The Complete Guide to Industrial Hydrogen Gas Generators for Welding

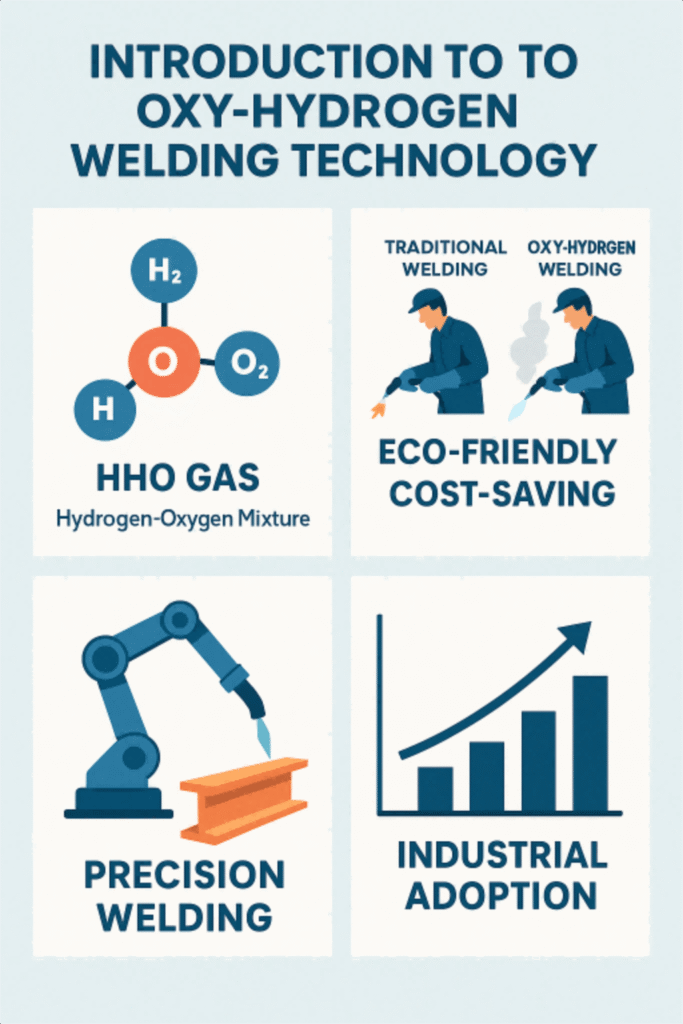

1. Introduction to Oxy-Hydrogen Welding Technology

Industrial oxy-hydrogen generators are transforming how manufacturers approach metalworking. Using a clean-burning mix of hydrogen and oxygen—commonly known as HHO gas—these systems are delivering high-precision welding and cutting while slashing operational costs and emissions.

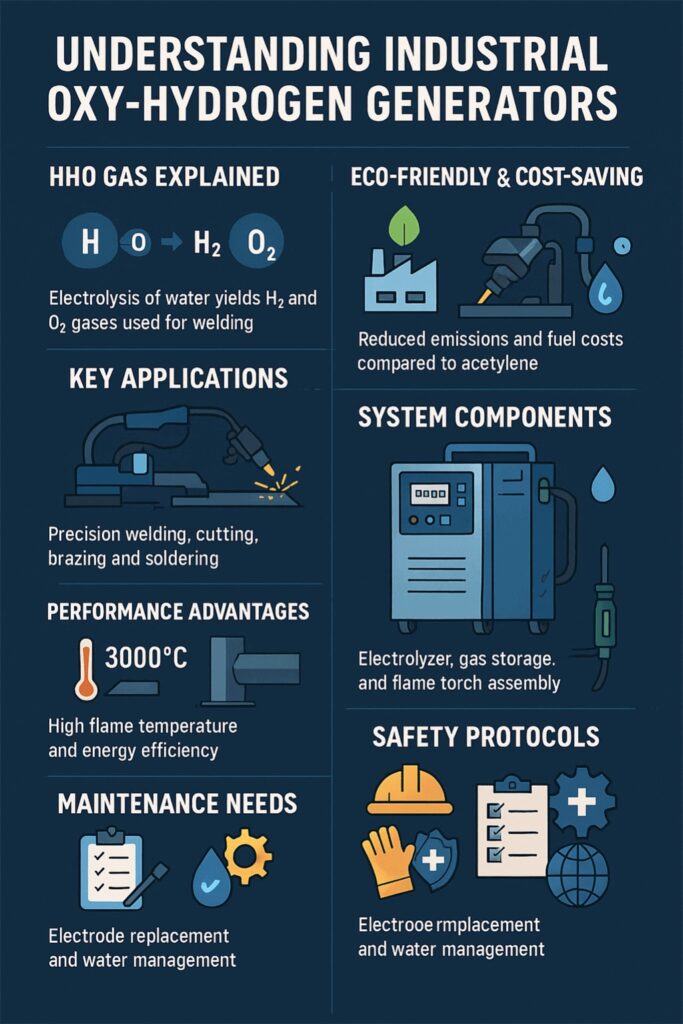

What is HHO Gas and How It Works

HHO gas is generated via electrolysis, separating distilled water into its elemental gases—hydrogen and oxygen. This gas mixture is then fed into a torch, creating a high-temperature, clean flame ideal for industrial welding applications.

Benefits Over Traditional Welding Methods

- Eco-friendly: No carbon emissions—just water vapor.

- Efficient: On-demand gas eliminates the need for gas cylinders.

- Cost-effective: Significant fuel savings compared to acetylene or propane.

Market Adoption in Industrial Sectors

From automotive manufacturing to aerospace, more companies are adopting HHO welding machines for their clean energy profile and pinpoint precision.

2. Key Applications in Industrial Settings

Precision Welding for Metal Fabrication

Oxyhydrogen welding excels in producing clean, high-strength welds on delicate and precision-engineered components.

High-Efficiency Cutting Operations

These systems can cut through thick steel or aluminum plates cleanly with minimal slag, making them perfect for shipbuilding and heavy machinery industries.

Brazing and Soldering Applications

Ideal for HVAC systems and plumbing, the precise flame control supports high-quality brazing and soldering.

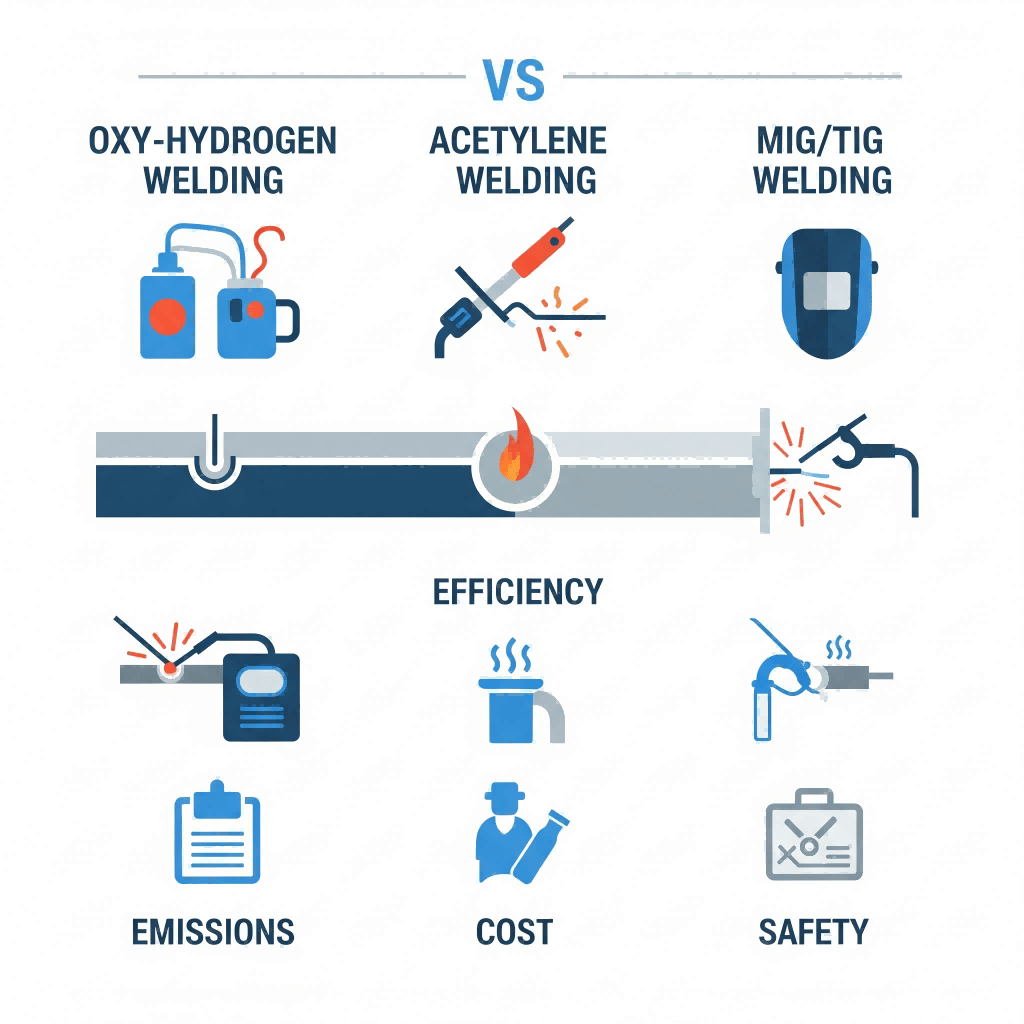

Comparison With Other Welding Methods

| Welding Type | Energy Efficiency | Emissions | Setup Cost |

|---|---|---|---|

| Oxy-Hydrogen (HHO) | High | Zero CO₂ | Medium |

| Acetylene | Medium | High CO₂ | High |

| TIG/MIG | Medium | Low-Moderate | High |

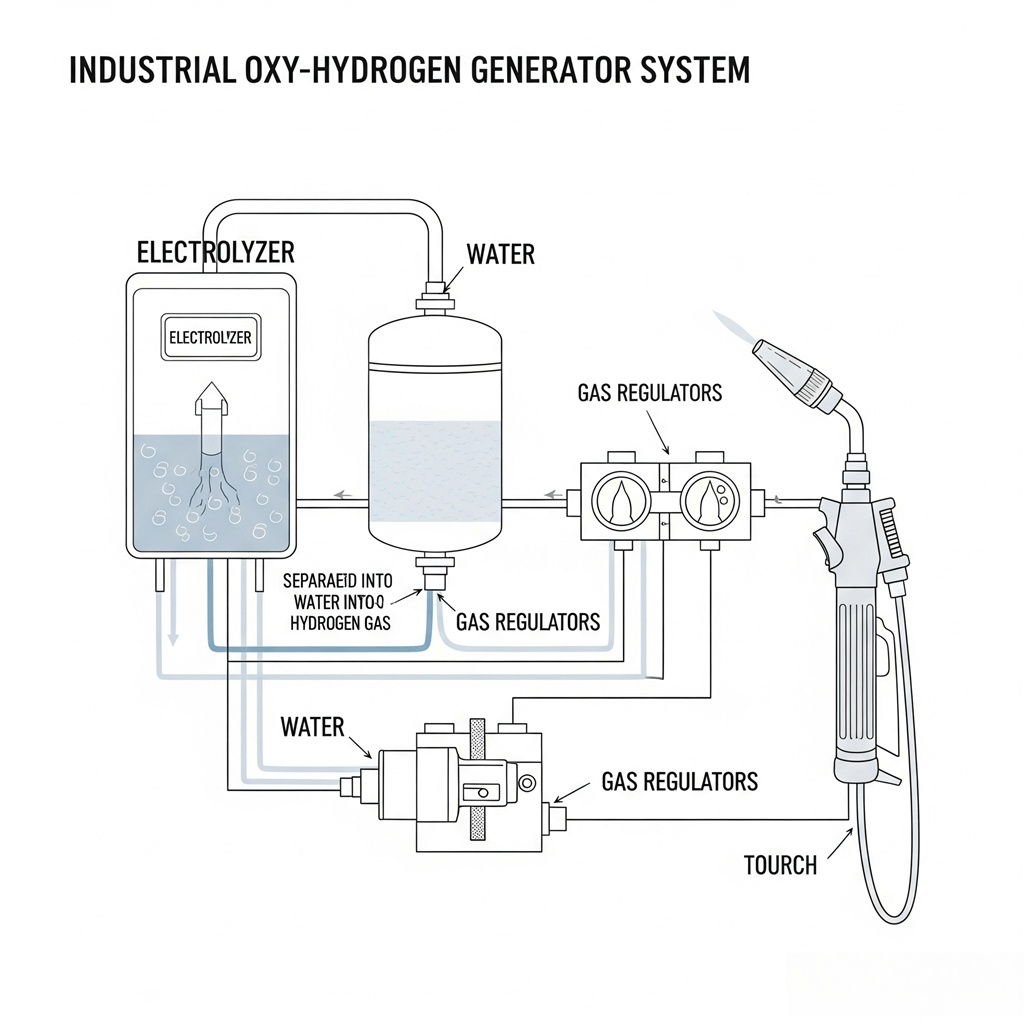

3. System Components & Technical Design

Electrolyzer Unit and Water Purification

The core component, the electrolyzer, uses purified water and electricity to generate HHO gas efficiently.

Gas Storage and Pressure Regulation

While most systems operate on-demand, some industrial units include buffers and regulators for consistent flame output.

Flame Torch Assembly and Controls

Modern torches are equipped with adjustable nozzles, ignition systems, and flame stabilization technologies.

Safety Cut-Off Mechanisms

Automatic shutoff valves, backfire arrestors, and gas leak sensors ensure workplace safety.

Portable vs. Stationary System Configurations

- Portable Units: Ideal for mobile repair services and fieldwork.

- Stationary Systems: Suited for high-volume industrial applications.

4. Performance Advantages

Energy Efficiency Metrics

Oxy-hydrogen generators consume less electricity per unit of output gas compared to traditional gas supply chains.

Flame Temperature and Precision Control

With flame temperatures reaching over 2800°C (5072°F), these systems allow for incredibly fine control over heat application.

Material Compatibility

HHO is suitable for welding:

- Stainless steel

- Mild steel

- Aluminum

- Copper

- Brass

Production Capacity

High-grade models can run 24/7 with consistent output, minimizing downtime in manufacturing plants.

5. Safety Protocols & Operational Best Practices

Gas Leak Detection Systems

Integrated sensors detect leaks instantly, triggering alarms and automatic shutoffs.

Ventilation Requirements

Despite being non-toxic, proper airflow prevents heat buildup and enhances worker comfort.

Personal Protective Equipment (PPE)

Operators should wear flame-resistant gloves, face shields, and eye protection.

Emergency Shutdown Procedures

Each system includes emergency stop buttons and manual override features.

OSHA Compliance Considerations

Ensure that your installation follows Occupational Safety and Health Administration (OSHA) guidelines for gas usage.

6. Maintenance & Long-Term Operation

Daily/Weekly Maintenance Checklist

- Check water levels

- Inspect hose integrity

- Test leak sensors

Electrode Replacement Schedule

Electrodes may last up to 2000 hours depending on usage and water quality.

Water Quality Management

Use deionized or distilled water to prevent scale and prolong electrolyzer life.

Troubleshooting Common Issues

- Low gas output? Check water level or electrode wear.

- Backfire? Ensure flashback arrestor is functioning.

Expected Service Life and ROI

Industrial units typically last 5–10 years, with ROI achieved in under 18 months for most operations.

7. Cost Analysis & Environmental Benefits

Comparative Fuel Cost Savings

HHO gas costs up to 70% less than acetylene or propane when calculated over time.

Reduced Carbon Footprint

Zero emissions = better sustainability scores and compliance with green standards.

Government Incentives

Many countries offer subsidies or tax breaks for adopting eco-friendly welding technologies.

Payback Period Calculation

Initial investment: \$8,000–\$20,000 Average monthly fuel savings: \$1,000+ Estimated payback period: 8–16 months

8. Selecting the Right Industrial HHO Generator

Capacity Requirements for Different Operations

| Industry | Recommended Capacity (L/hr) |

|---|---|

| Small workshops | 300–500 |

| Medium factories | 800–1200 |

| Heavy industry | 1500+ |

Key Specifications to Evaluate

- Gas output (L/h)

- Power consumption (kWh)

- Flame temperature

- Safety certifications

Top Manufacturers Comparison

- GreenFlame Tech

- EcoHHO Systems

- HydroPro Solutions

OEM vs. Standard Models

OEM units offer tailored output levels and automation compatibility for unique use cases.

9. Future Trends in Hydrogen Welding Technology

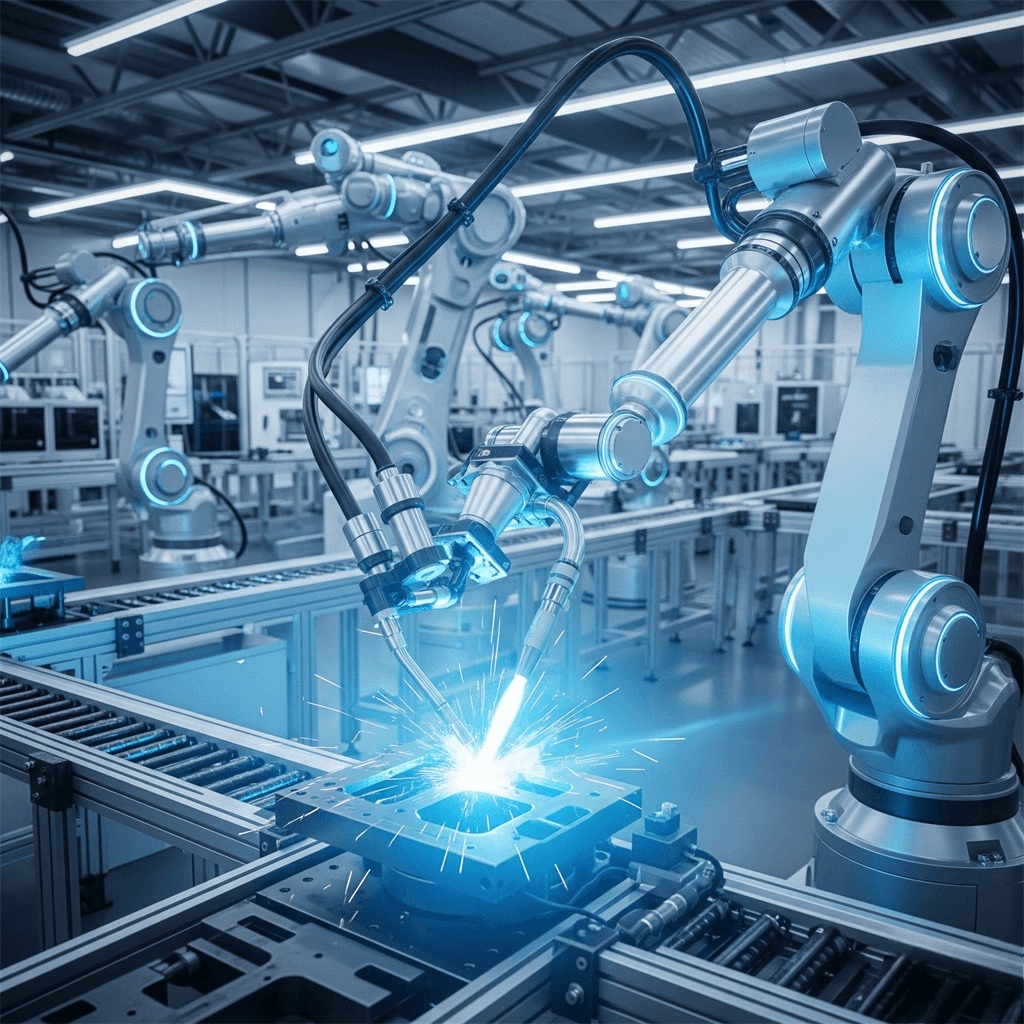

Automation Integration

Pairing oxy-hydrogen torches with robotic arms for high-speed, repeatable welds.

Smart Monitoring Systems

IoT-based diagnostics and remote system monitoring for predictive maintenance.

Hybrid Energy Solutions

HHO systems powered by solar or wind energy for fully off-grid welding.

Industry 4.0 Compatibility

Data integration with ERP and MES systems for enhanced production control.

10. Conclusion & Next Steps

The transition to industrial oxy-hydrogen generators marks a new era in welding technology—one that emphasizes efficiency, sustainability, and precision.

Ready to Experience the Difference?

✅ Request a customized quote based on your operational needs

✅ Download our free technical specifications sheet

✅ Book a live demo with one of our welding engineers

Frequently Asked Questions (FAQs)

Q1: Is oxy-hydrogen welding safe?

Yes, when used properly. Built-in safety systems like backfire arrestors and leak detectors ensure operational safety.

Q2: What materials can be welded with an HHO generator?

Common materials include stainless steel, aluminum, copper, brass, and carbon steel.

Q3: How often does the system need maintenance?

Basic checks should be done daily, with major servicing every 6–12 months depending on usage.

Q4: Can HHO replace traditional gas welding completely?

In many industries, yes. It’s especially effective where clean, high-precision welds are needed.

Q5: Are there government incentives available?

Yes. Many regions offer rebates or tax incentives for switching to green technologies.