feedstock quality that enables reproducible results.

Catalysis and Material Science Studies

Catalysis research often involves studying reactions under precisely controlled conditions where hydrogen purity is critical. Even minor impurities can alter reaction pathways, affect catalyst performance, or introduce unwanted side reactions. Steam reforming hydrogen generators provide the controlled environment essential for meaningful catalysis research.

Material science applications, particularly those involving hydrogen storage materials or hydrogen-resistant alloys, require consistent hydrogen quality for valid testing. The ability to control hydrogen purity and flow characteristics makes steam reforming generators ideal for these demanding applications.

Educational and Training Purposes

Educational institutions benefit enormously from laboratory hydrogen generators. They provide students with hands-on experience using the same technology they’ll encounter in industrial settings, while offering the safety and convenience advantages crucial for educational environments.

The compact size and automated operation of modern generators make them perfect for teaching applications where safety, reliability, and ease of use are paramount. Students learn real-world hydrogen handling techniques without the complexity and safety concerns of cylinder-based systems.

Technical Specifications and Performance

Capacity Ranges for Laboratory Units

Laboratory steam reforming hydrogen generators typically produce between 0.5 and 20 normal cubic meters per hour (Nm³/h), with most units optimized for the 2-10 Nm³/h range that covers typical laboratory demands. This capacity range perfectly matches the requirements of most analytical instruments and small-scale research applications.

The beauty of these systems lies in their scalability. Unlike cylinder-based systems where you’re locked into fixed capacities, hydrogen generators can modulate their output to match demand. During periods of low usage, the system automatically reduces production, saving energy and extending catalyst life.

Hydrogen Purity Levels and Standards

Purity specifications for laboratory hydrogen generators typically exceed 99.999%, with many units achieving 99.9999% purity or better. This ultra-high purity is maintained consistently, unlike cylinder hydrogen which can degrade due to storage conditions and contamination from handling.

The key impurities monitored include carbon monoxide (typically <1 ppm), carbon dioxide (<10 ppm), methane (<10 ppm), and moisture (<3 ppm). These specifications meet or exceed the requirements of most analytical instruments and research applications.

Footprint and Installation Considerations

Modern laboratory hydrogen generators are designed with space constraints in mind. Typical units occupy less than one square meter of floor space, with many designed for benchtop installation. The compact design doesn’t compromise functionality – these units pack industrial-grade technology into laboratory-friendly packages.

Installation requirements are minimal compared to traditional hydrogen storage systems. Most units require only electrical power, natural gas connection, and water supply. The absence of high-pressure storage eliminates many of the safety and regulatory concerns associated with cylinder-based systems.

Utility Requirements and Connections

Utility requirements are straightforward but critical for optimal performance. Electrical requirements typically range from 3-15 kW depending on unit capacity, with most units operating on standard laboratory power supplies. Natural gas consumption varies with hydrogen production rate but is generally very efficient.

Water requirements are minimal – most units consume less than 10 liters per day of deionized water. The water quality requirements are easily met with standard laboratory water purification systems, making integration into existing laboratory infrastructure seamless.

Operational Excellence and Best Practices

Startup and Shutdown Protocols

Proper startup and shutdown procedures are essential for maximizing system life and ensuring consistent performance. Modern hydrogen generators feature automated startup sequences that bring the system to operating conditions safely and efficiently. The typical startup time ranges from 30-60 minutes, depending on unit size and ambient conditions.

During startup, the system gradually heats the reformer to operating temperature while purging air from the system with inert gas. This prevents the formation of explosive mixtures while ensuring clean startup conditions. The automated nature of this process eliminates operator error and ensures consistent startup performance.

Maintenance and Catalyst Management

Regular maintenance is the key to long-term reliability and performance. Most laboratory hydrogen generators require minimal routine maintenance – typically limited to periodic inspection of connections, replacement of filters, and monitoring of catalyst performance indicators.

Catalyst replacement represents the major maintenance activity, typically required every 1-3 years depending on operating conditions and usage patterns. Modern systems feature modular catalyst designs that minimize replacement time and system downtime. Many units provide advance warning of catalyst degradation, allowing scheduled replacement during convenient maintenance windows.

Troubleshooting Common Issues

Common operational issues are typically minor and easily resolved. Flow rate variations often indicate filter blockage or pressure regulator issues – both easily addressed with routine maintenance. Purity degradation usually signals catalyst aging or contamination, addressed through catalyst regeneration or replacement.

Modern diagnostic systems provide detailed error codes and troubleshooting guidance, making problem resolution straightforward even for non-technical operators. Remote diagnostic capabilities allow manufacturers to provide real-time support, often resolving issues without on-site service calls.

Safety Considerations in Laboratory Environments

Ventilation and Gas Detection Requirements

Proper ventilation is critical when operating hydrogen generators in laboratory environments. Hydrogen’s tendency to accumulate at ceiling level requires adequate ventilation to prevent concentration buildup. Most installations require ventilation rates of at least 1 cubic foot per minute per square foot of floor area.

Gas detection systems provide essential early warning of potential leaks. Hydrogen detectors should be positioned at ceiling level and calibrated regularly to ensure reliable operation. Many modern hydrogen generators include integrated leak detection systems that automatically shut down operation if hydrogen is detected.

Emergency Procedures and Safety Protocols

Emergency procedures must be clearly defined and regularly practiced. In the event of a hydrogen leak, the primary response is to evacuate the area, eliminate ignition sources, and shut off the gas supply. Automated emergency shutdown systems provide rapid response to detected hazards.

Fire suppression systems should be designed specifically for hydrogen fires, which burn with an almost invisible flame. Water spray systems are often preferred over traditional suppression agents, as they provide both fire suppression and cooling of adjacent equipment.

Regulatory Compliance Standards

Compliance with NFPA 55 (Compressed Gases and Cryogenic Fluids Code) and other applicable standards is mandatory for safe operation. These standards address installation requirements, safety systems, and operational procedures necessary for safe hydrogen handling.

Local building codes may impose additional requirements depending on installation location and capacity. Working with qualified professionals during system design and installation ensures compliance with all applicable regulations and standards.

Cost Analysis and Economic Benefits

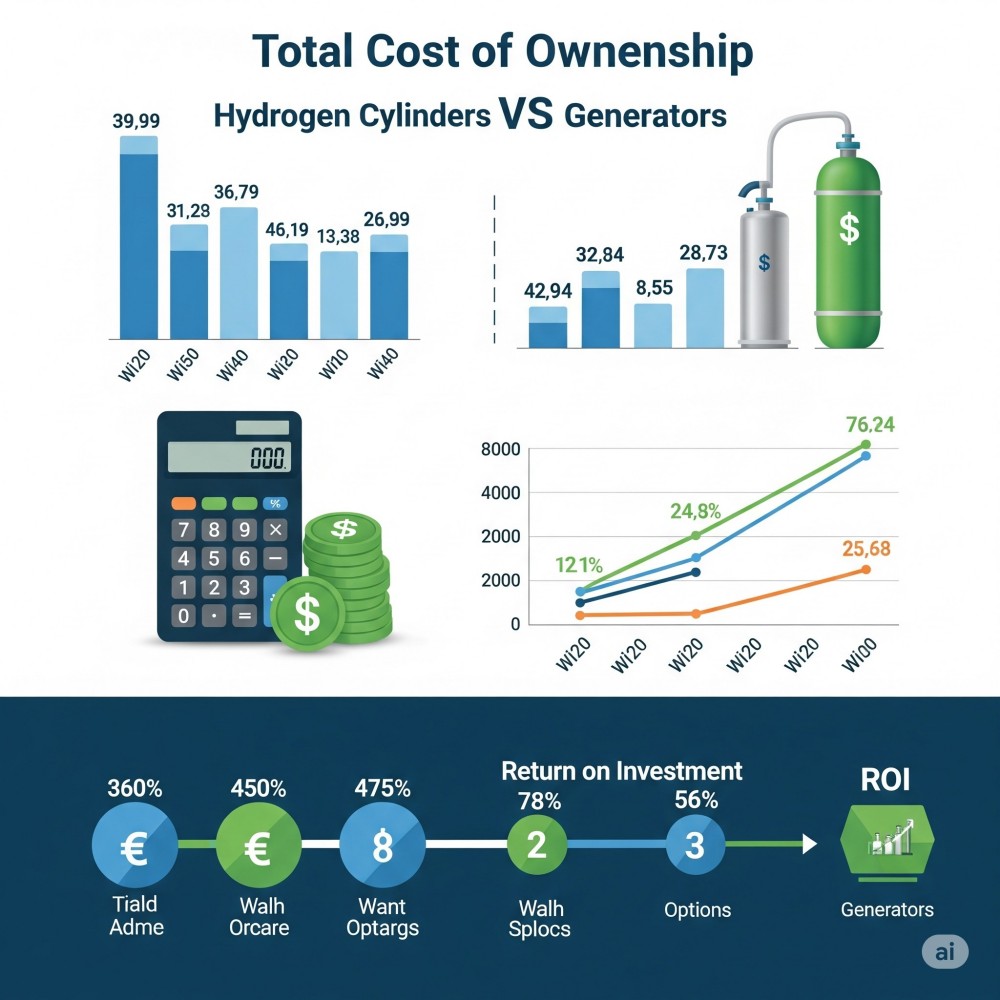

Capital Investment vs. Operating Costs

The initial investment in a laboratory hydrogen generator typically pays for itself within 1-3 years through reduced operating costs. While the capital cost is higher than installing cylinder-based systems, the ongoing savings in gas costs, delivery charges, and cylinder rental fees quickly offset the initial investment.

Operating costs are predictable and generally lower than cylinder-based systems, particularly for facilities with consistent hydrogen demand. Energy costs represent the primary ongoing expense, with natural gas and electricity consumption scaling directly with hydrogen production.

Comparison with Cylinder Hydrogen Supply

Cylinder-based hydrogen supply involves multiple cost elements often overlooked in simple price comparisons. Beyond the cost of the gas itself, facilities must account for cylinder rental fees, delivery charges, hazmat fees, and the labor costs associated with cylinder handling and inventory management.

Hydrogen generators eliminate most of these hidden costs while providing superior convenience and reliability. The ability to produce hydrogen on-demand eliminates inventory concerns and ensures continuous availability for critical research activities.

Total Cost of Ownership Calculations

Total cost of ownership analysis reveals the true economic benefits of hydrogen generators. Over a typical 10-year system life, generators often provide 30-50% cost savings compared to cylinder-based systems, with higher savings percentages for facilities with greater hydrogen consumption.

The calculation must include factors beyond simple gas costs: reduced labor requirements, eliminated delivery scheduling, improved safety, and enhanced research productivity all contribute to the overall economic benefit.

Leading Manufacturers and Product Comparison

Top Laboratory Hydrogen Generator Brands

The laboratory hydrogen generator market features several established manufacturers offering proven technologies. Parker Hannifin leads the market with their comprehensive line of Balston and Parker branded generators, offering solutions from small benchtop units to larger laboratory installations.

Linde provides industrial-grade technology adapted for laboratory use, focusing on high-capacity applications and demanding research environments. Their systems emphasize reliability and long-term performance in continuous-duty applications.

Comparative Analysis of Key Models

When comparing different manufacturers and models, key differentiators include hydrogen purity specifications, production capacity, footprint requirements, and integrated safety features. Some manufacturers focus on maximum purity for analytical applications, while others emphasize high capacity for multiple instrument installations.

Service and support capabilities represent critical selection factors often overlooked during initial evaluation. Manufacturers with strong local service networks provide significant advantages in terms of system uptime and long-term support.

Emerging Technologies and Innovations

The hydrogen generator market continues evolving with new technologies focused on improved efficiency, reduced footprint, and enhanced automation. Micro-reformer technologies promise even smaller installations suitable for single-instrument applications.

Integration with renewable energy sources represents an emerging trend, with some manufacturers developing systems capable of operating on biogas or hydrogen-enriched natural gas. These developments align with growing emphasis on sustainable laboratory operations.

Future Trends in Laboratory Hydrogen Generation

Integration with Renewable Energy

The future of laboratory hydrogen generation increasingly involves renewable energy integration. Systems capable of utilizing biogas, renewable natural gas, or even renewable electricity for electrolytic hydrogen production are becoming commercially viable.

This integration aligns with institutional sustainability goals while potentially reducing operating costs. Universities and research institutions are leading adoption of these technologies as part of broader carbon neutrality initiatives.

Smart Monitoring and IoT Capabilities

Internet of Things (IoT) integration is transforming hydrogen generator monitoring and control. Modern systems feature web-based interfaces allowing remote monitoring from anywhere with internet access. Predictive maintenance algorithms analyze operating data to predict maintenance requirements before problems occur.

Smart systems can integrate with building management systems, automatically adjusting hydrogen production based on laboratory schedules and usage patterns. This intelligence reduces energy consumption while ensuring hydrogen availability when needed.

Micro-Reformer Developments

Micro-reformer technology represents the cutting edge of laboratory hydrogen generation. These ultra-compact systems target single-instrument applications, providing dedicated hydrogen supply for individual GCs or other analytical instruments.

Micro-reformers promise the ultimate in convenience and efficiency, potentially making on-site hydrogen generation economically viable even for low-consumption applications previously served only by cylinders.

Conclusion

Laboratory steam reforming hydrogen generators represent a transformative technology that’s reshaping how research facilities approach hydrogen supply. By combining the reliability and efficiency of industrial steam reforming with the convenience and safety requirements of laboratory environments, these systems offer compelling advantages over traditional cylinder-based supply methods.

The technology has matured to the point where hydrogen generators are no longer experimental – they’re proven, reliable tools that enhance laboratory capabilities while reducing costs and improving safety. As research demands continue growing and sustainability becomes increasingly important, on-site hydrogen generation will become the standard rather than the exception.

Whether you’re running a single gas chromatograph or supplying hydrogen to multiple research applications, steam reforming generators offer the flexibility, reliability, and economic benefits that make them the smart choice for modern laboratories. The question isn’t whether to adopt this technology – it’s which system best meets your specific requirements.

Frequently Asked Questions (FAQs)

Q1: How long does it take for a laboratory hydrogen generator to pay for itself?

A: Most laboratory hydrogen generators achieve payback within 1-3 years, depending on hydrogen consumption levels and local gas costs. Facilities with higher hydrogen usage typically see faster payback periods, often recovering their investment within 18 months through eliminated cylinder costs and delivery fees.

Q2: What purity levels can laboratory steam reforming hydrogen generators achieve?

A: Modern laboratory hydrogen generators routinely achieve purity levels exceeding 99.999%, with many units capable of 99.9999% or better. This ultra-high purity meets or exceeds the requirements of virtually all analytical instruments and research applications, often surpassing the quality of cylinder-supplied hydrogen.

Q3: How much space does a laboratory hydrogen generator require?

A: Space requirements vary by capacity, but most laboratory units occupy less than one square meter of floor space. Many models are designed for benchtop installation, making them suitable even for space-constrained laboratories. The compact design doesn’t compromise performance or safety features.

Q4: What safety considerations are important when installing a hydrogen generator in a laboratory?

A: Key safety considerations include adequate ventilation (particularly at ceiling level where hydrogen accumulates), gas detection systems, proper electrical installations, and compliance with NFPA 55 and local codes. Most modern generators include integrated safety systems and automatic shutdown capabilities for maximum protection.

Q5: How often do hydrogen generators require maintenance, and what does it involve?

A: Routine maintenance is minimal, typically involving periodic filter changes and system inspections. Major maintenance centers around catalyst replacement, usually required every 1-3 years depending on usage. Most systems provide advance warning of maintenance requirements, allowing scheduled service during convenient periods to minimize research disruption.

Please don’t forget to leave a review.