I. Introduction: Revolutionizing Industrial Welding with Oxy-Hydrogen Technology

Industrial welding is a cornerstone of modern manufacturing, but traditional gas welding methods pose challenges. From rising gas prices to risks related to gas storage and inconsistent weld quality, the demand for safer, cleaner, and more efficient welding solutions is growing.

Enter the industrial oxy-hydrogen generator for welding—a game-changer harnessing the power of water to produce fuel gases on demand.

Oxy-hydrogen generators work by using electrolysis, specifically advanced PEM (Proton Exchange Membrane) electrolyzer technology, to split purified water into high-purity hydrogen and oxygen. These gases are instantly available for combustion at the welding torch, producing a highly controllable flame with minimal waste and superior precision.

Businesses in aerospace, electronics, HVAC, automotive, and metal fabrication are increasingly adopting this technology to improve welding precision, ensure safety, boost operational efficiency, and reduce reliance on gas cylinders.

Hele Titanium Hydrogen (heletitaniumhydrogen.com) leads this transition as a pioneering PEM electrolyzer manufacturer, providing customized, scalable solutions for industrial oxy-hydrogen generator for welding needs.

This article explores how industrial oxy-hydrogen welding systems offer unmatched benefits in performance, safety, maintenance, and cost-efficiency—making them the future of precision welding.

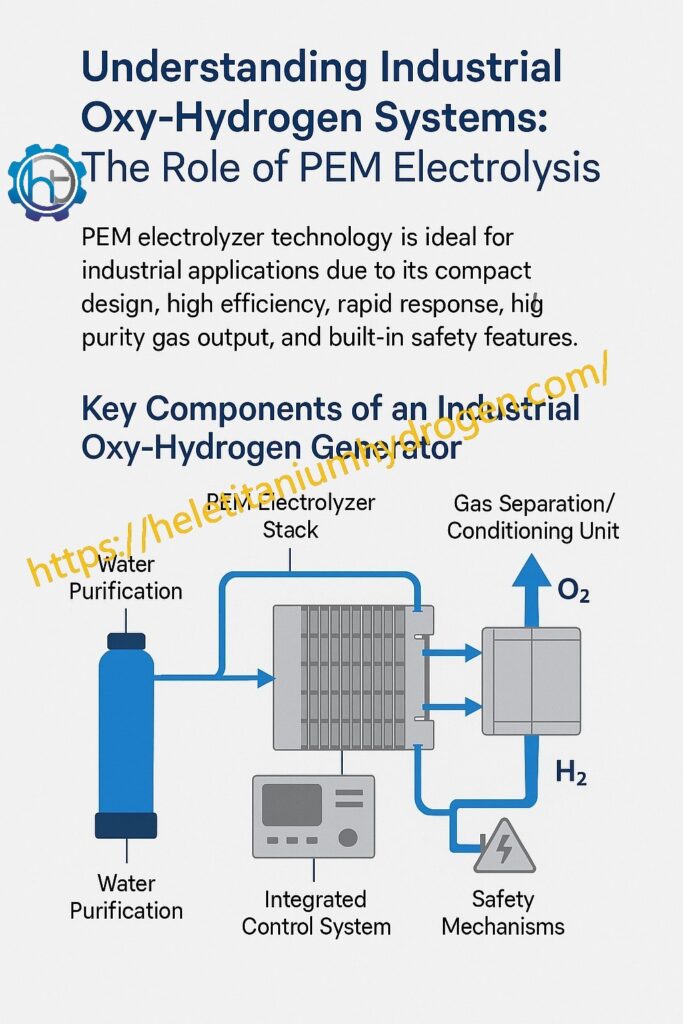

II. Understanding Industrial Oxy-Hydrogen Systems: The Role of PEM Electrolysis

The Power Within: How PEM Electrolyzer Technology Works

At the heart of every industrial oxy-hydrogen generator is the PEM electrolyzer. This system uses a solid polymer electrolyte to conduct protons while separating gases. Water enters the system and is split into hydrogen and oxygen with an electric current—offering several distinct advantages:

- Compact Design: Space-saving integration ideal for factory environments.

- Rapid Response: Immediate gas output upon power-up—no warm-up delay.

- High Purity: Gases reach over 99.9% purity, critical for precision welding.

- Inherent Safety: Eliminates the need to store explosive gases on-site.

PEM technology is exceptionally suited for industrial applications, delivering reliability and efficiency in high-demand environments. Hele Titanium Hydrogen, a renowned PEM electrolyzer manufacturer, is known for engineering robust, modular systems that scale with your operation.

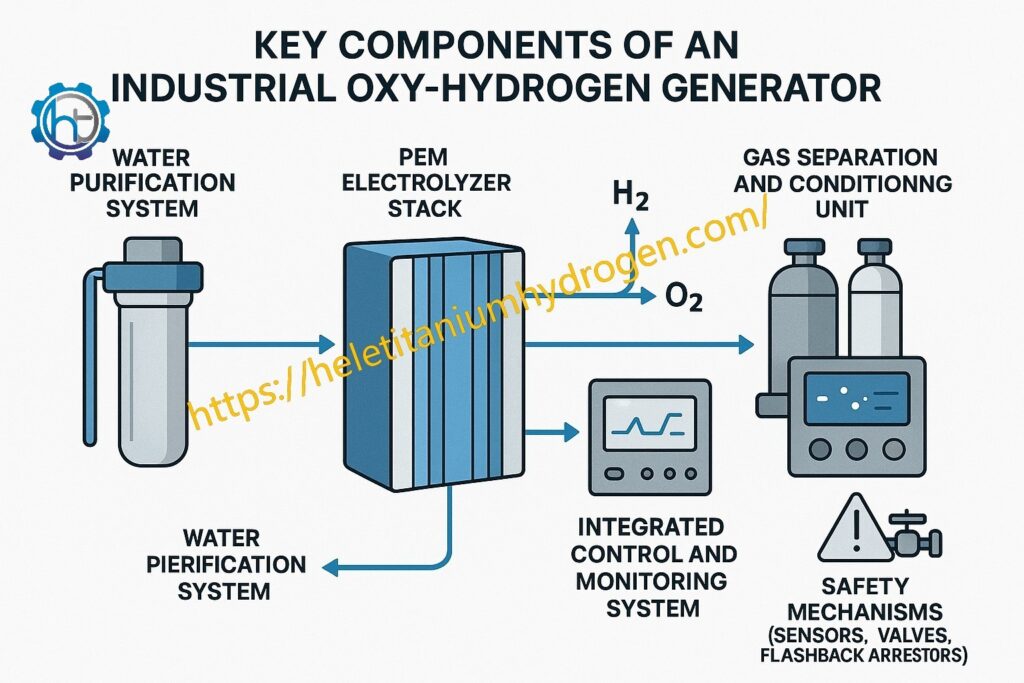

Key Components of an Industrial Oxy-Hydrogen Generator

| Component | Function |

|---|---|

| PEM Electrolyzer Stack | Core unit where water is split into H₂ and O₂. |

| Water Purification System | Ensures feedwater meets conductivity specs to prevent membrane damage. |

| Gas Separation Unit | Removes moisture and ensures gas purity for flame stability. |

| Control & Monitoring System | Automates operation, includes error alerts, and enables remote access. |

| Safety Features | Flashback arrestors, leak detection, auto-shutdown, overpressure relief. |

These elements work together seamlessly, offering operators precision control, minimal maintenance, and round-the-clock reliability.

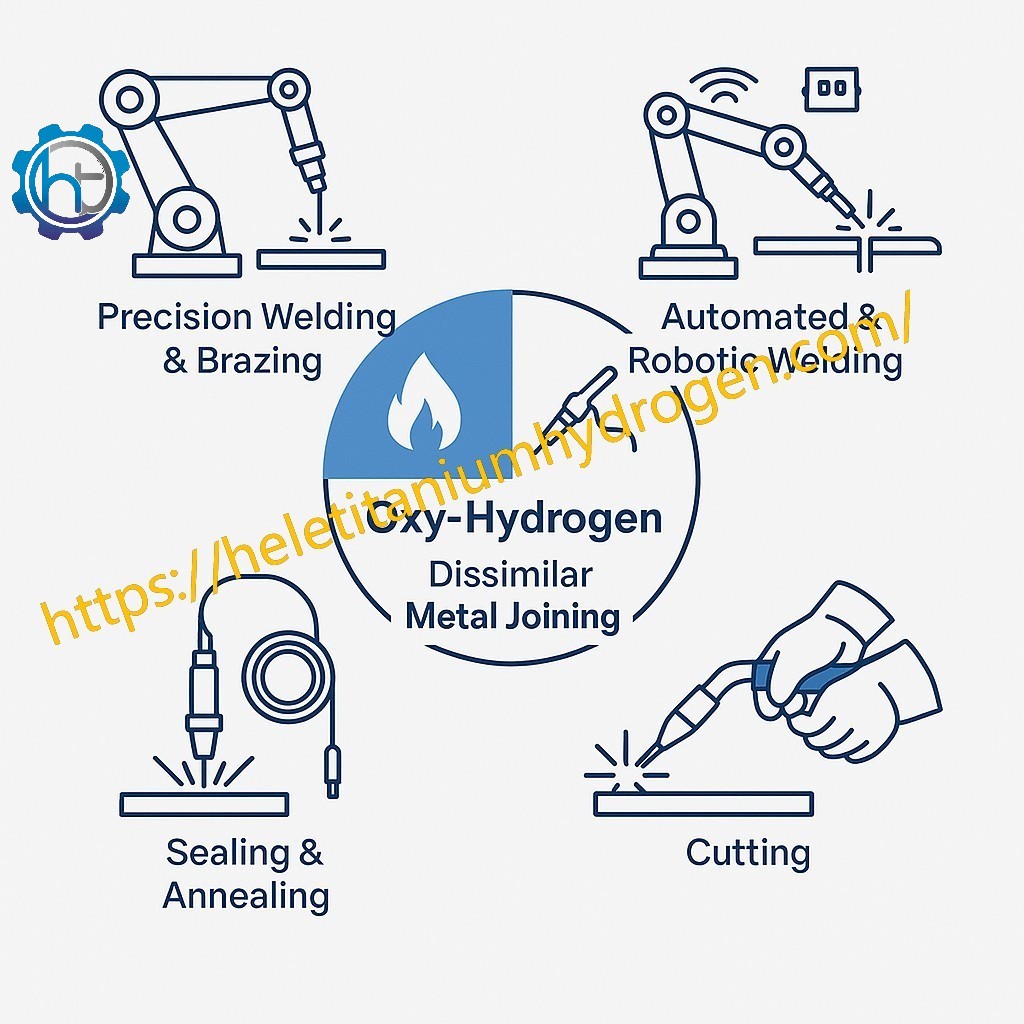

III. Versatile Welding Applications for Oxy-Hydrogen

Achieving Precision Across Diverse Industries

Industrial oxy-hydrogen generators aren’t just innovative—they’re versatile. Their applications span many industries that demand high-accuracy welding:

🔧 Precision Welding & Brazing

The fine, high-temperature flame makes it perfect for electronic components, medical instruments, and jewelry. It produces less heat stress and offers clean joints without flux.

🤖 Automated & Robotic Welding

These systems integrate smoothly into robotic arms and CNC setups, enabling repeatable welds with tight control and minimal human oversight.

🧲 Dissimilar Metal Joining

When working with alloys or composite metals, oxy-hydrogen provides clean fusion with reduced oxidation—ideal for aerospace and automotive components.

🔥 Sealing, Annealing, and Glass Working

From hermetic sealing of sensors to softening glass tubing, the precise flame allows fine-tuned control across temperatures and materials.

Industries embracing these applications include:

- Automotive & Aerospace

- Manufacturing & HVAC

- Electronics & Optics

- Medical Devices & Instrumentation

- Glassblowing & Jewelry

The flexibility of the oxy-hydrogen generator for welding makes it a universal asset across manufacturing sectors.

IV. Enhanced Safety Protocols with On-Demand Generation

Prioritizing Safety in Industrial Environments

Traditional welding setups often rely on high-pressure gas cylinders—posing significant risks during storage, transport, and use. These include potential explosions, gas leaks, and handling injuries.

By contrast, oxy-hydrogen generators produce only what is needed, when it is needed. This on-demand generation model significantly reduces risk:

- No storage of explosive gases

- Immediate shutdown during malfunctions

- Consistent flame quality

Hele Titanium Hydrogen integrates advanced safety protocols into every system:

- Leak Detection Sensors: Immediately shut down the system if abnormalities occur.

- Automatic Pressure Relief Valves: Prevent overpressurization.

- Flashback Arrestors: Stop flame propagation.

- Error Diagnostics: Informs operators of real-time system health.

- Compliance: Meets global industrial safety standards including CE, ISO, and UL.

This all adds up to a safer workspace with less downtime and fewer liabilities.

V. Performance Metrics: Quantifying the Industrial Advantage

Measuring Efficiency, Purity, and Reliability

Investing in an industrial oxy-hydrogen generator for welding is not just about safety or eco-consciousness—it’s about measurable performance:

| Metric | Benefit |

|---|---|

| Gas Purity (99.9%+) | Ensures clean, strong welds with no contaminant gases. |

| Production Rate | Systems can produce up to 30–60 L/min or more, scalable as needed. |

| Energy Efficiency | PEM systems use energy proportionally—ideal for companies managing utility costs. |

| Uptime Reliability | Designed for 24/7 operation with minimal failures. |

| Ownership Cost | Lower operating costs than cylinder refills; ROI visible within months. |

Case Study Example: An aerospace component manufacturer replaced acetylene with an oxy-hydrogen system, reducing gas costs by 40% annually and improving weld pass rates by 25%.

These metrics make it clear: PEM-powered oxy-hydrogen generators are engineered for maximum value in demanding industrial environments.

Continuing the article from where we left off…

VI. Maintenance Requirements for Optimal Industrial Performance

Ensuring Longevity and Consistent Output

Like all high-performance industrial equipment, oxy-hydrogen generators require regular maintenance to function at peak efficiency. Fortunately, modern systems are designed to be low-maintenance, reducing overhead and downtime.

Here’s what typical maintenance for an industrial oxy-hydrogen generator for welding includes:

🔄 Routine Maintenance Tasks

- Visual Inspections: Regular checks for leaks, discoloration, or unusual sounds.

- Monitoring via Control Panel: The integrated interface continuously tracks pressure, flow rates, and gas purity, making diagnostics easier.

- Filter Replacements: Water filters should be changed periodically based on usage and water quality.

- PEM Stack Monitoring: The electrolyzer stack has a long life (often 10,000+ hours) but should be inspected for degradation in high-use applications.

- Software Updates: Keeping the system’s firmware updated ensures optimal control, diagnostics, and safety management.

Using deionized or distilled water as per manufacturer guidelines is essential. Poor water quality can reduce membrane lifespan or damage internal components.

Hele Titanium Hydrogen supports its clients through:

- Scheduled maintenance reminders

- On-site and remote diagnostics

- Spare part availability and rapid dispatch

- Optional annual service plans with priority support

This proactive approach ensures that businesses experience minimal downtime and maximum return on investment.

VII. Why Choose Hele Titanium Hydrogen as Your PEM Electrolyzer Manufacturer?

Your Partner for Reliable Industrial Welding Solutions

Selecting the right PEM electrolyzer manufacturer is as crucial as choosing the right system. Here’s why Hele Titanium Hydrogen stands out:

✅ Unmatched Expertise

Specializing in PEM electrolyzer technology for over a decade, the company has deep technical knowledge in engineering hydrogen generation systems tailored for welding.

🧩 Custom-Built Solutions

Systems are designed based on client-specific requirements—whether you’re integrating into a robotic welding line or need a portable unit for field applications.

⚙️ Superior Component Quality

Only high-grade materials and components are used to ensure durability, high performance, and low operational costs over time.

🛡️ Safety and Compliance

Hele Titanium Hydrogen adheres to international safety standards (ISO, CE, UL) and incorporates multi-tiered safety systems into every build.

📞 Exceptional Technical Support

Clients benefit from 24/7 technical assistance, user training programs, and ongoing system optimization consulting.

💬 Proven Track Record

With successful deployments in aerospace, automotive, electronics, and advanced manufacturing sectors, the company has earned trust across industries.

When you’re investing in industrial-grade hydrogen generation, you need a partner—not just a supplier. Hele Titanium Hydrogen delivers that reliability.

VIII. Conclusion: The Future of Industrial Welding Applications

Industrial welding is evolving rapidly. As businesses seek greater control over quality, safety, and operational costs, the shift toward oxy-hydrogen welding systems is becoming inevitable.

By utilizing water and electricity to produce clean-burning gases on demand, these systems reduce risk, improve precision, and offer clear economic benefits.

Partnering with a specialized PEM electrolyzer manufacturer like Hele Titanium Hydrogen ensures that your organization benefits from tailored solutions backed by years of engineering experience and reliable after-sales support.

Ready to upgrade your welding capabilities? Visit https://heletitaniumhydrogen.com to request a custom quote or schedule a consultation.

Frequently Asked Questions (FAQs)

1. What is an oxy-hydrogen generator used for in welding?

An oxy-hydrogen generator produces hydrogen and oxygen gases from water, which are used for high-precision welding, brazing, and cutting applications in industrial settings.

2. Is oxy-hydrogen welding safe?

Yes, it’s safer than traditional gas cylinder systems. The gas is generated on demand, reducing storage risks. Modern systems also include advanced safety features like leak detection and flashback arrestors.

3. What industries benefit from industrial oxy-hydrogen generators?

Industries like automotive, aerospace, HVAC, electronics, glass manufacturing, and medical device production commonly use these systems for their high-precision and clean weld capabilities.

4. How often does a PEM electrolyzer need maintenance?

Routine maintenance like water filter changes and system checks should be done every few months, while the electrolyzer stack may last several years depending on usage.

5. Can an oxy-hydrogen generator replace acetylene in welding?

Absolutely. Oxy-hydrogen offers a similar or even superior flame temperature with cleaner combustion and fewer safety concerns, making it an effective acetylene alternative.

6. Why choose Hele Titanium Hydrogen as your equipment supplier?

Because they offer custom-built systems, prioritize safety, use high-quality components, and provide excellent technical support tailored for industrial welding applications.