Introduction: The Rise of On-Site Hydrogen Generation

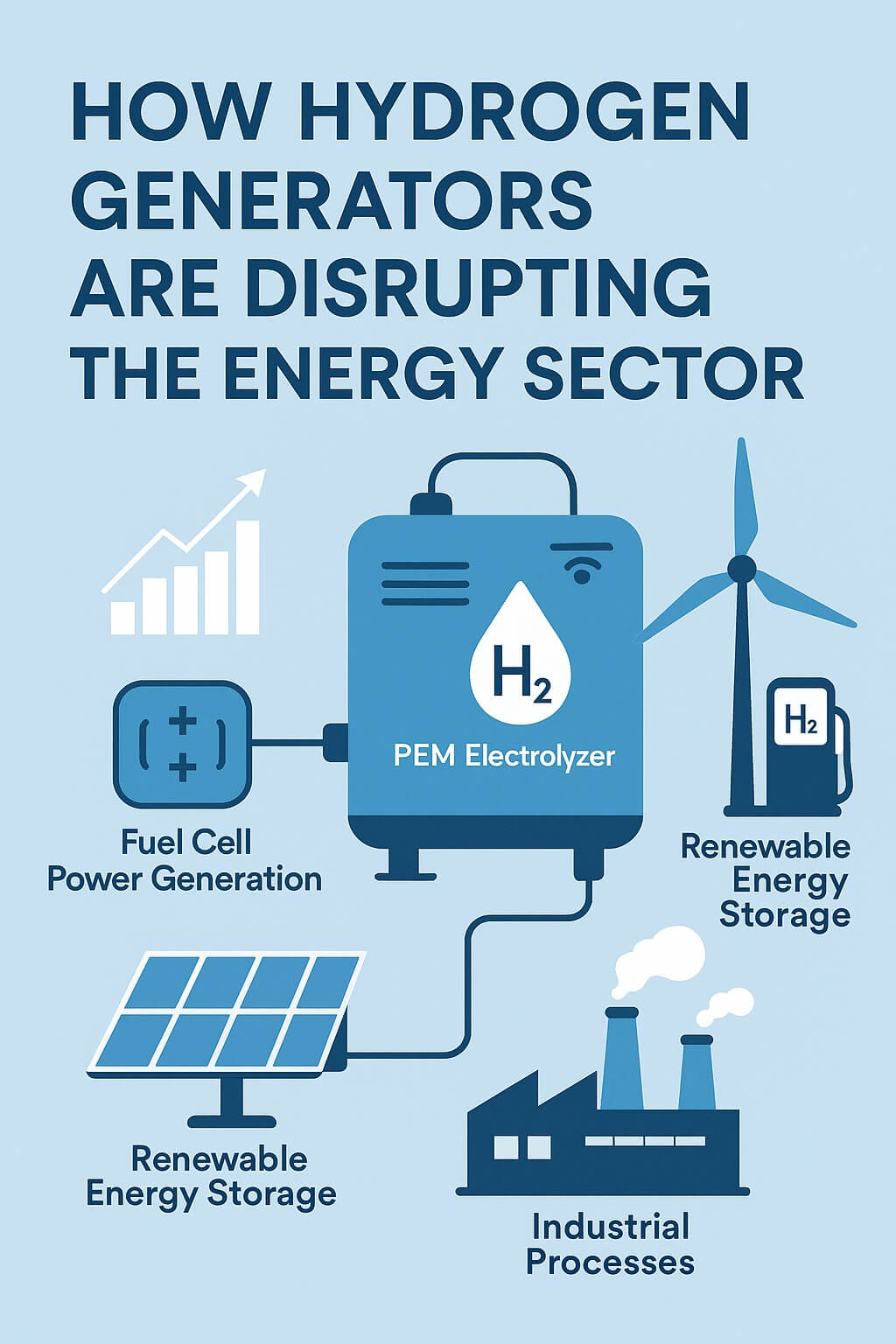

Hydrogen has long been hailed as the fuel of the future. Once considered an exotic energy source, it’s now making major inroads in manufacturing as industries seek cleaner, more efficient solutions. In recent years, on-site hydrogen generation has emerged as a game-changer, especially for operations that require a steady, reliable, and pure hydrogen supply.

Traditionally, hydrogen was produced off-site and delivered via tube trailers or cylinders—methods that posed challenges in cost, logistics, and safety. Now, thanks to advancements in electrolyzer technology, businesses can generate hydrogen directly where it’s needed, reducing carbon emissions and operational complexity.

Among the various capacities available, the 10KW industrial hydrogen generator stands out as a highly versatile and efficient solution for small to medium-scale industrial applications. It offers a sweet spot between output and footprint, making it ideal for many manufacturing setups.

Understanding the 10KW Industrial Hydrogen Generator

What is an Industrial Hydrogen Generator?

An industrial hydrogen generator is a system designed to produce hydrogen gas on demand, typically through the process of electrolysis. In electrolysis, an electric current splits water (H₂O) into its base elements—hydrogen and oxygen.

There are two primary types of electrolysis technologies used today:

- Proton Exchange Membrane (PEM) Electrolysis: Known for high purity output, quick response times, and compact design. It uses a solid polymer electrolyte.

- Alkaline Electrolysis: A more mature and cost-effective technology that utilizes a liquid electrolyte, typically potassium hydroxide.

Both systems involve an electrolyzer stack, control units, and auxiliary components to manage gas purity and safety.

Why 10KW?

A 10KW hydrogen generator is ideal for businesses that require a moderate but consistent hydrogen supply without the need for bulky or high-capacity systems. This capacity:

- Supports decentralized hydrogen production.

- Provides enough output for processes such as welding, electronics cleaning, or R&D fuel cell testing.

- Is scalable—multiple 10KW units can be installed in modular configurations for larger demand.

Key Components and Features

| Component | Function |

|---|---|

| Electrolyzer Stack | Core unit that performs electrolysis and produces hydrogen gas. |

| Power Supply & Control System | Regulates voltage and current; ensures stable operation. |

| Gas Purification System | Removes moisture and impurities to meet purity standards. |

| Drying System | Ensures dry hydrogen output, especially critical in electronics and fuel cell industries. |

| Safety Features | Includes leak detectors, pressure relief valves, and auto shutdown mechanisms. |

Industrial Applications Requiring 10KW Capacity

Metal Processing

Hydrogen plays a vital role in heat treatment and annealing of metals, where its reducing properties prevent oxidation. Additionally, hydrogen-assisted welding and cutting techniques provide cleaner cuts and stronger welds, crucial for aerospace and precision metal fabrication.

Electronics Manufacturing

In semiconductor fabrication and circuit board production, ultra-pure hydrogen is needed for processes like cleaning, etching, and creating inert environments. A 10KW generator provides the required purity and flow rate for such controlled environments.

Chemical Processing

Hydrogen is central to many chemical reactions. A 10KW generator supports small-scale hydrogenation, such as converting unsaturated compounds into saturated ones, and can also be used in ammonia synthesis for lab-scale fertilizer production.

Food and Beverage Industry

Hydrogen is sometimes used in edible oil hydrogenation to alter texture and shelf-life. It may also play a role in Modified Atmosphere Packaging (MAP) to prolong freshness in certain products, though this depends on scale and purity.

Other Niche Applications

- Research and Development Labs: For prototype testing or fuel cell evaluations.

- Hydrogen Fuel Cell Testing: Ensures consistency in trials and development cycles.

Generator Specifications: Key Performance Indicators

| Parameter | Typical Value for 10KW Unit | Importance |

|---|---|---|

| Hydrogen Production Rate | 1.5–2.0 Nm³/hr | Determines output volume; must match process needs. |

| Purity Level | 99.999% (5N) | High purity needed for electronics, fuel cells, and lab use. |

| Operating Pressure | Up to 30 bar (with compressor option) | Higher pressure needed for storage or direct process feed. |

| Power Consumption | 10 kW | Relates directly to efficiency and operational cost. |

| Water Consumption | ~0.9 L/hr | Important for locations with limited water supply. |

| Footprint | Approx. 1.2m x 0.8m | Compact enough for constrained production areas. |

Integration with Production Systems

Seamless Integration

10KW hydrogen generators are typically skid-mounted or enclosed in compact cabinets, making them easy to install and connect to existing pipelines or machinery. Their modularity ensures minimal disruption to ongoing operations.

Automation and Control

Modern systems support remote monitoring via IoT platforms, allowing operators to track performance and make adjustments in real time. SCADA (Supervisory Control and Data Acquisition) integration ensures consistent operation within larger production ecosystems.

Safety Considerations for Integration

Hydrogen is flammable, so safety protocols are paramount. Integration involves:

- Hazard Assessments: Site-specific risk evaluations.

- Safety Protocols: Emergency shutdown systems, flame arrestors, and fire-rated enclosures.

Efficiency Metrics and Cost Analysis

Energy Efficiency

Most 10KW generators achieve efficiencies of 60–70%, meaning a good portion of the electricity used is effectively converted into hydrogen energy.

Return on Investment (ROI)

Compared to delivered hydrogen, on-site generation can reduce costs by up to 50%, especially when local electricity is cheap or subsidized. Typical ROI is 2–4 years depending on usage.

Cost per Kilogram of Hydrogen

| Method | Estimated Cost/kg |

|---|---|

| Delivered Hydrogen | $6.00–$10.00 |

| On-site 10KW System | $3.50–$5.00 |

Government Incentives

Many governments offer tax breaks, rebates, and funding for clean energy technologies. In the U.S., DOE grants and Inflation Reduction Act credits can significantly lower acquisition costs.

Maintenance and Service

Routine Maintenance Tasks

- Electrolyte Replacement: Only for alkaline systems; PEM is maintenance-free in this regard.

- Filter Changes: To maintain gas purity.

- System Inspections: Regular checks for wear and leak detection.

Preventative Maintenance

Manufacturers typically recommend semi-annual or annual service schedules to maintain optimal performance and reduce downtime.

Remote Monitoring

Systems equipped with diagnostic tools can alert operators to irregularities before they escalate, ensuring reliability.

Support and Spare Parts

Choose suppliers with local service networks and quick turnaround for parts to avoid prolonged shutdowns.

Case Studies: Real-World Applications of 10KW Hydrogen Generators

Example 1: Aerospace Parts Manufacturer

Installed a 10KW PEM hydrogen generator to support heat treatment ovens. Resulted in:

- 20% reduction in production downtime.

- $15,000/year savings in hydrogen delivery costs.

- Improved environmental compliance scores.

Example 2: Semiconductor Cleaning Lab

Switched from bottled hydrogen to on-site generation:

- Increased safety and purity control.

- Reduced hydrogen costs by 40%.

- Enabled 24/7 uninterrupted operation.

Choosing the Right 10KW Industrial Hydrogen Generator

Factors to Consider

- Application Fit: Ensure output and pressure meet operational needs.

- Purity Requirements: Higher-end applications need 5N or better.

- Budget Constraints: Consider total cost of ownership.

- Supplier Credentials: Check certifications, past clients, and reviews.

Questions to Ask Suppliers

- What are the output specs and efficiency?

- Do you offer warranty, training, and installation?

- What’s included in the after-sales support?

Conclusion: The Future of On-Site Hydrogen Generation in Manufacturing

The shift toward decentralized, clean, and efficient energy is unmistakable. With their compact footprint, impressive efficiency, and adaptable applications, 10KW industrial hydrogen generators are poised to become essential equipment in forward-thinking manufacturing facilities.

As companies race to reduce emissions and gain energy independence, now is the time to invest in on-site hydrogen generation. Explore suppliers, evaluate your needs, and begin your journey toward a more sustainable future.

Frequently Asked Questions (FAQs)

1. How much hydrogen can a 10KW generator produce per hour? A typical 10KW unit produces around 1.5–2.0 Nm³/hr, depending on operating conditions and technology used.

2. Is PEM or alkaline electrolysis better for a 10KW system? PEM electrolysis offers higher purity and is better for compact spaces, while alkaline systems are generally more cost-effective.

3. Can 10KW hydrogen generators run continuously? Yes, most are designed for 24/7 operation, provided maintenance schedules are followed.

4. What is the lifespan of a 10KW hydrogen generator? With proper maintenance, units can last 10–15 years or more.

5. How is safety managed with on-site hydrogen generation? Generators come with leak detection, ventilation systems, and emergency shutdowns to ensure safety.

6. Are there subsidies available for hydrogen generator installation? Yes, many countries offer government grants, tax incentives, or rebates for hydrogen-related equipment.